Long-wall structure concrete curing device and curing method thereof

A technology for concrete and long walls, applied in the field of construction, can solve the problems of surface wetness, difficult to guarantee humidity uniformity, poor thermal insulation effect of formwork insulation system, rapid water loss on concrete surface, etc. Implement simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

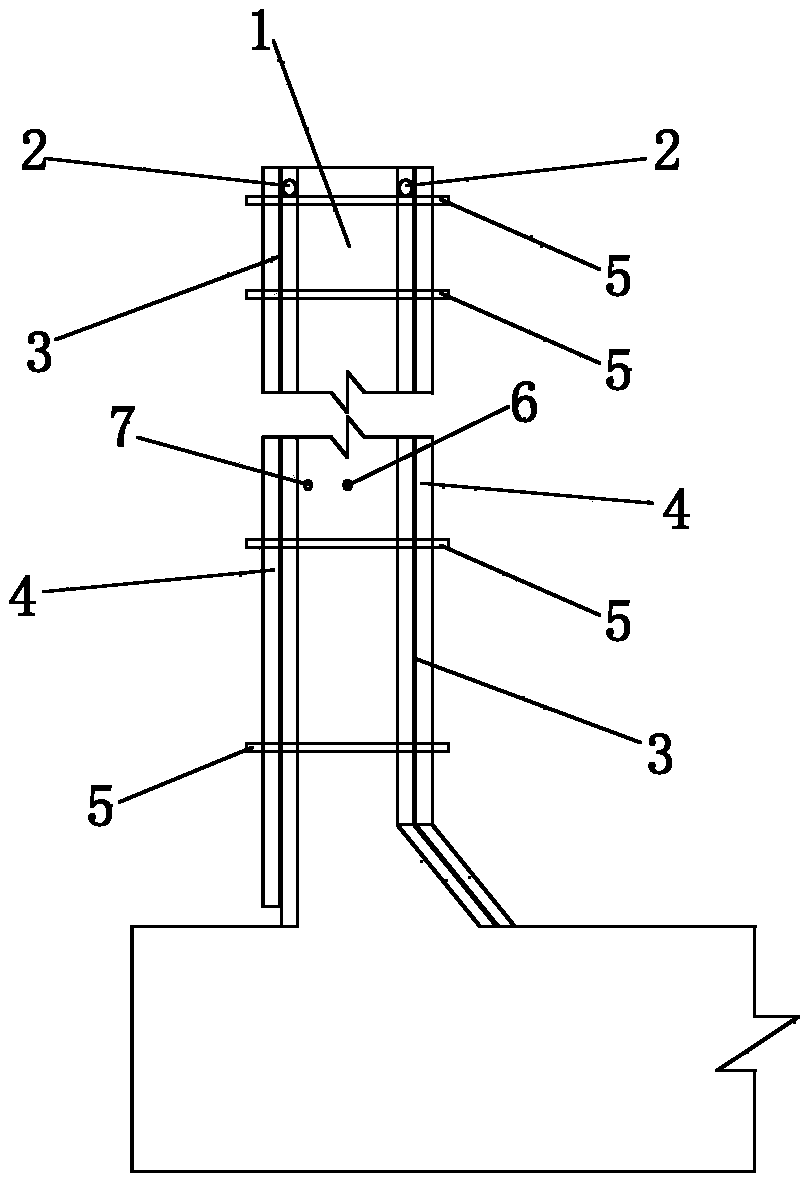

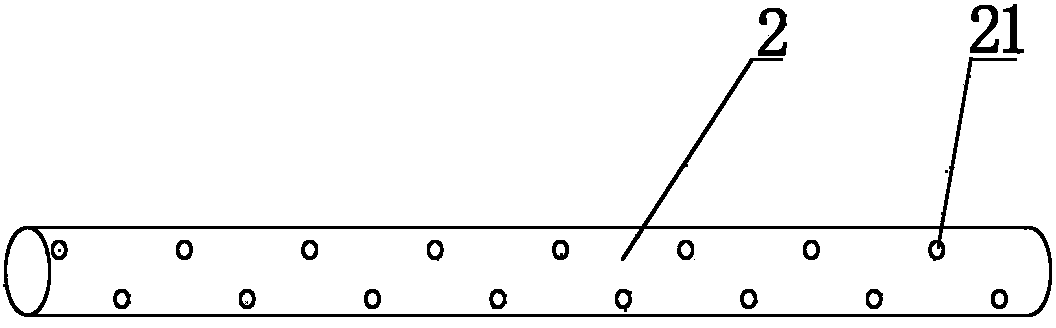

[0031] Such as figure 1 and figure 2 The long wall structure concrete maintenance device shown includes a moisturizing device, a heat preservation device and a temperature measuring device. The moisturizing device includes a spray pipe 2 and a water inlet pipe. The spray pipe 2 is arranged on both sides of the top of the long wall concrete wall 1. Use the template on the top of the wall 1 to pull the bolt 5 to fix the spray pipe 2. The distance between the center of the spray pipe 2 and the outside of the wall 1 is 20mm, and the distance from the top of the wall is 50mm. A valve is set on the water inlet pipe, and the spray pipe 2 is made of a PVC pipe with a diameter of 15 mm. Small holes 21 with a diameter of 4 mm are drilled on the spray pipe 2 at a distance of 300 mm. The thermal insulation device includes a plastic film 3 and a thermal insulation material 4, the thermal insulation material 4 is a thermal insulation quilt, the plastic film 3 is wrapped on the outside of ...

Embodiment 2

[0033] Such as figure 1 and figure 2 The long wall structure concrete curing device shown includes a moisturizing device, a heat preservation device and a temperature measuring device. The moisturizing device includes a spray pipe 2 and a water inlet pipe. The spray pipe 2 is arranged on both sides of the top of the long wall concrete wall 1. Use the template on the top of the wall 1 to pull the bolt 5 to fix the spray pipe 2. The distance between the center of the spray pipe 2 and the outside of the wall 1 is 30mm, and the distance from the top of the wall is 150mm. A valve is arranged on the water inlet pipe. The spray pipe 2 adopts a PVC pipe with a diameter of 25 mm, and drills small holes 21 with a diameter of 6 mm at a distance of 500 mm on the spray pipe 2. 3 and thermal insulation material 4, the thermal insulation material 4 is thermal insulation rock wool, the plastic film 3 is wrapped on the outside of the spray pipe 2 and the wall 1, the thermal insulation rock ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com