Ultralow-heat binder composition with high-temperature type latent-heat compound and method for lowering hydration heat of concrete by using same

A technology of compound and binder, applied in the field of ultra-low heat binder composition, to achieve the effect of improving thermal cracking index, excellent latent heat effect, and reducing temperature stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

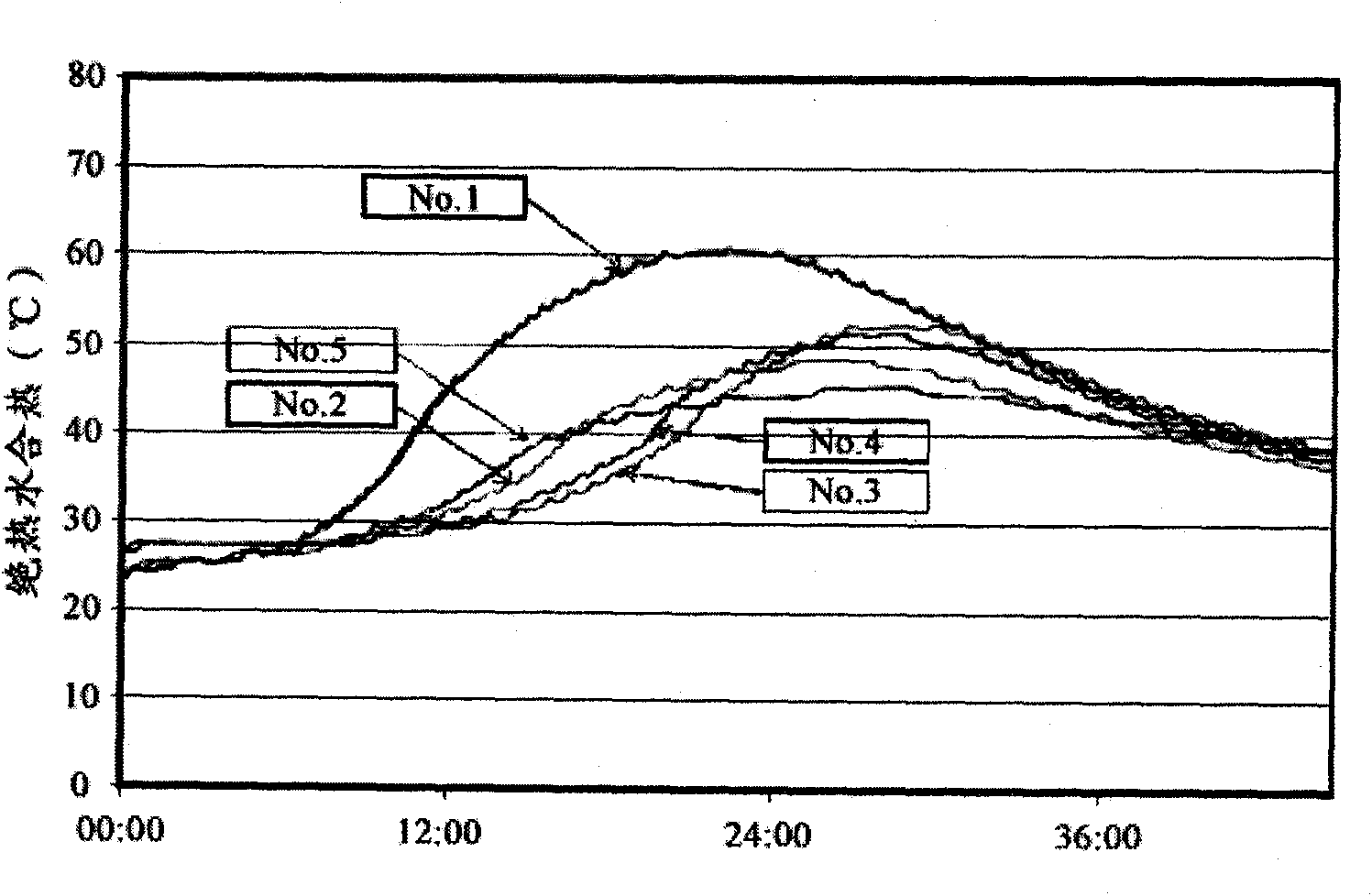

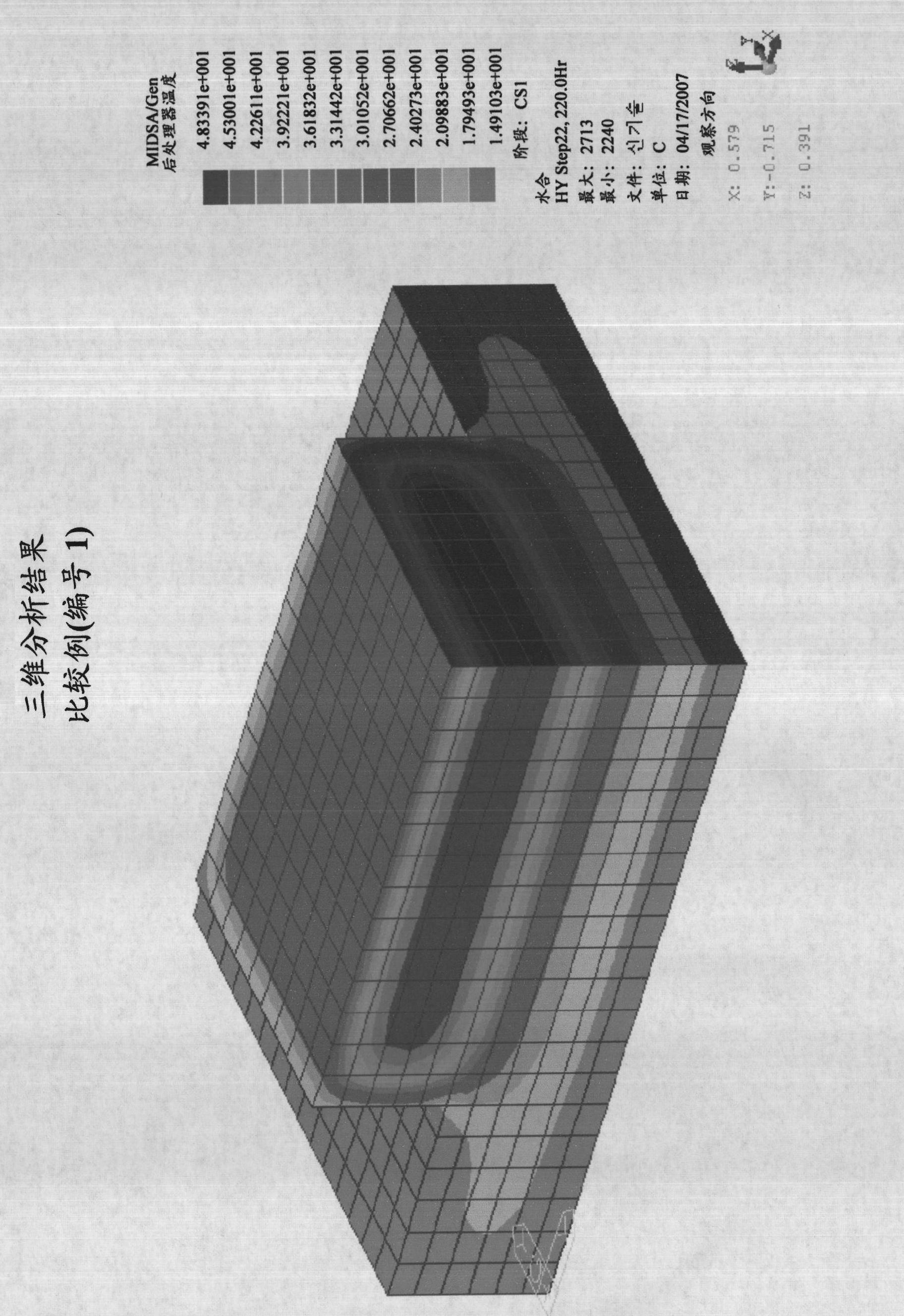

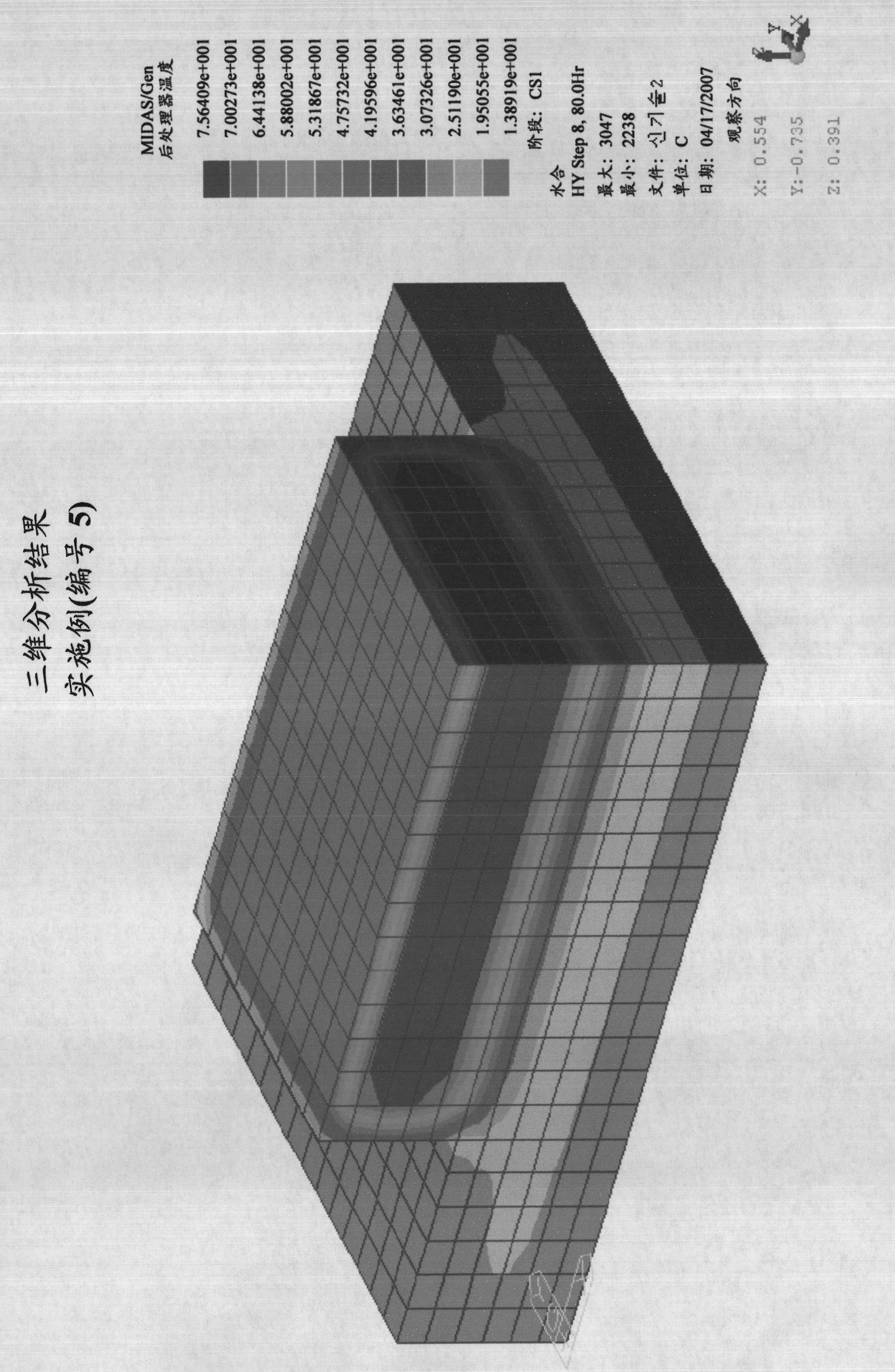

[0041] The latent heat effect latent heat compound-containing ultra-low heat binder of the present invention, and its ability to control concrete physical properties and heat of hydration will now be described in detail.

[0042] According to the mixing standard 25-24-21 (meaning that the maximum particle size of aggregates used in concrete mixing is 25mm, the design strength of 28 days is 24MPa and the slump indicating fluidity is 21em), verified by the embodiments of the present invention and comparative examples The physical properties and heat of hydration properties of the controlled concrete are shown in Table 1 below.

[0043] Table 1

[0044]

[0045] ※Maximum grain size of coarse grain: 25mm, design standard strength: 24.0MPa, slump: 18±2.5cm

[0046] The comparative example is a low heat concrete (No. 1) containing an existing ternary low heat binder consisting of 40wt% Ordinary Portland Cement (OPC), 40wt% Blast Furnace Slag (BFS) and 20wt% Fly Ash (FA). The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com