Patents

Literature

52results about How to "Difficulty occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

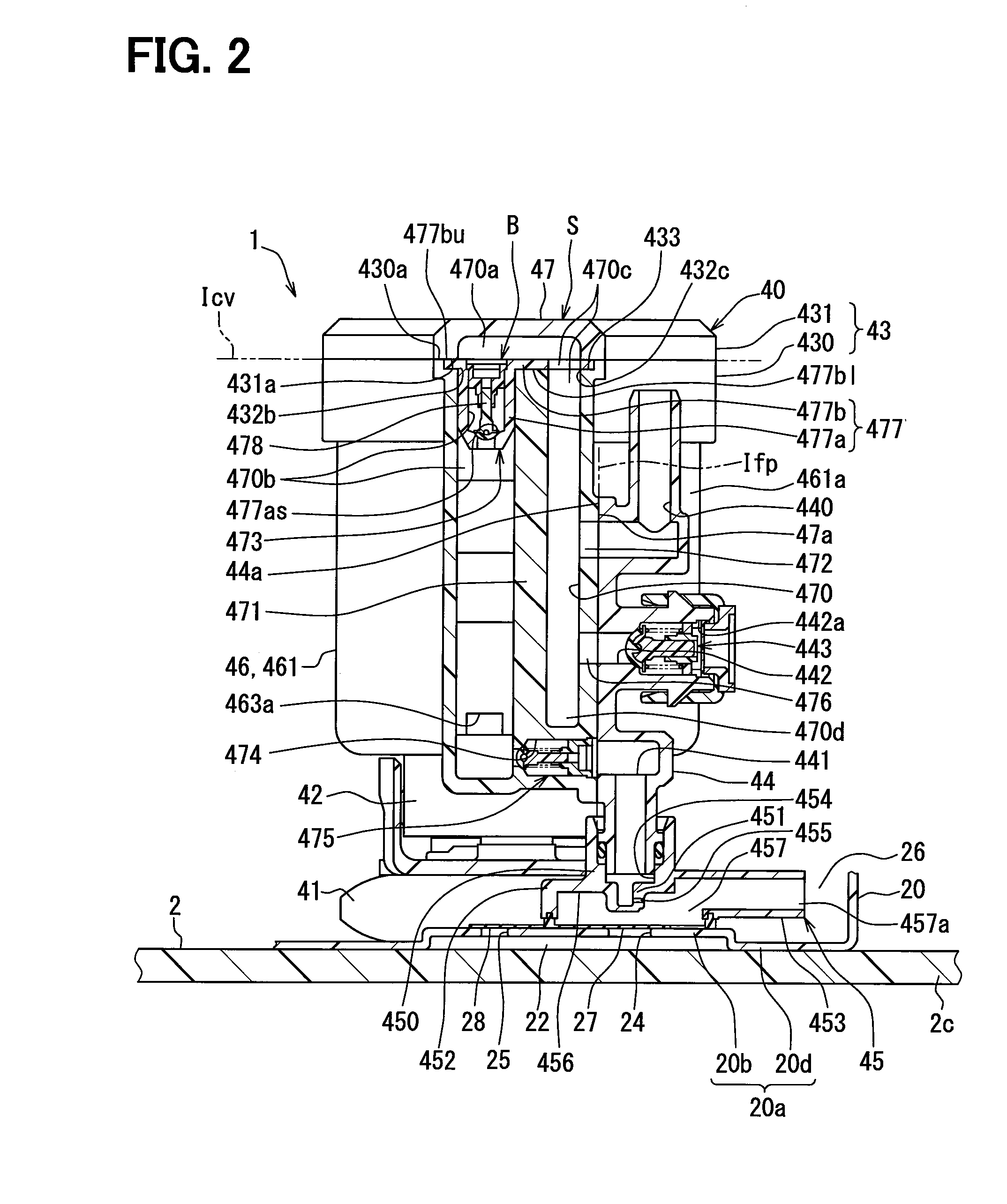

Image pickup device-equipped rear-view mirror

ActiveUS20090040778A1Reduce reflected light intensityGood anti-glare effectOptical signallingTelevision systemsRefractive indexTransmittance

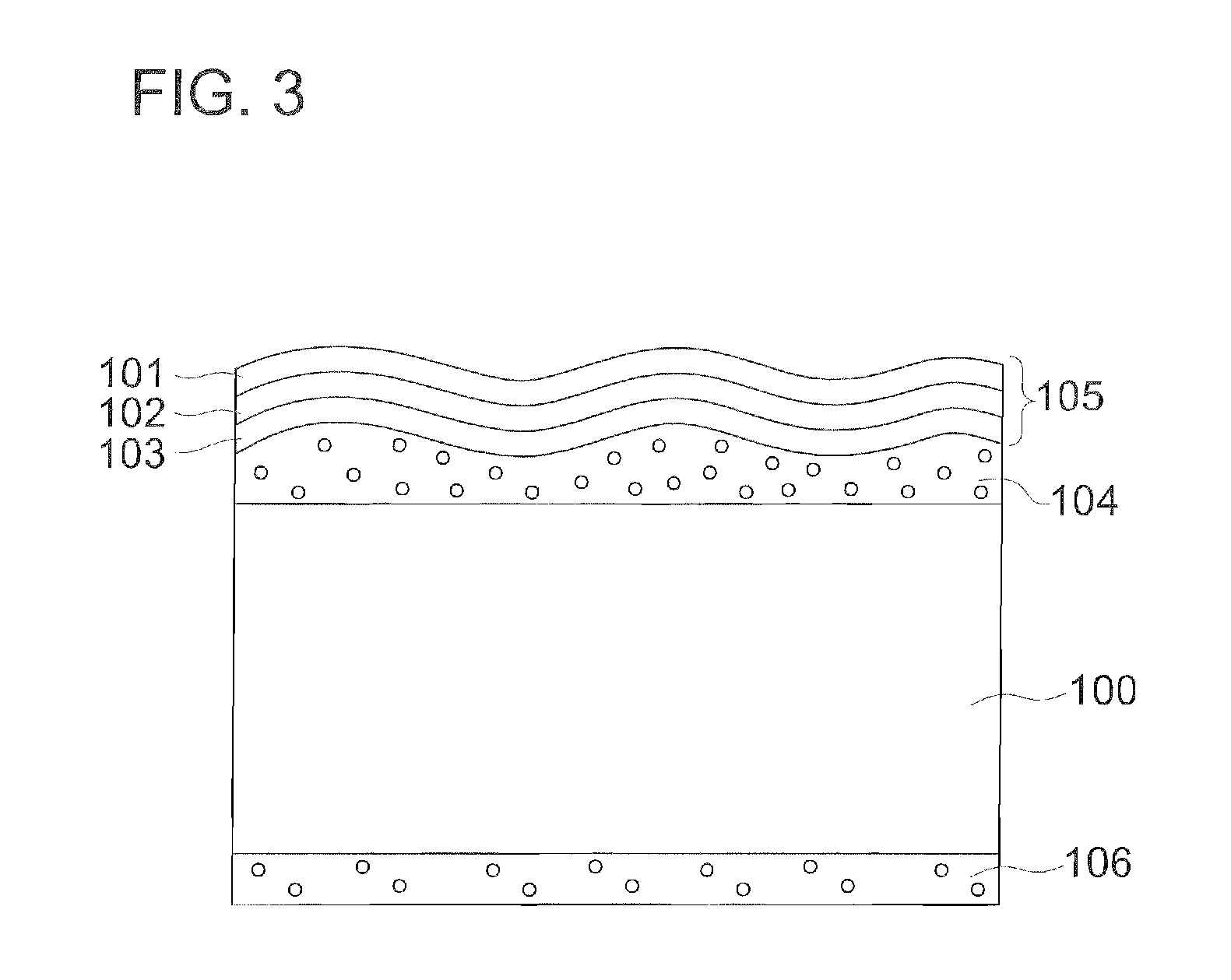

The present invention is intended to provide an image pickup device-equipped rear view mirror with improved image pickup performance, glare prevention and appearance (design) in addition to improved performance as a vehicle mirror. A mirror element is formed by forming a reflecting film consisting of high refractive index material films and a low refractive index material film on a back surface of a transparent glass substrate. The integrating sphere reflectance of the mirror element in the visible range is 40% to 60% and the near-infrared transmittance is no less than 70% for the whole or part of the band belonging to the near-infrared range within the entire sensitive wavelength range of the near-infrared camera. A black mask member is attached to an entire back surface of the reflecting film. The near-infrared camera is arranged behind the black mask member. The region corresponding to the area for the image-pickup by the near-infrared camera within the entire region of the black mask member is formed of a visible-light absorption and near-infrared transmission filter. The near-infrared transmittance of the visible-light absorption and near-infrared transmission filter is no less than 70% for the whole or part of the band belonging to the near-infrared range within the entire sensitive wavelength range of the near-infrared camera.

