Method for repairing draught fan concrete foundation cavity through high polymers

A concrete foundation and polymer technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as unsatisfactory repair effect, formation safety, and fans need to be shut down for health period, and achieve technical advantages and economic and social benefits. Remarkable, small construction disturbance, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

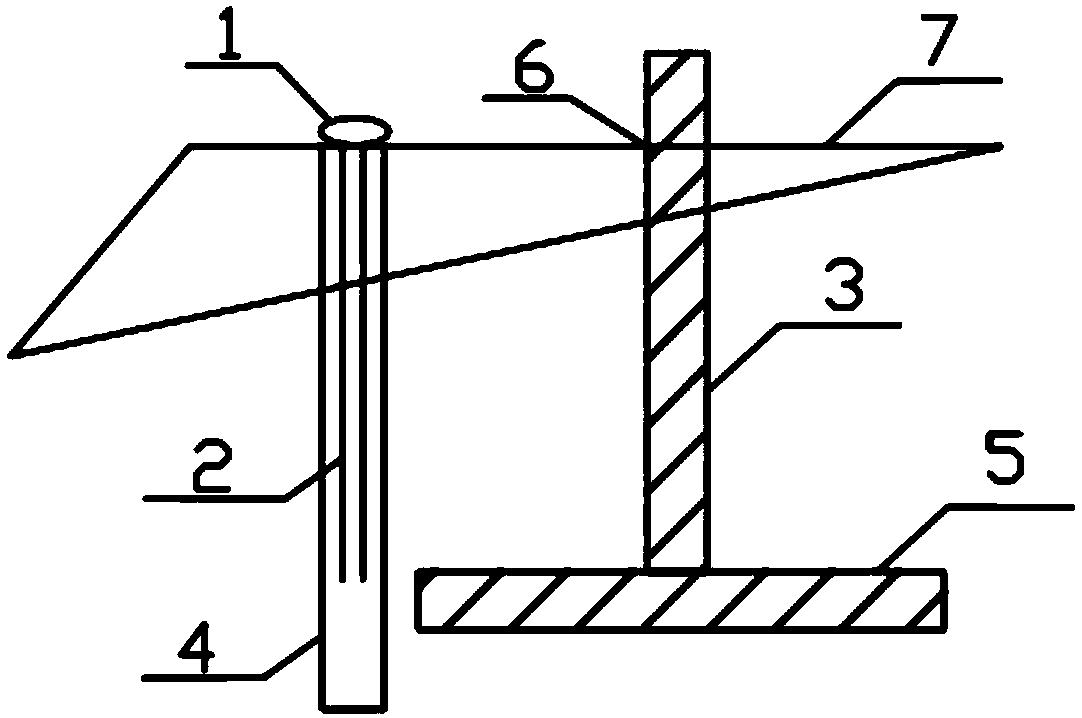

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0033] Step 1 Investigate the degree of tearing and damage of the waterproof material at the joint 6 of the fan concrete cap and the tower tube, and the crack width, and use sealant to seal the crack 6 between the concrete cap and the tower tube; and measure the concrete strength of the concrete cap 7 according to the corresponding regulations.

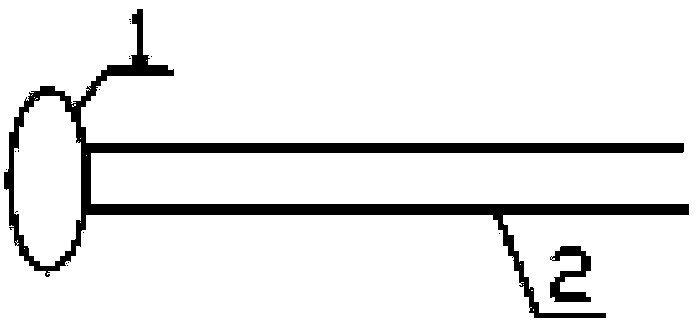

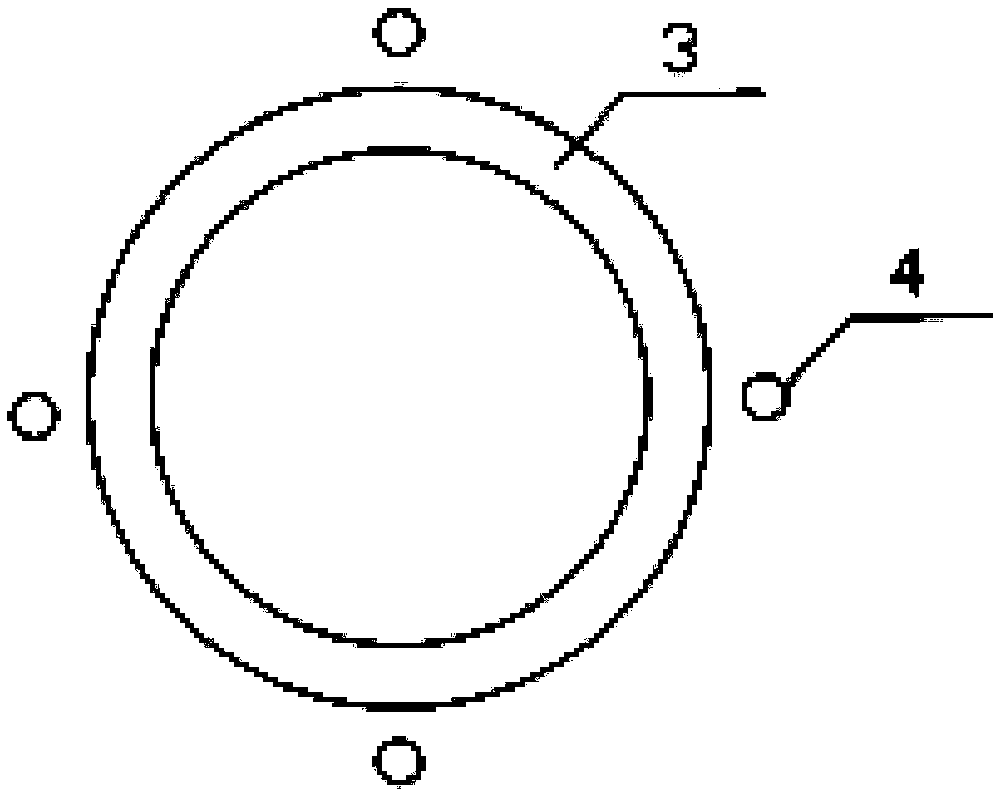

[0034] Step 2 Use the water drilling method or the dry operation method to avoid the perforated ribs and evenly drill four exploration holes 4 vertically on the concrete cap. The micro camera 9 connected by the transmission line 8 is put into the probe hole, slowly descends and continuously rotates to the bottom of the hole to observe the cracks and voids inside the concrete structure, and the whole process is recorded and saved. Micro camera equipment has its own light source and has the function of real-time data t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com