Surface treatment agent for vulcanized rubber

一种表面处理剂、硫化橡胶的技术,应用在橡胶层状产品、化学仪器和方法、合成树脂层状产品等方向,能够解决涂膜剥落等问题,达到抑制沉降、提高操作性、抑制变形的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

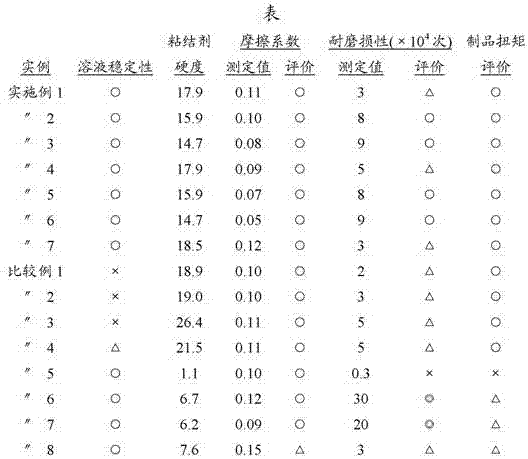

Examples

Embodiment 1

[0052] PTFE resin particles (AGC Semichemical product Fluon 172J, 22 parts by weight

[0053] Particle size is 0.2μm)

[0054] Oligomer-based fluorosurfactant (same company product Surflon S-611) 4 ″

[0055] 1,2-polybutadiene containing NCO group (Nippon Soda products TP-1001, 98 ″

[0056] butyl acetate solution with a solid content concentration of 50% by weight)

[0057] Butyl acetate [AcOBu] 876″

[0058] A surface treatment agent (1000 parts by weight in total) containing the above various components was prepared, and measurements and evaluations of the following items were performed.

[0059] Solution stability: A surface treatment agent was prepared in a glass container, and the presence or absence of sedimentation was visually checked over time.

[0060] (Evaluation) ○: No settlement

[0061] △: Settled after a long time

[0062] ×: immediate settlement

[0063] Adhesive hardness: On a metal plate, only the adhesive component of the coating agent (excluding the...

Embodiment 2

[0079] In Example 1, the amount of 1,2-polybutadiene containing NCO groups was changed to 77 parts by weight, the amount of butyl acetate was changed to 868 parts by weight, and 29 parts by weight of fluorine resin containing OH groups were used. Composition solution (DIC product Defensa TR-103, solution with OH value of 4.1 mgKOH / g, MEK-AcOBu-MEK mixed solvent solution with a solid content concentration of 30% by weight).

Embodiment 3

[0081] In Example 1, the amount of PTFE resin particles was changed to 21 parts by weight, the amount of 1,2-polybutadiene containing NCO groups was changed to 90 parts by weight, and the amount of butyl acetate was changed to 878 parts by weight, and then 8 parts by weight of silicone oil (Shin-Etsu Silicone product KF-96H 1 million cs) was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com