Owner:MURAKAMI CORP

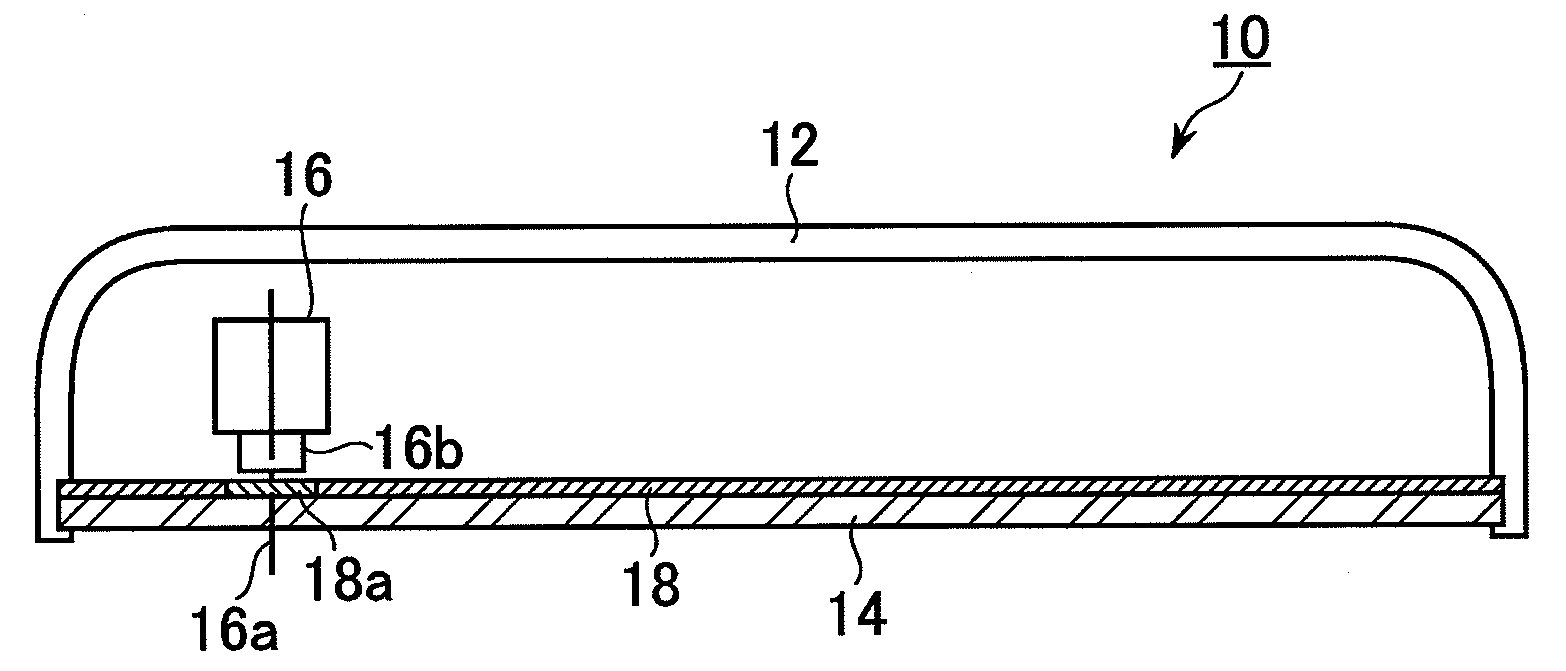

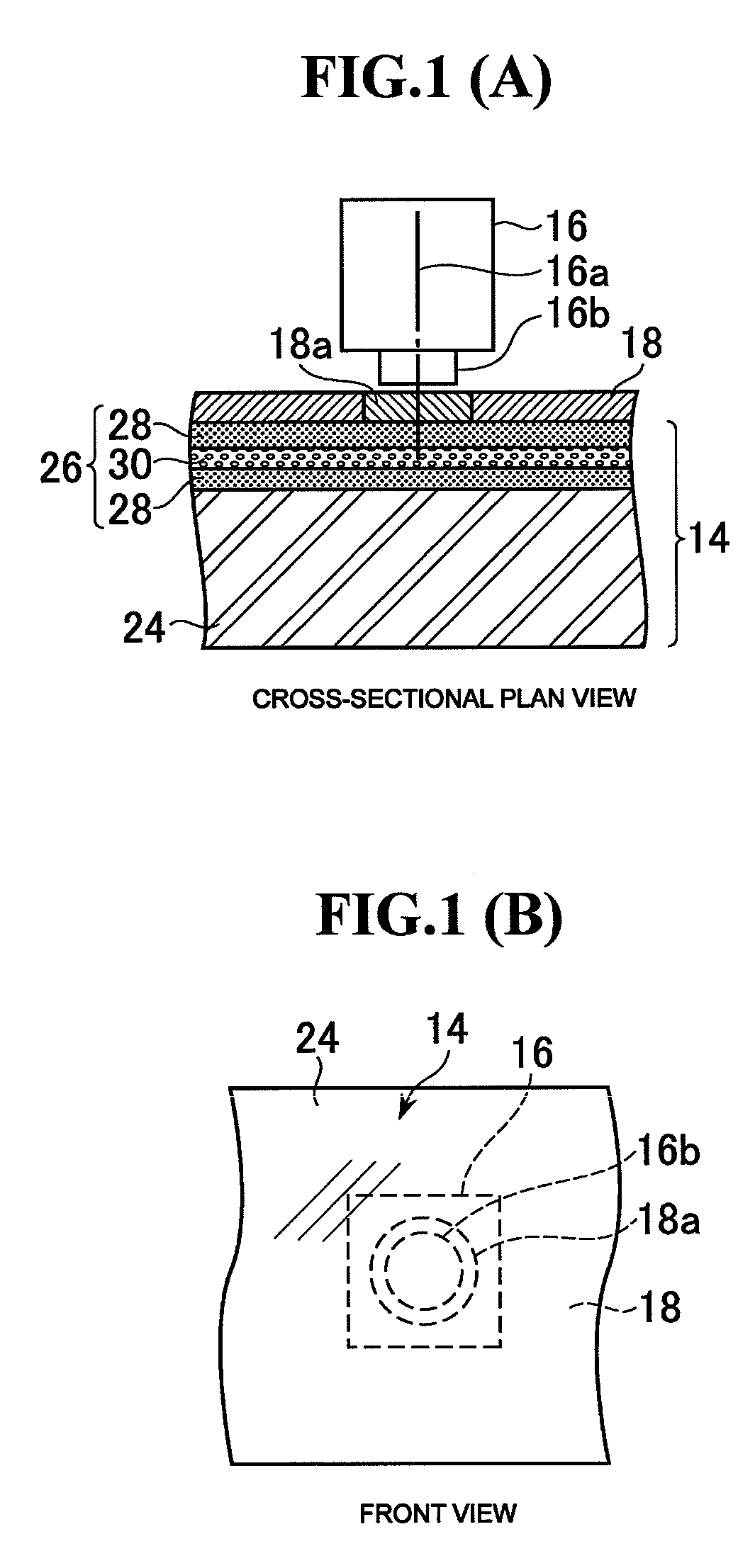

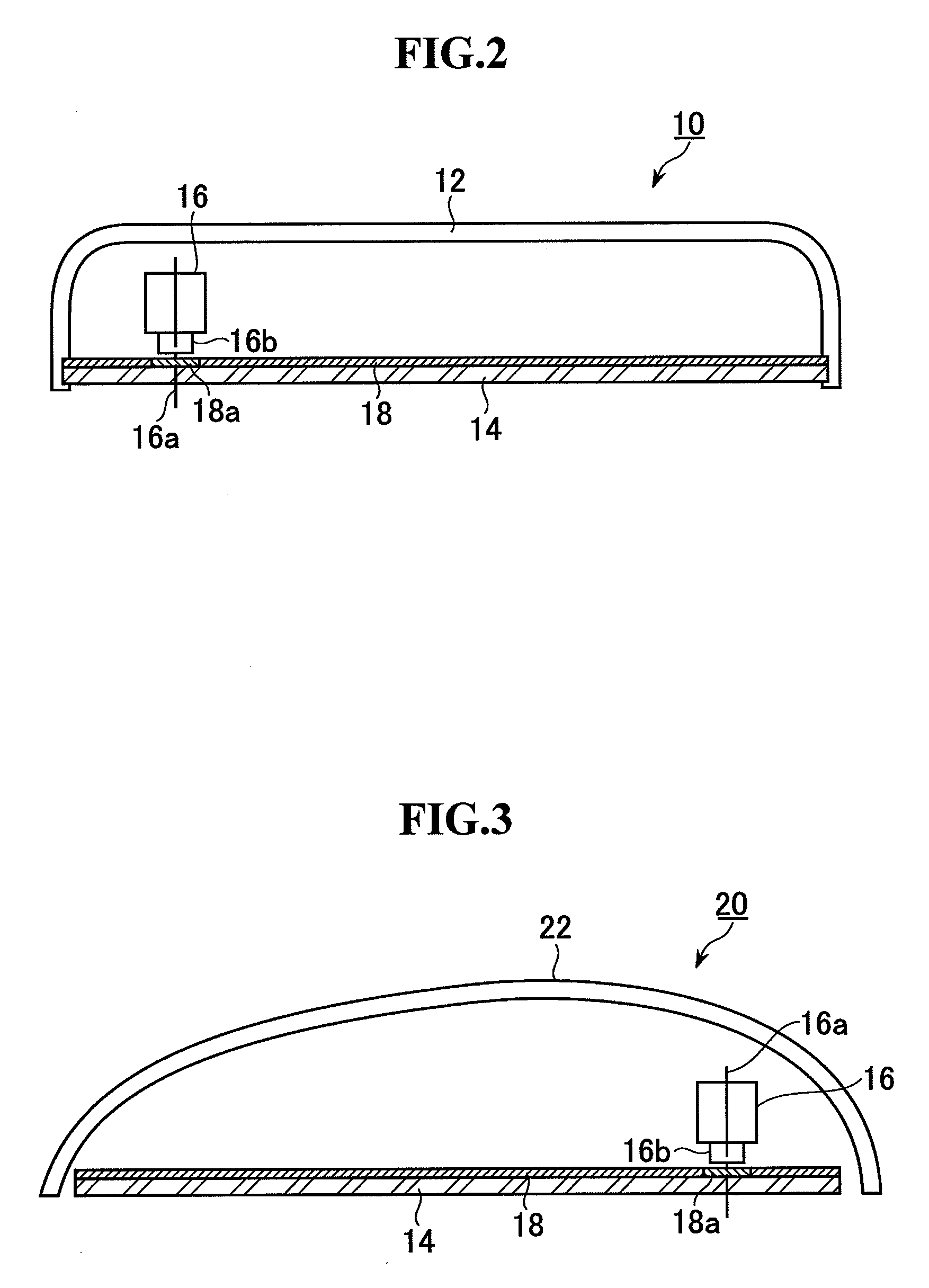

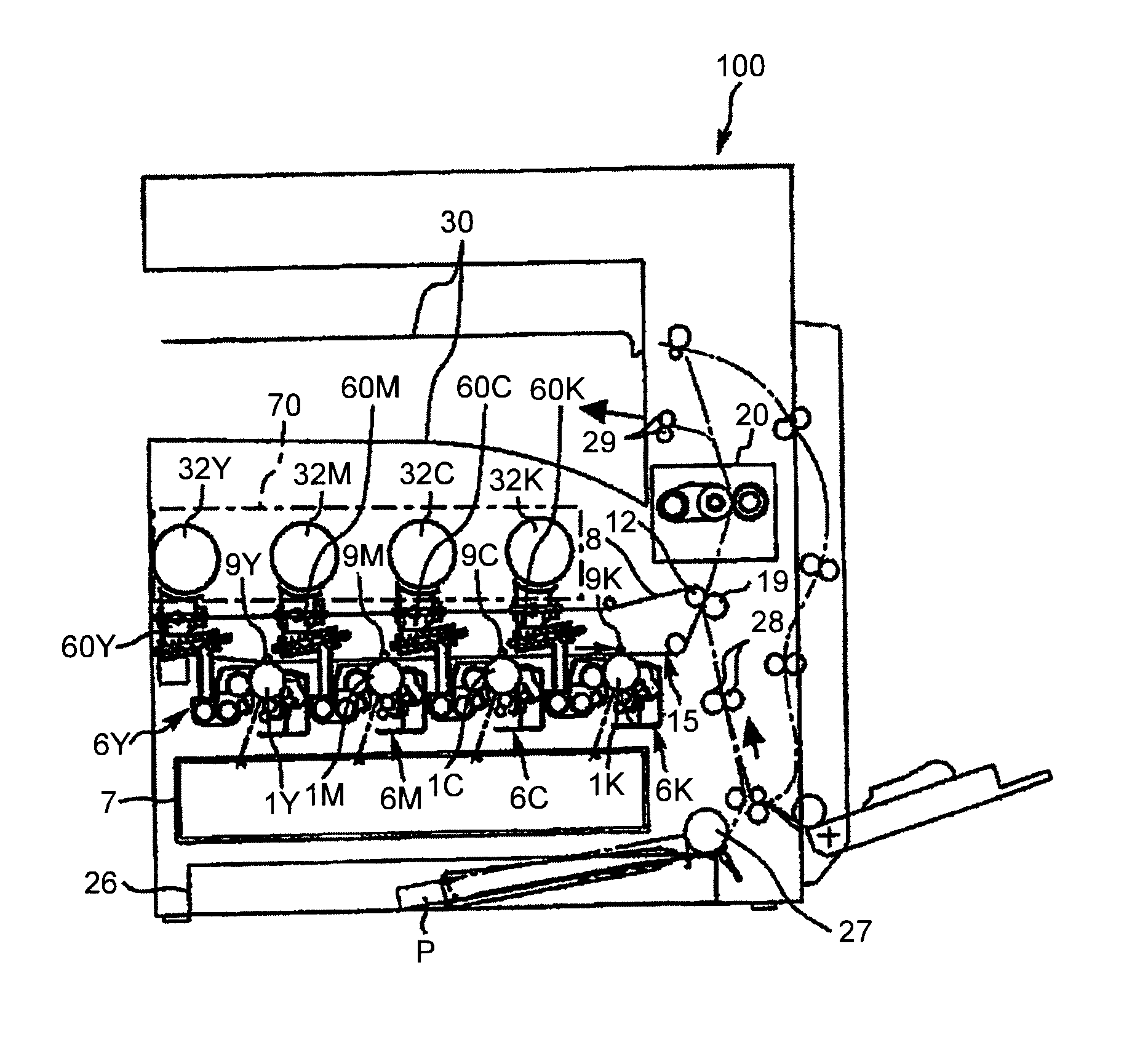

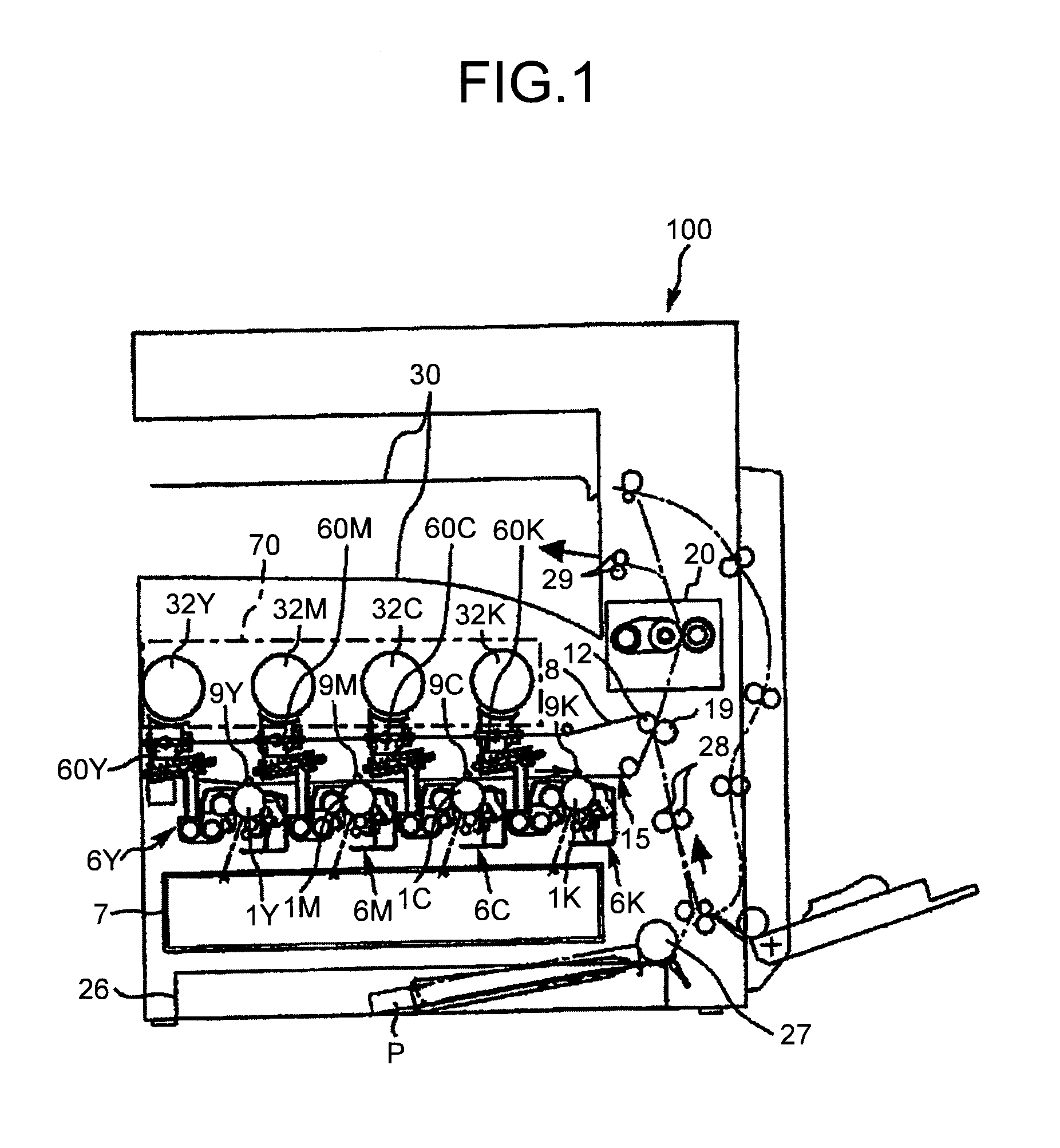

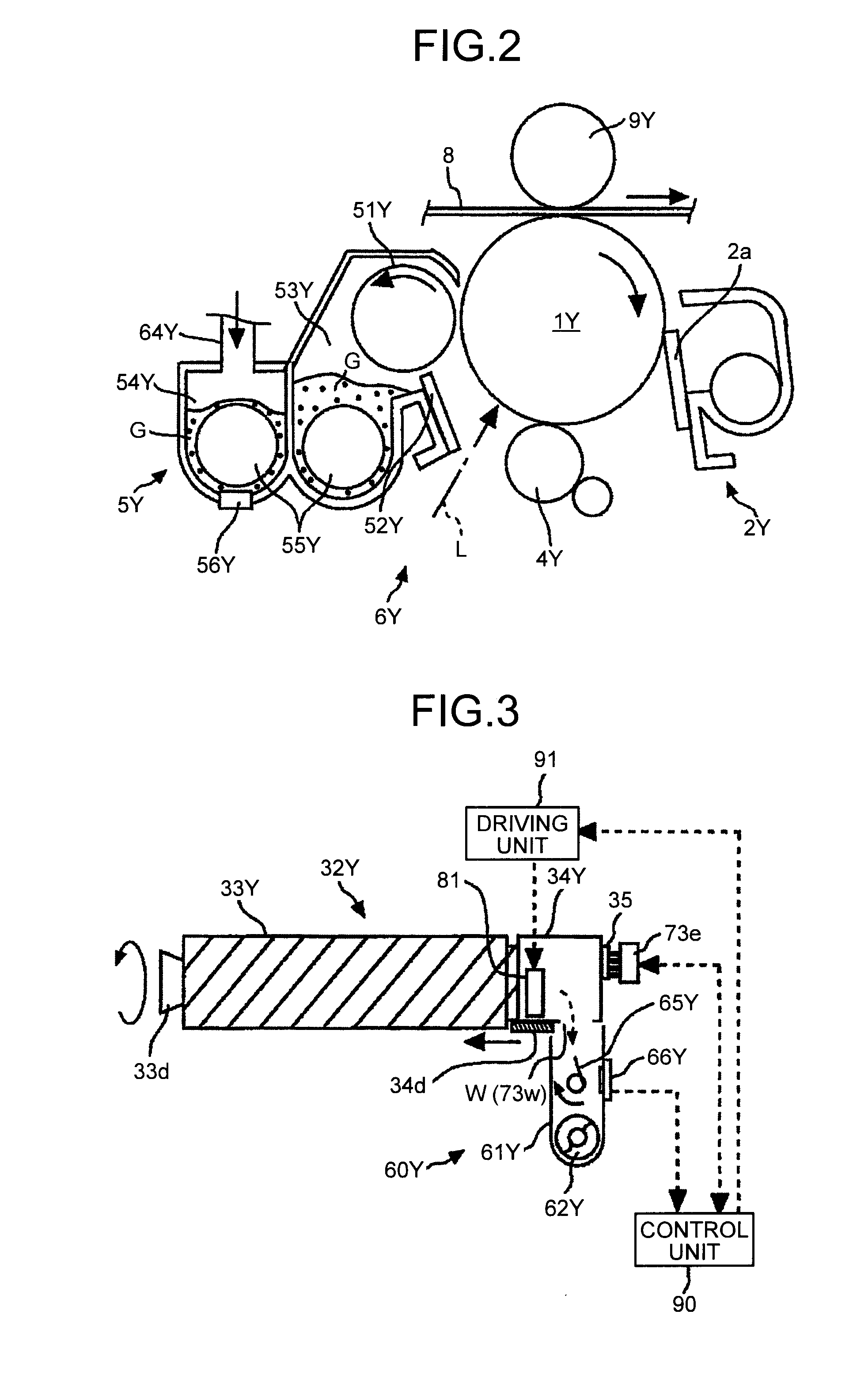

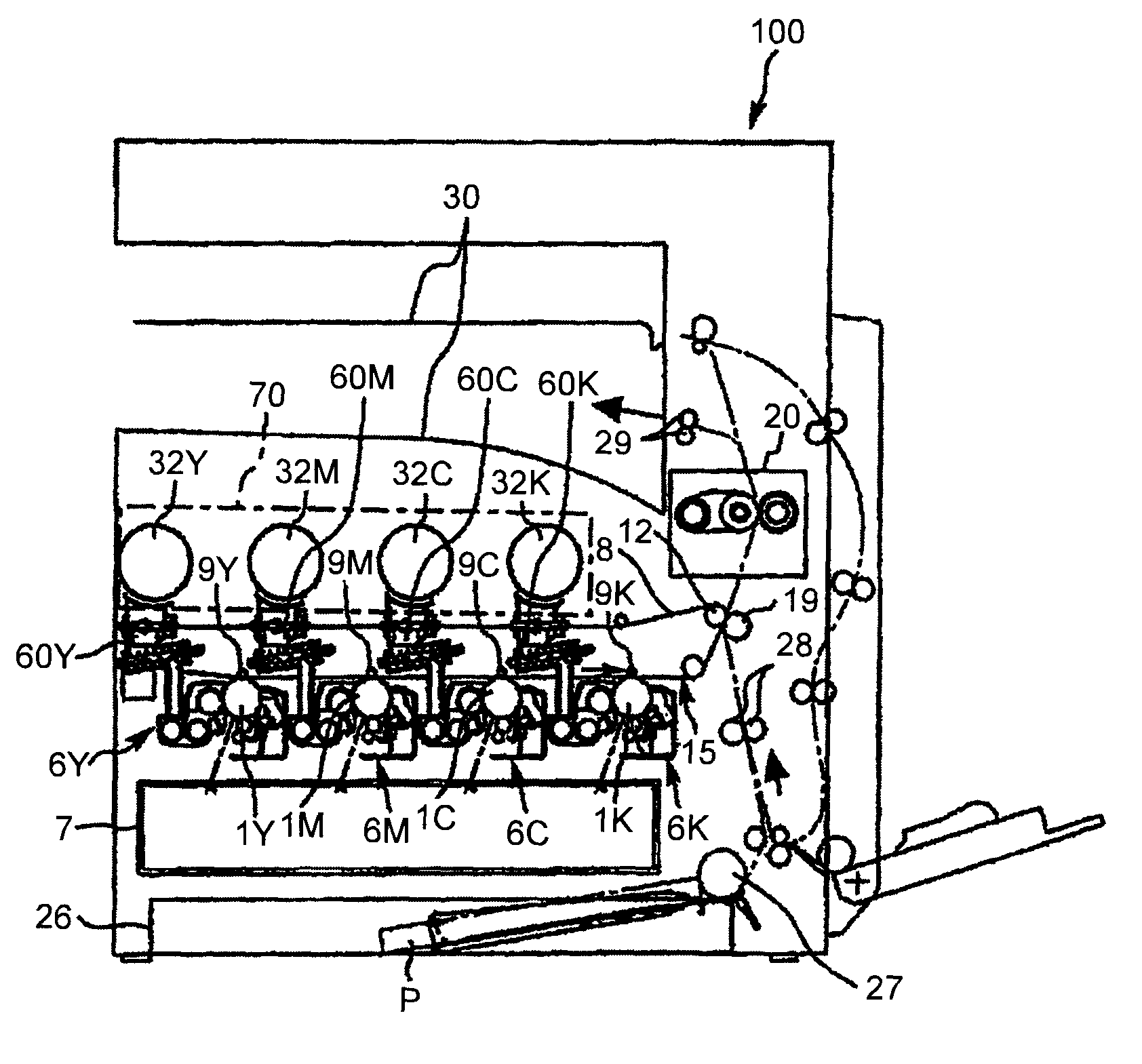

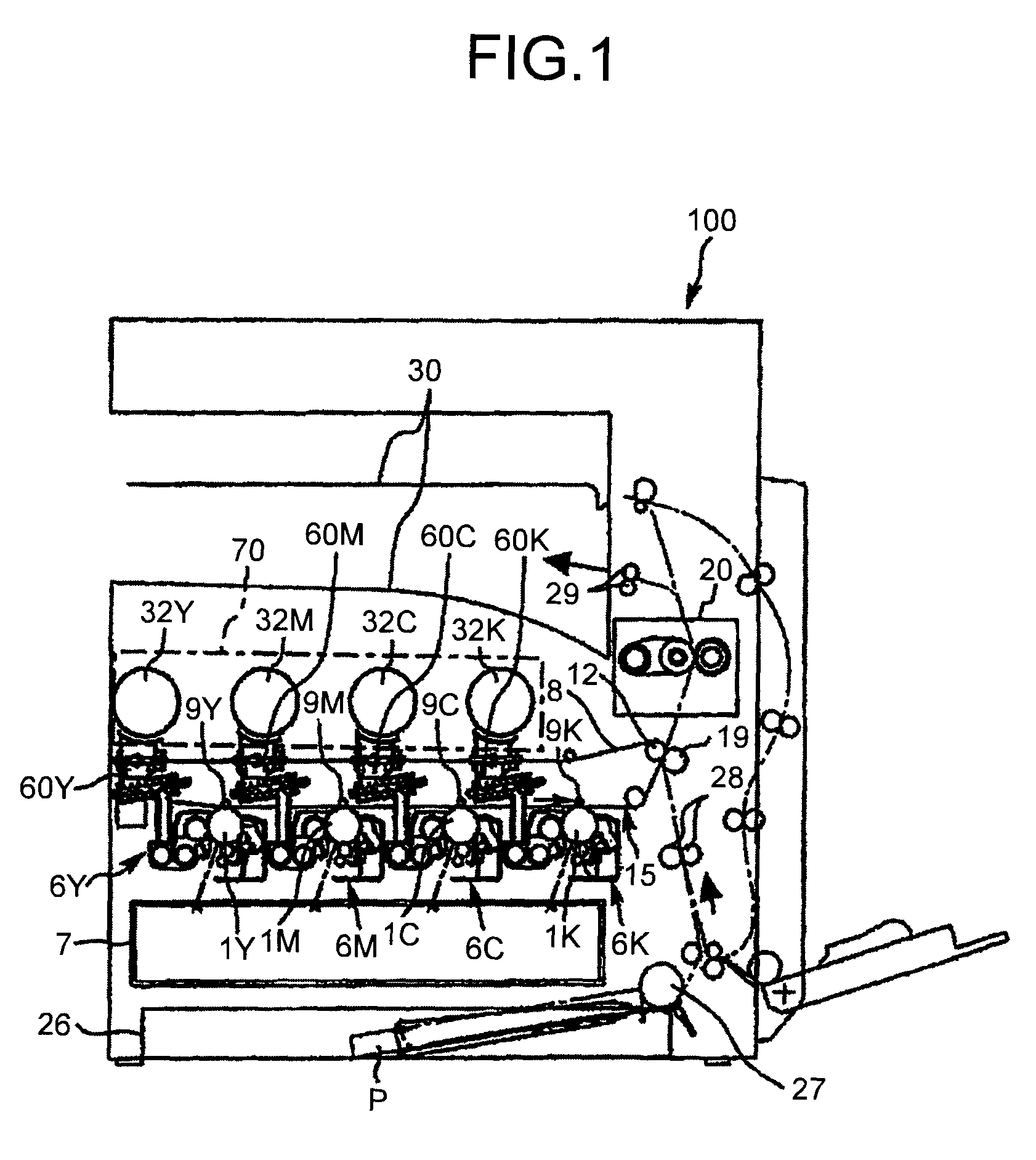

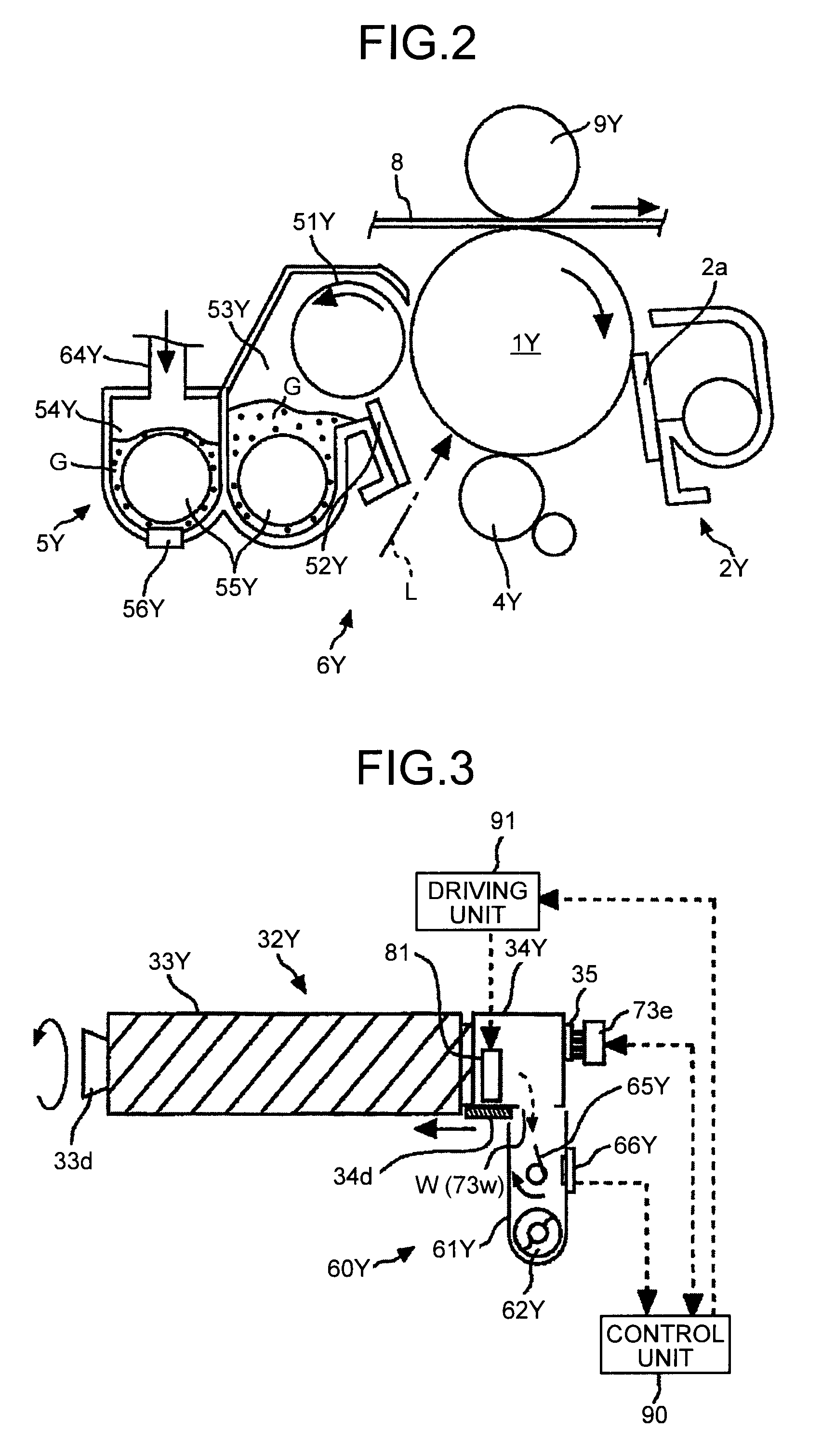

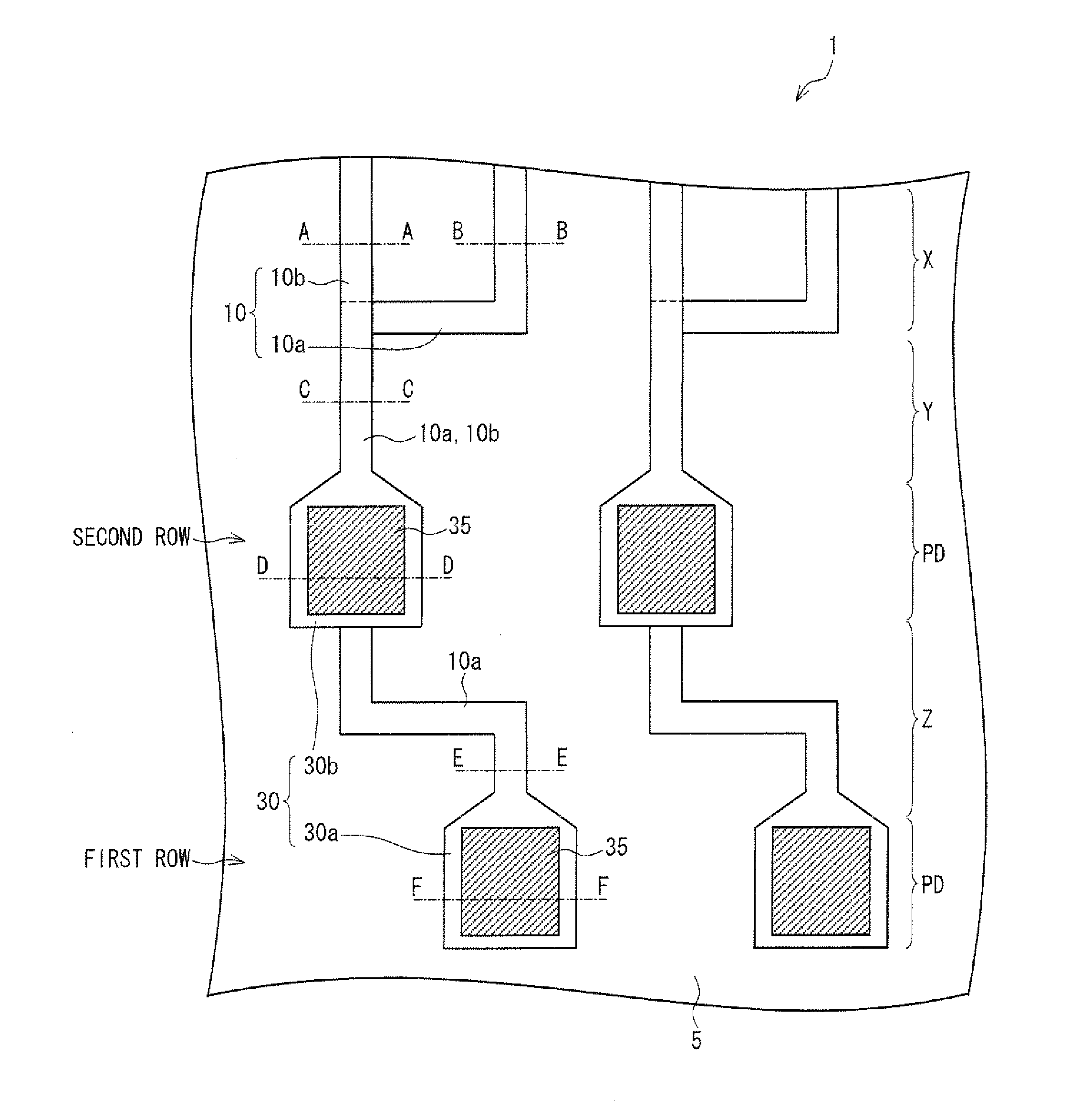

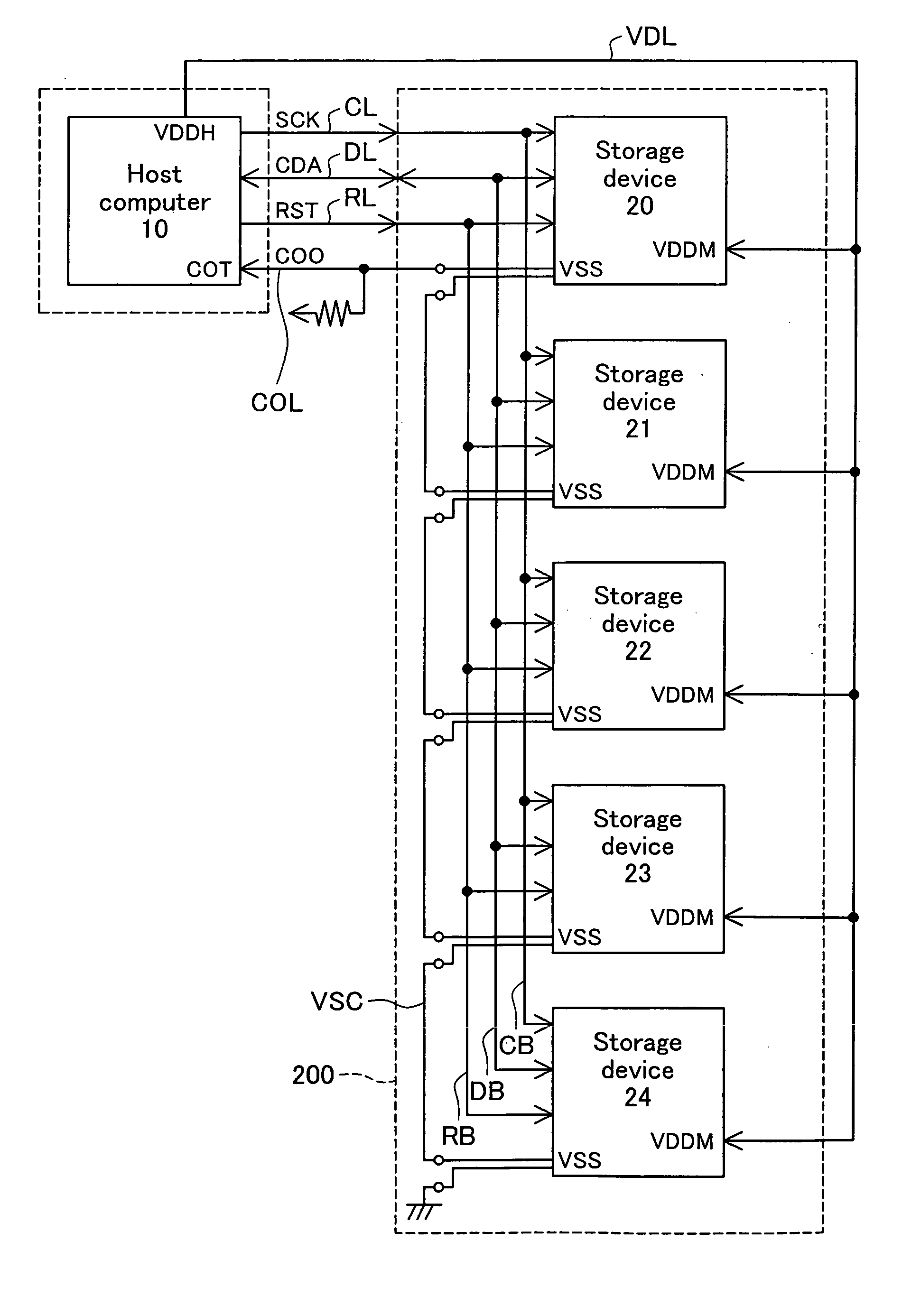

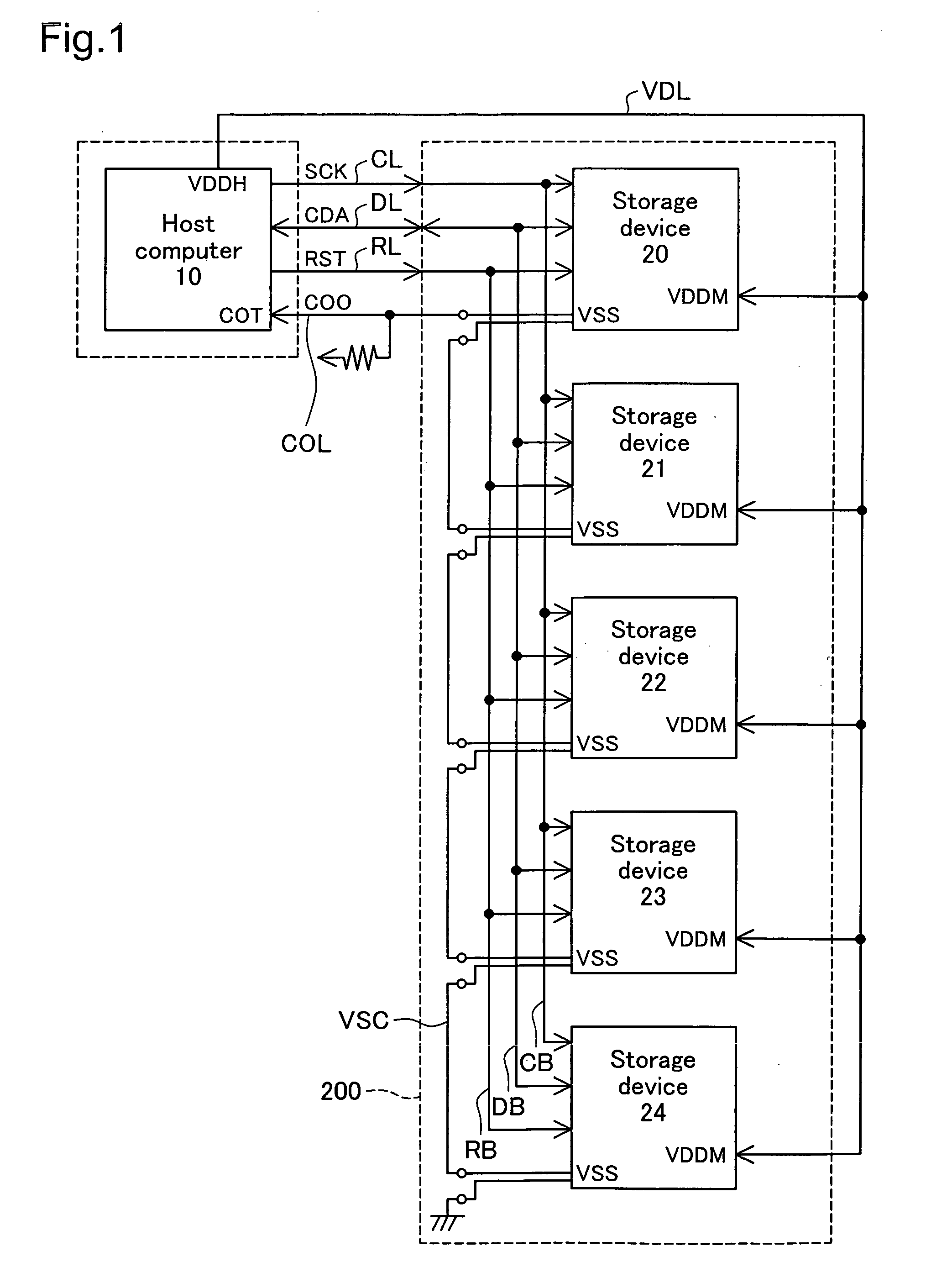

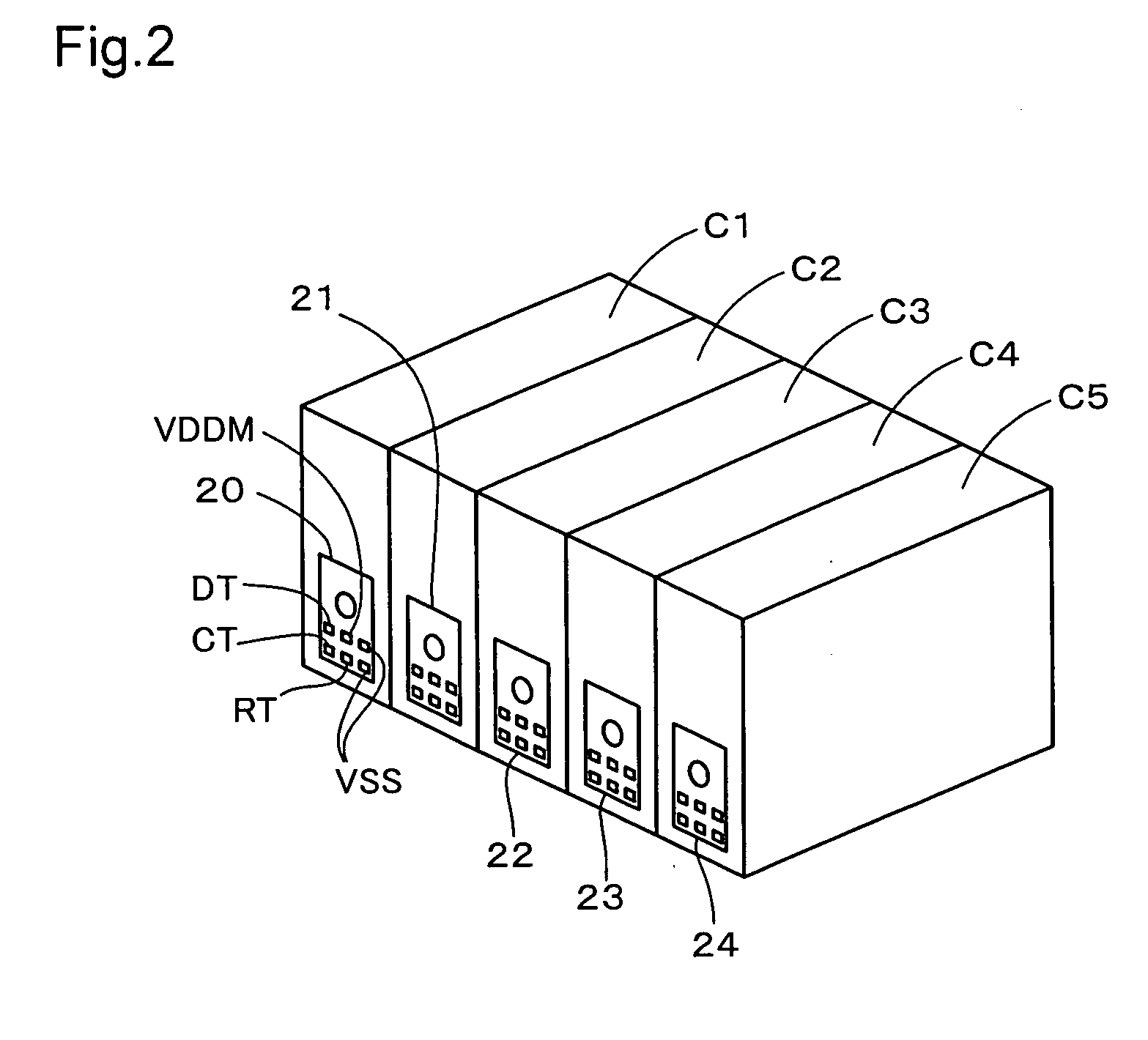

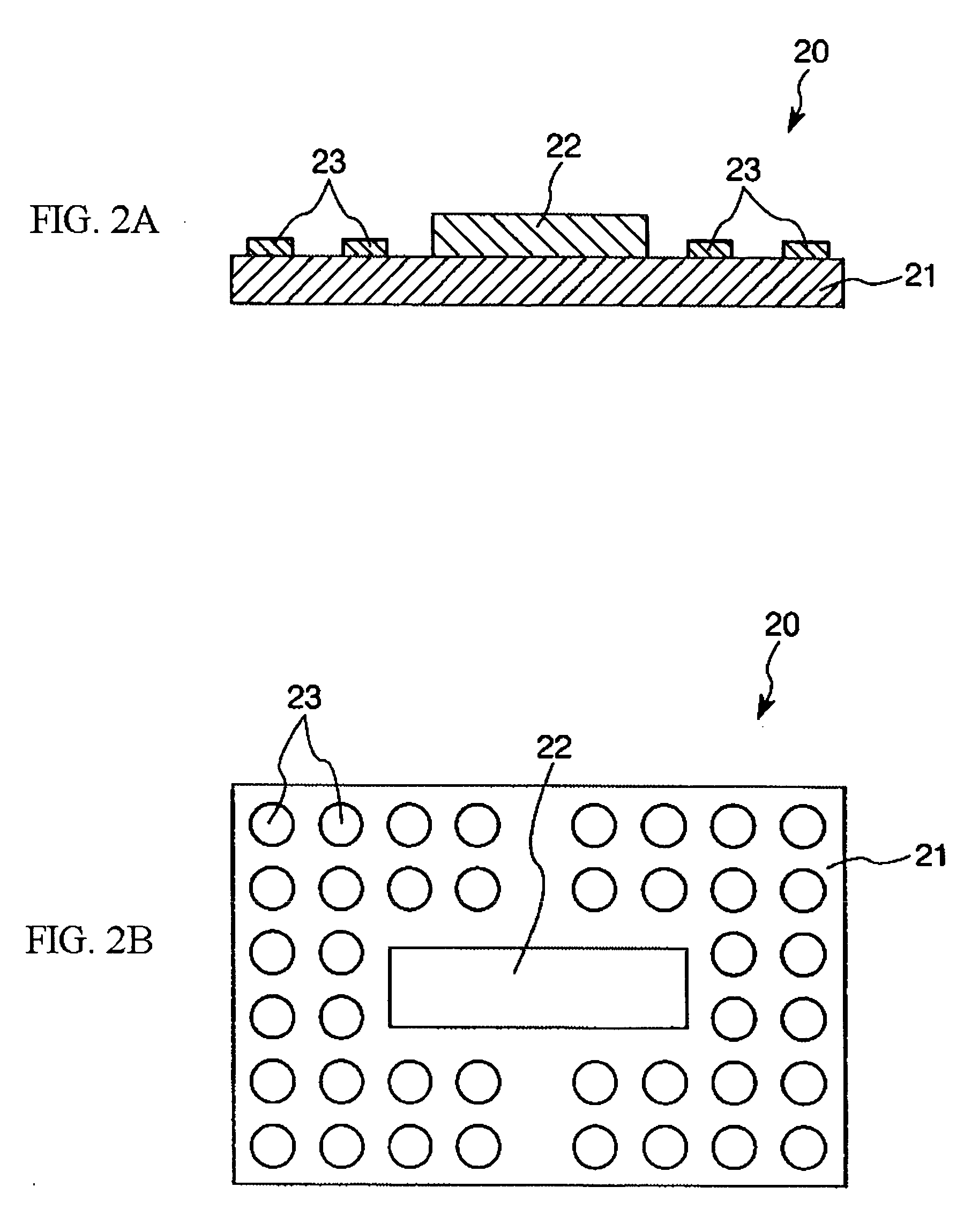

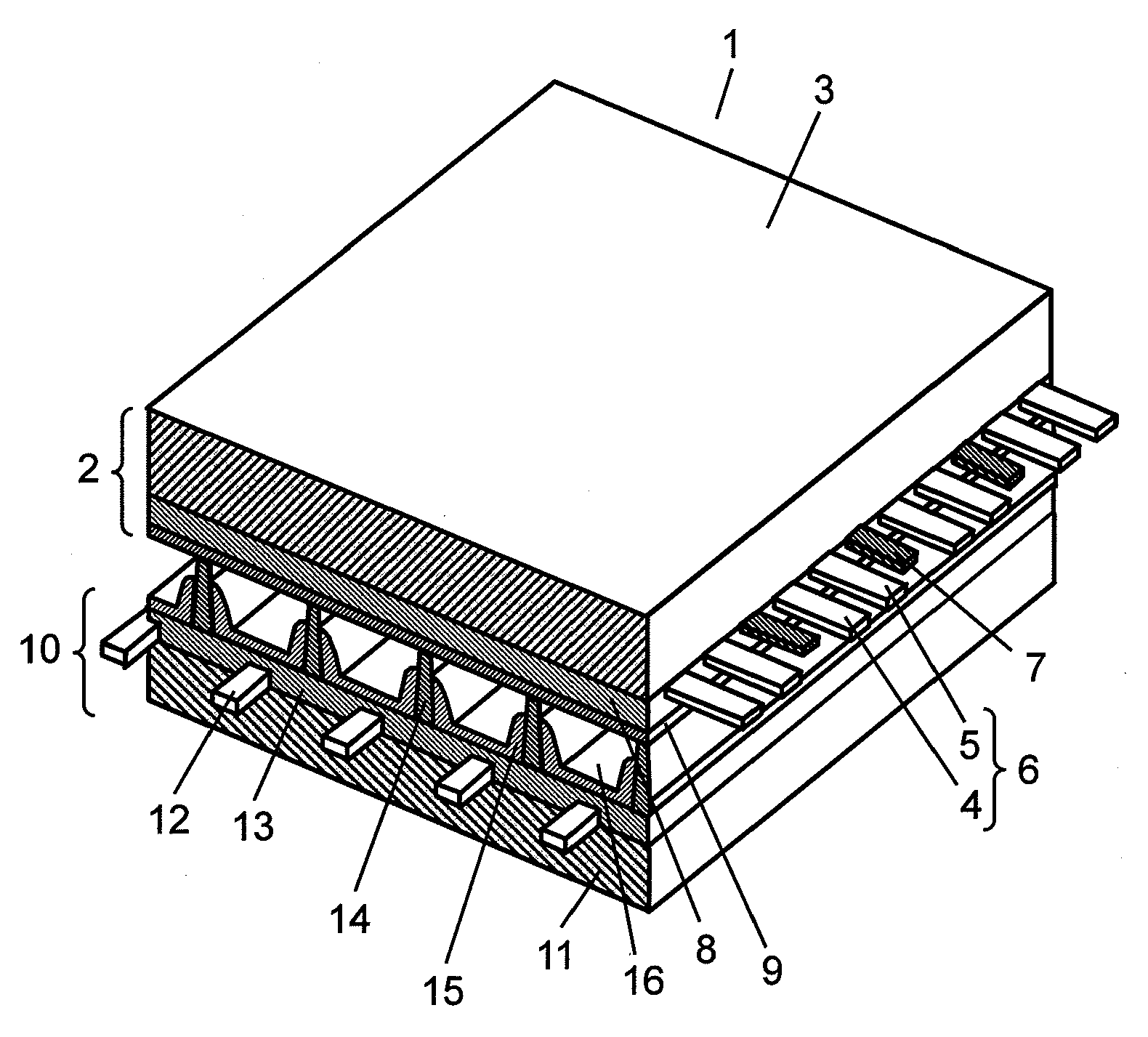

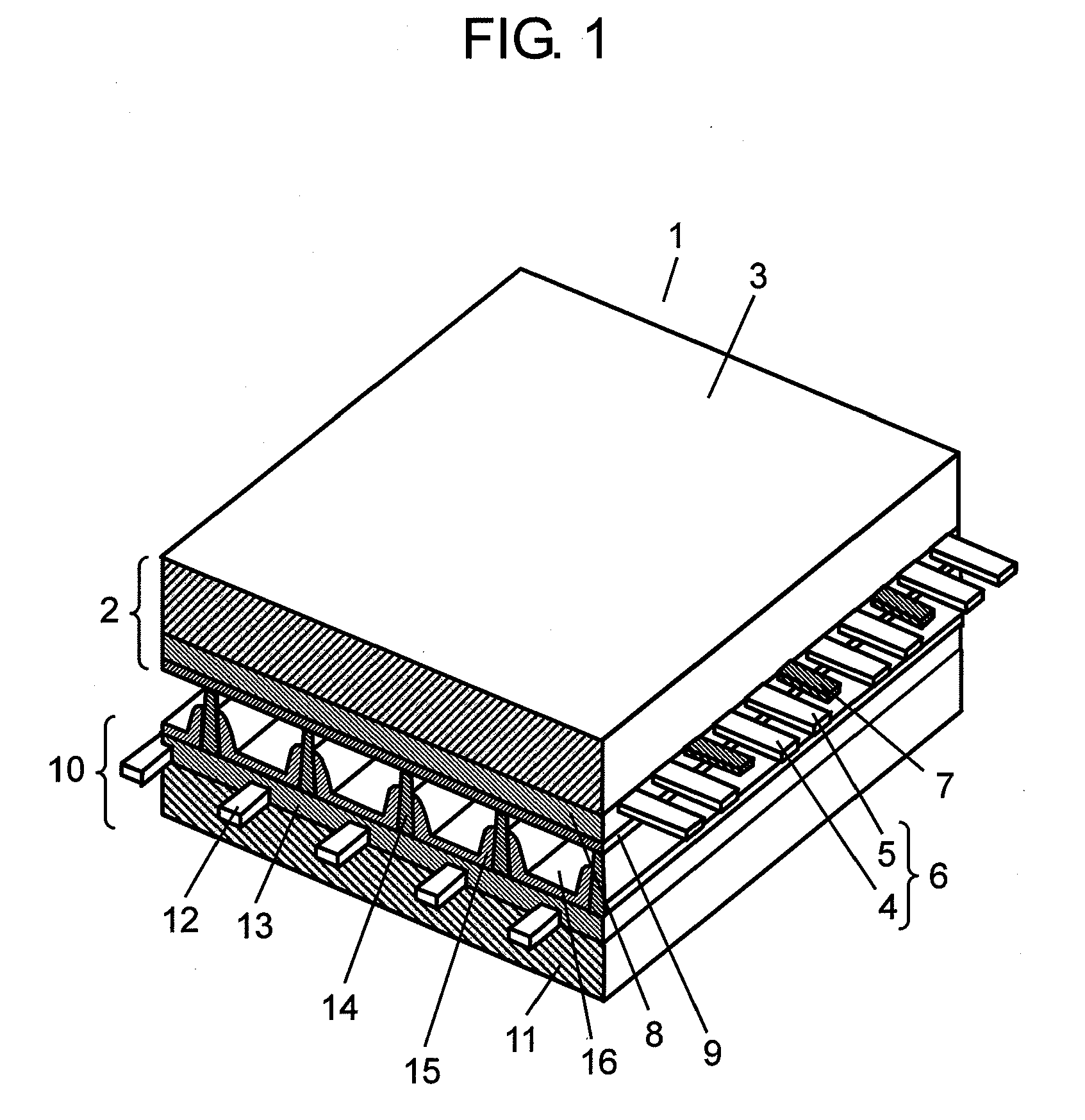

Information storage device, removable device, developer container, and image forming apparatus

ActiveUS20120200871A1Difficulty occurDigitally marking record carriersVisual presentation using printersImage formationEngineering

