Novel wear-resistant superhard metallurgical frequency conversion roller structure and manufacturing process of frequency conversion roller

A manufacturing process and roll structure technology, applied in metal material coating process, metal rolling, manufacturing tools, etc., can solve problems such as unfavorable long-term use, affecting the service life of the motor, affecting production efficiency, etc., to extend the working life and improve The effect of long service life and good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

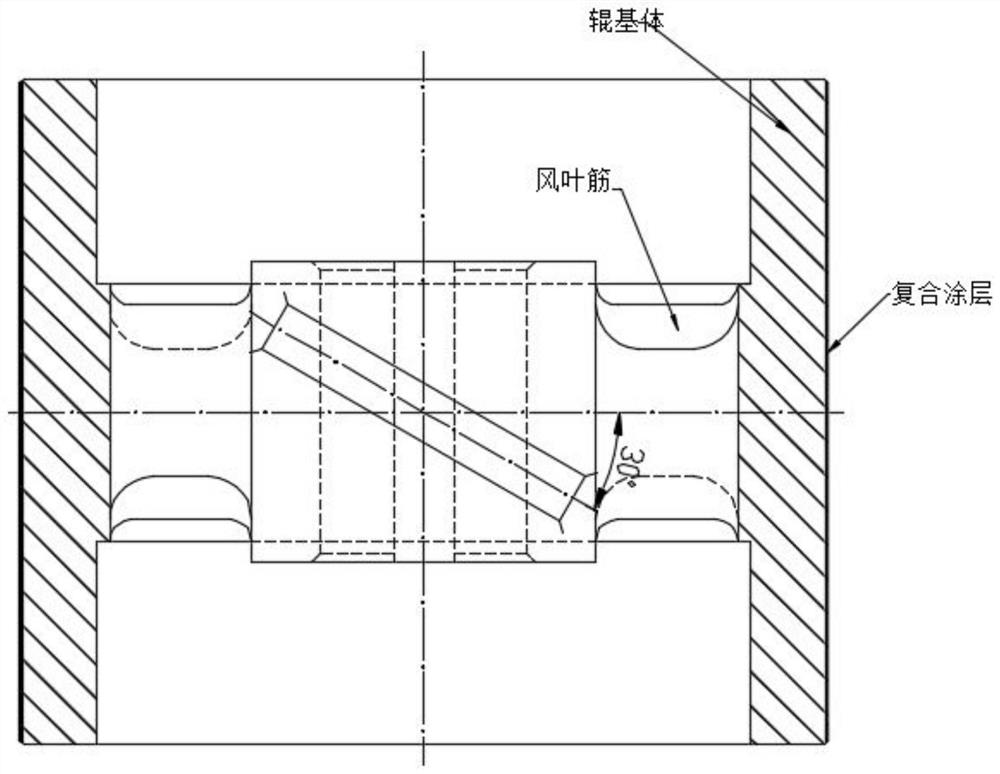

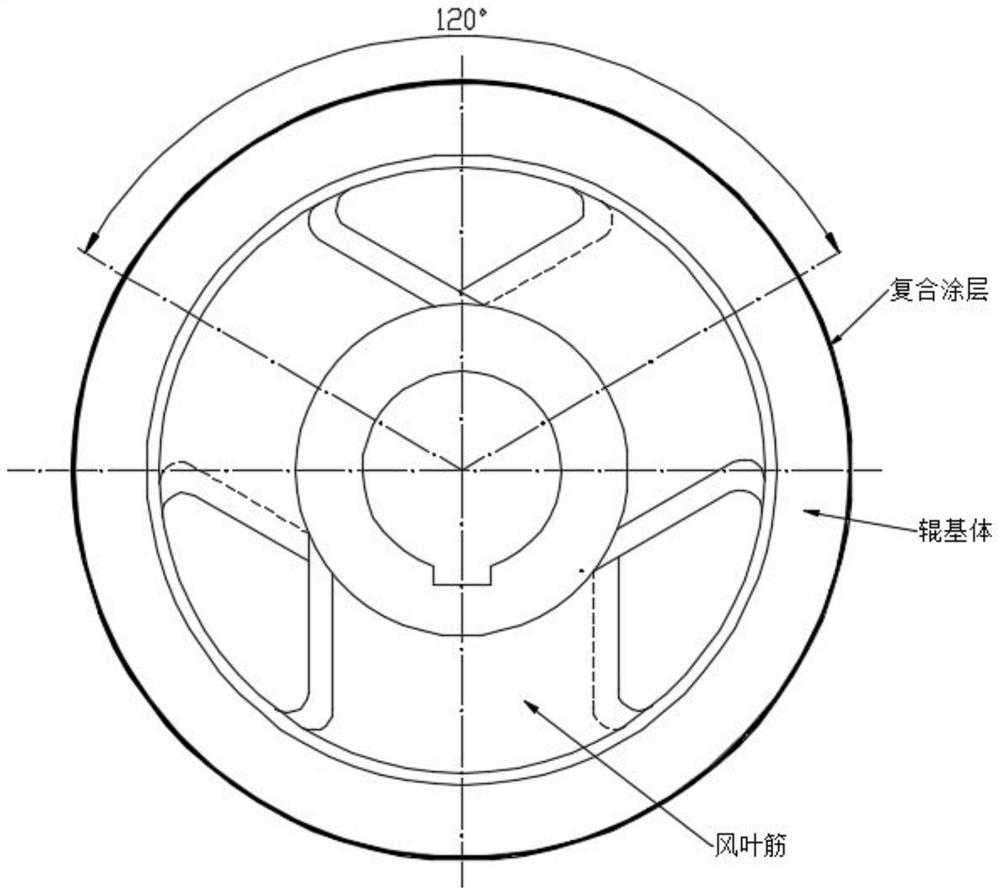

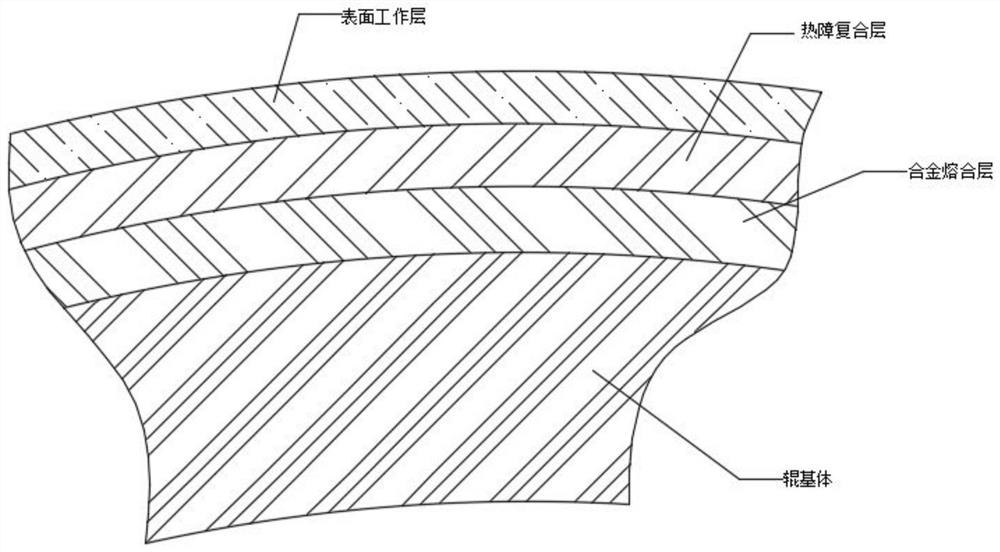

[0031] Embodiment 1: as Figure 1 to Figure 3 As shown, a new type of wear-resistant superhard metallurgical frequency conversion roller structure, including a roller base; inside the roller base, there are multiple fan ribs distributed in the circumferential direction at equal intervals. When used with a variable frequency motor, driven by the variable frequency motor, the roller base can be rotated at high speed, and the bearing will be blown by the action of the air blade ribs, and at the same time, the high temperature generated during its own conveying process can be conveyed to the outside, greatly improving To improve the service life of the frequency conversion roller, the outer surface of the roller base is provided with a spiral roughening structure. After the spiral roughening of the surface of the roller base, the contact area with the composite coating increases, and the two can be effectively combined to ensure that both The bonding strength between them; the out...

Embodiment 2

