Injection molding blade pickup mechanical hand

A technology of manipulators and blades, which is applied in the direction of household components, household appliances, and other household appliances, which can solve the problems of inconvenient picking and achieve the effect of reducing noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

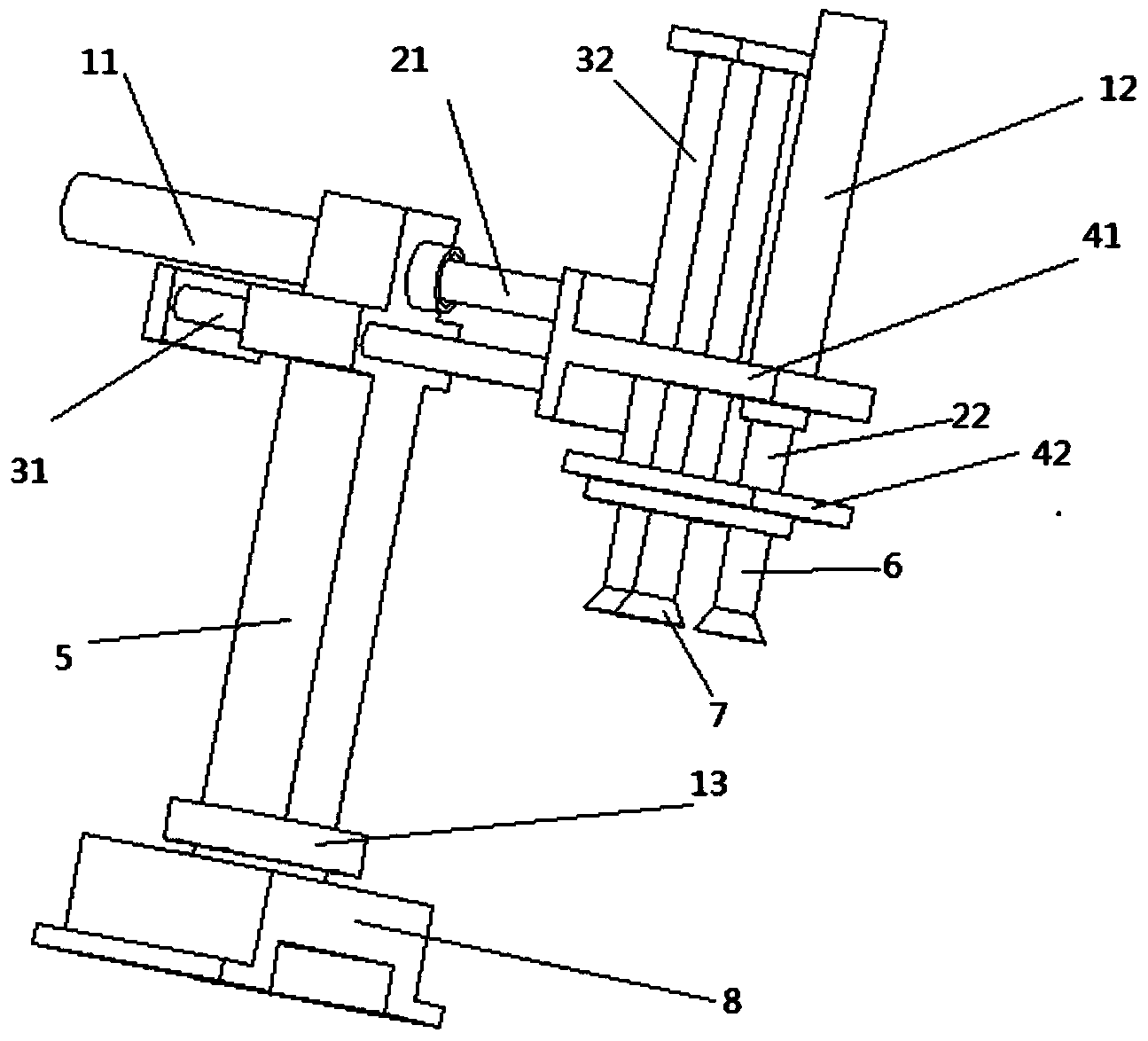

[0008] An injection molding blade picking manipulator is composed of a horizontal cylinder 11, a vertical cylinder 12, a swing cylinder 13, a cylindrical guide rail 31, a cylindrical guide rail 32, a base 8, a body 5, a support plate 41, a support plate 42, a piston rod 21, and a piston rod 22. , telescopic tube 6, and vacuum suction cup 7, the piston rod 21 moves back and forth in the horizontal cylinder 11, the front end of the piston rod 21 is connected with the support plate 41, the horizontal cylinder 11 is fixed on the body 5, and the cylindrical guide rail 31 is installed on the The lower part of the horizontal cylinder 11, the piston rod 22 reciprocates up and down in the vertical cylinder 12, the vertical cylinder 12 is fixed on the support plate 41, the front end of the piston rod 22 is connected with the support plate 42, and the telescopic tube 6 is installed under the support plate 42 , the telescopic tube 6 is connected with the vacuum chuck 7, and the body 5 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com