Polyvinyl chloride low temperature toughening modifier and polyvinyl chloride mixture containing same

A toughening modifier, polyvinyl chloride technology, applied in the field of polyvinyl chloride modifier, to achieve the effect of increasing the elongation at break, broadening the scope of use, and improving the competitiveness of the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

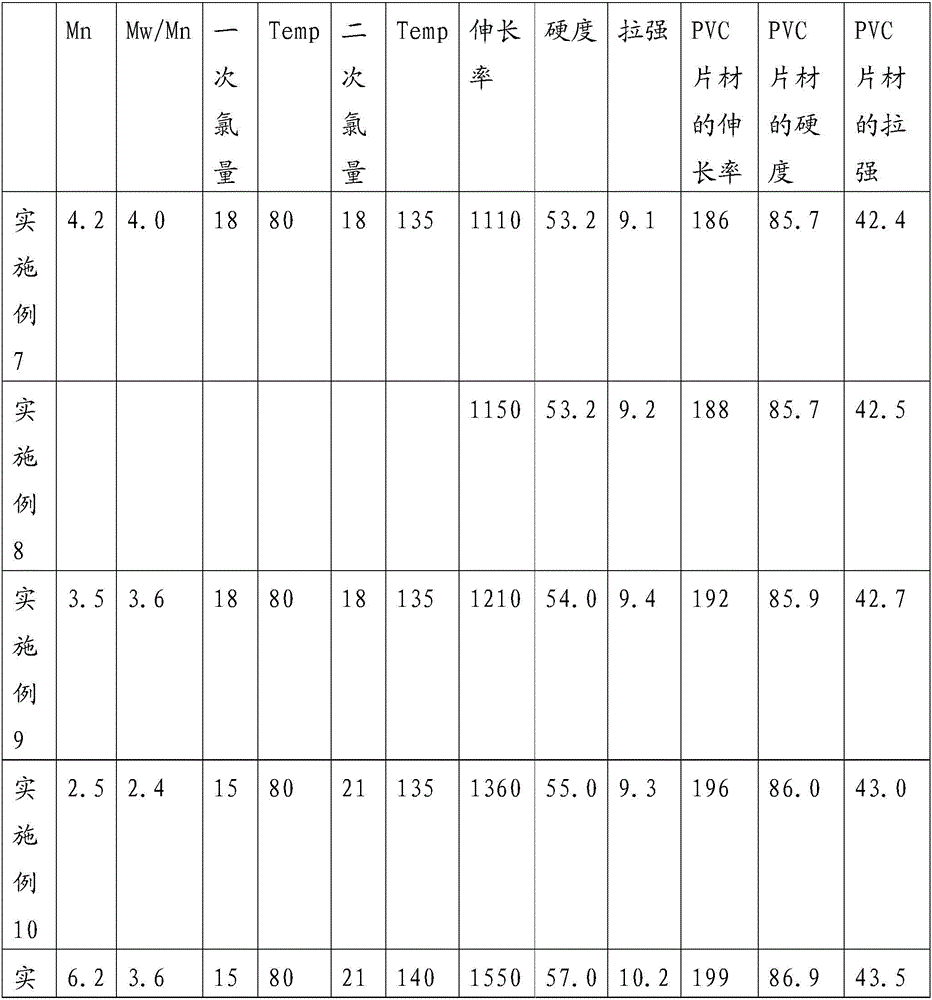

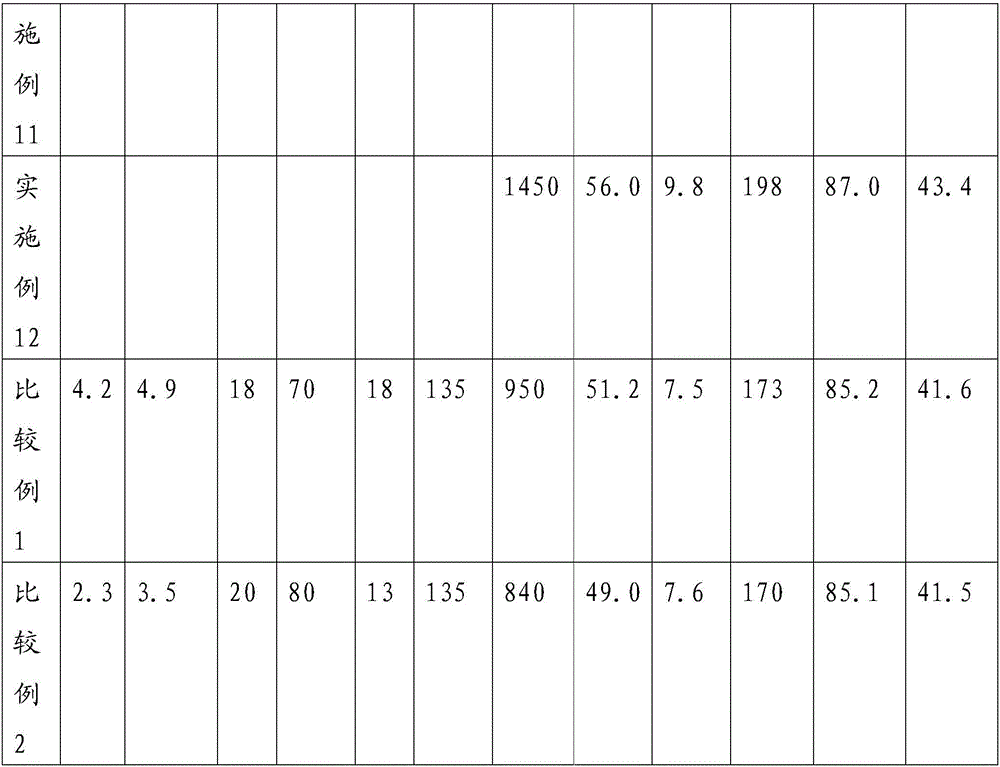

Embodiment 1

[0047] In a 24-cubic reactor equipped with a stirring paddle, add 0.25 parts of methyl methacrylate / acrylic acid copolymer soluble in water as a dispersant, and add 0.24 parts of polyoxyethylene lauryl ether as an emulsifier, Add water then, make total water consumption and all auxiliary raw materials be 250 parts, add the number average molecular weight (Mn) of 30 parts again and be 42,000, molecular weight distribution (Mw / Mn=4.0), particle diameter D 50 100 micron high-density polyethylene, after the temperature of the reaction material rises to 80°C under stirring, 18 parts of chlorine gas is introduced at a rate of 18 parts / hour, and then the temperature is raised to 135°C while the chlorine gas is passed through, and the temperature is raised. The time was 1 hour, and the heating and chlorine gas flow were carried out at the same time. After the reaction temperature reached 135° C., the temperature was kept at 135° C., and the remaining 18 parts of chlorine gas were fed a...

Embodiment 2

