Conductive particle, method for producing same, anisotropic conductive film, assembly and connection method

一种导电性粒子、各向异性的技术,应用在导电黏合剂连接、导电连接、分散在不导电无机材料中的导电材料等方向,能够解决连接可靠性降低、不能提高耐腐蚀性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1)

[0152]

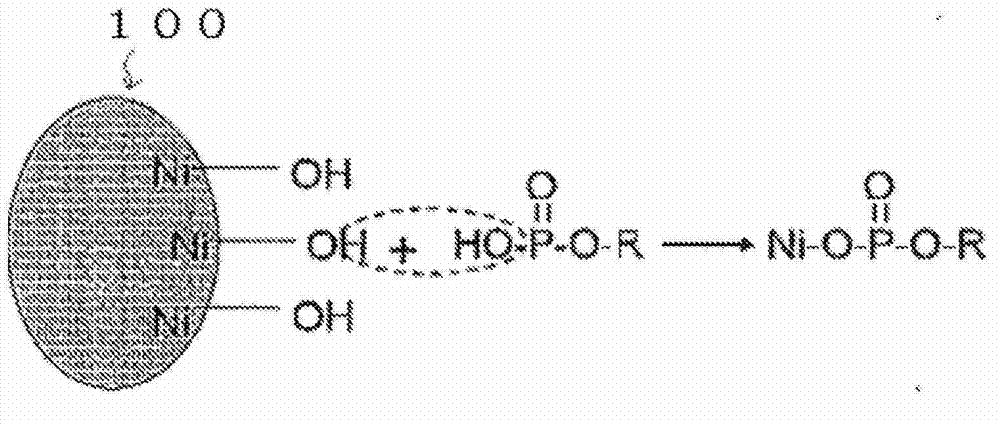

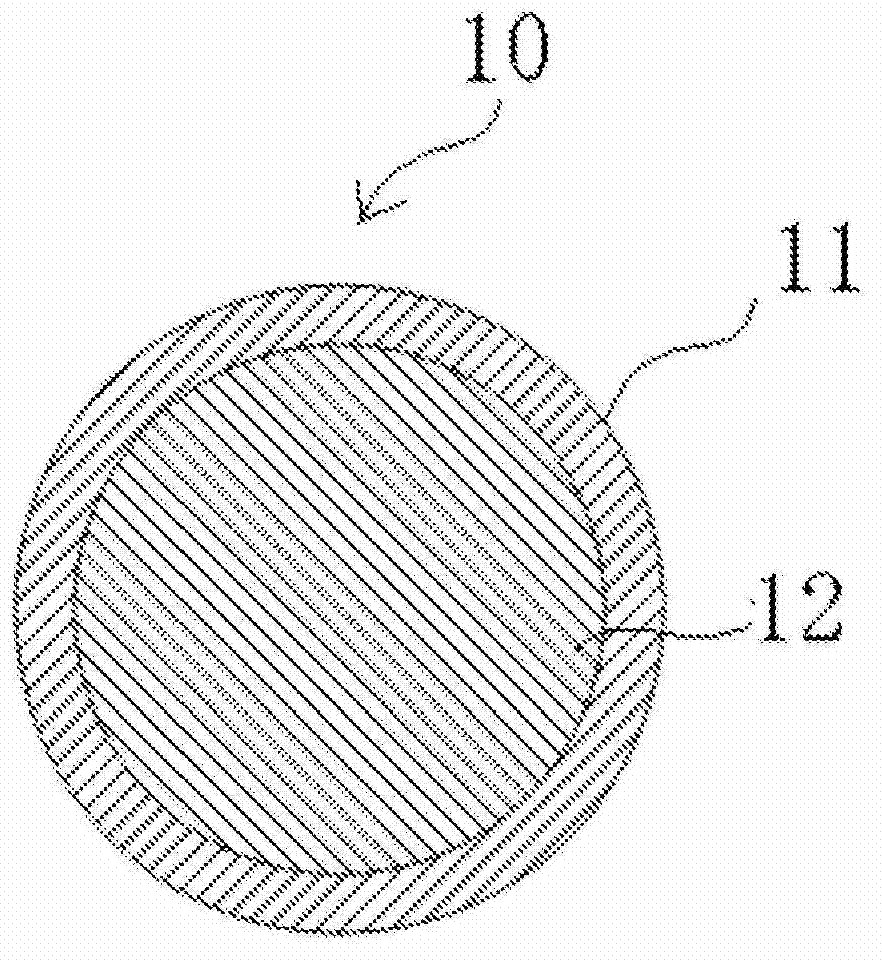

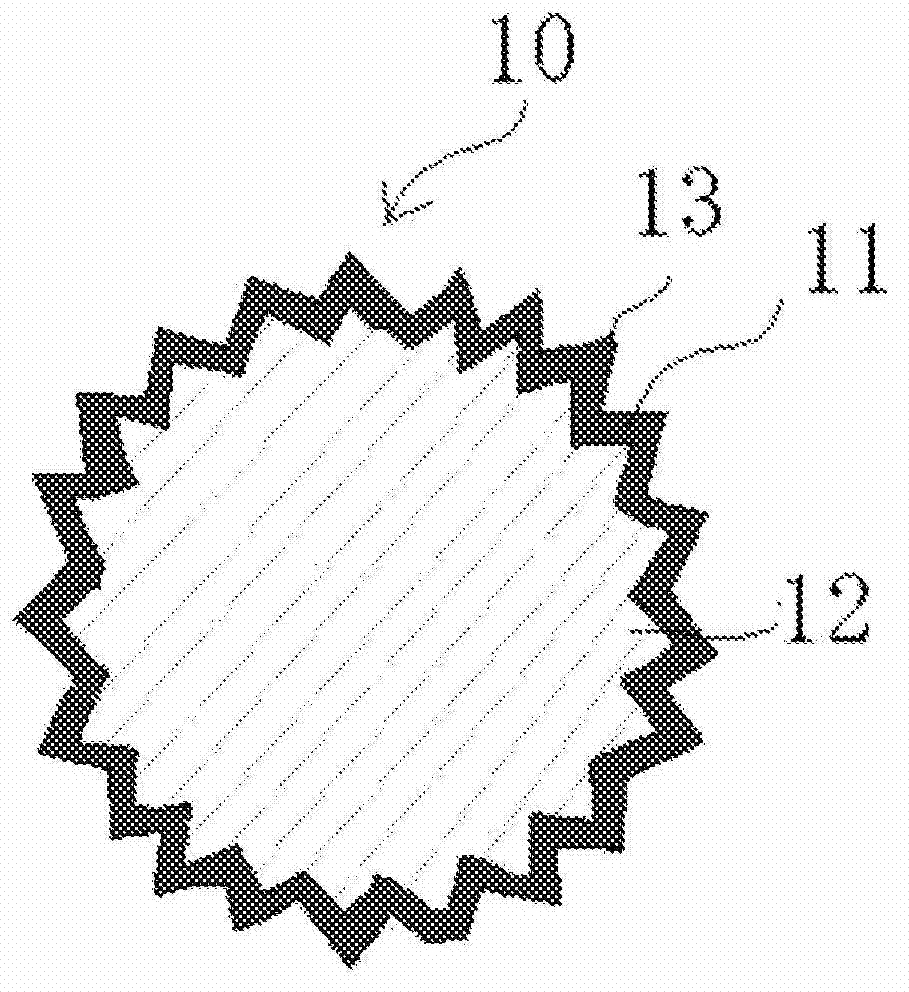

[0153] Styrene resin particles with a number average particle diameter of 3.8 μm (manufactured by Sekisui Chemical Industry Co., Ltd., trade name: Micropar) were put into an aqueous solution of thallium nitrate, and stirred while heating to 60° C., at a rate of 30 mL / min. A mixed solution of nickel sulfate (manufactured by Aldrich), sodium hypophosphite (manufactured by Aldrich), sodium citrate (manufactured by Aldrich), and thallium nitrate (manufactured by Aldrich) adjusted to a predetermined pH with ammonia water or sulfuric acid was added at a high speed, In this way, nickel plating is performed. This plating solution was filtered, and the filtrate was washed with pure water, and then dried in a vacuum dryer at 80°C to prepare a nickel plating with a phosphorus concentration of 1.3% by mass and an average thickness of 101 nm on which a conductive layer was formed. layer of nickel-plated particles A.

[0154]

[0155] In addition, to measure the thickness of t...

manufacture example 2)

[0157]

[0158] Except that the mixing ratio of nickel sulfate, sodium hypophosphite, sodium citrate, and thallium nitrate in the mixed solution of Production Example 1 was changed, the phosphorus concentration in which the conductive layer was formed was 2.6% by mass, and the average Nickel particles B were plated on a nickel-plated layer having a thickness of about 101 nm.

manufacture example 3)

[0160]

[0161] Except that the mixing ratio of nickel sulfate, sodium hypophosphite, sodium citrate, and thallium nitrate in the mixed solution of Production Example 1 was changed, the phosphorus concentration in which the conductive layer was formed was 4.8% by mass, and the average Nickel-plated particles C of a nickel-plated layer having a thickness of about 102 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com