An information storage device installed in a removable device configured to be removably installed in an image forming apparatus body, includes: an information storage unit that stores information communicated between the image forming apparatus body and the removable device; a terminal that comes in contact with a body side terminal; and a substrate that holds the information storage unit and the terminal and includes a hole configured to be engaged with a protruding section installed in the image forming apparatus body. The terminal includes a plurality of terminals each including one of a plurality of metallic plates arranged in a transverse direction thereof. An earth terminal, which comes in contact with a body side earth terminal formed in the protruding section, is formed in the hole. The hole is disposed at a position sandwiched between two metallic plates among the plurality of metallic plates.

Owner:RICOH KK

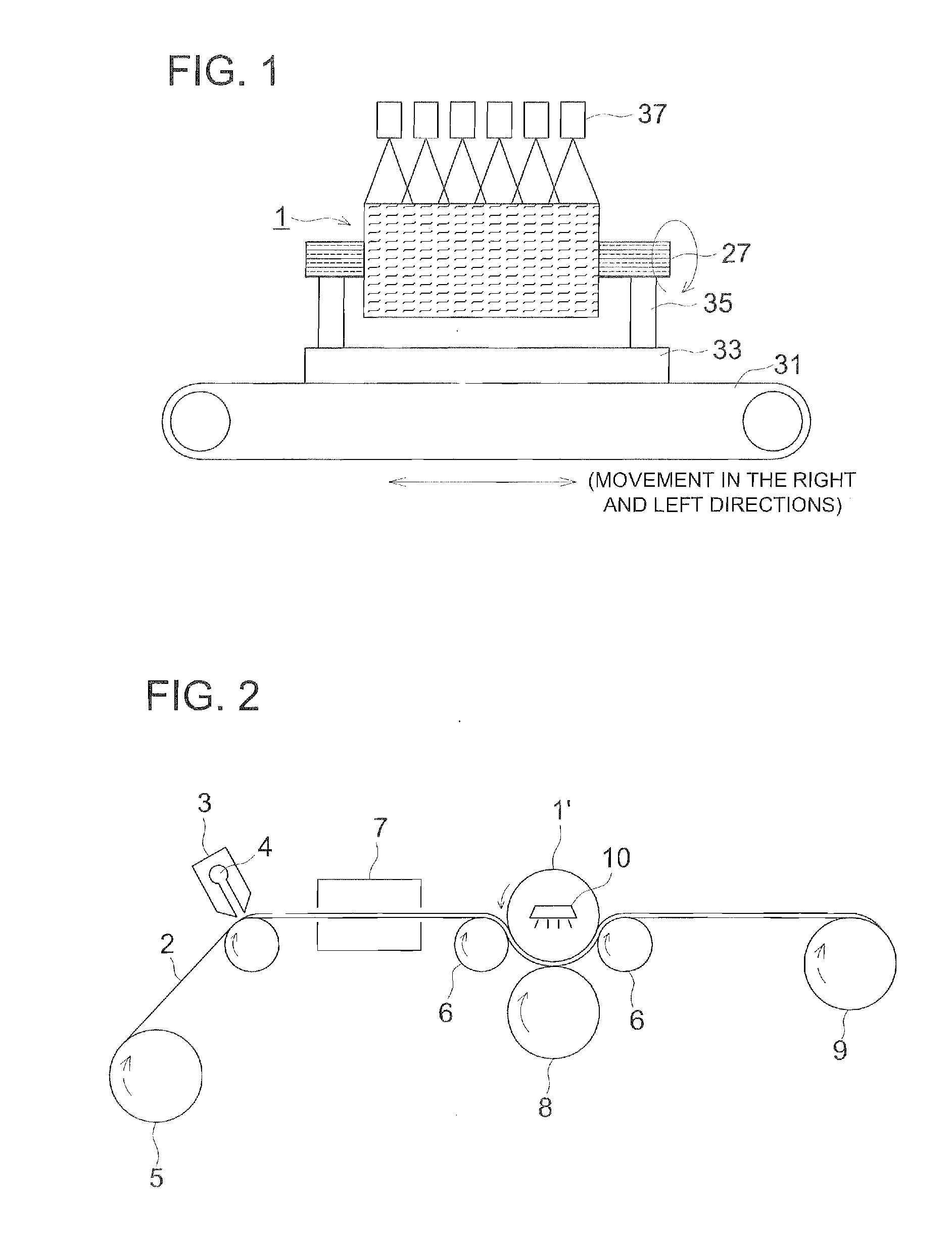

Process for producing film with concavo-convex pattern

InactiveUS20090267270A1Excellent peelabilityImprove productivityElectric/magnetic/electromagnetic heatingEngineering

The present invention provides a process for producing a concavo-convex pattern film which excels in its peelability from an embossing roll and in coatability of an anti-reflection layer, etc. There is provided a process of producing a concavo-convex pattern film by forming a concavo-convex pattern on the surface of a transparent resin film employing an embossing roll having on the surface a convex-concavo pattern, characterized in that the embossing roll is made of glass and a photocatalyst layer is provided on the surface of the embossing roll, characterized in that the process comprises the steps of introducing a UV curable resin composition between the embossing roll and a transparent resin film provided around the embossing roll to form a UV curable resin layer, exposing the UV curable resin layer to UV rays to form a UV cured resin layer having on the surface a concavo-convex pattern, the UV rays being emitted from the interior of the embossing roll, and peeling the UV cured resin layer together with the transparent resin film from the embossing roll.

