Modified polyvinyl chloride door seal and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, applied in the field of modified polyvinyl chloride door seals and its preparation, can solve the problems of easy yellowing of polyurethane elastomers, failure to meet the aging performance requirements of electrical plastic parts, etc., and achieve good Anti-aging yellowing performance, avoiding the growth of bacteria and mold, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

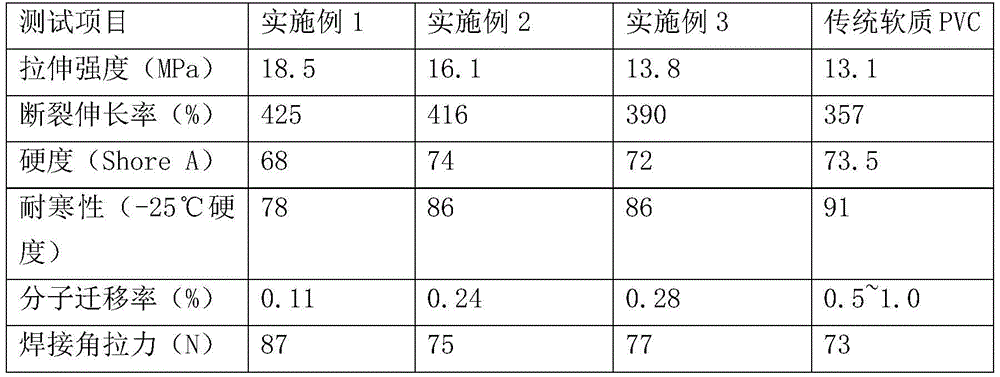

Examples

Embodiment 1

[0035] The modified polyvinyl chloride door seal of this embodiment includes the following components in parts by weight: 40 parts of polyvinyl chloride resin powder, 15 parts of anti-yellowing thermoplastic elastomer, cyclohexane 1,2-dicarboxylic acid diiso 5 parts of nonyl ester (DINCH), 20 parts of trioctyl trimellitate (TOTM), 5 parts of dioctyl adipate (DOA), 5 parts of epoxy soybean oil, 10 parts of polyester oligomer, filler 10 parts, 1 part of stabilizer, 3 parts of compatibilizer, 1 part of lubricant, 0.1 part of pigment;

[0036] Anti-yellowing thermoplastic elastomers include, by weight, 30 parts of polybutylene adipate polyol (molecular weight 1000), 30 parts of polyoxypropylene polyol (molecular weight 1000), hexamethylene diisocyanate (HDI ) 10 parts, isophorone diisocyanate 30 parts, butanediol 10 parts;

[0037] The stabilizer is calcium / zinc composite stabilizer, the lubricant is stearic acid and erucamide, the compatibilizer is halogenated polyethylene, and ...

Embodiment 2

[0045] The modified polyvinyl chloride door seal of the present embodiment comprises the following components in parts by weight: 50 parts of polyvinyl chloride resin powder, 5 parts of anti-yellowing thermoplastic elastomer, 5 parts of trioctyl trimellitate (TOTM) 10 parts of epoxy soybean oil, 5 parts of polyester oligomer, 15 parts of filler, 3 parts of stabilizer, 1 part of compatibilizer, 3 parts of lubricant, 1 part of pigment;

[0046] The anti-yellowing thermoplastic elastomer includes, by weight, 12 parts of polyethylene adipate polyol (molecular weight: 1000), 48 parts of polytetrahydrofuran ether polyol (molecular weight: 1000), and 10 parts of dicyclohexylmethane diisocyanate , 30 parts of isophorone diisocyanate, 10 parts of ethylenediamine;

[0047] The stabilizer is calcium / zinc composite stabilizer, the lubricant is oleic acid amide, low molecular weight polytetrafluoroethylene, the compatibilizer is ethylene-vinyl acetate grafted maleic anhydride (EVA-g-MAH), ...

Embodiment 3

[0054] The modified polyvinyl chloride door seal of this embodiment includes the following components in parts by weight: 45 parts of polyvinyl chloride resin powder, 10 parts of anti-yellowing thermoplastic elastomer, cyclohexane 1,2-dicarboxylic acid diiso 3 parts of nonyl ester (DINCH), 10 parts of trioctyl trimellitate (TOTM), 3 parts of dioctyl adipate (DOA), 8 parts of epoxy soybean oil, 8 parts of polyester oligomer, filler 10 parts, 1 part of stabilizer, 3 parts of compatibilizer, 1 part of lubricant, 0.5 part of pigment;

[0055] The anti-yellowing thermoplastic elastomer includes by weight parts: 30 parts of polycaprolactone polyol (molecular weight 1000), 30 parts of polycarbonate polyol (molecular weight 1000), 20 parts of hexamethylene diisocyanate (HDI), 20 parts of isophorone diisocyanate, 10 parts of butylene glycol;

[0056] The stabilizer is calcium / zinc composite stabilizer, the lubricant is stearic acid and erucamide, the compatibilizer is halogenated poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com