[0049] Add water in the 24 cubic reactor that stirring paddle is housed, the polymethyl methacrylate / acrylic acid copolymer dispersion agent of 0.1 part, the initiator of 0.05 part, use total water consumption and all auxiliary raw materials, be 250 parts , then add 30 parts of sample 1, stir the temperature of the reaction material to 80°C, then add 3 parts of butyl acrylate and 3 parts of methyl methacrylate, keep the temperature at 80-85°C, and react for 3 hours , cooled to below 40°C, centrifuged, and dried to obtain a rubber powder (sample 2) with an elongation at break of 1150%, a hardness of 53.2, and a tensile strength of 9.2. The conversion rate of the reaction was 99.3%, and the particle size of the powder was 310 microns.

Embodiment 3

[0051] In a 24-cubic reactor equipped with a stirring paddle, add 0.25 parts of methyl methacrylate / acrylic acid copolymer dissolved in water as a dispersant, and add 0.24 parts of polyoxyethylene lauryl ether as an emulsifier, Add water then, make total water consumption and all auxiliary raw materials, be 250 parts, add the Mn of 30 parts again and be 35,000, Mw / Mn=3.6, particle diameter D 50 100 micron high-density polyethylene, after the temperature of the reaction material rises to 80°C under stirring, 18 parts of chlorine gas is introduced at a rate of 18 parts / hour, and then the temperature is raised to 135°C while the chlorine gas is passed through, and the temperature is raised. The time was 1 hour, and the heating and chlorine gas flow were carried out at the same time. After the reaction temperature reached 135° C., the temperature was kept at 135° C., and the remaining 18 parts of chlorine gas were fed at a rate of 18 parts per hour. Then keep temperature between 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com