Owner:KONICA MINOLTA OPTO

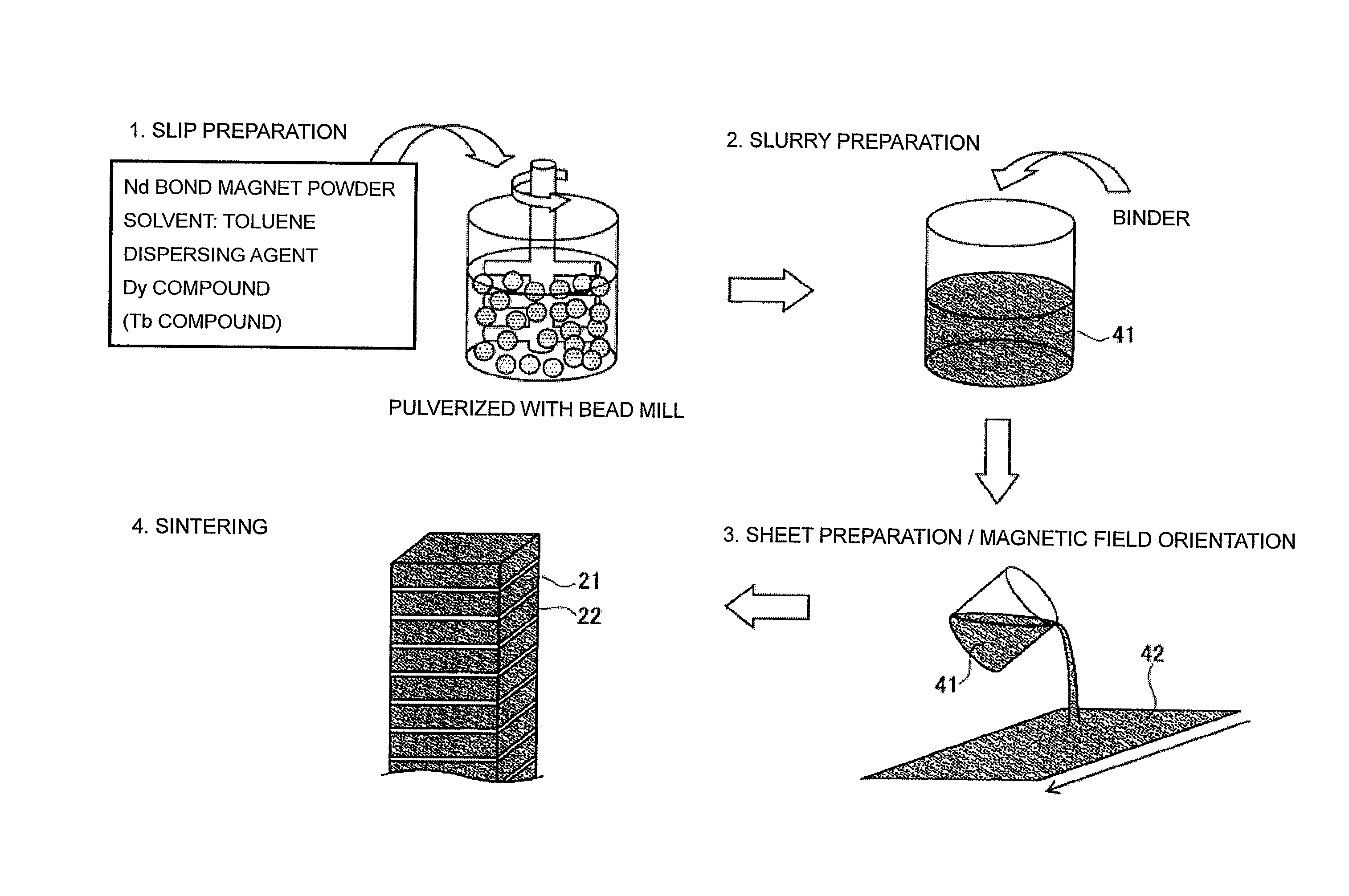

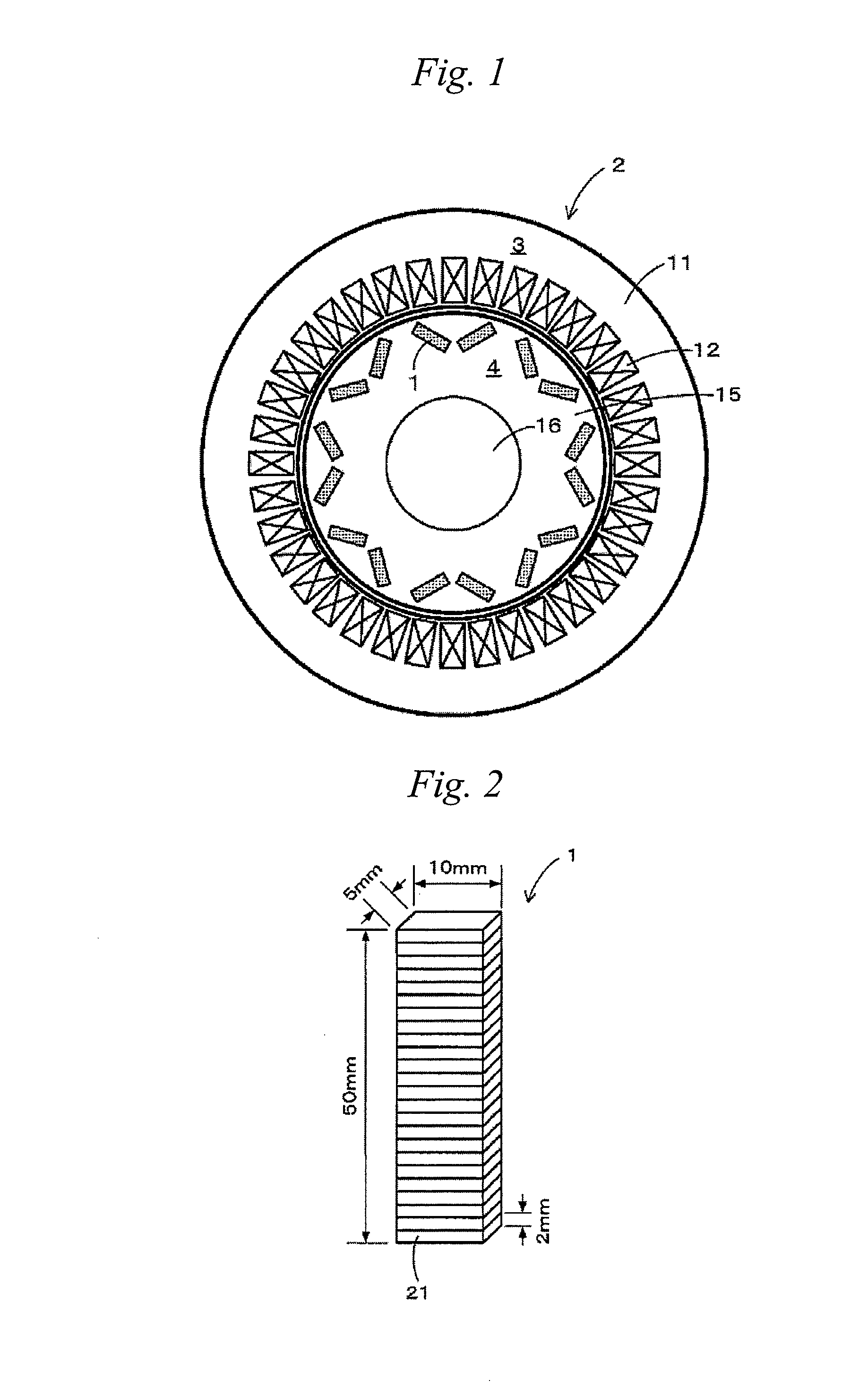

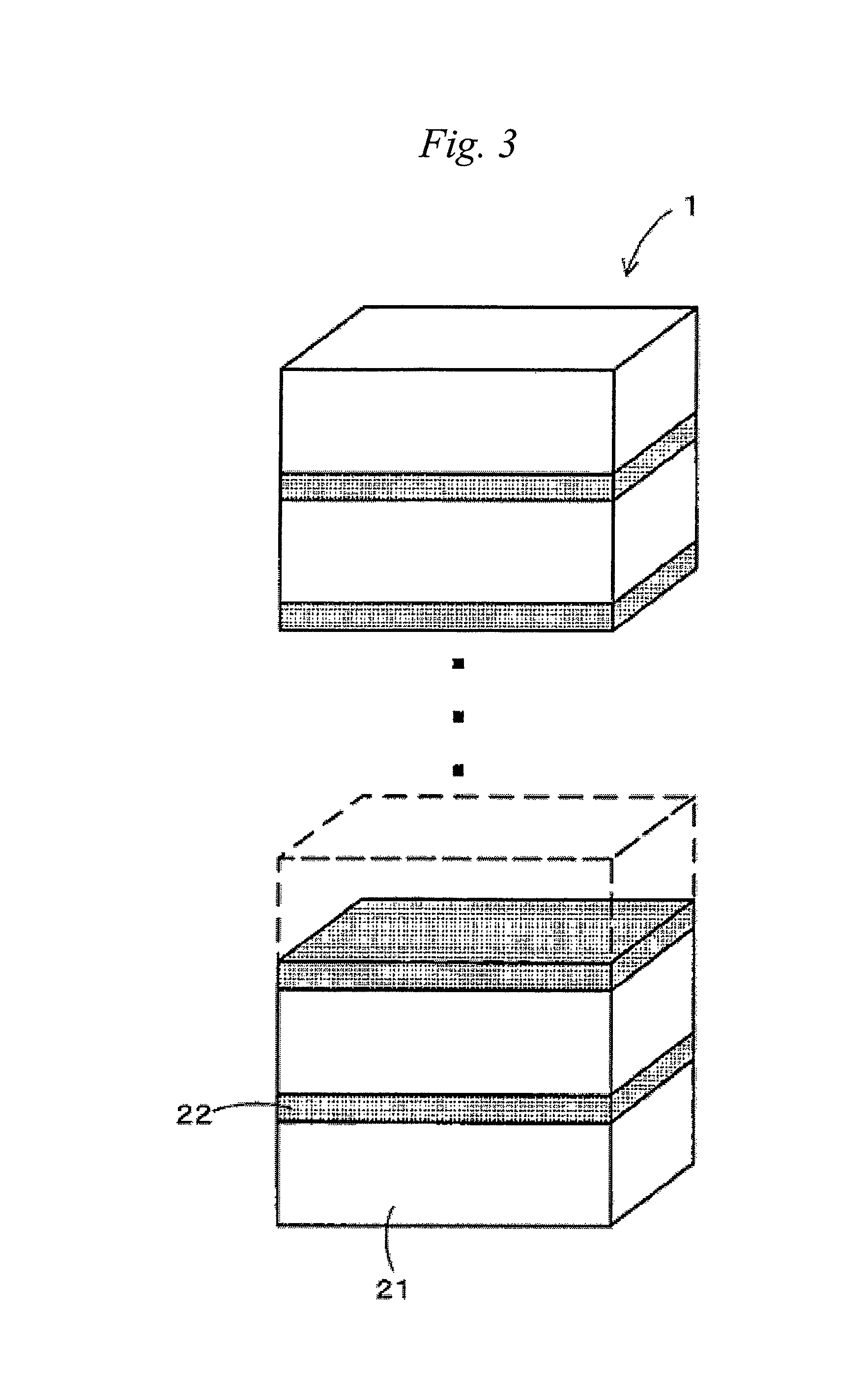

Permanent magnet for motor, and method for manufacturing the permanent magnet for motor

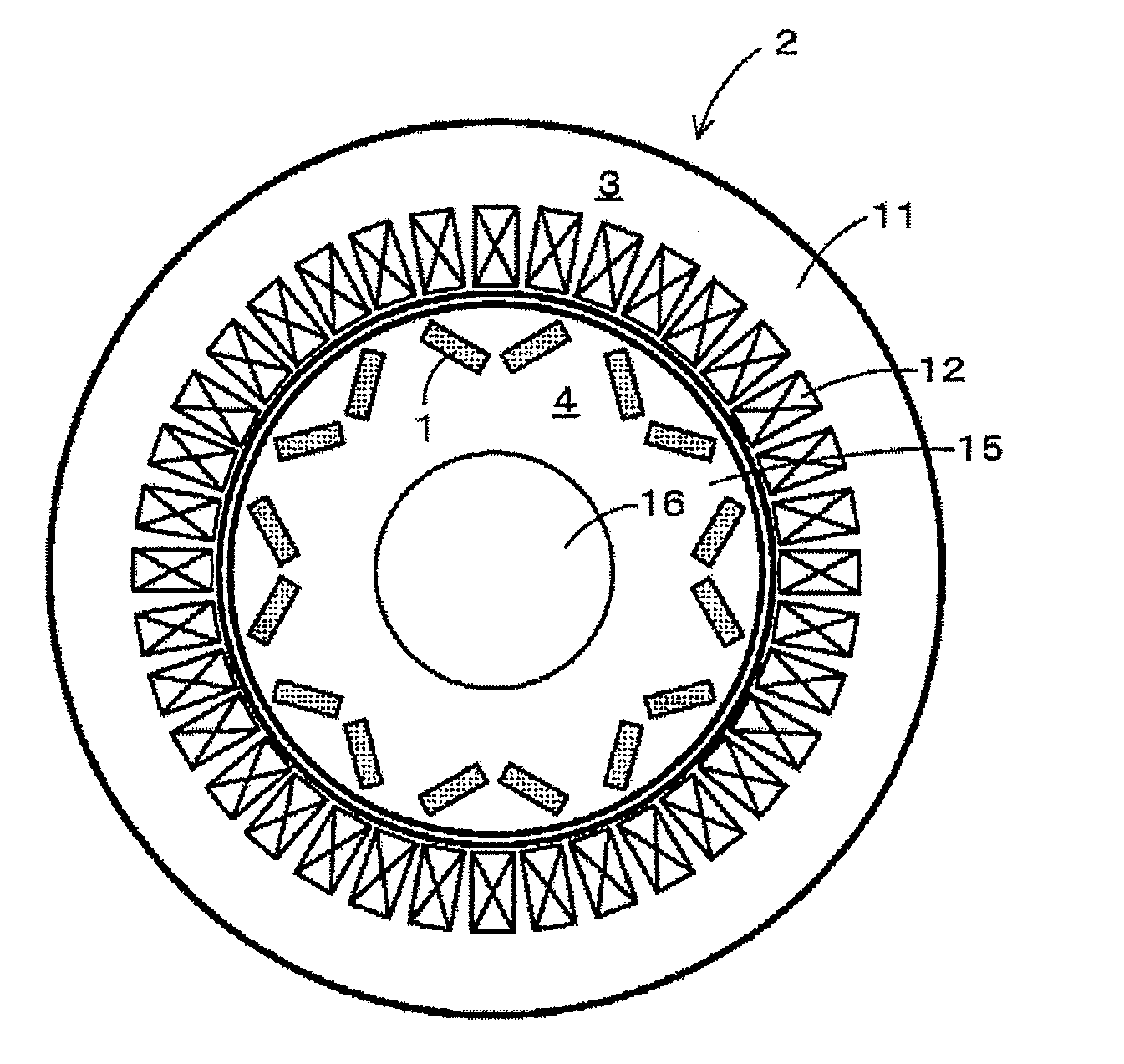

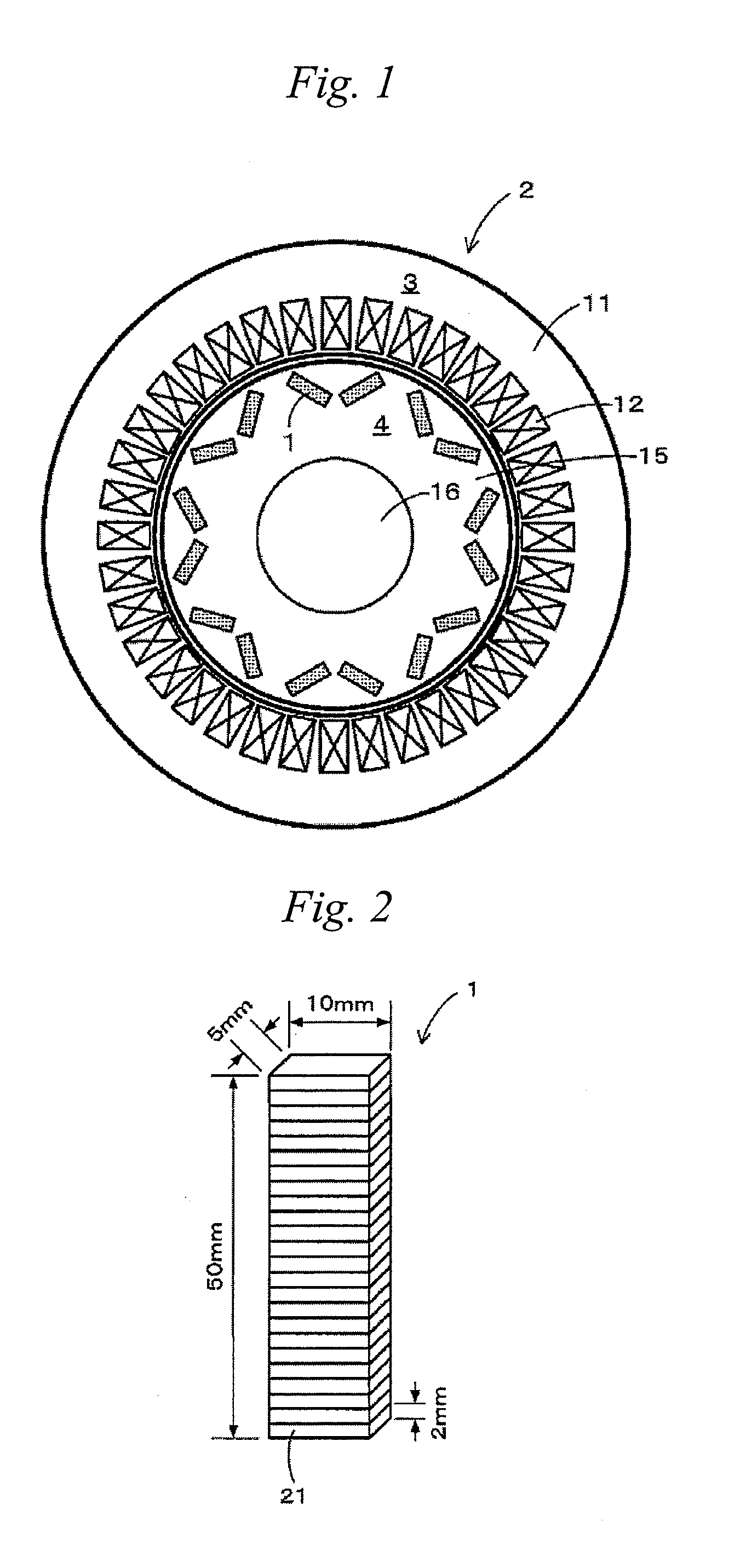

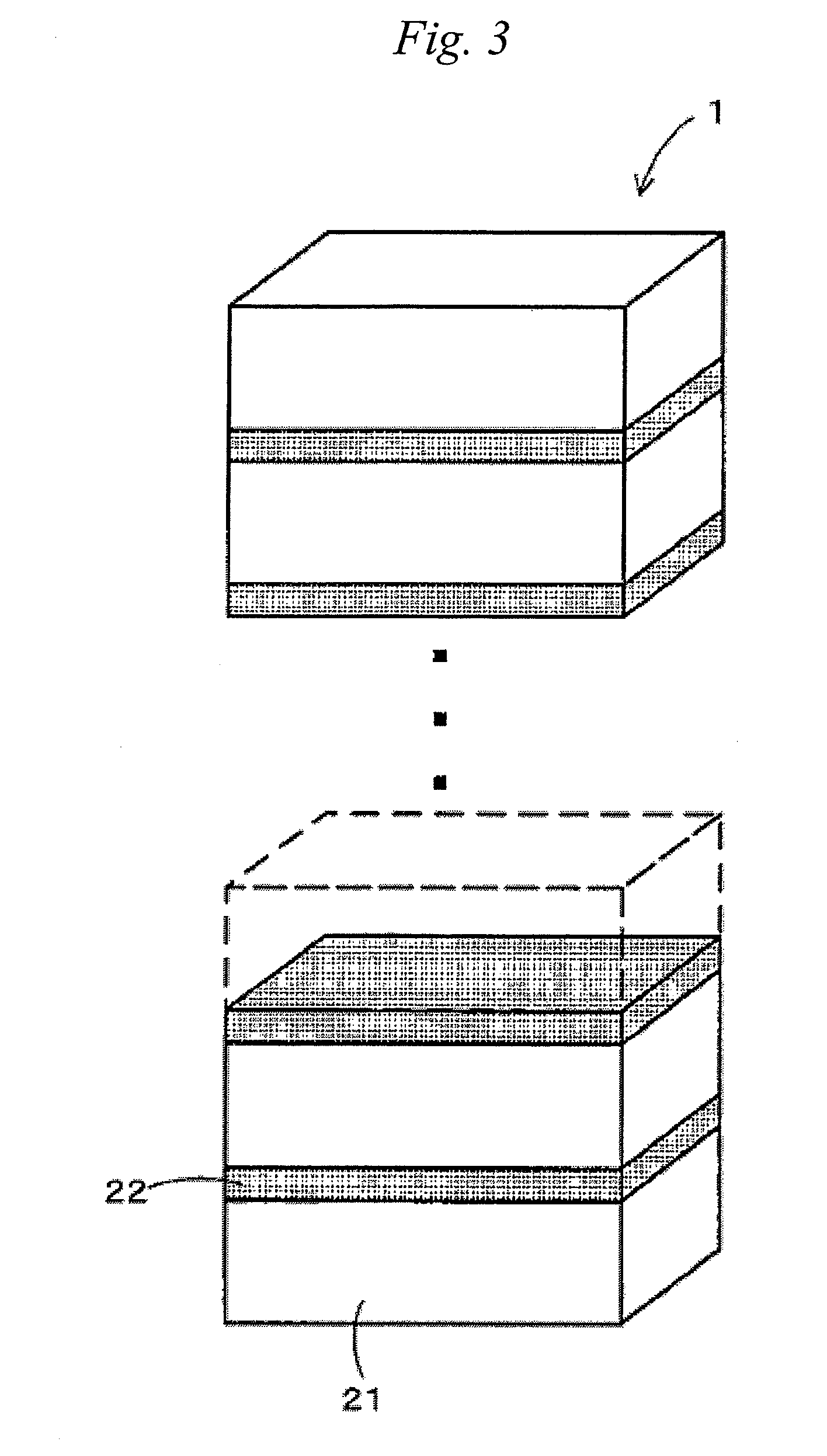

ActiveUS20110012460A1Total current dropDifficulty occurMagnetic circuit rotating partsSynchronous machinesEngineeringPermanent magnet motor

The present invention relates to a permanent magnet for a motor, to be buried in a permanent magnet motor, including: a plurality of sheet magnets for lamination, and an insulating layer arranged between the plurality of sheet magnets for lamination. Since the invention has the above-mentioned constitution, the permanent magnets are free from the problems of temperature elevation and coercive force depression, therefore making it possible to provide a high-power small-sized motor. Furthermore, it is unnecessary to perform the conventional correcting processing after sintering, which can simplify the production steps, and therefore, it becomes possible to mold the permanent magnet with a high degree of dimension accuracy.

