Anti-freezing concrete and preparation method thereof

A technology for concrete and cementitious materials, applied in the field of concrete, can solve the problems of excessive admixtures, complex process, difficult mixing ratio design, etc., and achieve the effects of excellent frost resistance, simple formula, and uncomplicated production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of frost-resistant concrete, the raw materials used are composed of aggregate, cementitious material, water-reducing agent, waterproofing agent and water, calculated on the basis of each cubic meter of frost-resistant concrete:

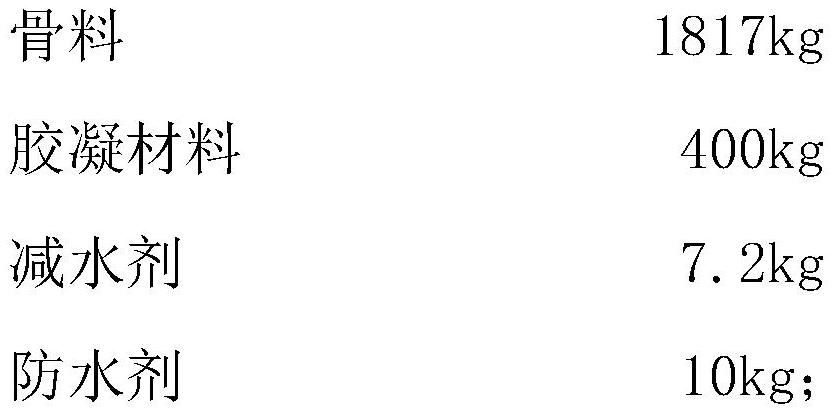

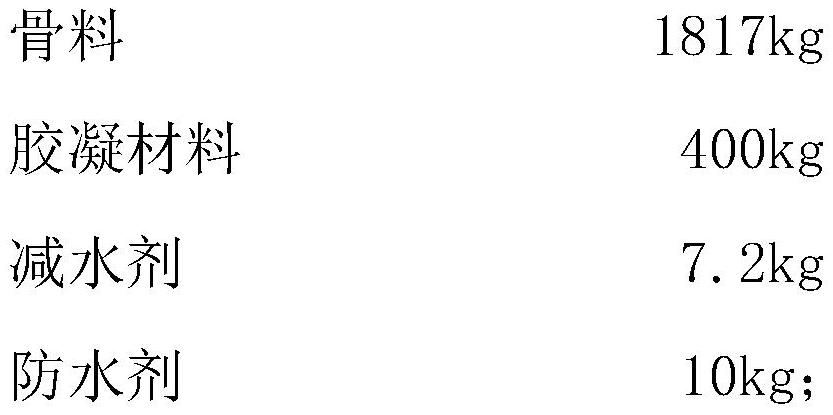

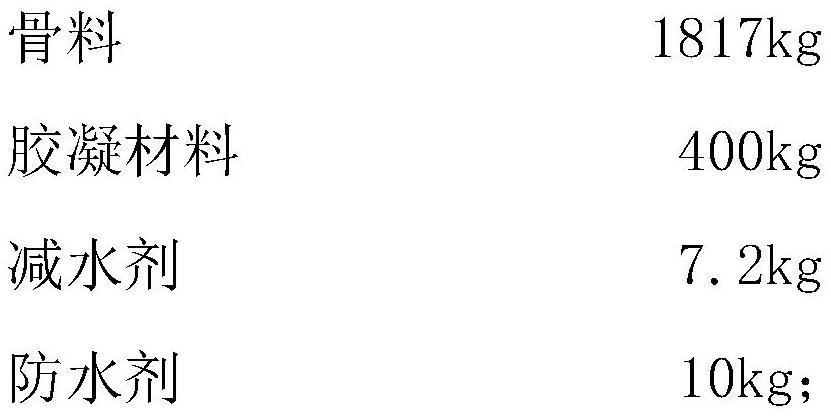

[0040] The amount of raw material aggregate, cementitious material, water reducing agent and waterproofing agent used is as follows:

[0041]

[0042] The amount of raw material water used is 176kg, which is calculated according to the ratio of water: gelling material weight ratio of 0.44:1;

[0043] The aggregate is composed of 745kg medium sand and 1072kg crushed stone, the ratio of medium sand and crushed stone is calculated by weight ratio, medium sand: crushed stone is 1:1.44;

[0044] The medium sand has a fineness modulus of 2.7, a porosity of 42%, and an apparent density of 2610kg / m 3 , the particle size is 0.35-0.50mm;

[0045] The 1072kg gravel is mixed by 429kg of 5mm≤particle diameter D<20mm gravel and 643kg of 20mm≤part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com