Self-assembled boron carbide-graphene composite ceramic and preparation method thereof

A graphene composite and boron carbide technology, which is applied in the field of ceramic materials, can solve the problems of introducing impurities and graphene agglomeration, and achieve the effects of inhibiting agglomeration, high density and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

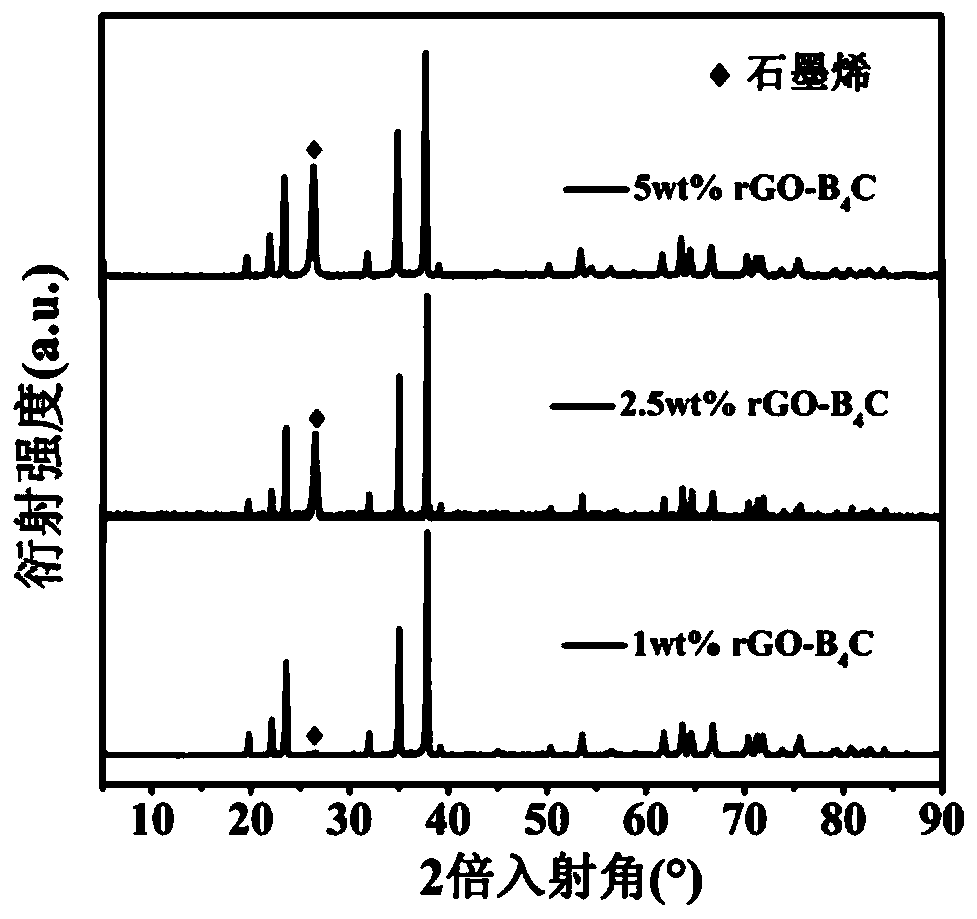

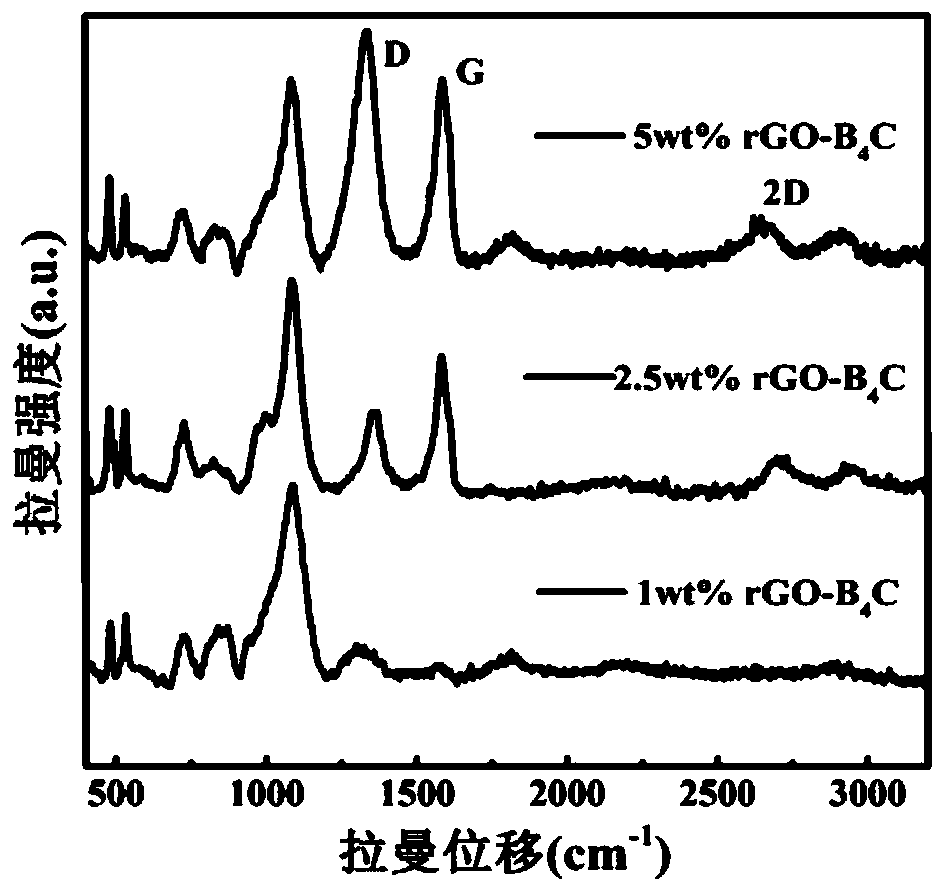

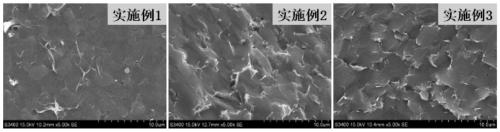

Embodiment 1

[0035] A preparation method of self-assembled boron carbide-graphene composite ceramics, comprising the following steps:

[0036] 1) Preparation of graphene oxide dispersion: Weigh 0.2 g of graphene oxide, add to 200 mL of water, stir magnetically for 1 h, and then ultrasonically disperse for 2 h to obtain a graphene oxide aqueous solution with a concentration of 1 mg / mL;

[0037] 2) Preparation of acrylamide solution: Weigh 0.2g of acrylamide, add it into 20mL of deionized water, and stir magnetically for 0.5h to obtain an acrylamide solution;

[0038] 3) Ultrasonic dispersion after mixing and stirring: Weigh 10 g of boron carbide micropowder, add it to the acrylamide solution prepared in step 2), stir magnetically for 0.5 h, then mix with the graphene oxide solution obtained in step 1), stir magnetically for 0.5 h, Ultrasonic dispersion for 1 h to obtain a mixed solution;

[0039]4) Self-assembly polymerization process: heat the mixed solution obtained in step 3) to 60°C in...

Embodiment 2

[0044] A preparation method of self-assembled boron carbide-graphene composite ceramics, comprising the following steps:

[0045] 1) Preparation of graphene oxide dispersion: Weigh 0.5 g of graphene oxide, add to 500 mL of water, stir magnetically for 1 h, and then ultrasonically disperse for 2 h to obtain a graphene oxide aqueous solution with a concentration of 1 mg / mL;

