Fireworks Lead Conveying Device

A conveying device and fireworks lead technology, which is applied in the directions of transportation and packaging, pyrotechnics, and delivery of filamentous materials, etc. It can solve the problems of reducing the strength of the lead wire, affecting the timing of discharge, and reducing the hardness of the lead wire, so as to ensure reliability and eliminate potential safety hazards. , the effect of maintaining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

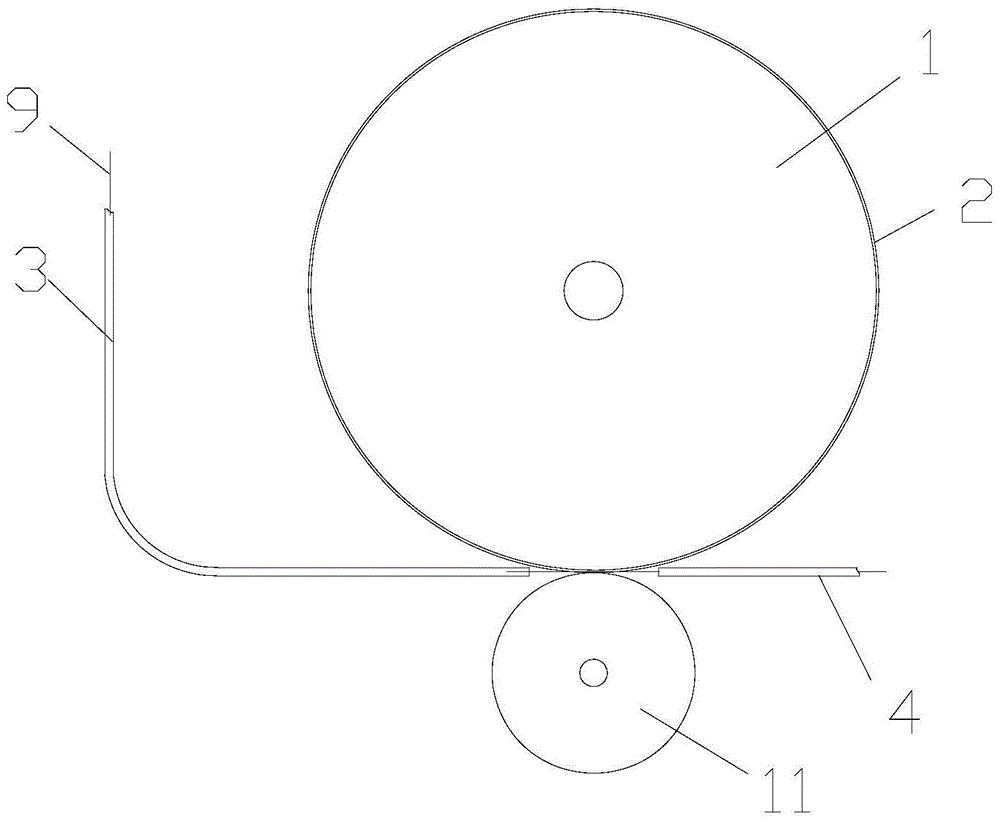

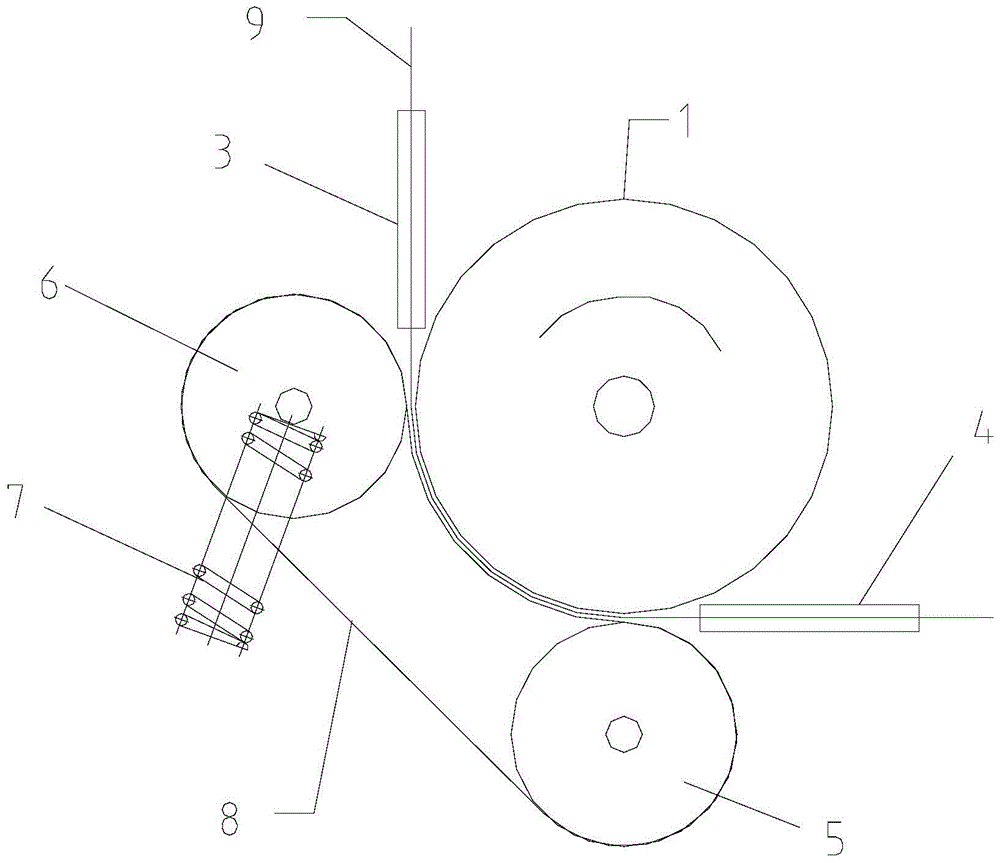

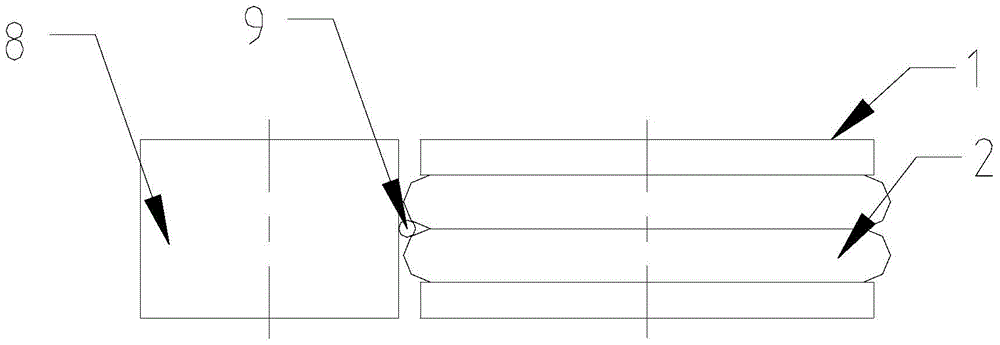

[0033] See Figure 4 with Figure 5 , The firework lead delivery device provided by the present invention includes a driving wheel 1, two O-shaped rubber rings 2 arranged on the circumference of the driving wheel 1, a lead inlet guide tube 3 and a lead outlet guide tube 4, and a first Roller 5 and a second roller 6, the second roller 6 is installed on the adjusting device 7, a flexible conveyor belt 8 is wound around the first roller 5 and the second roller 6, and the flexible conveyor belt 8 partially wraps the driving wheel 1 The outer periphery of the O-shaped rubber ring 2, the lead inlet guide tube 3 is aligned with the package inlet of the driving wheel 1 and the flexible conveyor belt 8, and the wire outlet guide tube 4 is aligned with the package outlet of the driving wheel 1 and the flexible conveyor belt 8. The outer circle of the driving wheel 1 is provided with a synchronous gear 101, the outer side of the flexible conveyor belt 8 is provided with a first synchronous...

Embodiment 2

