Low-temperature spraying cement-based mortar material for trenchless pipeline repair and preparation method thereof

A pipeline repair and mortar material technology, applied in the field of building materials, can solve problems such as the aging of underground pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

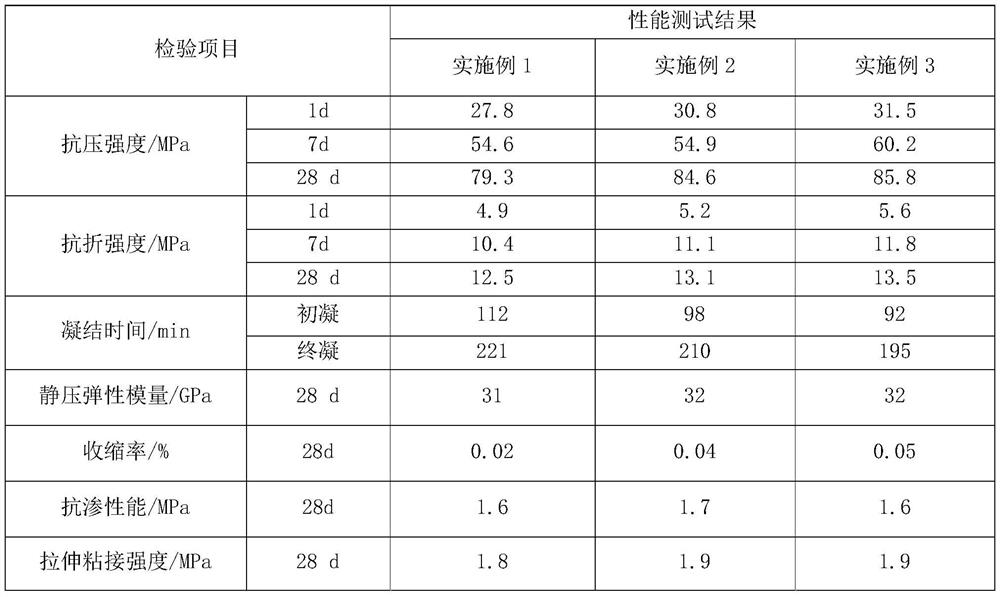

Embodiment 1

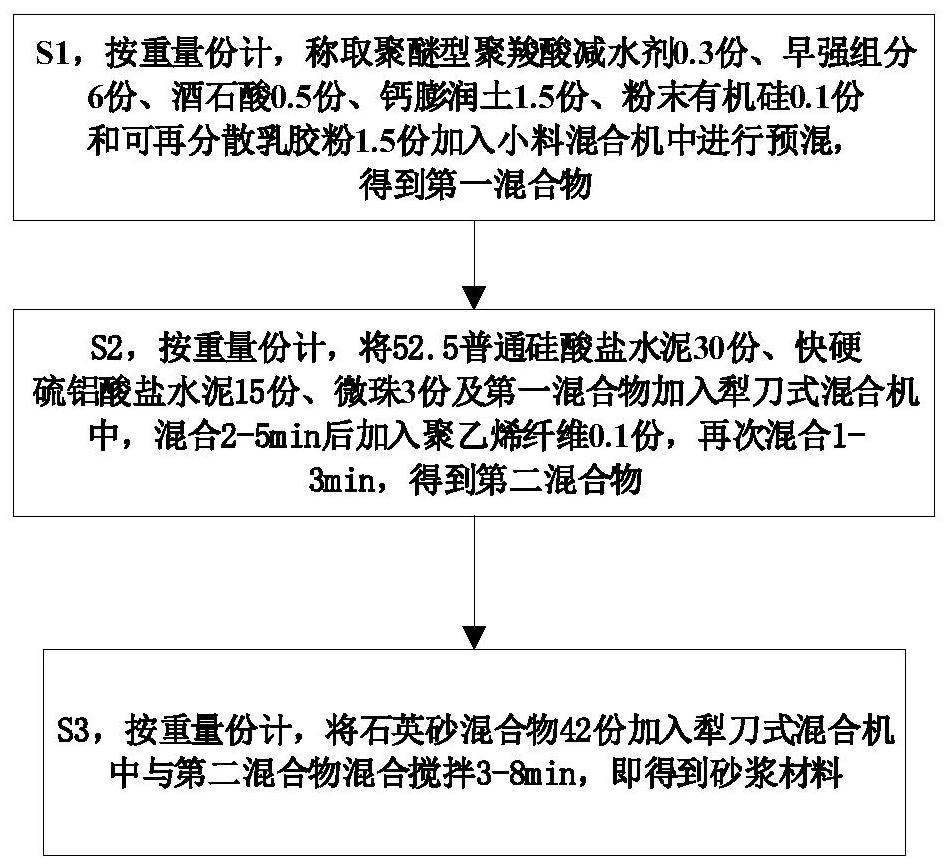

[0033] refer to figure 1 , Embodiment 1 of the present invention provides a kind of preparation method of spraying cement-based mortar material for low-temperature trenchless pipeline repair, comprising the following steps:

[0034] Step S1, in parts by weight, weigh 0.3 parts of polyether polycarboxylate superplasticizer, 6 parts of early strength components, 0.5 parts of tartaric acid, 1.5 parts of calcium bentonite, 0.1 parts of powdered silicone and 1.5 parts of redispersible latex powder Parts were added to a small material mixer for premixing to obtain the first mixture; wherein, by weight, each part of the early strength component was composed of 10 parts of modified nano-silica, 70 parts of dodecacalcium heptaaluminate, calcium formate 10 parts and 5 parts of triethanolamine; modified nano-silica is prepared by the following process: by weight, 100 parts of nano-silica is added to a mixed solution of absolute ethanol and ultrapure water with a volume ratio of 1:1 , ul...

Embodiment 2

[0040] Embodiment 2 provides a method for preparing a sprayed cement-based mortar material for low-temperature trenchless pipeline repair, comprising the following steps:

[0041] Step S1, in parts by weight, weigh 0.25 parts of polyester polycarboxylate water reducer, 5 parts of early strength components, 0.4 parts of boric acid, 1 part of metakaolin, 0.1 part of polyether defoamer, redispersible Add 2 parts of latex powder into a small material mixer for premixing to obtain the first mixture; wherein, in parts by weight, each part of early strength component consists of 10 parts of modified nano-silica, 65 parts of dodecacalcium heptaaluminate , 2.5 parts of calcium formate, and 6.5 parts of triisopropanolamine; modified nano-silica is prepared by the following process: by weight, adding 100 parts of nano-silica to absolute ethanol and In the mixed solution of ultrapure water, ultrasonically disperse for 30 minutes, adjust the pH to 3~4, then add 100 parts of γ-aminopropyltrie...

Embodiment 3

[0047] Embodiment 3 provides a method for preparing a low-temperature trenchless pipeline repair sprayed cement-based mortar material, comprising the following steps:

[0048] Step S1, in parts by weight, weigh 0.2 parts of polyamide-polyethylene glycol branched water reducer, 4.5 parts of early strength components, 0.15 parts of sodium gluconate, 1.5 parts of sepiolite, and 0.15 parts of powdered silicone 1.8 parts, 1.8 parts of redispersible latex powder are added in the small material mixer and carry out premixing, obtain the first mixture; Wherein, by weight, every part of early strength component is made of 25 parts of modified nano silicon dioxide, heptaaluminate Composed of 70 parts of dodecacalcium, 12 parts of calcium formate, and 8 parts of ethylene glycol; modified nano-silica is prepared by the following process: by weight, 100 parts of nano-silica is added to the inorganic compound with a volume ratio of 1:1. In the mixed solution of water ethanol and ultrapure wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com