Local softening method of high-strength alloy steel carburized parts

A technology of local softening and alloying steel, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment baths, etc., can solve problems such as failure to achieve the purpose of annealing, affecting the performance of the locking pin 1 parts, difficulty in induction coils, etc., to achieve low cost, heating Fast, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

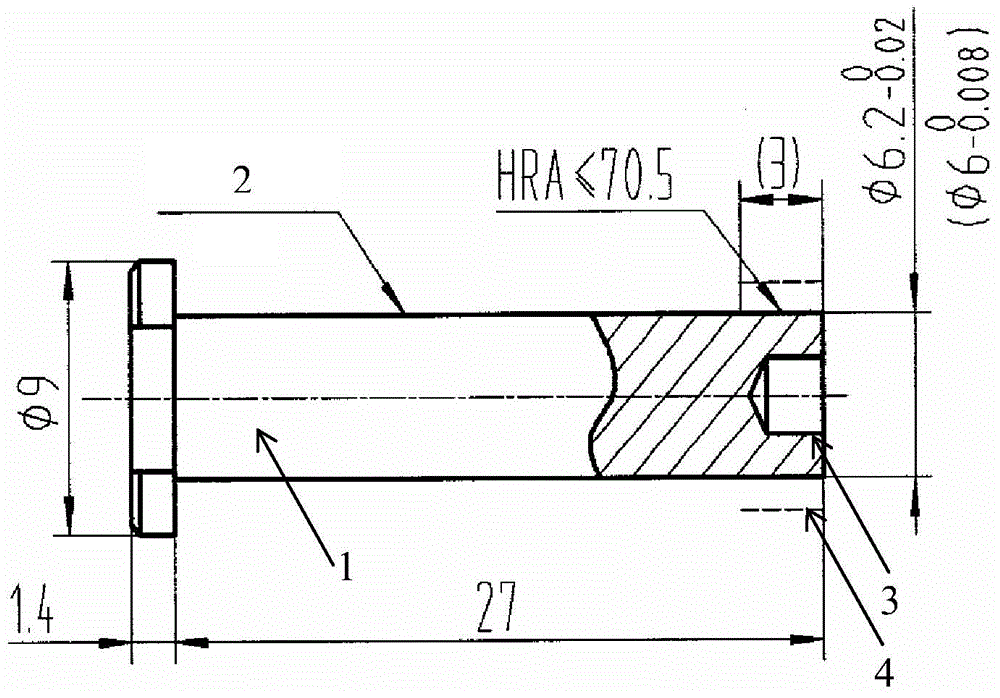

[0021] Such as figure 1 As shown, the thimble hole 3 part of the small end of the locking pin 1 (the position 3mm inward of the end face) needs to be annealed and softened. The annealed part of 4 is adjacent to the carburized surface 2, the hardness of the carburized surface 2 is required to be ≥61HRC, and the hardness of the annealed part is required to be ≤40HRC.

