Rigid self-compacting waterproof concrete for underground engineering building construction and preparation method thereof

A waterproof concrete and building construction technology, applied in the field of self-waterproof concrete, can solve the problems of excessive local alkalinity, decreased concrete strength, and reduced durability, and achieve the effects of enhancing mechanical properties, improving compactness, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

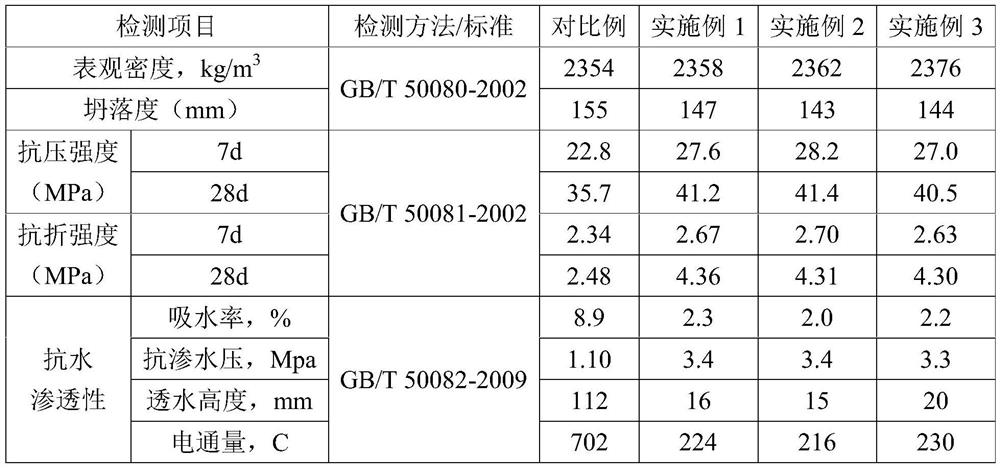

Examples

Embodiment 1

[0038] The rigid self-compacting waterproof concrete for underground engineering construction of the present embodiment is composed of the following components by weight: 315 parts of Portland cement, 1100 parts of coarse aggregate, 680 parts of fine aggregate, 80 parts of coated sand, 18 Parts of silica fume, 5.2 parts of admixture, 23 parts of expansion agent; the water-binder ratio is 0.38;

[0039] The coated sand uses fine sand as the core, and the surface of the fine sand is covered with a siliceous film layer formed by organic silicon material and a powder layer mainly formed by waterproof admixture; the fine sand is combined with organic silicon material, waterproof The mass ratio of the admixture is 70:3.2:6.8;

[0040] Wherein, the silicone material is composed of the following components by weight: 2.2 parts of sodium trimethylsiliconate, 1.0 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane;

[0041] The waterproof admixture is composed of the following components ...

Embodiment 2

[0048] The rigid self-compacting waterproof concrete for underground engineering construction of the present embodiment is composed of the following components by weight: 320 parts of Portland cement, 1080 parts of coarse aggregate, 700 parts of fine aggregate, 85 parts of coated sand, 19 part of silica fume, 5.4 parts of admixture, and 23.5 parts of expansion agent; the water-binder ratio is 0.38;

[0049] The coated sand uses fine sand as the core, and the surface of the fine sand is covered with a siliceous film layer formed by organic silicon material and a powder layer mainly formed by waterproof admixture; the fine sand is combined with organic silicon material, waterproof The mass ratio of the admixture is 75:3.0:7.0;

[0050] Wherein, the silicone material is composed of the following components by weight: 2.1 parts of sodium trimethylsiliconate, 0.9 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane;

[0051] The waterproof admixture is composed of the following compon...

Embodiment 3

[0054] The rigid self-compacting waterproof concrete for underground engineering construction of the present embodiment is composed of the following components by weight: 325 parts of Portland cement, 1070 parts of coarse aggregate, 710 parts of fine aggregate, 90 parts of coated sand, 20 parts part of silica fume, 5.6 parts of admixture, and 24 parts of expansion agent; the water-binder ratio is 0.38;

[0055] The coated sand uses fine sand as the core, and the surface of the fine sand is covered with a siliceous film layer formed by organic silicon material and a powder layer mainly formed by waterproof admixture; the fine sand is combined with organic silicon material, waterproof The mass ratio of the admixture is 80:2.6:7.4;

[0056] Wherein, the organosilicon material is composed of the following components by weight: 1.8 parts of sodium trimethylsiliconate, 0.8 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane;

[0057] The waterproof admixture is composed of the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com