Motor stator iron core pressing hydraulic machine

A technology for motor stators and hydraulic presses, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems affecting the centering and assembly accuracy of stator iron cores, high labor intensity of workers, and high production costs, so as to improve efficiency, press-fit quality, and save money. The effect of low resources and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

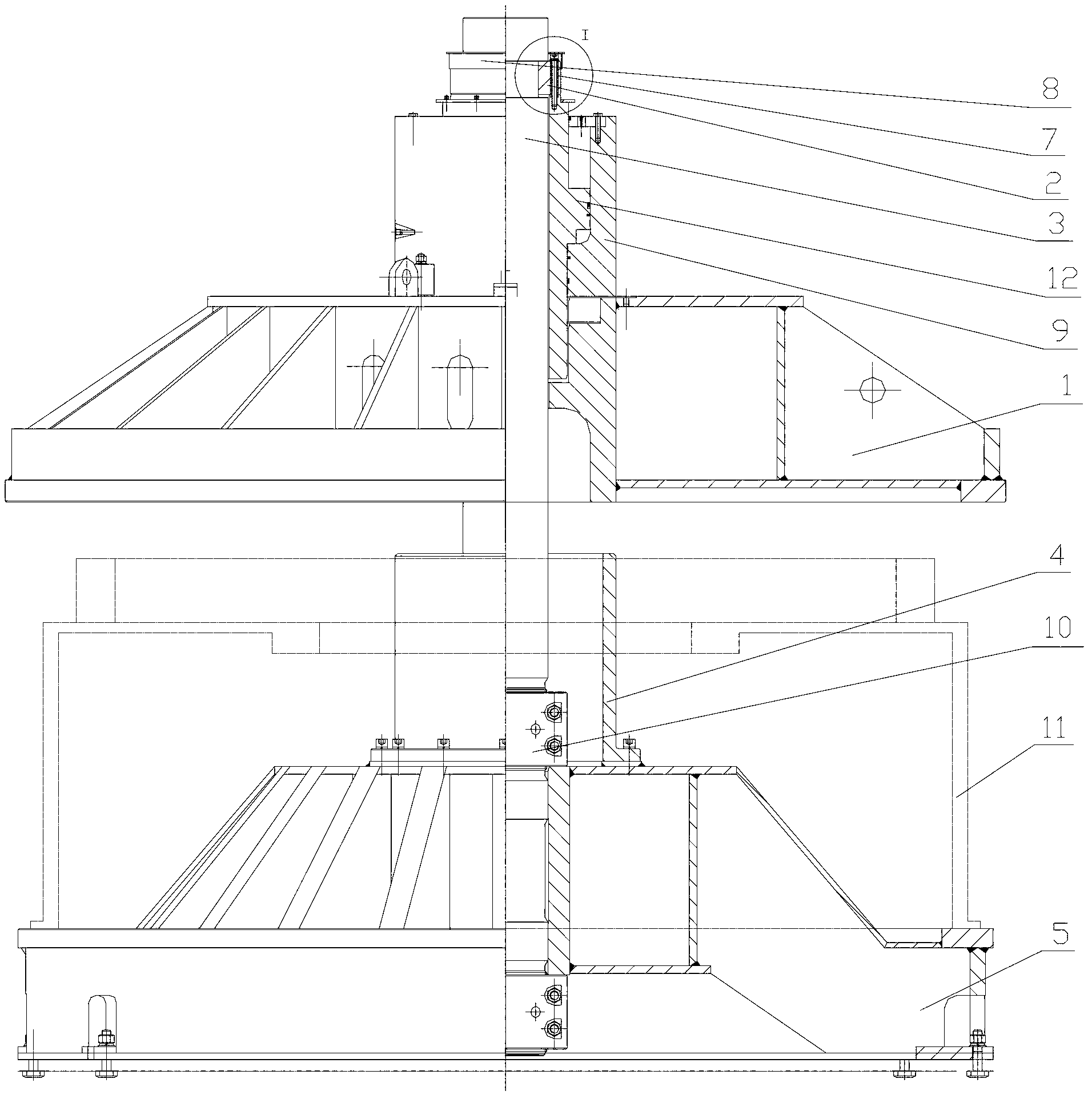

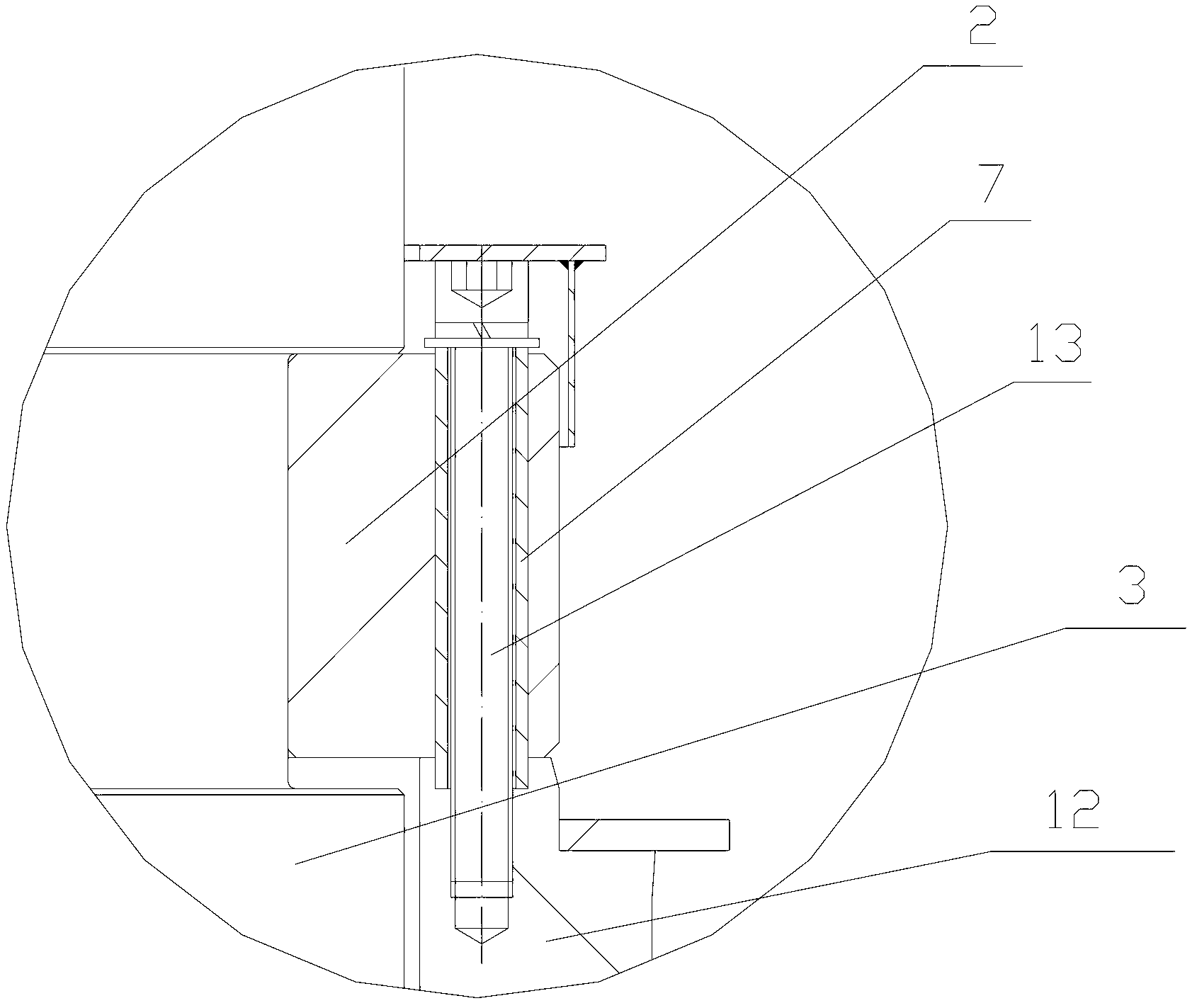

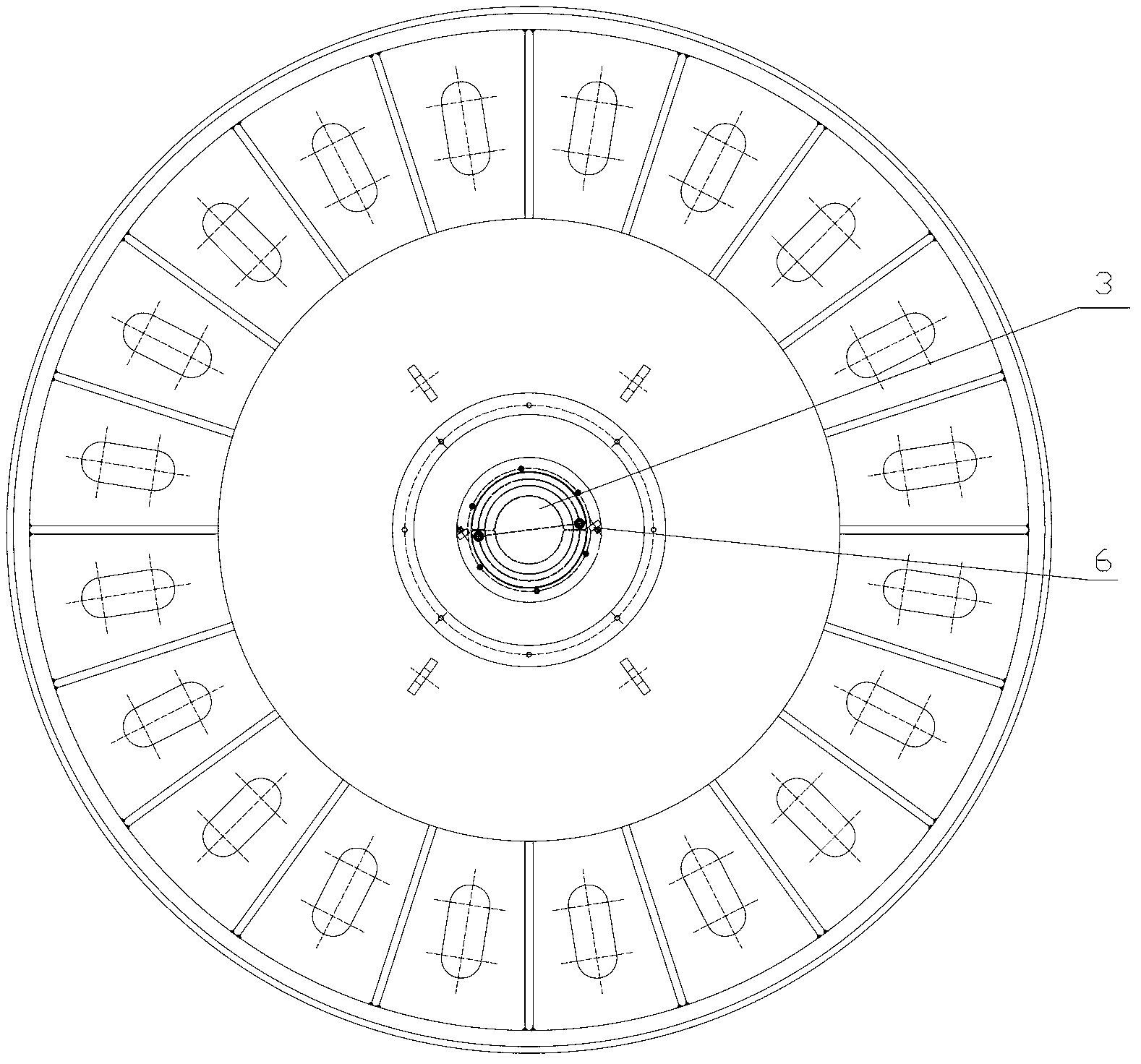

[0024] See Figure 1 ~ Figure 3 , a motor stator core press-fitting hydraulic machine, including an upper pressure plate 1, a tie rod 3, a limit sleeve 4, a lower pressure plate 5, a stopper 6, a sleeve 7, a cover 8, a main cylinder 9 and a mold base 11, the upper Both the pressure plate 1 and the lower pressure plate 5 are welded parts, which are welded by the upper ring, the lower ring, the rib plate, the support arm and the inner cylinder, among which the inner cylinder of the upper pressure plate 1 has a gap with the tie rod 3 Coordinated, the main ribs and the center are radially distributed in a ring, forming an umbrella structure. The lower platen 5 is fixed on the ground through T-shaped screws, and the upper ring of the lower platen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com