Vehicle body front structure

A front body and structure technology, which is applied to the superstructure, substructure, subassembly of the superstructure, etc., can solve the problems of easy deformation, difficult positioning, and difficult use, and achieves easy plastic processing, improved assembly accuracy, and easy handling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

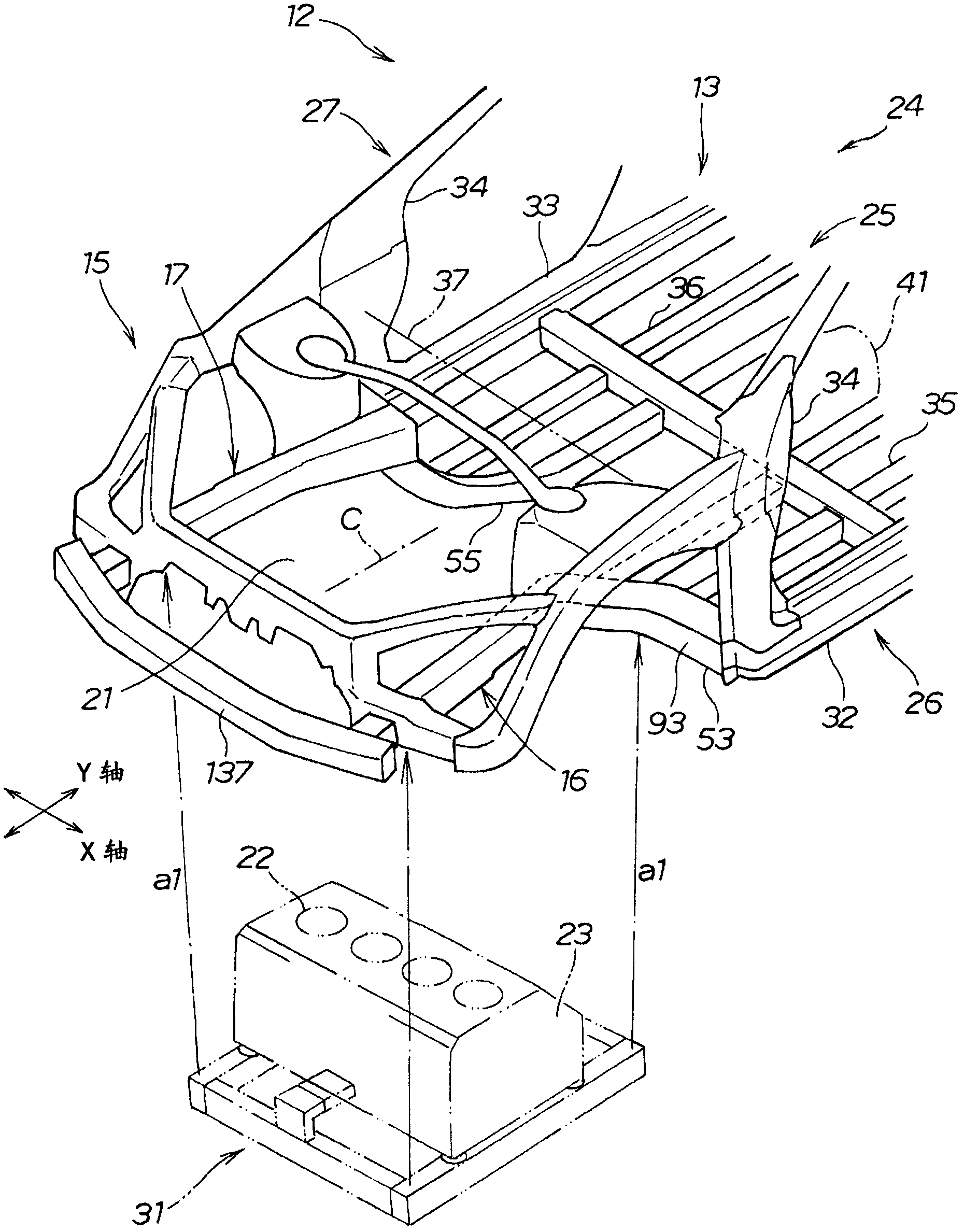

[0068] refer to figure 1 , the vehicle 12 is, for example, an FF (front-engine, front-wheel drive) vehicle, and includes a vehicle body 13 . The engine 22 and the transmission 23 are arranged in the engine compartment 21 located in the front body 15 and supported by the body 13 .

[0069] The vehicle body 13 has an underbody 25 including a front body 15 and a floor, and left and right side bodies 26 , 27 . The front body 15 has an engine room 21 and left and right front side frames 16 and 17 provided below the engine room 21 . The engine 22 is mounted on the subframe 31, and the engine 22 is attached to the left and right front side frames 16 and 17 from below the front body 15 as indicated by the arrow a1. The left and right front side frames 16, 17 are connected to the left and right side bodies 26, 27, respectively.

[0070] The left side body 26 has a left side sill 32 continuous with the left front side frame 16 , and a left front pillar 34 erected at the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com