[0042] Embodiment 2: The components of the alloy fusion layer include by weight: 0.8 parts of C, 15 parts of Cr, 3.0 parts of B, 5.0 parts of Si, 13 parts of Fe, the balance being Ni and trace residual impurities, Calculated according to REC=(B+Si) / 5(C+Cr)+Cr / 6Ni, the chemical composition satisfies 0.14≤REC≤0.15; wherein, the composition of the thermal barrier composite layer includes by weight: 0.50 parts of C, 17 parts of Cr, 3.0 parts of B, 5.0 parts of Si, 15 parts of Fe, 3.4 parts of Co, the balance is Ni and trace residual impurities, according to REC=(B+Si) / 5(C+Cr)+ Calculated by (Cr+Co) / 6(Ni+Co)+Co / 8(Ni+Co), the chemical composition satisfies 0.14≤REC≤0.16; wherein, the composition of the surface working layer includes by weight: 2.1 parts of C , 12 parts of Cr, 3.9 parts of B, 3.5 parts of Si, 14 parts of Fe, 37 parts of W, the balance being Ni and trace residual impurities, according to REC=(B+Si) / 5(C+Cr)+ Calculated by (Cr+W) / 6(Ni+W)+W / 12(Ni+W), the chemical compos...

Embodiment 3

[0043] Embodiment 3: The components of the alloy fusion layer include by weight: 1.0 parts of C, 16 parts of Cr, 3.8 parts of B, 4.2 parts of Si, 15 parts of Fe, and the balance is Ni and trace residual impurities, Calculated according to REC=(B+Si) / 5(C+Cr)+Cr / 6Ni, the chemical composition satisfies 0.11≤REC≤0.14; wherein, the composition of the thermal barrier composite layer includes by weight: 0.65 parts of C, 15 parts of Cr, 3.8 parts of B, 3.5 parts of Si, 16 parts of Fe, 2.6 parts of Co, the balance is Ni and trace residual impurities, according to REC=(B+Si) / 5(C+Cr)+ Calculated by (Cr+Co) / 6(Ni+Co)+Co / 8(Ni+Co), the chemical composition satisfies 0.15≤REC≤0.16; wherein, the composition of the surface working layer includes by weight: 2.3 parts of C , 10 parts of Cr, 3.6 parts of B, 3.7 parts of Si, 15 parts of Fe, 33 parts of W, the balance being Ni and trace residual impurities, according to REC=(B+Si) / 5(C+Cr)+ Calculated by (Cr+W) / 6(Ni+W)+W / 12(Ni+W), the chemical compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com