Novel concrete synergist and its manufacturing process

A technology of concrete synergists and reinforcing components, applied in concrete synergists, admixtures that significantly improve various properties of concrete, and in the field of manufacturing technology of the above-mentioned concrete synergists, can solve the problem of large slump loss and changes in concrete Bleeding, high energy consumption and other problems to achieve the effect of reducing slump loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

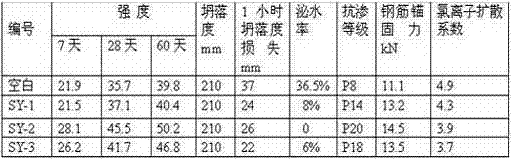

[0021] The weight ratio of various synergists is as follows: anti-bleeding component 704g, reinforcing component 85g, densifying component 80g, dispersing component 60g, air-entraining component 6g, compounding component 65g. Mix and stir to make a synergist. The dosage of synergist is 0.6%, and the test is carried out according to Table 1, and the results are shown in Table 2.

[0022] The slump loss of the SY-1 test is 13mm less than that of the blank test, that is, 35.1%. The bleeding is reduced from 36.5% to 8%. 4.3, saving 40 kg per cubic concrete cement. The 7-day, 28-day, and 60-day strengths are slightly higher than blank concrete.

[0023] The mix ratio of SY-2 remains the same, 0.6% synergist is added, the test slump loss is 11mm less than that of the blank test, that is, 29.7%, the bleeding is reduced from 36.5% to 0%, the impermeability level is increased to P20, and the steel bar is anchored The strength increased by 30.6%, and the chloride ion diffusion coeffi...

Embodiment 2

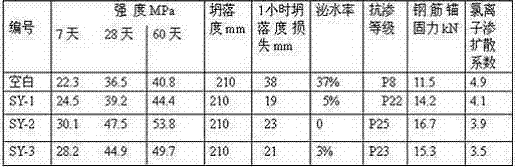

[0028] The specific weight ratio of various synergists is as follows: anti-bleeding component 692g, reinforcing component 105g, densifying component 70g, dispersing component 60g, air-entraining component 8g, compounding component 65g. Mix and stir to make a synergist. The dosage of synergist is 0.6%, and the test is carried out according to Table 1, and the results are shown in Table 3.

[0029] The slump loss of the SY-1 test is 18mm less than that of the blank test, that is, 50%, the bleeding is reduced from 37% to 5%, the impermeability level is increased to P22, the anchorage force of the steel bar is increased by 23.5%, and the chloride ion diffusion coefficient is reduced from 4.9 4.1, saving 40 kg per cubic concrete cement. The strength of 7 days, 28 days and 60 days is significantly higher than that of blank concrete, namely 2.2MPa, 2.7 MPa and 3.6MPa.

[0030] The mix ratio of SY-2 remains the same, 0.6% synergist is added, the test slump loss is 15mm less than tha...

Embodiment 3

[0035] The weight ratio of various synergists is as follows: anti-bleeding component 718g, reinforcing component 115g, densifying component 60g, dispersing component 50g, air-entraining component 7g, compounding component 50g. Mix and stir to make a synergist. The dosage of synergist is 0.6%, and the test is carried out according to Table 1, and the results are shown in Table 4.

[0036] The slump loss of the SY-1 test is 11mm less than that of the blank test, which is 30.6%, the bleeding is reduced from 36% to 7%, the impermeability level is increased to P19, the anchorage force of the steel bar is increased by 19.5%, and the chloride ion diffusion coefficient is increased from 4.8 Reduced to 4.4, saving 40 kg per cubic concrete cement. The 7-day, 28-day, and 60-day strengths are slightly higher than blank concrete.

[0037] The mix ratio of SY-2 remains the same, 0.6% synergist is added, the test slump loss is 10mm less than that of the blank test, that is, 27.8%, the blee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com