[0046] 2) Preparation of acrylamide solution: Weigh 0.5g of acrylamide, add it into 50mL of deionized water, and stir magnetically for 0.5h to obtain an acrylamide solution;

[0047] 3) Ultrasonic dispersion after mixing and stirring: Weigh 10 g of boron carbide micropowder, add it to the acrylamide solution prepared in step 2), stir magnetically for 0.5 h, then mix with the graphene oxide solution obtained in step 1), stir magnetically for 0.5 h, Ultrasonic dispersion for 1 h to obtain a mixed solution;

[0048] 4) Self-assembly polymerization process: heat the mixed solution obtained in step 3) to 60°C i...

Embodiment 3

[0053] A preparation method of self-assembled boron carbide-graphene composite ceramics, comprising the following steps:

[0054] 1) Preparation of graphene oxide dispersion: Weigh 1 g of graphene oxide, add it to 500 mL of water, stir it magnetically for 1 h, and then ultrasonically disperse it for 2 h to obtain a graphene oxide aqueous solution with a concentration of 2 mg / mL;

[0055] 2) Prepare acrylamide solution: weigh 1 g of acrylamide, add it into 100 mL of deionized water, and stir magnetically for 0.5 h to obtain an acrylamide solution;

[0056] 3) Ultrasonic dispersion after mixing and stirring: Weigh 10 g of boron carbide micropowder, add it to the acrylamide solution prepared in step 2), stir magnetically for 0.5 h, then mix with the graphene oxide solution obtained in step 1), stir magnetically for 0.5 h, Ultrasonic dispersion for 1 h to obtain a mixed solution;

[0057] 4) Self-assembly polymerization process: heat the mixed solution obtained in step 3) to 60°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com