Turbonator cooling system provided with water cooling stator and inner fan type rotor

A turbogenerator and internal fan technology, applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of high rotor core and rotor winding temperature, unreasonable ventilation design, etc., to improve the safety and stability of operation The effect of ability, ability to lower temperature, and ability to increase heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

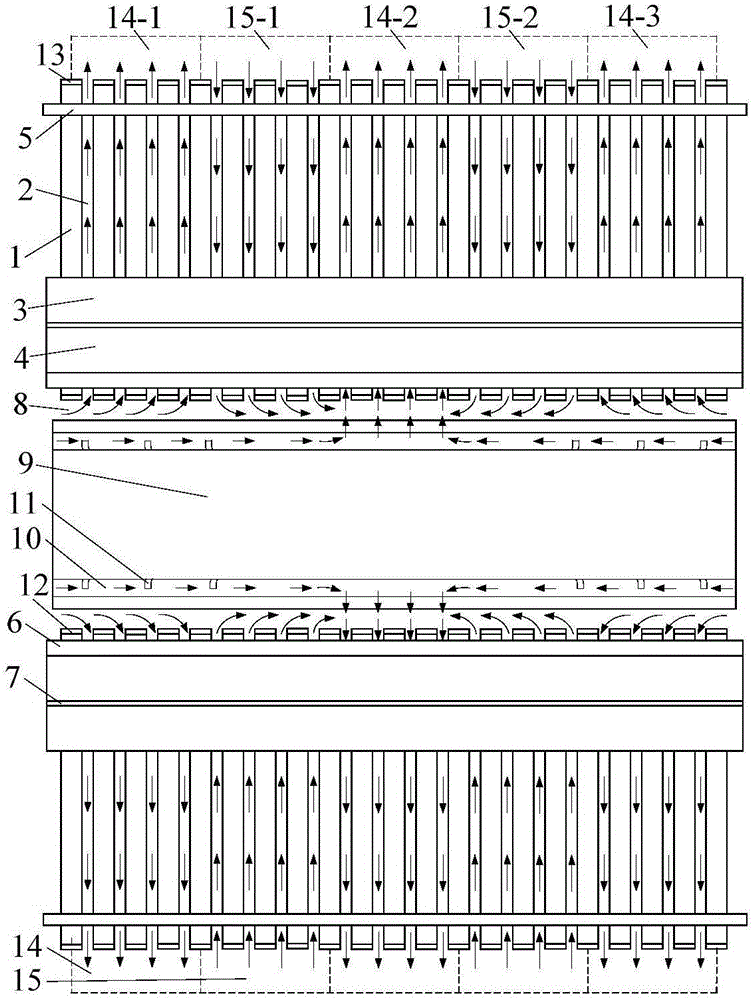

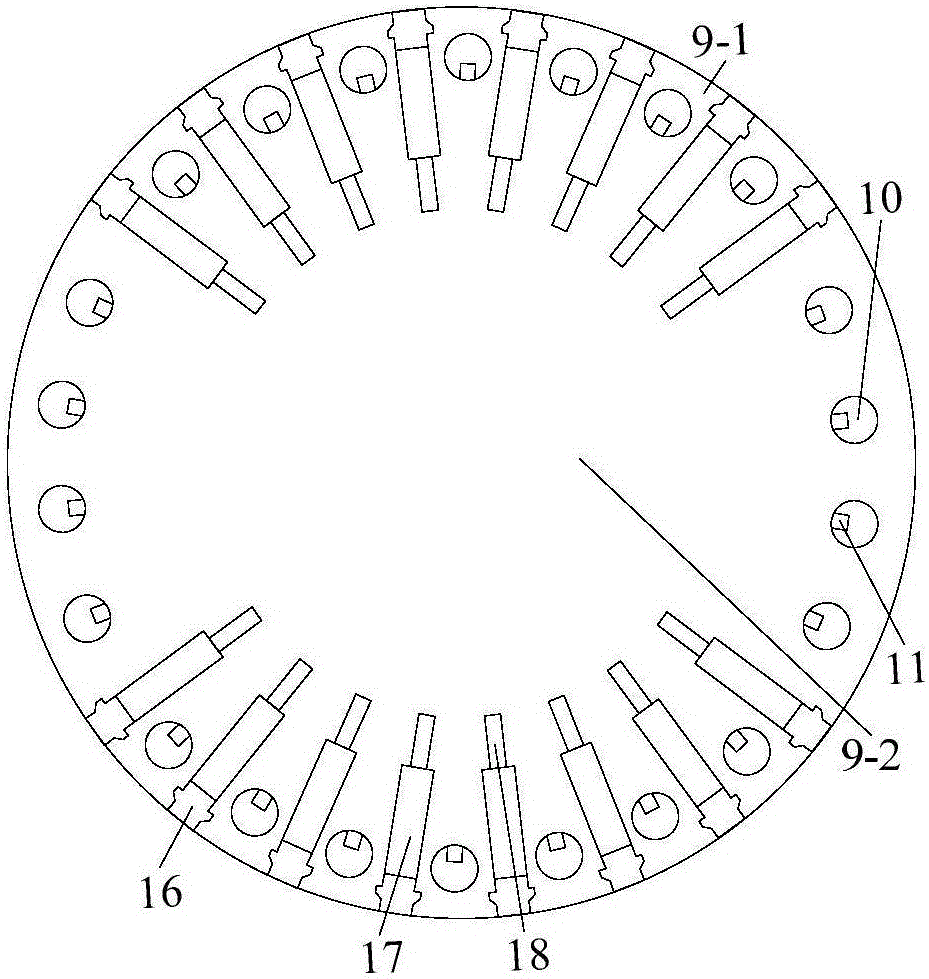

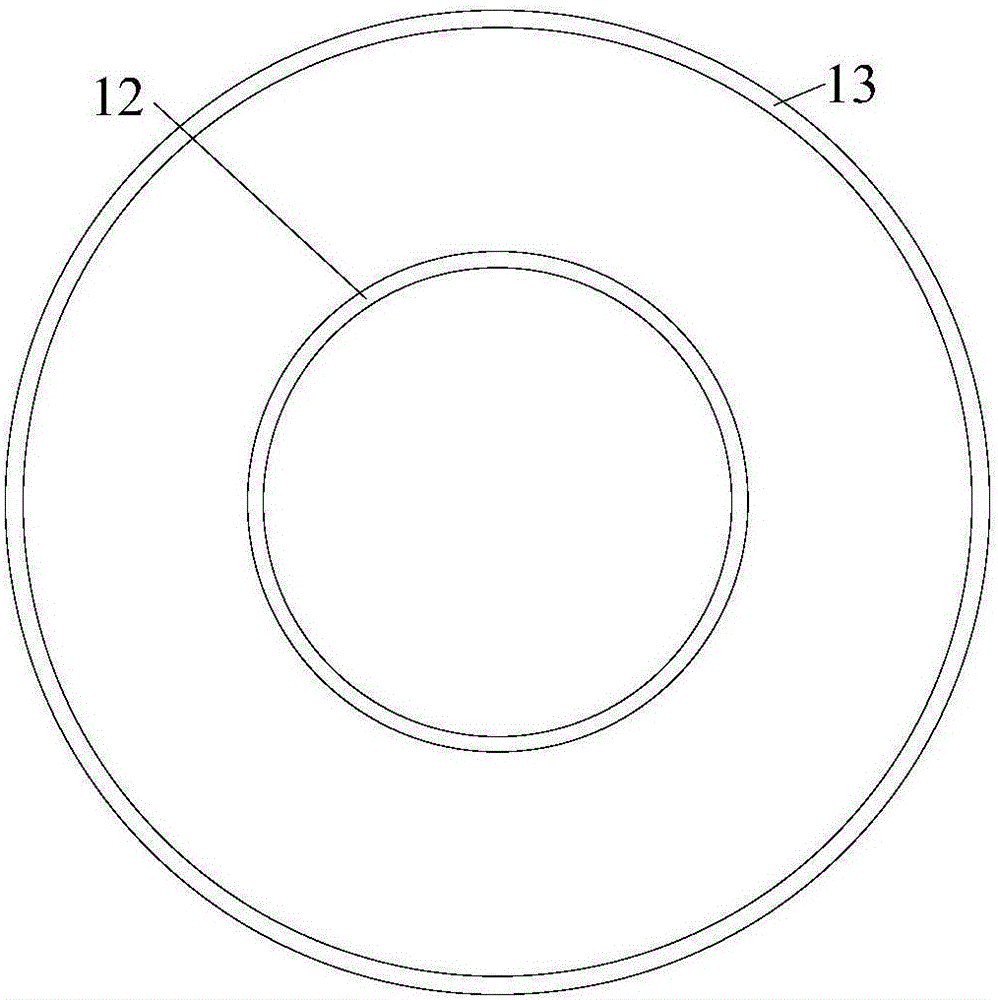

[0026] Specific implementation mode one: combine figure 1 , figure 2 , image 3, Figure 4 with Figure 5 To illustrate this embodiment, a turbogenerator cooling system with a water-cooled stator and an internal fan rotor of the present invention includes a stator, a rotor 9 and an air gap 8 between the stator and the rotor, the stator includes a stator core segment 1 , stator upper layer winding 4 and stator lower layer winding 3 arranged on stator core section 1, stator interlayer insulation 7 arranged between stator upper layer winding 4 and stator lower layer winding 3, stator slot wedge 6, positioning rib 5, the stator The core segments 1 are arranged at equal intervals along the axial direction, and stator radial ventilation grooves 2 are arranged between adjacent stator core segments 1, and the stator radial ventilation grooves 2 communicate with the air gap 8, and also include stator outer surrounding water channels 13 and the stator inner surrounding waterway 12,...

specific Embodiment approach 2

