Preparation method of composite cement with low clinker dosage and high flexural compression ratio

A technology of composite cement and folding ratio, applied in the direction of cement production, etc., can solve the problems of limited application range and dosage, large water demand, low activity, etc., achieve good crack resistance, eliminate increased water demand, and initial porosity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] At present, the dosage and properties of commercially available Portland cement (P.II) and ordinary Portland cement (P.O) are shown in Table 2. The bulk density of Portland cement and ordinary Portland slurry is about 50%, and its 28-day folding ratio is about 0.2.

[0049] Table 2 Proportion and properties of Portland cement and ordinary Portland cement

[0050]

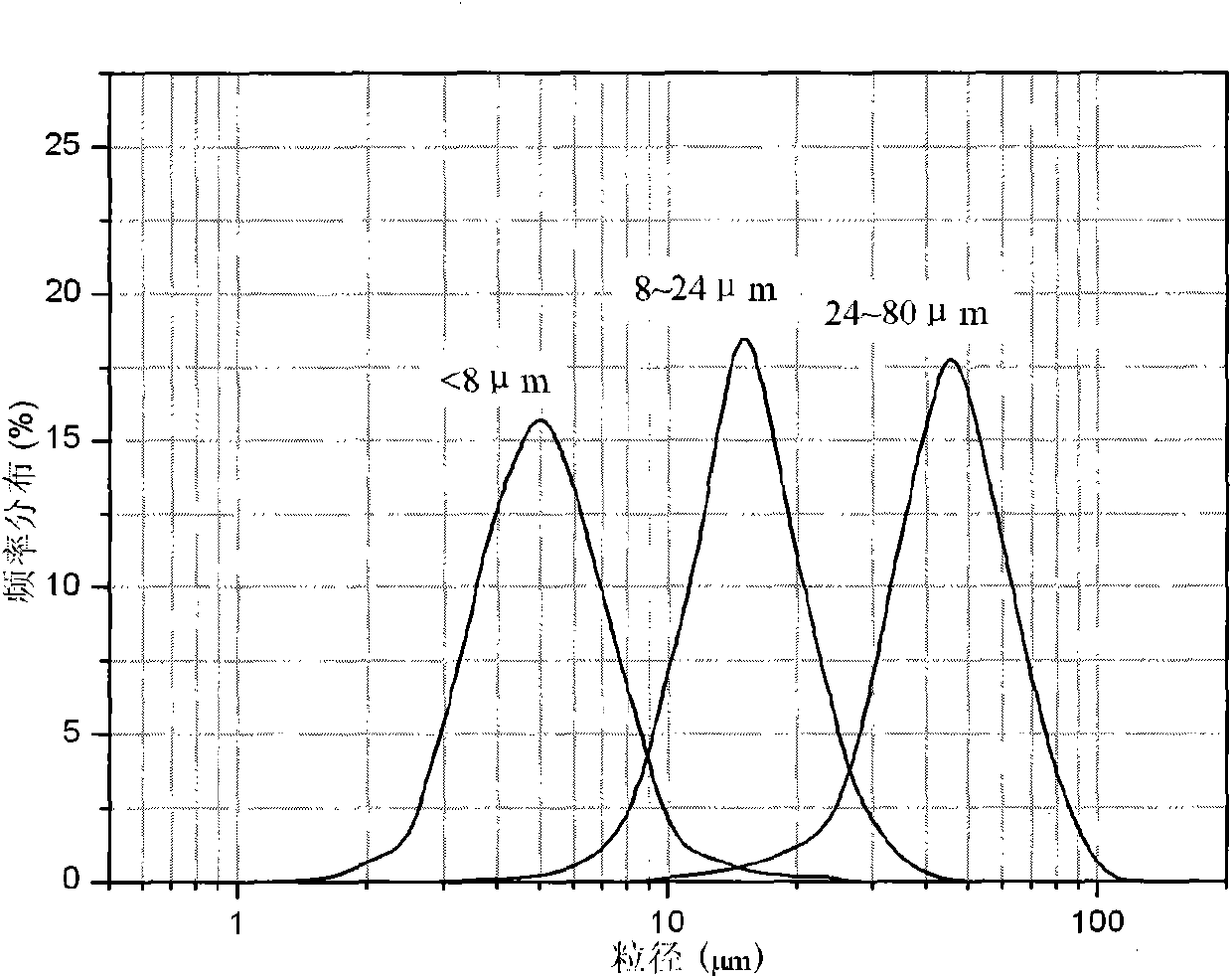

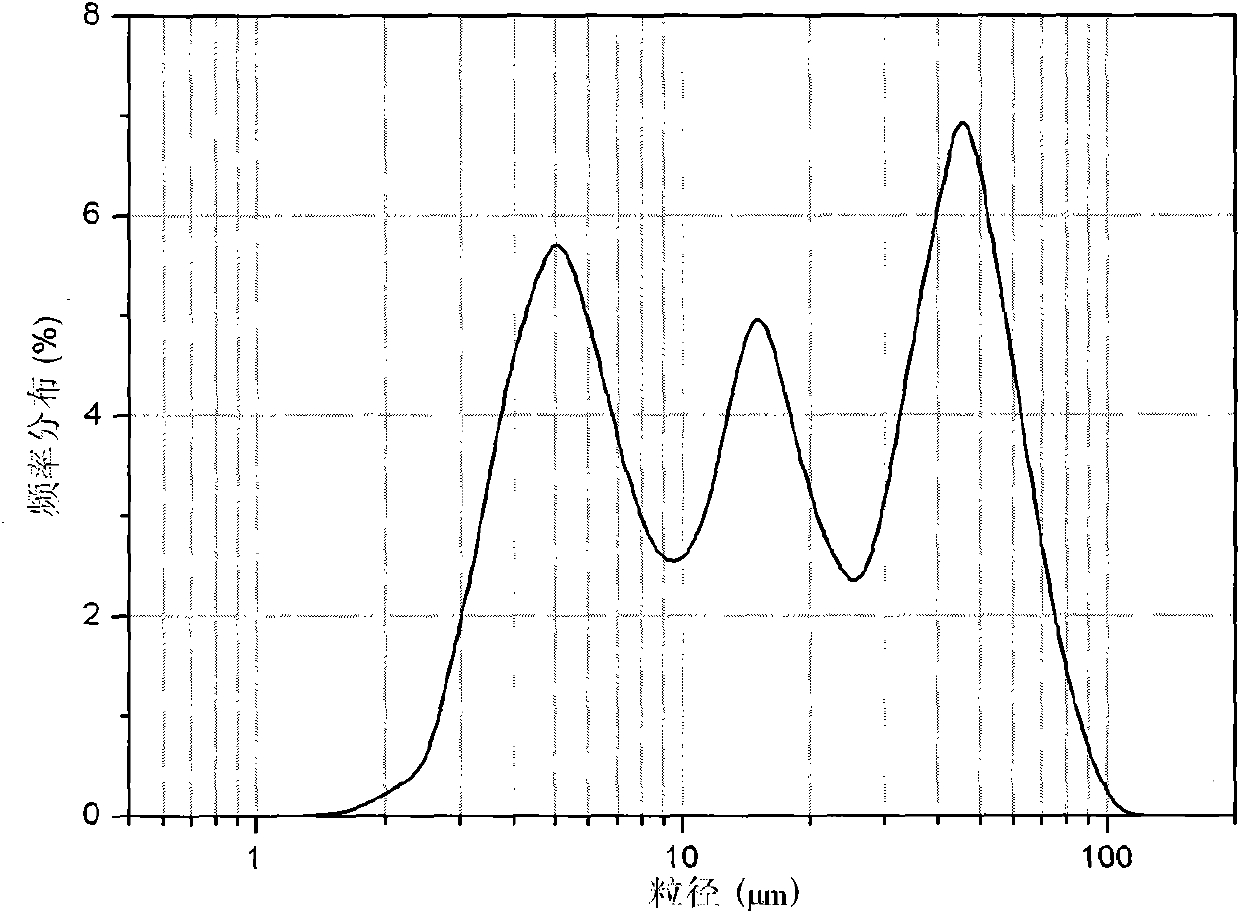

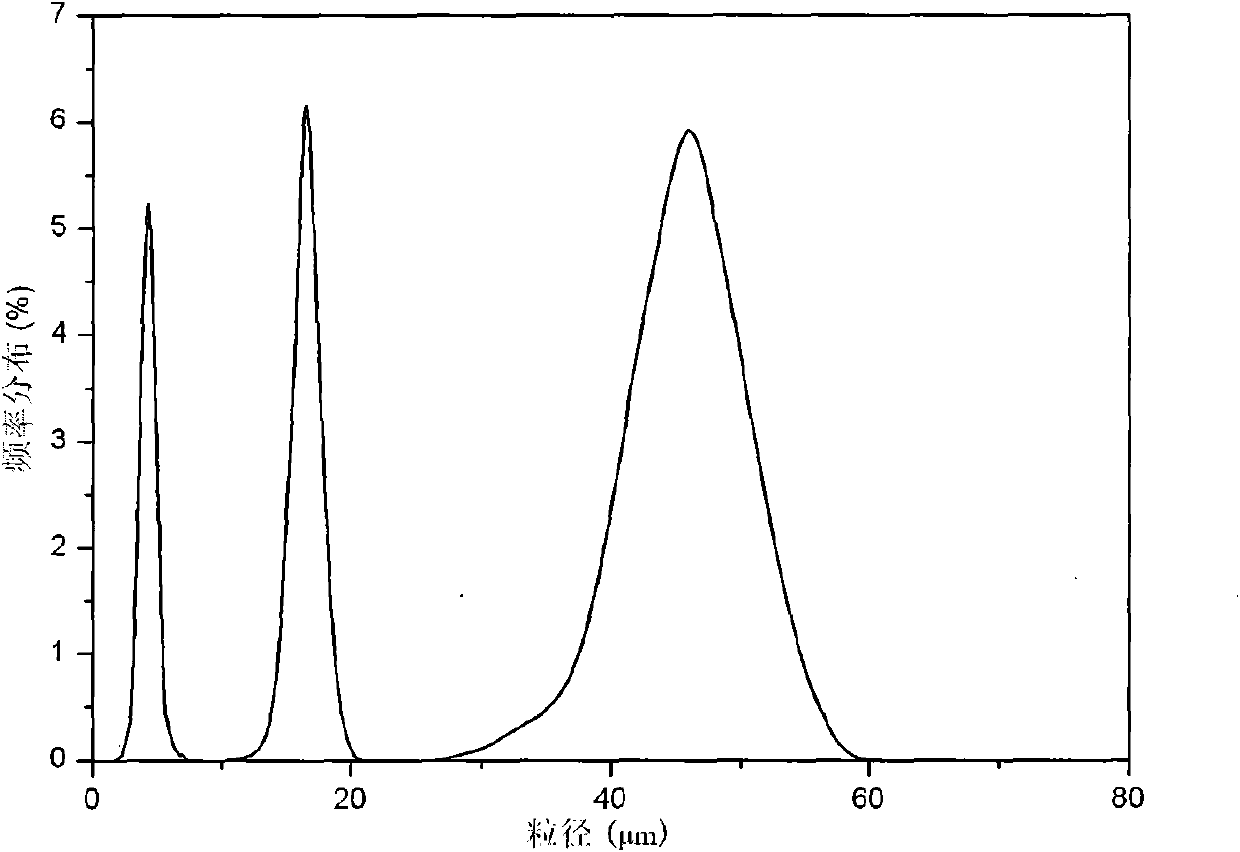

[0051] According to the method of the present invention, the above-mentioned cementing components that meet the "interval narrow distribution" are distributed according to the content of each interval and the type of cementitious material in Table 3, and the prepared composite cement particle distribution is as follows: Figure 5 , Image 6 shown. Due to the limited classification efficiency of the particle classifier, there is a certain degree of overlap in each interval, and the prepared composite cement with the particle characteristics of "narrow interval distribution and overall wide distribution" h...

Embodiment 2

[0055] Table 4 shows the properties of the composite cement prepared by using the above-mentioned gelling components conforming to the "narrow interval distribution" according to the content of each interval and the type of gelling material in Table 4.

[0056] Table 4 Proportion and performance of composite cement with particle characteristics of "narrow distribution in intervals and wide distribution in the whole"

[0057]

[0058]

Embodiment 3

[0060] Table 5 shows the performance of the composite cement prepared by using the above-mentioned gelling components that meet the "narrow interval distribution" according to the content of each interval and the type of gelling material in Table 5.

[0061] Table 5 Proportion and performance of composite cement with particle characteristics of "narrow distribution in intervals and wide distribution in the whole"

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com