Underground station strong constraint superposed wall lining cast-in-place concrete structure crack control method

A technology of concrete structure and lining concrete, which is used in underwater structures, infrastructure engineering, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

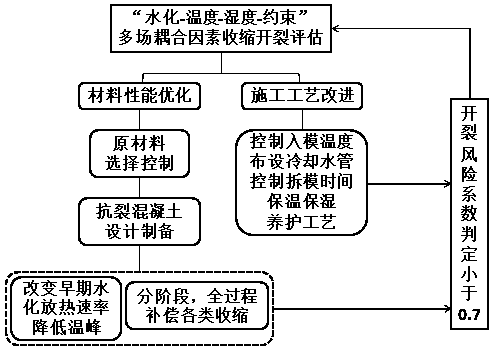

Problems solved by technology

Method used

Image

Examples

Embodiment 1

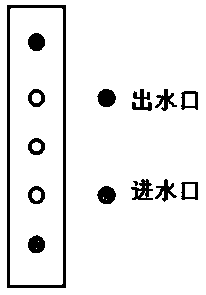

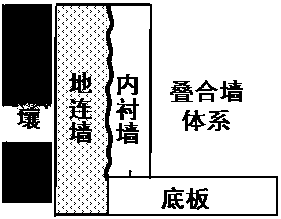

[0114] Apply the crack control method of the cast-in-situ concrete structure of the strong constrained laminated wall lining of the present invention to the construction of the main structure of an underground station. The station is an island-type single-column double-span wiring station. 4. Four foundation pits in area 1-b are constructed. The total length of the station is 590.68m, and the width is 20.14m. The open-cut method is adopted for construction. The underground enclosure structure adopts an 800mm ground connection wall, and the thickness of the inner lining is 400mm. The concrete design number is C35P8. 56d electric flux ≤ 1700C, the formwork process adopts steel formwork, the waterproof level is the first level, and the requirements for crack resistance and seepage resistance are high. For its structure, see figure 2 .

[0115] Apply the crack control technology of the present invention to the construction of part of the inner lining of the superimposed wall of t...

Embodiment 2

[0124] Apply the crack control method of the cast-in-situ concrete structure of the strong constraint laminated wall lining of the present invention to the laminated wall lining structure of the main structure of an underground station of rail transit. About 3.0m, and the buried depth of the floor is about 18.1m. The structure of the station adopts a double-column and three-span cast-in-place reinforced concrete box structure system. The lining wall of the standard section is 400mm, and the end well is 600mm. C35P8, the waterproof grade is the first grade, and the requirements for anti-crack and anti-seepage are high, and the electric flux of 56d is ≤1700C. The crack control technology of the present invention was used for the construction of part of the superimposed wall linings of No. 1, 3, and 5 foundation pits of the station. The construction time was from June 2018 to September 2018, spanning the entire summer high temperature season.

[0125] According to the crack cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric flux | aaaaa | aaaaa |

| Activity index | aaaaa | aaaaa |

| Fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com