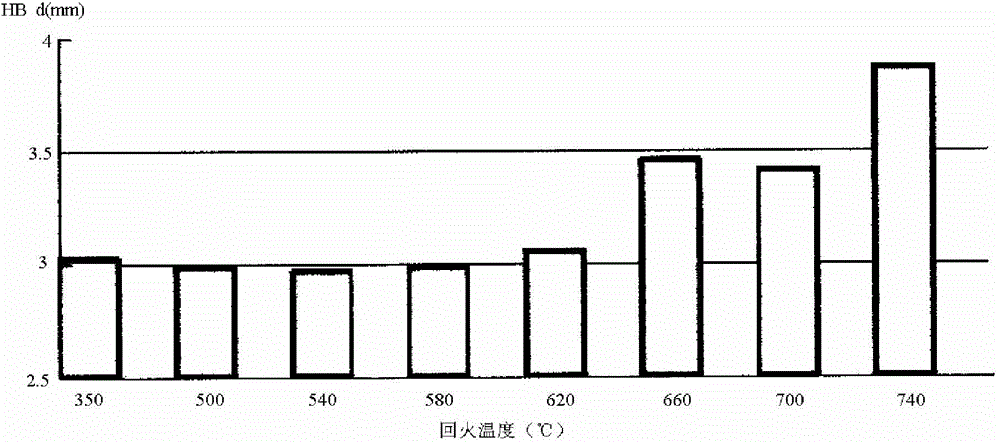

[0022] Such as figure 2 As shown, the influence of tempering temperature on hardness of 16Cr3NiWMoVNbE steel after quenching, the tempering temperature is above 600 ℃, and the matrix hardness begins to decrease with the increase of tempering temperature.

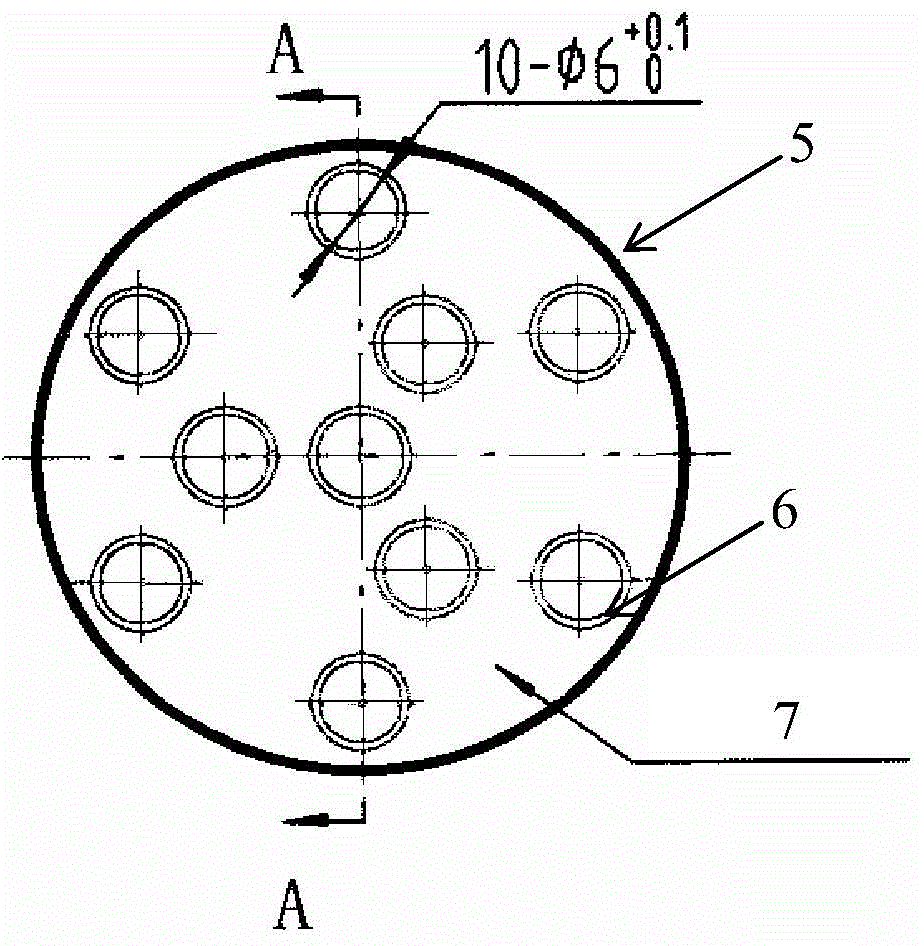

[0023] Such as Figure 3-Figure 5 As shown, the annealing and heat-insulating protection tooling 5 adopts a columnar structure of 304L stainless steel, and a mounting hole 6 is provided in the longitudinal direction of the columnar structure. The heat insulation protection tooling 5 is arranged on the positioning piece 9, the installation hole 6 of the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com