[0035] See Image 6 with Figure 7 , The firework lead delivery device provided by the present invention includes a driving wheel 1, two O-shaped rubber rings 2 arranged on the circumference of the driving wheel 1, a lead inlet guide tube 3 and a lead outlet guide tube 4, and a first The roller 5 and a second roller 6, the second roller 6 is installed on the adjusting device 7, a flexible conveyor belt 8 is wound around the first roller 5 and the second roller 6, and the flexible conveyor belt 8 partially wraps the driving wheel 1 The O-shaped rubber ring 2 on the outer circumference of the outer circumference of the rubber ring 2, the lead inlet guide tube 3 is aligned with the package inlet of the driving wheel 1 and the flexible conveyor belt 8, and the wire outlet guide tube 4 is aligned with the package outlet of the driving wheel 1 and the flexible conveyor belt 8. The outer circle of the driving wheel 1 is provided with a large synchronous gear 102, the outer circle of th...

Embodiment 3

[0037] See Figure 8 , The firework lead delivery device provided by the present invention includes a driving wheel 1, two O-shaped rubber rings 2 arranged on the circumference of the driving wheel 1, a lead inlet guide tube 3 and a lead outlet guide tube 4, and a first Roller 5 and a second roller 6, the second roller 6 is installed on the adjusting device 7, a flexible conveyor belt 8 is wound around the first roller 5 and the second roller 6, and the flexible conveyor belt 8 partially wraps the driving wheel 1 The O-shaped rubber ring 2 on the outer circumference of the outer circumference of the rubber ring 2, the lead inlet guide tube 3 is aligned with the package inlet of the driving wheel 1 and the flexible conveyor belt 8, and the wire outlet guide tube 4 is aligned with the package outlet of the driving wheel 1 and the flexible conveyor belt 8. The driving wheel 1 is coaxially provided with a large synchronization wheel 103, the first roller 5 is coaxially provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com