Water channel structure of cylinder cover

A cylinder head and water channel technology, applied in the directions of cylinder head, cylinder, engine components, etc., can solve the problem of uneven cooling in the four nose bridge areas, and achieve the effects of simple structure, reduced temperature stress, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

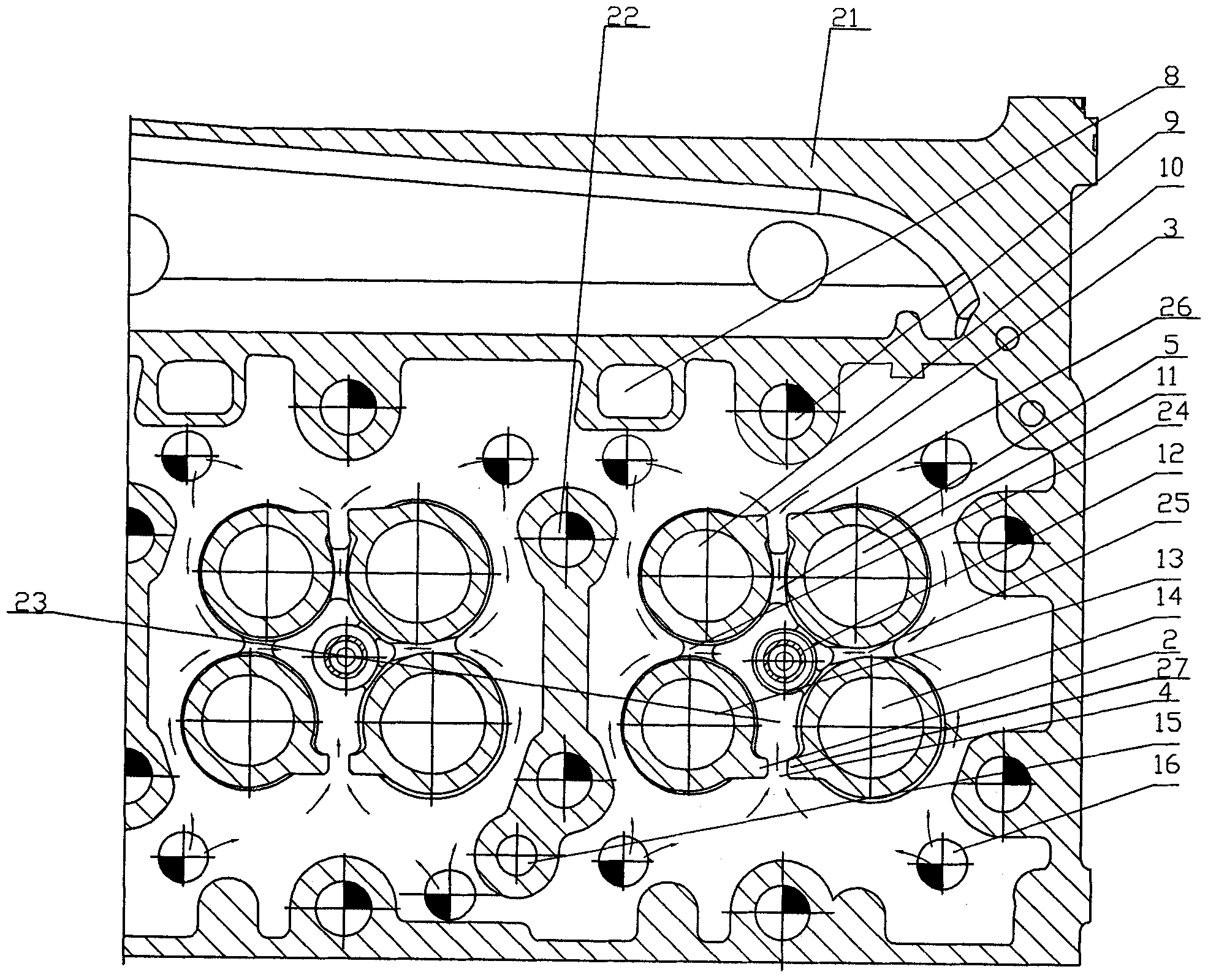

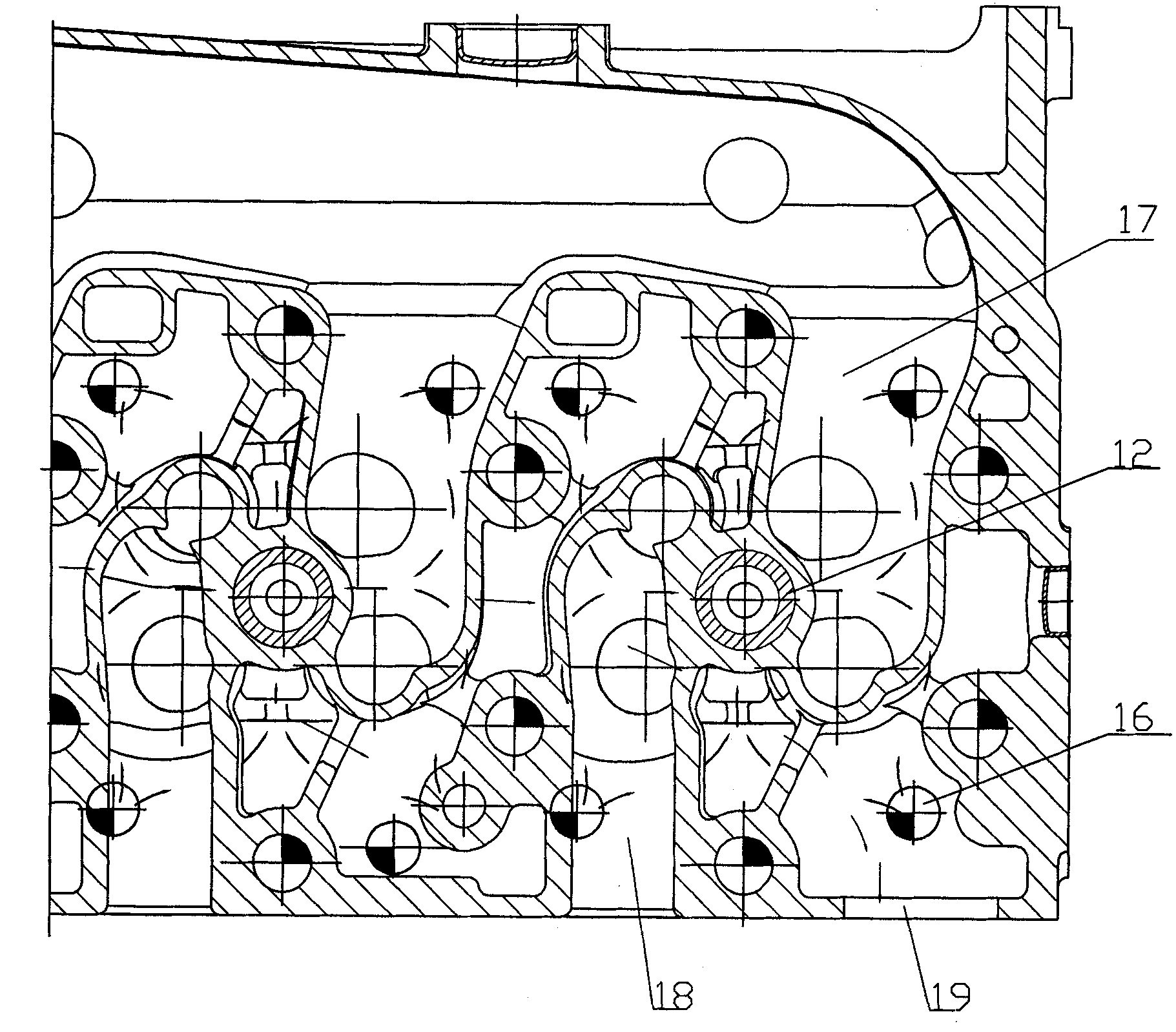

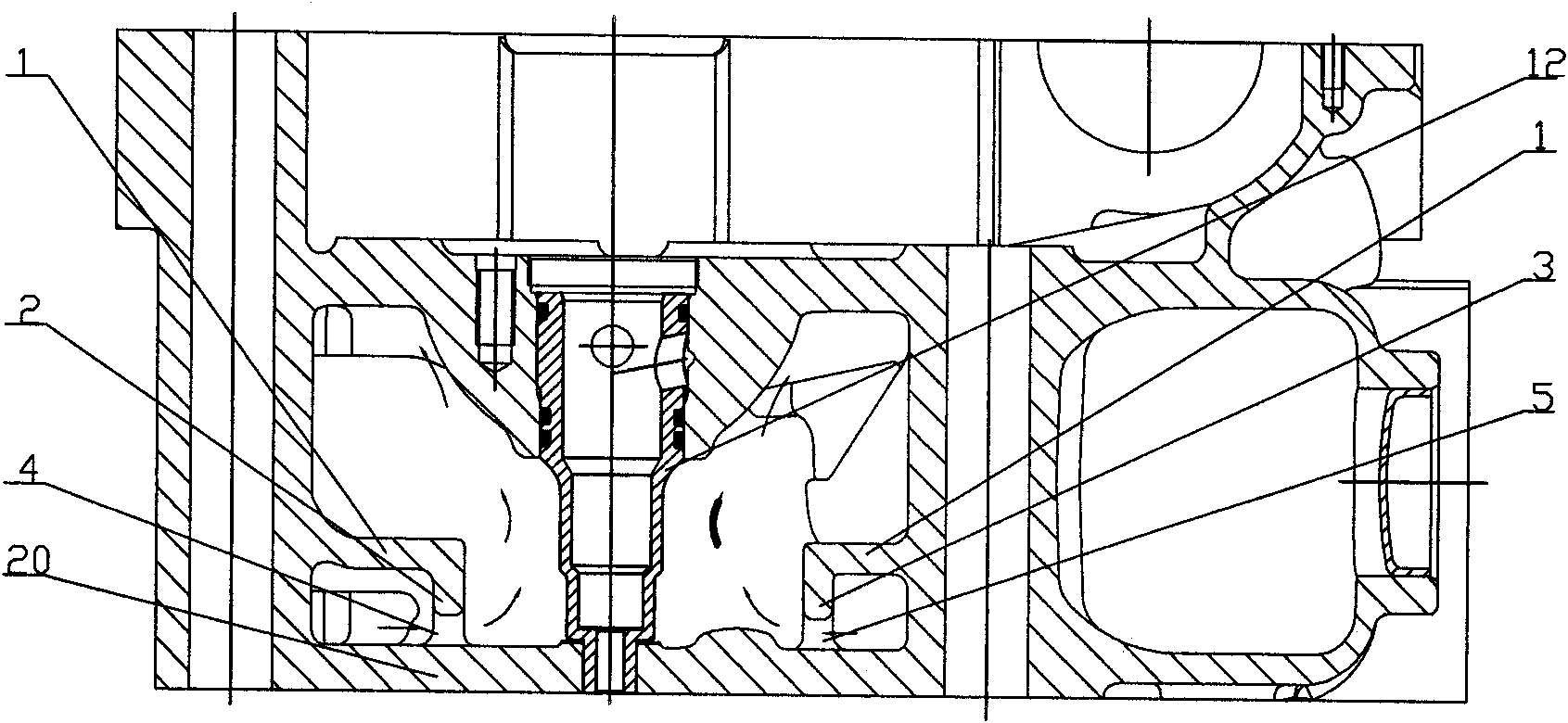

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0015] As shown in the figure: horizontal plate 1, third nose bridge convex plate 2, first nose bridge convex plate 3, second auxiliary waterway 4, first auxiliary waterway 5, lower waterway 6, upper waterway 7, respiratory tract 8, bolt holes 9, The first exhaust valve seat hole 10, the first intake valve seat hole 11, the injector bushing 12, the second exhaust valve seat hole 13, the second intake valve seat hole 14, the oil return hole 15, the water inlet Hole 16, air intake channel 17, exhaust channel 18, water outlet 19, cylinder head 21, oil inlet hole 22, communication channel 23, first communication hole 24, second communication hole 25, second nose bridge convex plate 26 and the first Four nose beam convex plates 27 and other parts constitute.

[0016] The cylinder head waterway structure includes the first intake valve seat hole 11, the first exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com