Coating system dedicated for outer wall reflecting and heat-insulating paint and construction method of coating system

A technology of reflective thermal insulation coating and construction method, applied in the field of coating systems, can solve the problems of easy cracking and water seepage, insufficient thermal insulation effect, etc., and achieve the effects of enhanced thermal insulation effect and increased thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

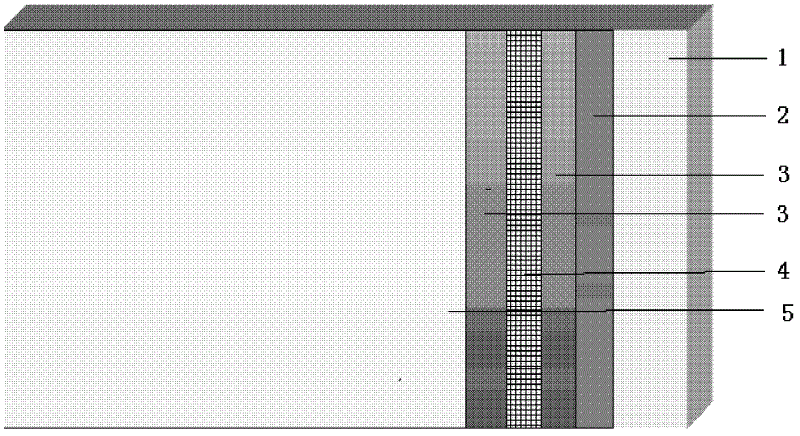

[0052] Such as figure 1 A special coating system for external wall reflective and thermal insulation coatings is shown. From the base wall surface 1, there are: thermal insulation leveling putty layer 2, anti-cracking layer, sealing primer and reflective thermal insulation coating topcoat layer 5. The anti-cracking layer is composed of two layers of thermal insulation putty 3 and a glass fiber mesh cloth 4 located in the middle. In specific implementation,

[0053] Insulation leveling putty by weight percentage is composed of the following components:

[0054] Ordinary Portland cement 30%,

[0055] Fly ash 20%,

[0056] Dispersible latex powder 1%,

[0057] Vitrified beads 38.4%,

[0058] Quartz sand 8%,

[0059] Hydroxypropyl cellulose 0.3%,

[0060] Wood fiber 1%,

[0061] Early strength agent 1%,

[0062] Water reducing agent 0.3%;

[0063] Glass fiber mesh cloth specification is 100g / m 2 , The mesh is 4×4mm, and the alkali resistance breaking strength value (50mm) 800N in the warp and w...

Embodiment 2

[0090] Such as figure 1 Shown is a special coating system for exterior wall reflective thermal insulation coatings. It is provided with: thermal insulation leveling putty 2, anti-crack layer, sealing primer and reflective thermal insulation coating topcoat 5 from the surface of the base wall. The anti-cracking layer is composed of thermal insulation putty 3 and glass fiber mesh cloth 4 located in the middle.

[0091] Thermal insulation and leveling putty is composed of the following components by weight percentage:

[0092] Ordinary Portland cement 40%,

[0093] Fly ash 15%,

[0094] Dispersible latex powder 1%,

[0095] Vitrified beads 37.4%,

[0096] Quartz sand 4%,

[0097] Hydroxypropyl cellulose 0.3%,

[0098] Wood fiber 1%,

[0099] Early strength agent 1%,

[0100] Water reducing agent 0.3%;

[0101] Glass fiber mesh cloth specification is 100g / m 2 , The mesh size is 4×4mm, and the alkali resistance breaking strength value (50mm) 800N in the warp and weft direction;

[0102] Insulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com