Isolation coating used for pre-laid and wet-laid waterproofing sheets and preparation method of coating

A technology of waterproofing membrane and isolation coating, applied in anti-corrosion coatings, reflective/signal coatings, coatings, etc., can solve the problem that inorganic particles cannot completely cover the pressure-sensitive adhesive layer, the combination of inorganic particles and pressure-sensitive adhesive is weak, and the isolation layer is flexible. It can improve the water resistance, low temperature flexibility and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

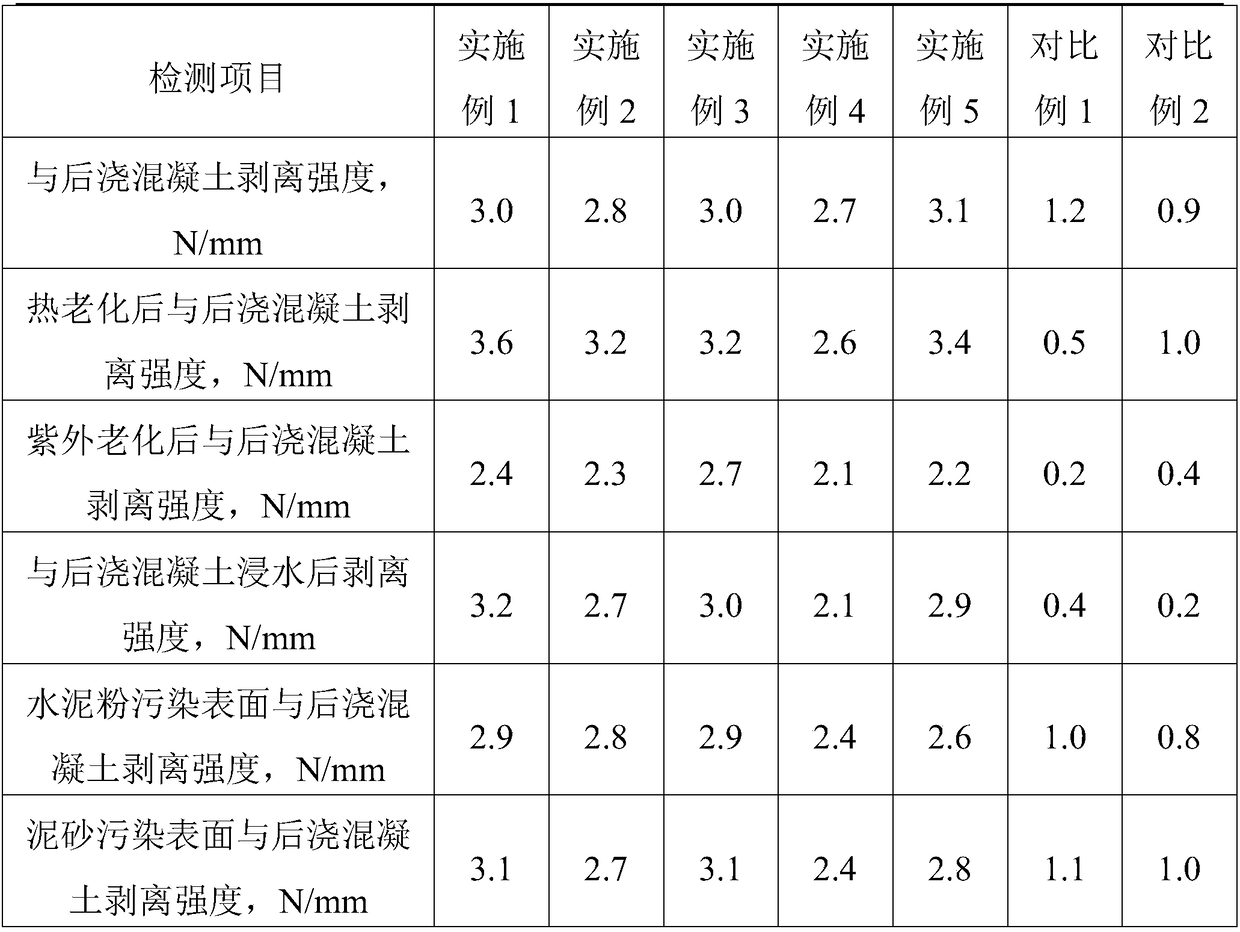

Examples

Embodiment 1

[0046] A kind of isolating coating for pre-paved wet-laid waterproof coiled material, its composition is as follows:

[0047] Modified acrylate copolymer emulsion (EC-4811 of Rohm and Haas) 30%;

[0048] VAE emulsion (Guangwei 707H) 9%;

[0049] volcanic ash powder 10%;

[0050] Microsilica 10%

[0051] Rutile titanium dioxide 5%;

[0052] Calcined Kaolin 10%

[0053] Sodium tripolyphosphate 0.2%;

[0054] Thickener 0.3%;

[0055] Defoamer 0.2%;

[0056] Leveling agent 0.3%;

[0057] Water 25%.

[0058] The isolation coating for the pre-paved wet-laid waterproof coil is prepared as follows:

[0059] (1) Put the measured modified acrylate copolymer emulsion and VAE emulsion into the dispersing kettle, and stir at a speed of 300-400rpm for 5 minutes;

[0060] (2) After pre-mixing the measured dispersant with 2% of the mass fraction of the formula, slowly put it into the dispersing kettle while stirring, control the rotation speed at 300-400rpm and stir for 5min;

[00...

Embodiment 2

[0066] A kind of isolating coating for pre-paved wet-laid waterproof coiled material, its composition is as follows:

[0067] Modified acrylate copolymer emulsion (EC-4811 of Rohm and Haas) 40%;

[0068] VAE emulsion ((Guangwei 707H)) 5%;

[0070] Microsilica 4%;

[0071] Rutile titanium dioxide 5%;

[0072] Calcined Kaolin 15%

[0073] Sodium tripolyphosphate 0.9%;

[0074] Thickener 0.6%;

[0075] Defoamer 0.1%;

[0076] Leveling agent 0.4%;

[0077] Water 26%.

[0078] The method described in Example 1 was used to prepare the isolation coating for pre-laying wet-laid waterproof coiled materials.

Embodiment 3

[0080] A kind of isolating coating for pre-paved wet-laid waterproof coiled material, its composition is as follows:

[0081] Modified acrylate copolymer emulsion (EC-4811 of Rohm and Haas) 13%;

[0082] VAE emulsion ((Guangwei 707H)) 10%;

[0083] volcanic ash powder 25%;

[0084] Micro silica fume 10%;

[0085] Rutile titanium dioxide 3%;

[0086] Calcined Kaolin 5%

[0087] Sodium tripolyphosphate 0.2%;

[0088] Thickener 0.2%;

[0089] Defoamer 0.5%;

[0090] Leveling agent 0.1%;

[0091] Water 33%.

[0092] The method described in Example 1 was used to prepare the isolation coating for pre-laying wet-laid waterproof coiled materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com