Aluminum-based amorphous nano composite powder core wire material and preparation method thereof

A powder-core wire, nano-composite technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of inability to apply and popularize materials, long production cycle, low efficiency, etc. Improve anti-corrosion performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

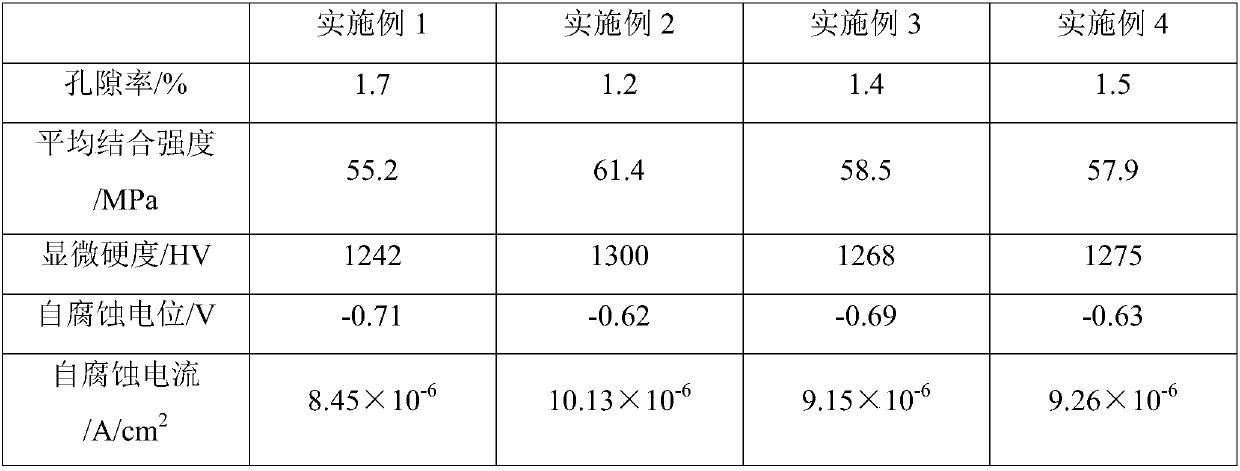

Examples

Embodiment 1

[0017] An aluminum-based amorphous nanocomposite powder core wire material, the wire material is made of a pure aluminum strip sheath wrapped powder core, and the mass percentage of the powder core to the powder core wire material is 40%; the powder core is composed of the following The alloy powder is mixed, and the mass percentage content of the powder core is as follows: chromium 4wt.%, silver 2wt.%, nickel 2wt.%, nano-silicon carbide 1.5wt.%, nano-alumina 3wt.%, nano-magnesia 1wt. %, the balance is iron.

[0018] The preparation method of the aluminum-based amorphous nanocomposite powder core wire material, the method comprises the following steps:

[0019] (1) Mix the 7 ingredients of the powder core, add to the powder mixer and mix for 2 hours;

[0020] (2) select pure aluminum strip for use, tie it into a U shape, then add the powder obtained in step (1) in the U-shaped pure aluminum strip groove;

[0021] (3) Close the U-shaped groove, wrap the powder in it, pass thr...

Embodiment 2

[0024] An aluminum-based amorphous nanocomposite powder core wire material, the wire material is made of a pure aluminum strip sheath wrapped powder core, and the mass percentage of the powder core in the powder core wire material is 42%; the powder core is composed of the following The alloy powder is mixed, and the mass percentage of powder core components is as follows: 5wt.% chromium, 3wt.% silver, 3wt.% nickel, 3wt.% nano-silicon carbide, 5wt.% nano-alumina, 2wt.% nano-magnesium oxide , The balance is iron.

[0025] The preparation method of the aluminum-based amorphous nanocomposite powder core wire material, the method comprises the following steps:

[0026] (1) Mix the 7 ingredients of the powder core, add to the powder mixer and mix for 3 hours;

[0027] (2) select pure aluminum strip for use, tie it into a U shape, then add the powder obtained in step (1) in the U-shaped pure aluminum strip groove;

[0028] (3) Close the U-shaped groove, wrap the powder in it, pass...

Embodiment 3

[0031] An aluminum-based amorphous nanocomposite powder core wire material, the wire material is made of a pure aluminum strip sheath wrapped powder core, and the mass percentage of the powder core to the powder core wire material is 45%; the powder core is composed of the following It is made by mixing alloy powder, and the mass percentage of powder core components is as follows: 6wt.% chromium, 4wt.% silver, 5wt.% nickel, 4wt.% nano-silicon carbide, 9wt.% nano-alumina, 5wt.% nano-magnesium oxide , The balance is iron.

[0032] The preparation method of the aluminum-based amorphous nanocomposite powder core wire material, the method comprises the following steps:

[0033] (1) Mix the 7 ingredients of the powder core, add to the powder mixer and mix for 4 hours;

[0034] (2) select pure aluminum strip for use, tie it into a U shape, then add the powder obtained in step (1) in the U-shaped pure aluminum strip groove;

[0035] (3) Close the U-shaped groove, wrap the powder in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com