Owner:NITTO DENKO CORP +1

Cutter wheel, device and method using the cutter wheel, method of dividing laminated substrate, and method and device for manufacturing cutter wheel

InactiveUS20040123717A1Less stressDifficulty occurFine working devicesGlass severing apparatusEngineeringMechanical engineering

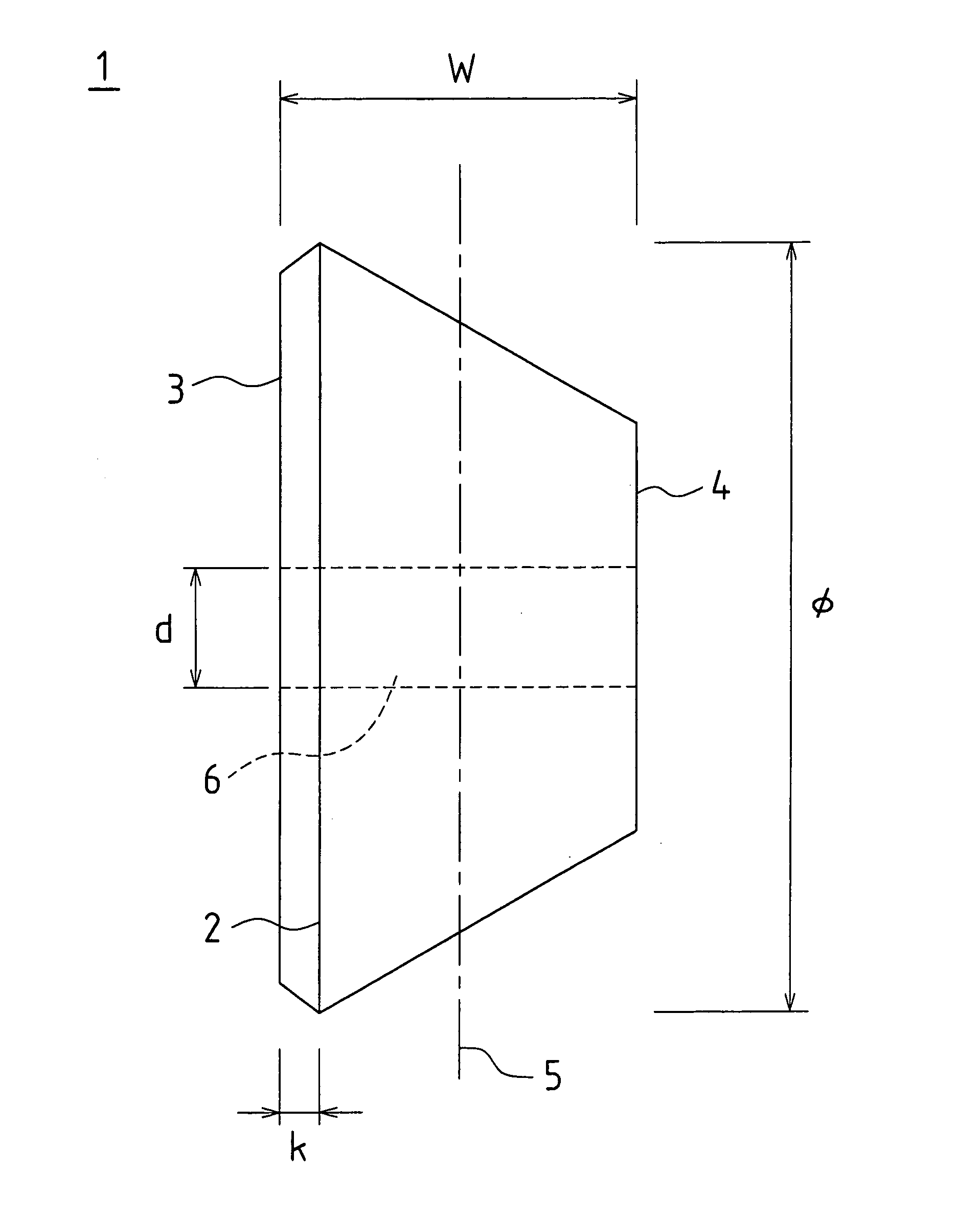

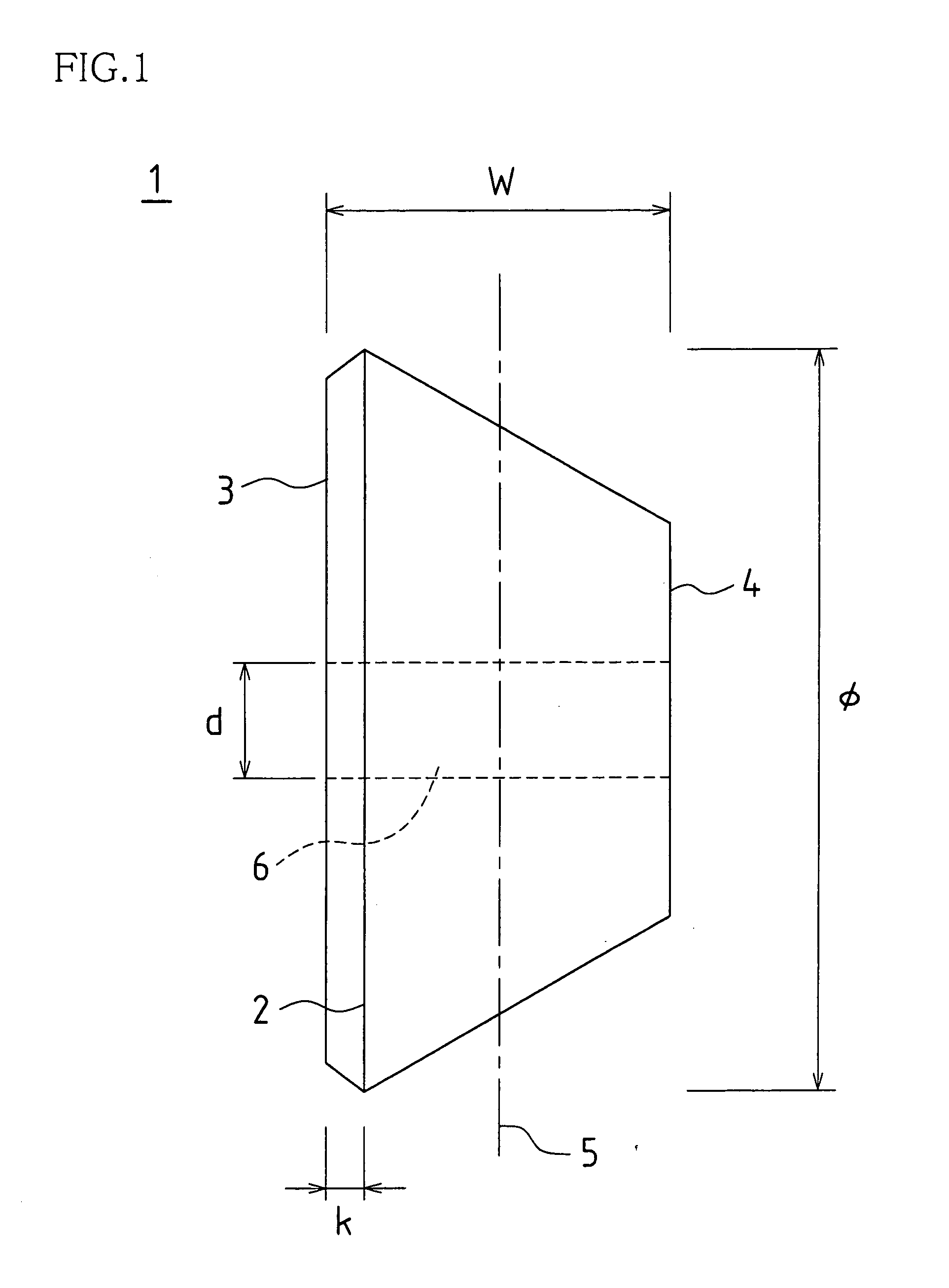

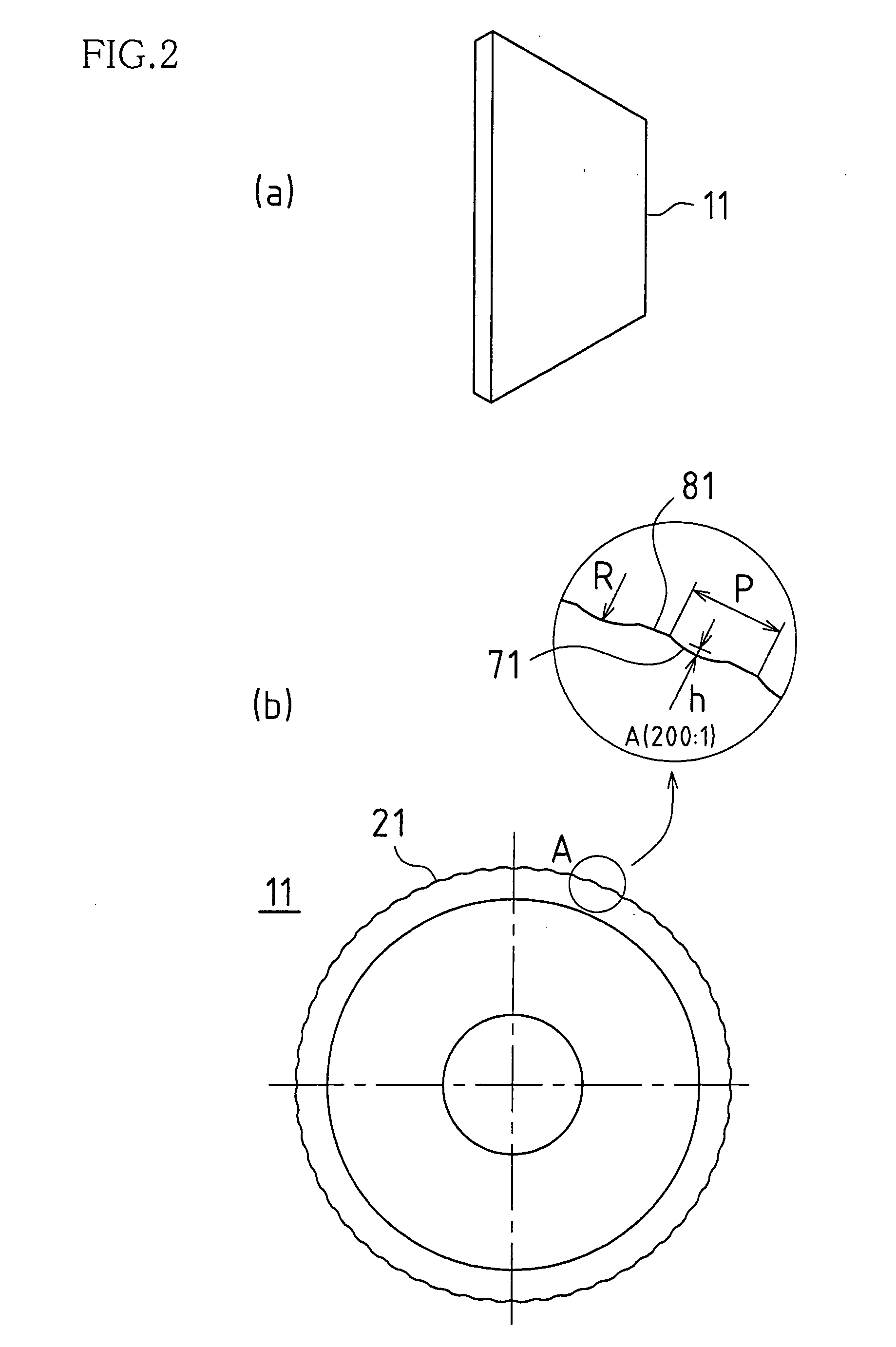

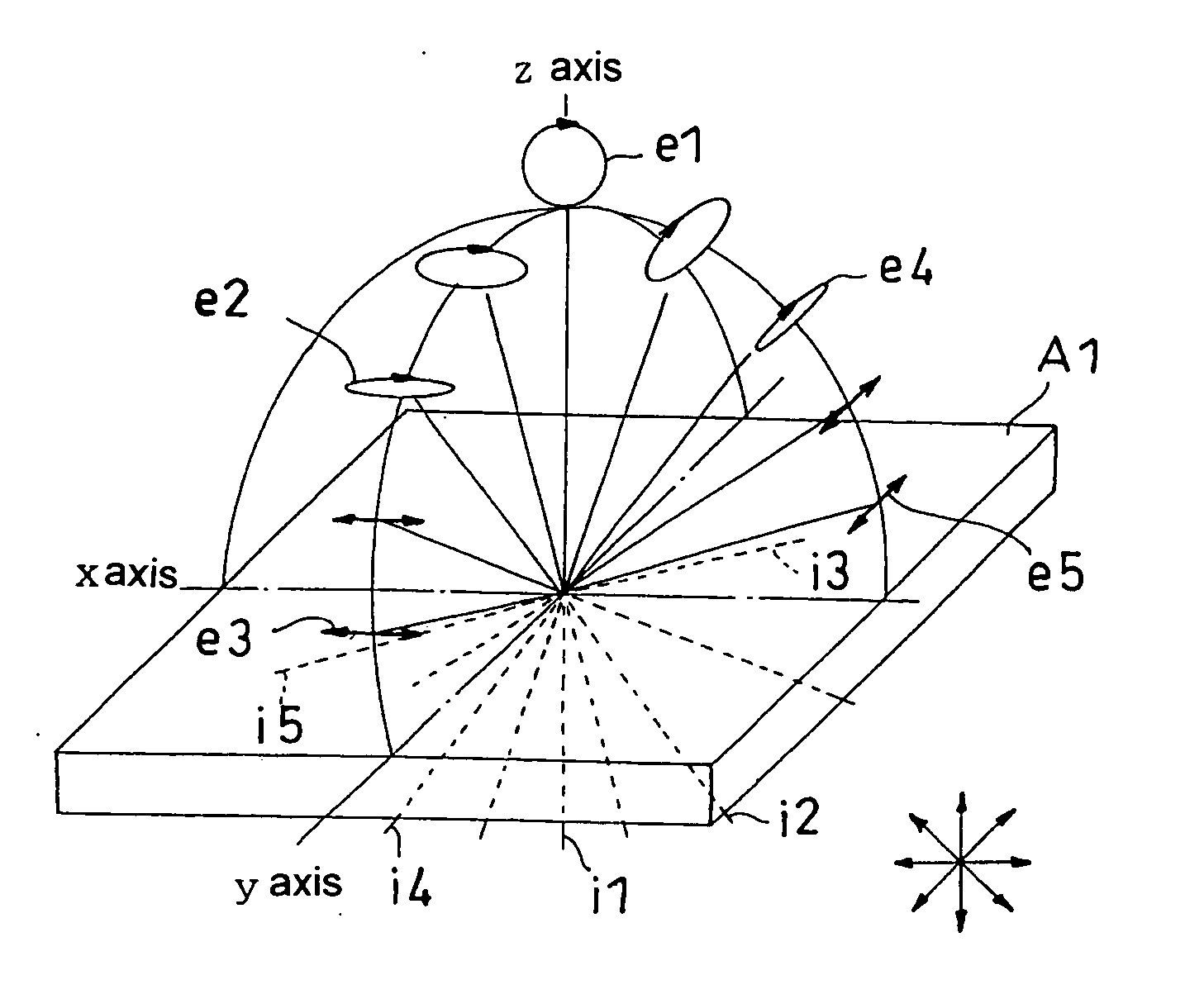

A cutter wheel 1 is formed with an insertion through-hole 6 at the center of the wheel, along with a blade-edge ridge 2 that is displaced to one side face from a center 5 between between wheel side faces 3 and 4. The larger the extent of displacement of the blade-edge ridge 2, that is, the greater the distance from the center 5 until the blade-edge ridge 2, or in other words, the smaller the distance between the left-side face 3 and the blade-edge ridge 2, the closer scribing can be performed to the convex portion and thin film X of the devices during scribing.