[0032] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , The difference between this embodiment and Embodiment 1 is that all the stator inner surrounding water channels 12 in the first stator hot air zone 14-1, the stator second hot air zone 14-2 and the stator third hot air zone 14-3 In series with each other, that is, the stator inner surrounding water channels of the three hot air zones are connected in series; all the stator outer surrounding water channels in the first stator hot air zone 14-1, the stator second hot air zone 14-2 and the stator third hot air zone 14-3 are connected in series. The water channels 13 are connected in series, that is, the water channels surrounding the stators in the three hot air zones are connected in series. The stator inner surrounding waterway 12 of the first stator cold wind zone 15-1 is connected in series with the stator inner surrounding waterway 12 of the stator second col...

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 The difference between this embodiment and Embodiment 1 is that the stator inner surround Type water pipes 12-2 are connected in series respectively; the stator outer surrounding water pipes 13-2 in each wind area of the stator first hot air area 14-1, the stator second hot air area 14-2 and the stator third hot air area 14-3 respectively connected in series; the stator inner surrounding water pipes 12-2 in each wind region of the first stator cold wind region 15-1 and the stator second cold wind region 15-2 are respectively connected in series; the stator first cold wind region 15-1 and the stator second cold wind region The stator outer surrounding water pipes 13-2 in each wind zone of the cold wind zone 15-2 are respectively connected in series. In the stator hot air zone 14, cooling water with a flow rate of 1.2m / s passes through all the stator inner sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com