High-toughness high-wear-resistance carbide-containing isothermal quenching nodular cast iron and preparation method thereof

A high wear resistance, isothermal quenching technology, applied in the field of wear-resistant materials, can solve the problems of low impact toughness, low CADI impact toughness, high crushing rate, improve impact toughness, good promotion prospects, good graphite roundness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

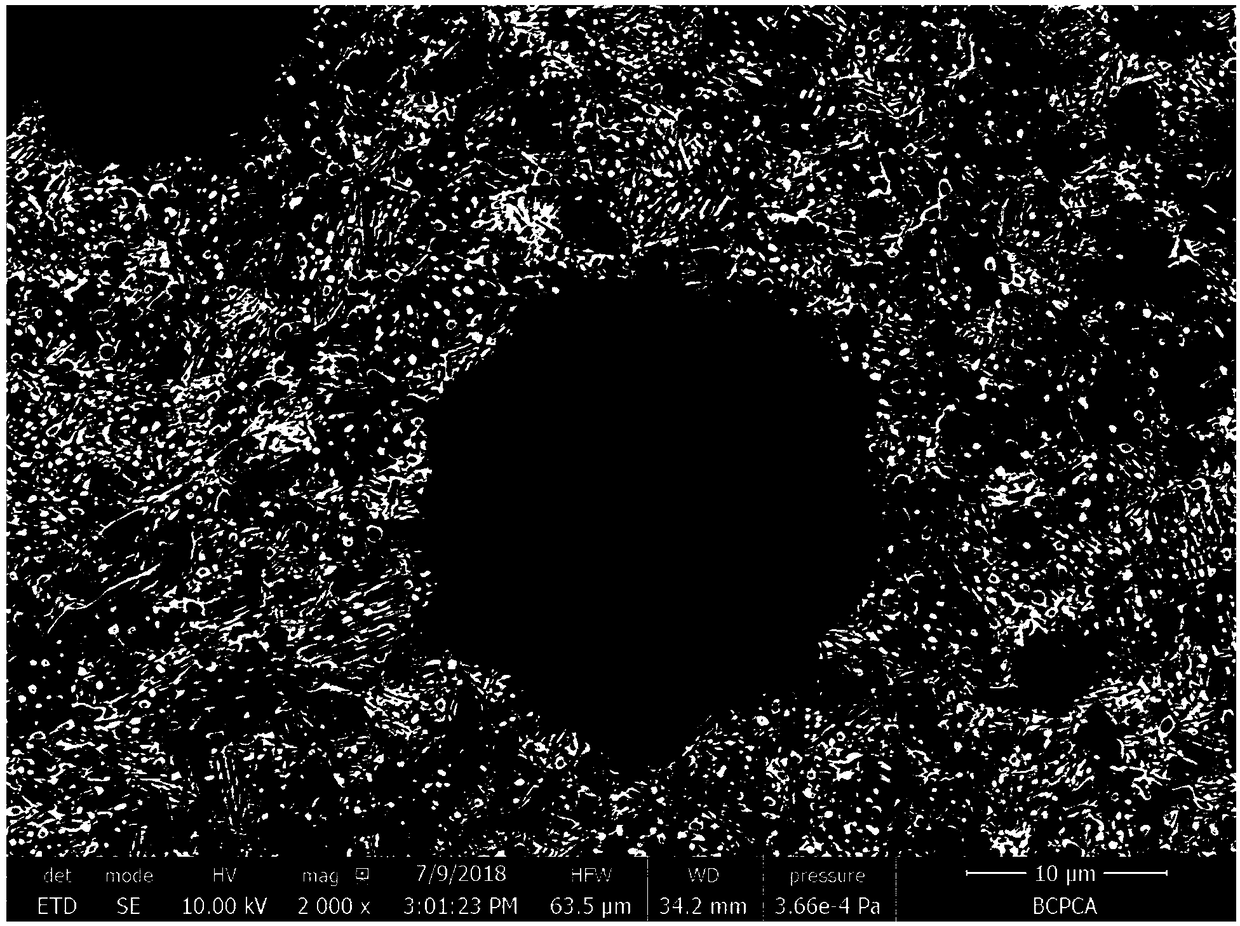

Image

Examples

Embodiment 1

[0027] A 500 kg intermediate frequency electric furnace was used to smelt molten iron (wt%) with the following chemical composition: C: 3.45, Si: 1.53, Mn: 0.51, Cr: 1.12, P: 0.035; S: 0.006, with the balance Fe. Heat to 1490°C, add 0.15% pure aluminum for deoxidation, and then transfer to ladle. The inoculants and nodulizers are placed at the bottom of the ladle, and the nodularization and inoculation treatments are carried out by the flushing method. The inoculant uses FeSi75 (75wt% Si), and the addition amount is 1.2wt%. The nodulizer uses FeSiMg6Re2 (6%Mg+2%Re+40wt%Si), the addition amount is 1.5wt%, stir the molten metal in the ladle to ensure complete reaction and remove the slag in the ladle. The pouring temperature is 1380°C. After cooling, the casting is boxed, cleaned and polished.

[0028] After coating the surface of the obtained casting with antioxidant, put it into a heat treatment furnace, heat it to 1100°C, and keep it warm for 10 minutes, take it out of the ...

Embodiment 2

[0030] A 500 kg intermediate frequency electric furnace was used to smelt molten iron with the following chemical composition (wt%): C: 3.56, Si: 1.48, Mn: 0.49, Cr: 1.34, P: 0.031; S: 0.007, with the balance Fe. Heat to 1500°C, add 0.15% pure aluminum for deoxidation, and then transfer to ladle. The inoculants and nodulizers are placed at the bottom of the ladle, and the nodularization and inoculation treatments are carried out by the flushing method. The inoculant uses FeSi75 (75wt% Si), and the addition amount is 1.2wt%. The nodulizer uses FeSiMg6Re2 (6%Mg+2%Re+40wt%Si), the addition amount is 1.5wt%, stir the molten metal in the ladle to ensure complete reaction and remove the slag in the ladle. The pouring temperature is 1351°C. After cooling, the castings are obtained after boxing, cleaning and grinding.

[0031] After coating the surface of the obtained casting with antioxidant, put it into a heat treatment furnace, heat it to 1090°C, and keep it warm for 13 minutes, ...

Embodiment 3

[0033] The cupola is used to smelt molten iron (wt%) with the following chemical composition: C: 3.52, Si: 1.60, Mn: 0.54, Cr: 1.45, P: 0.031; S: 0.007, and the balance is Fe. Heat to 1480°C, add 0.15% pure aluminum for deoxidation, and then transfer to ladle. The inoculants and nodulizers are placed at the bottom of the ladle, and the nodularization and inoculation treatments are carried out by the flushing method. The inoculant uses FeSi75 (75wt% Si), and the addition amount is 1.2wt%. The nodulizer uses FeSiMg6Re2 (6%Mg+2%Re+40wt%Si), the addition amount is 1.5wt%, stir the molten metal in the ladle to ensure complete reaction and remove the slag in the ladle. The pouring temperature is 1370°C. After cooling, the castings are obtained after boxing, cleaning and grinding.

[0034] After coating the surface of the obtained casting with antioxidant, put it into a heat treatment furnace, heat it to 1110°C, and keep it warm for 12 minutes, take it out of the furnace and air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com