Owner:MITSUBOSHI DIAMOND IND CO LTD

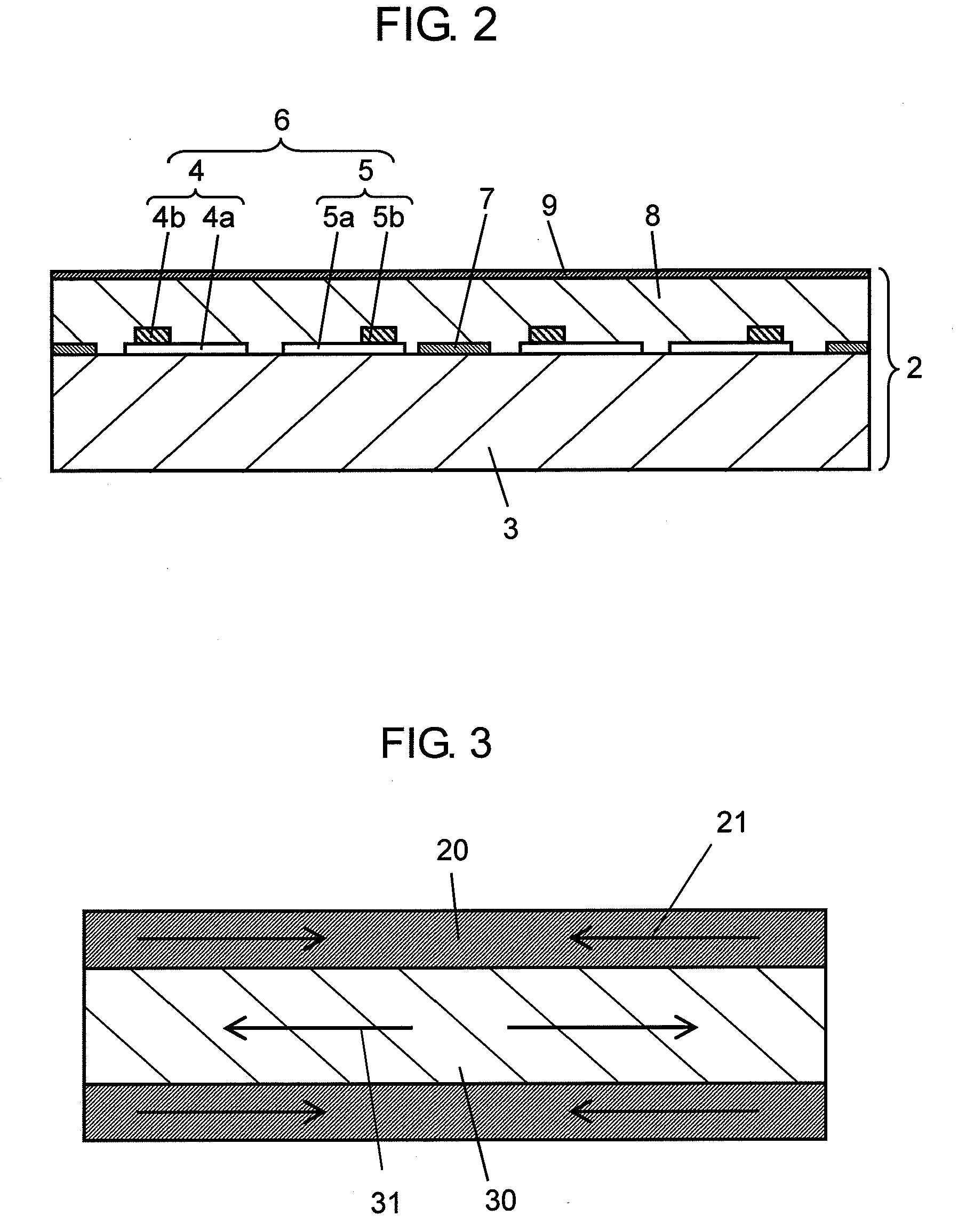

Optical element, light condensation backlight system, and liquid crystal display

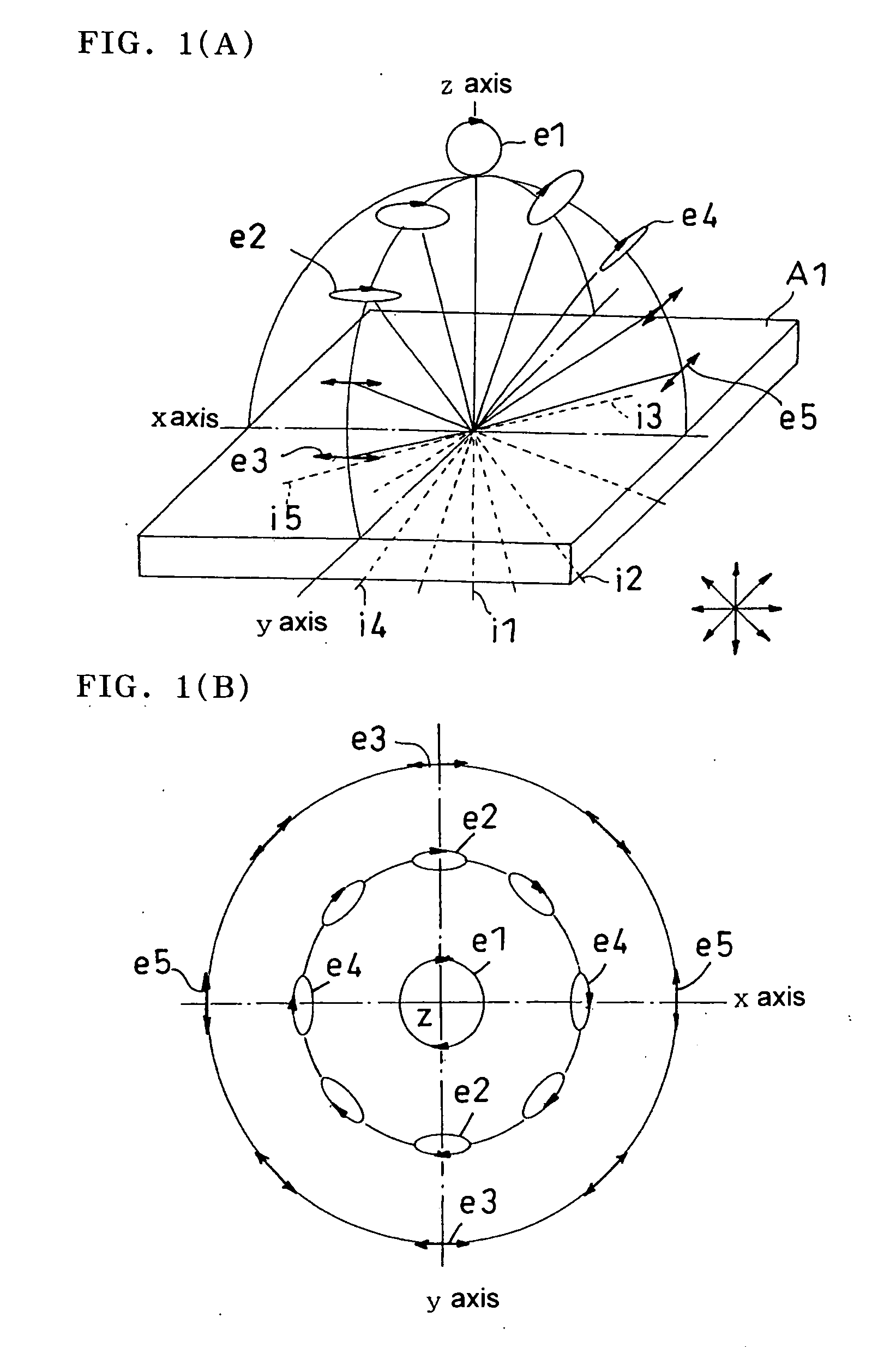

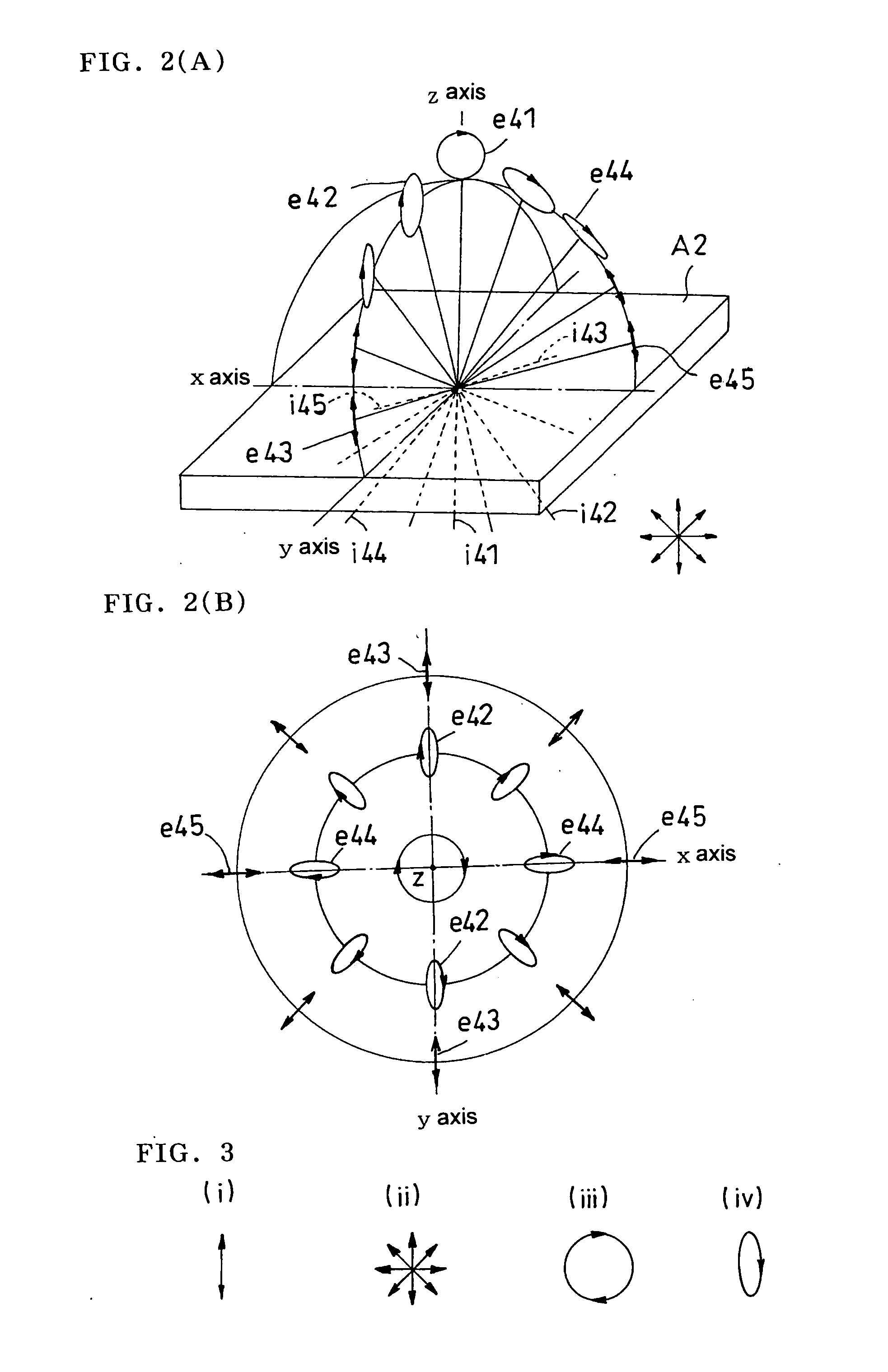

InactiveUS20070064168A1High light transmittanceGood shielding direction effectMechanical apparatusElongate light sourcesLiquid-crystal displayPolarizer

An optical element comprising: a polarizing element (A), separating incident light into polarization to then emit light, and made of a cholesteric liquid crystal, wherein the polarizing element (A) has a distortion rate with respect to emitting light to incident light in the normal direction of 0.5 or more and a distortion rate with respect to emitting light to incident light at an angle inclined from the normal direction by 60 degrees or more of 0.2 or less, the polarizing element (A) has a function increasing a linearly polarized light component of emitting light as incidence angle is larger; a ½ wavelength plate (B); a retardation layer (C) giving almost zero retardation to incident light in the front direction (normal direction) and giving a retardation to incident light in a direction inclined from the normal direction; and a ¼ wavelength plate (D); being arranged in this order, and further a linearly polarized light reflection polarizer (E), transmitting linearly polarized light with one polarization axis and selectively reflecting linearly polarized light with the other polarization axis perpendicular to the one polarization axis, is arranged on the ¼ wavelength plate (D) so that the transmission axis of the linearly polarized light reflection polarizer (E) and an axis of the transmitted light, which is transmitted through the polarizing element (A) to the ¼ wavelength plate (D) in this order, are the same direction. The optical element is capable of condensation and collimation of incident light from a light source and capable of suppressing transmission of light in an arbitrary direction.

Owner:NITTO DENKO CORP

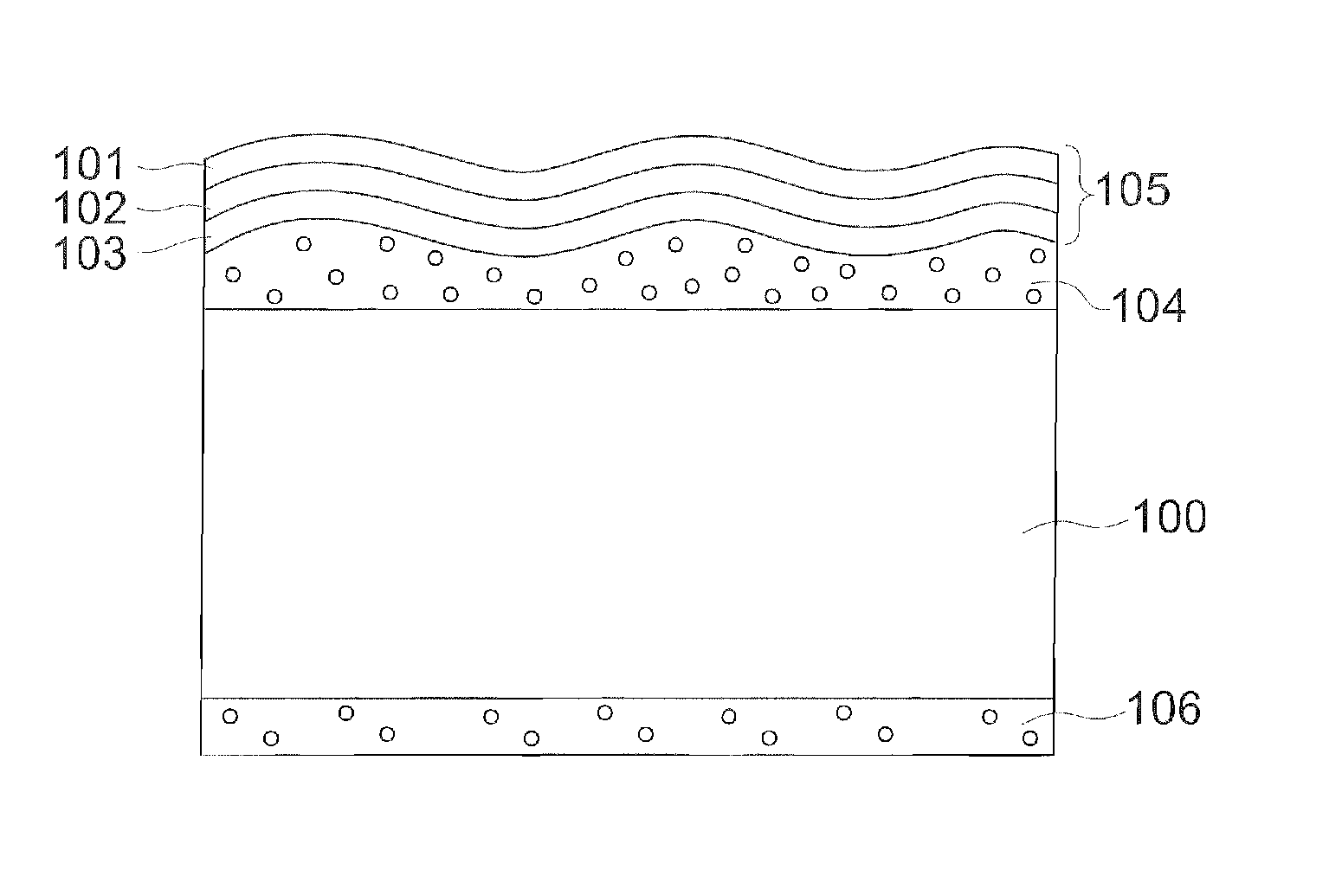

Protective Film for Polarizing Plate

ActiveUS20090086320A1High color reproductionLess occurrenceLiquid crystal compositionsPrismsTectorial membraneLiquid-crystal display

