Sprayable, waterproof, anticorrosive and erosion-resistant high-strength mortar and using method thereof

A kind of anti-erosion, high-strength technology, applied in the field of building materials, can solve problems such as the reduction of impermeability, and achieve the effect of high impermeability grade, excellent bonding strength and corrosion resistance, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In the present invention, based on the mass parts of Portland cement clinker, the sprayable waterproof, anti-corrosion and anti-erosion high-strength mortar includes 450-600 parts of active steel slag, preferably 450-550 parts, more preferably 500-550 parts part; the particle size of the active steel slag is preferably 30 to 50 mesh; the active steel slag is preferably steel slag modified by silica sol; the preparation method of the active steel slag preferably includes the following steps: after mixing steel slag and silica sol, Sequentially crushing and sieving to obtain active steel slag; the mass ratio of the steel slag to silica sol is preferably 100:0.15-0.25, more preferably 100:0.2, and the particle size of the steel slag is 10-80 mesh. In the present invention, the active steel slag is an aggregate with potential hydraulic activity, and the active minerals (such as tricalcium silicate and dicalcium silicate) can partially undergo hydration reaction to generate a...

Embodiment 1

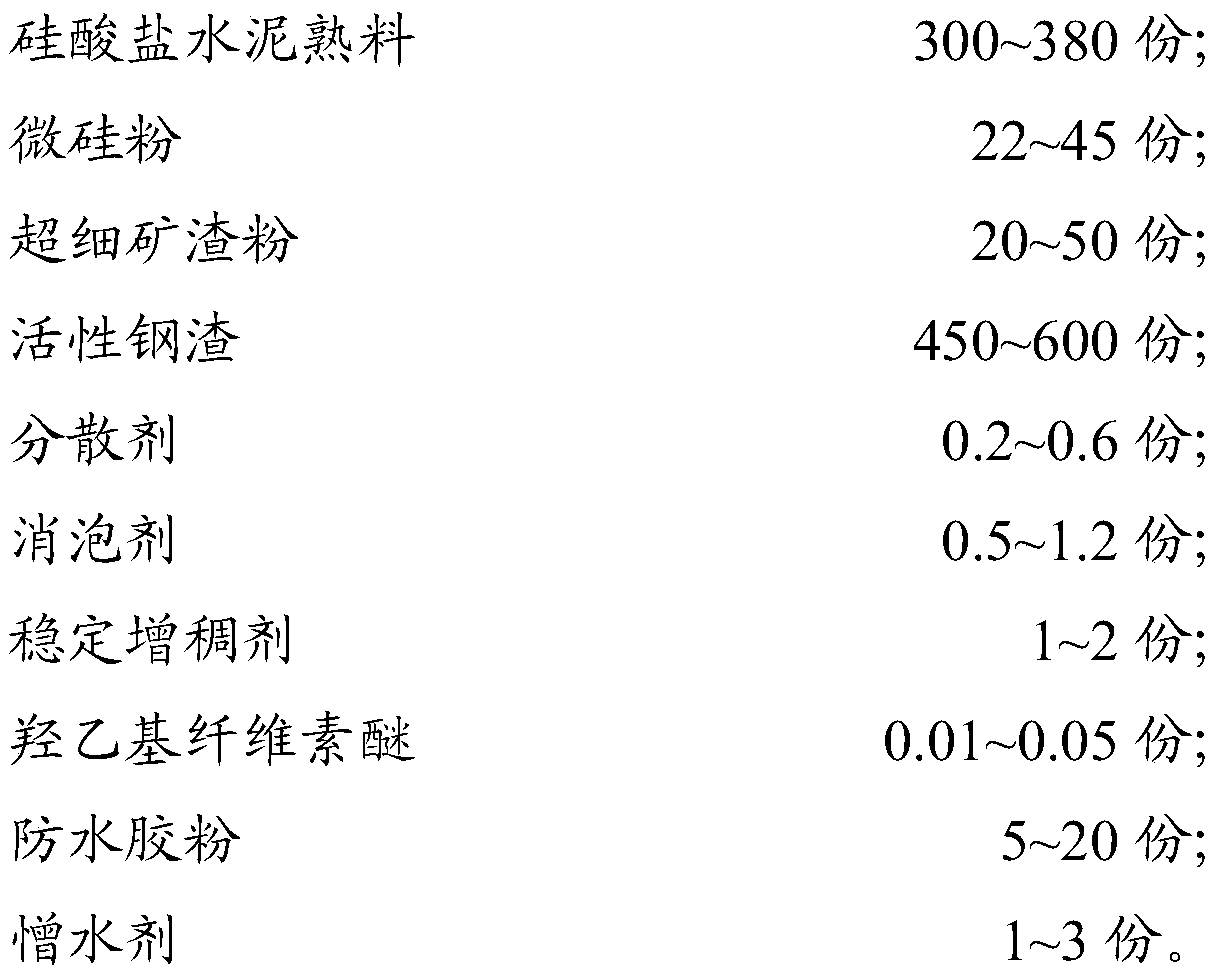

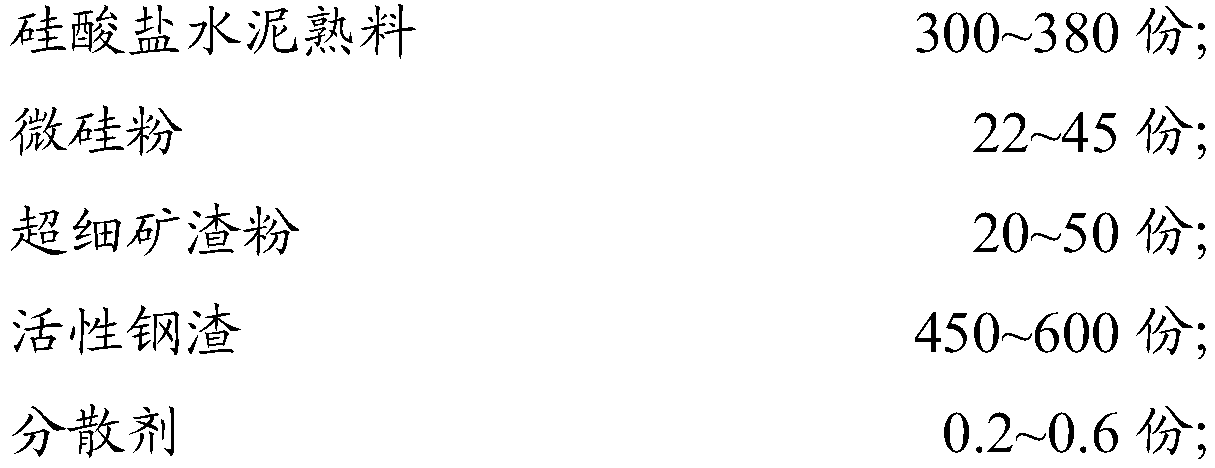

[0040] Weigh the solid raw material according to the following parts by mass:

[0041]

[0042]

[0043] Put the above-mentioned solid components into the mixer, stir evenly at a high speed, mix and stir the water and solid components according to the mass ratio of 0.13:1 for 5 minutes, and obtain a sprayable waterproof, anti-corrosion and anti-erosion high-strength mortar.

Embodiment 2

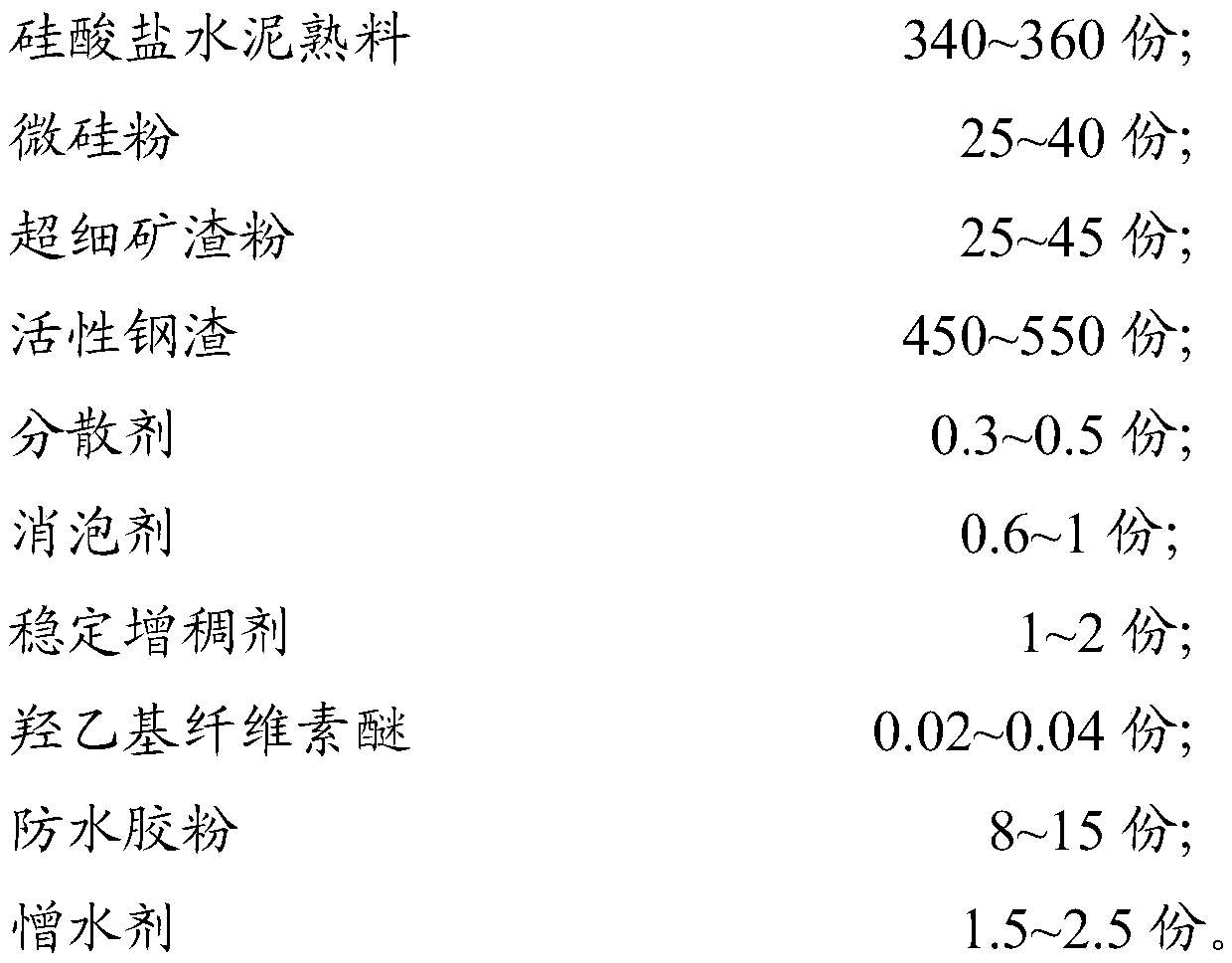

[0045] Weigh the solid raw material according to the following parts by mass:

[0046]

[0047] Put the above solid components into the mixer, stir evenly at high speed, mix water and solid components according to the mass ratio of 0.136:1 and stir for 5 minutes to obtain a sprayable waterproof, anti-corrosion and anti-erosion high-strength mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com