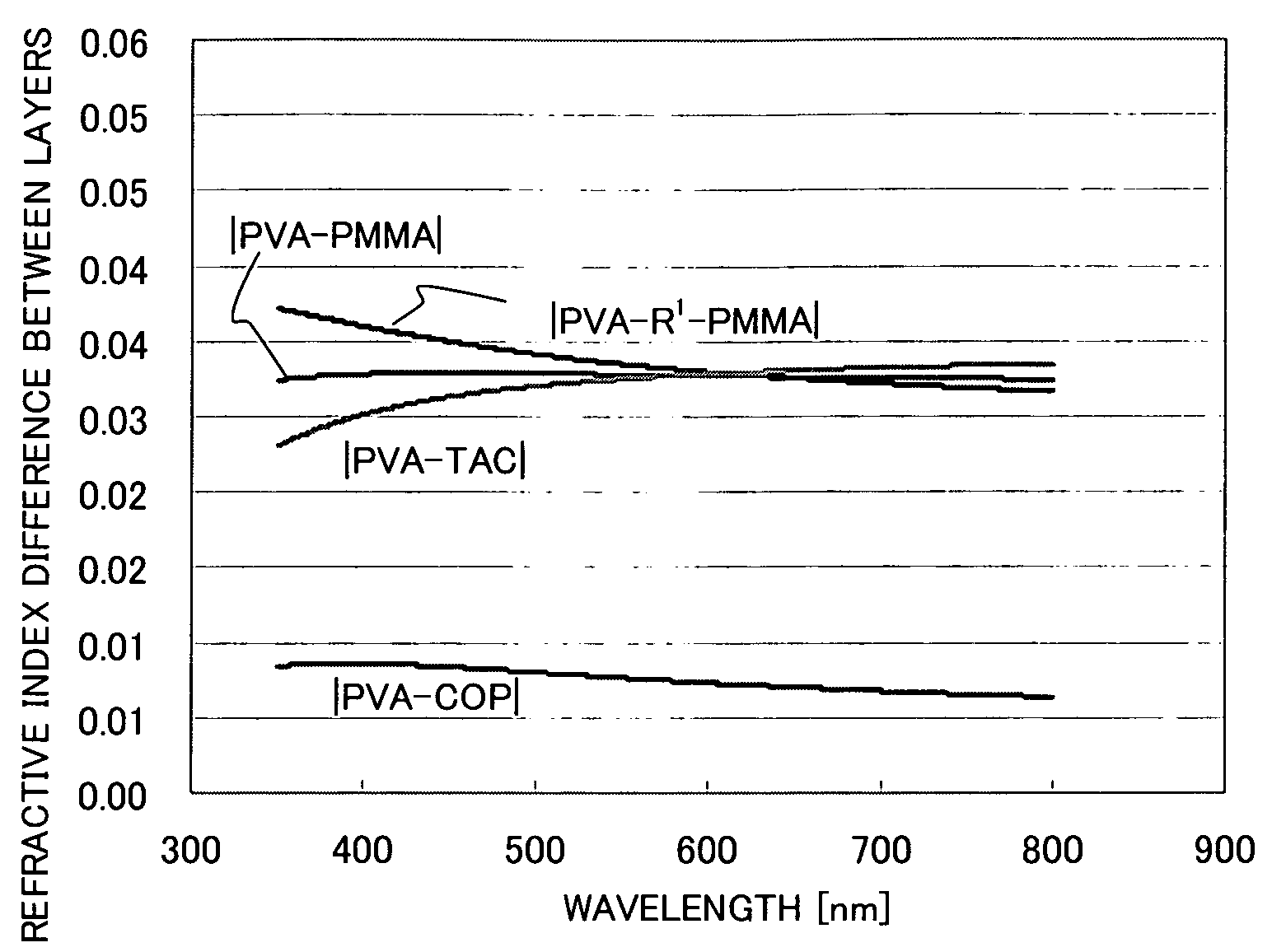

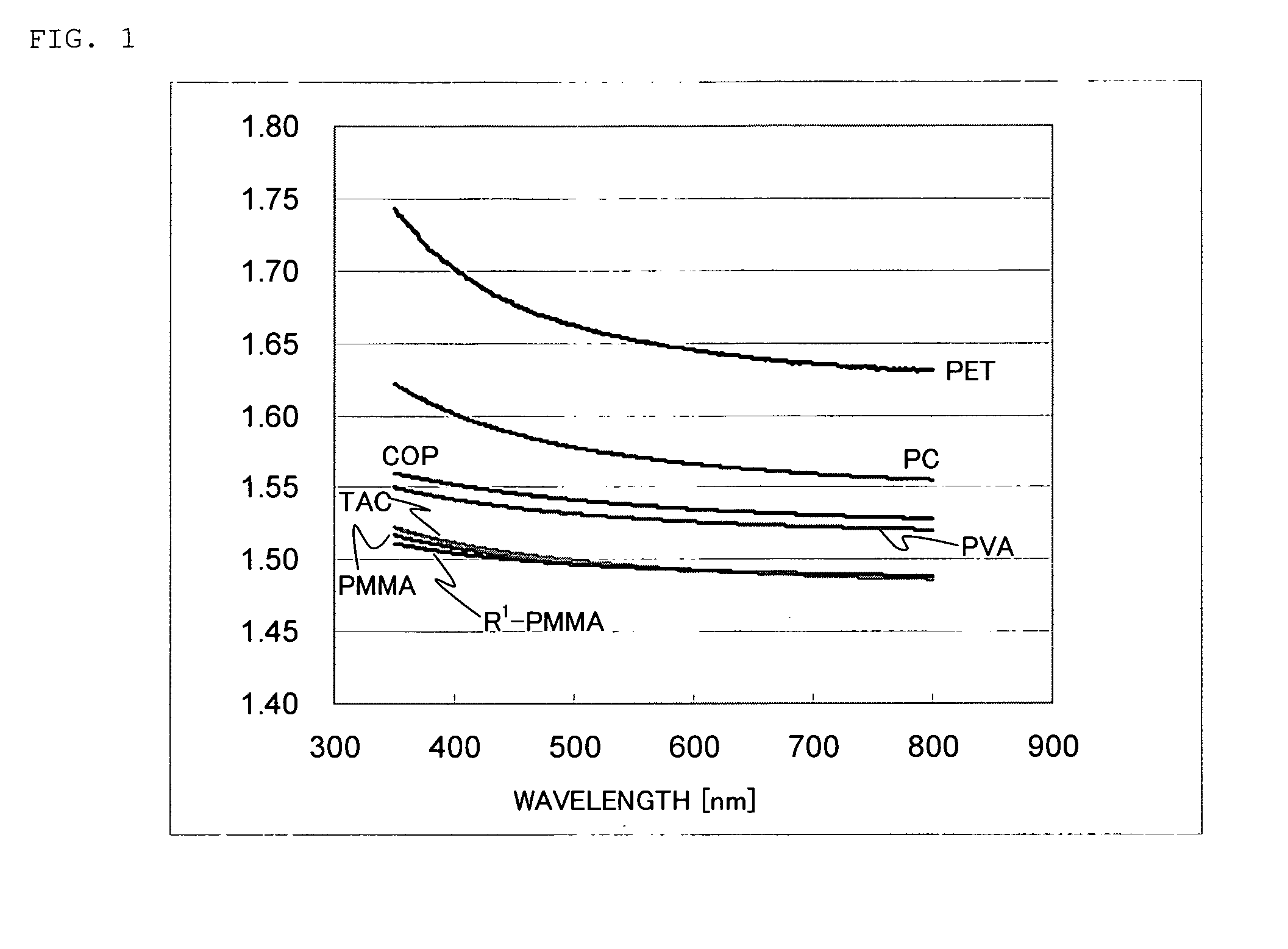

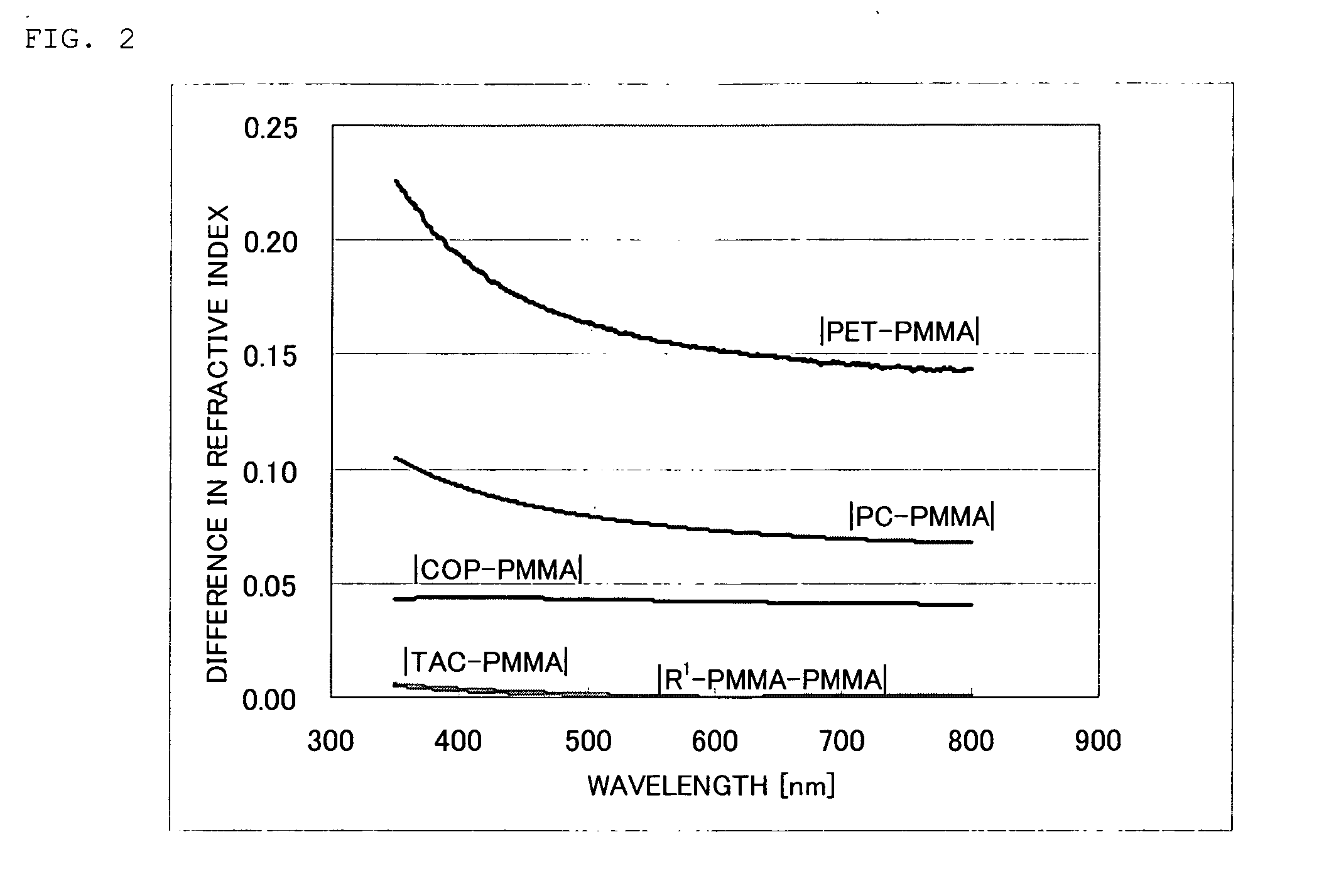

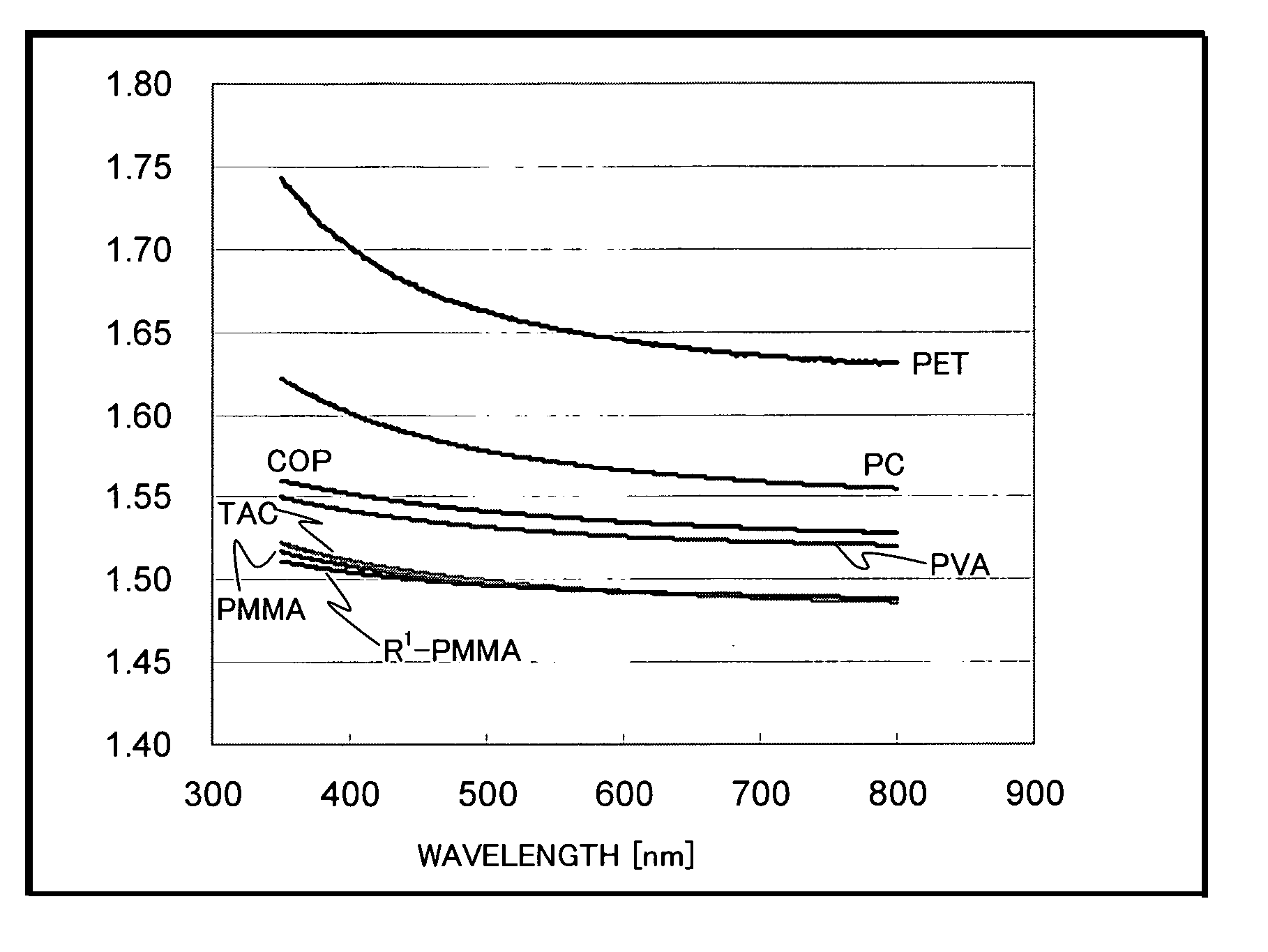

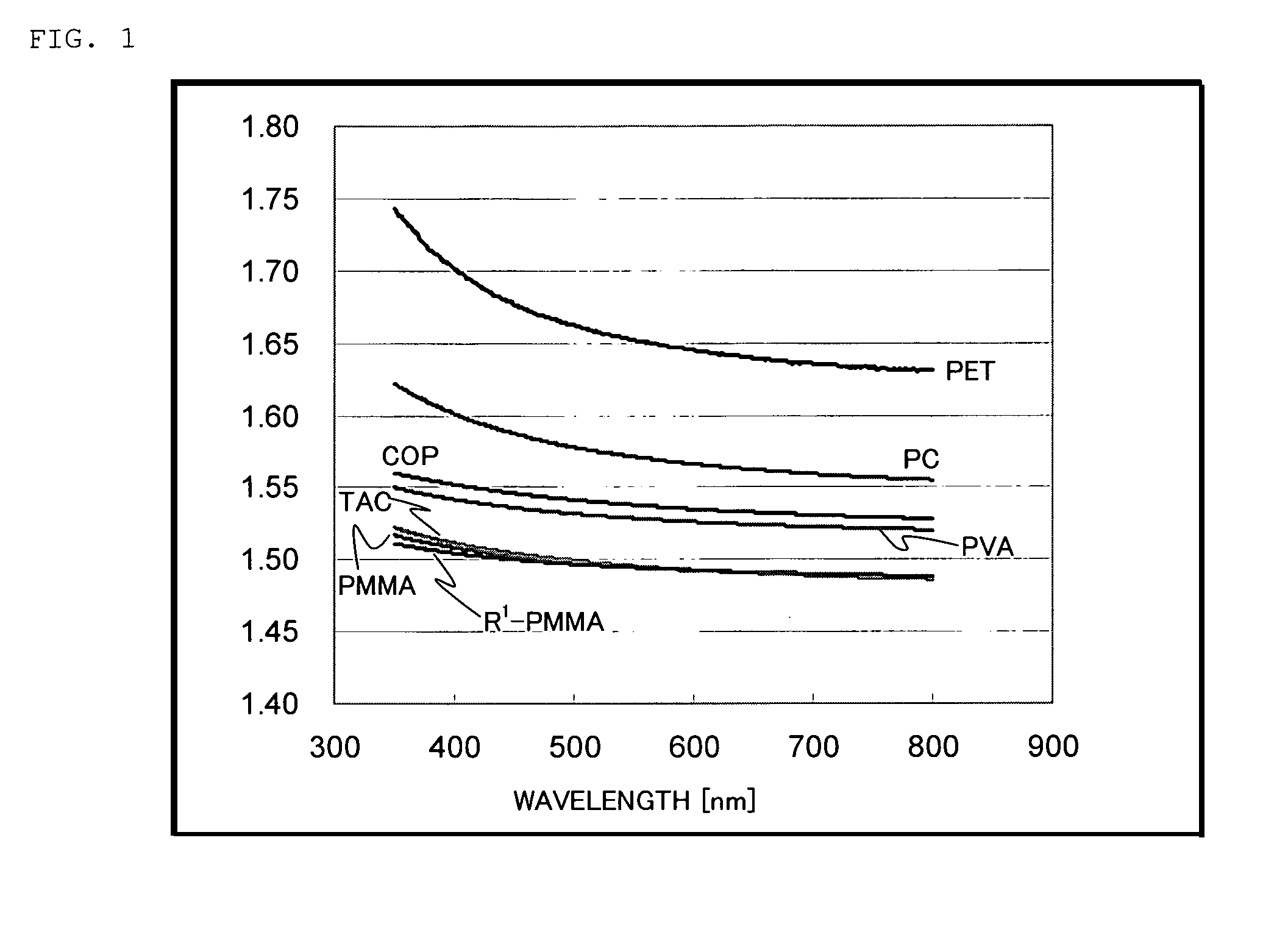

A protective film for polarizing plate comprising k layers (k is an integer of 2 or more) of thermoplastic resin layer laminated, whereina refractive index ni(380) at a wavelength of 380 nm and a refractive index ni(780) at a wavelength of 780 nm in the i th thermoplastic resin layer as well as a refractive index ni+1(380) at a wavelength of 380 nm and a refractive index ni+1(780) at a wavelength of 780 nm in the i+1 th thermoplastic resin layer have a relationship in∥ni(380)−ni+1(380)|−|ni(780)−ni+1(780)∥≦0.02(where, i is an integer of 1 to k−1). A polarizing plate is obtained by bonding the protective film for the polarizing plate and a polarizer. And a liquid crystal display comprising the polarizing plate and a liquid crystal panel.

Owner:ZEON CORP

Apparatus for manufacturing semiconductor devices, method of manufacturing the semiconductor devices, and semiconductor device manufactured by the apparatus and method

InactiveUS7455213B2Avoid it happening againSuppress manufacturing costSolid-state devicesSoldering apparatusSemiconductor packageAdhesive materials

Owner:SEIKO EPSON CORP

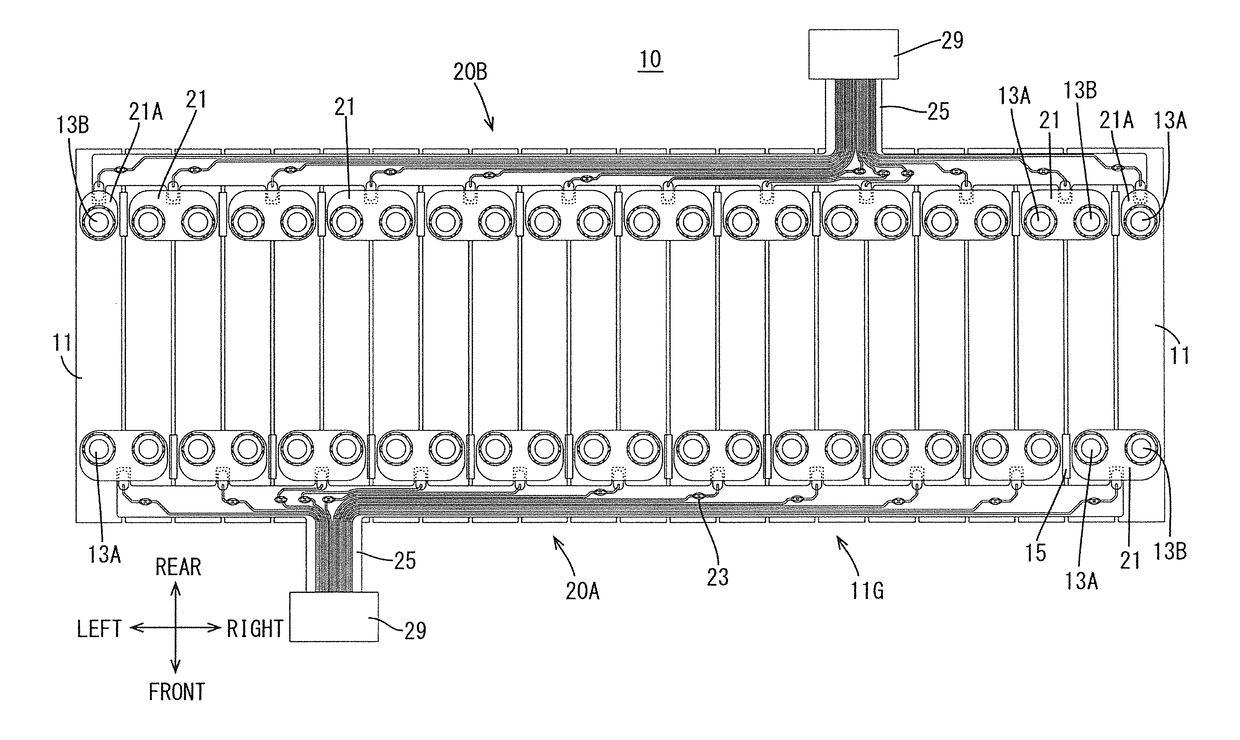

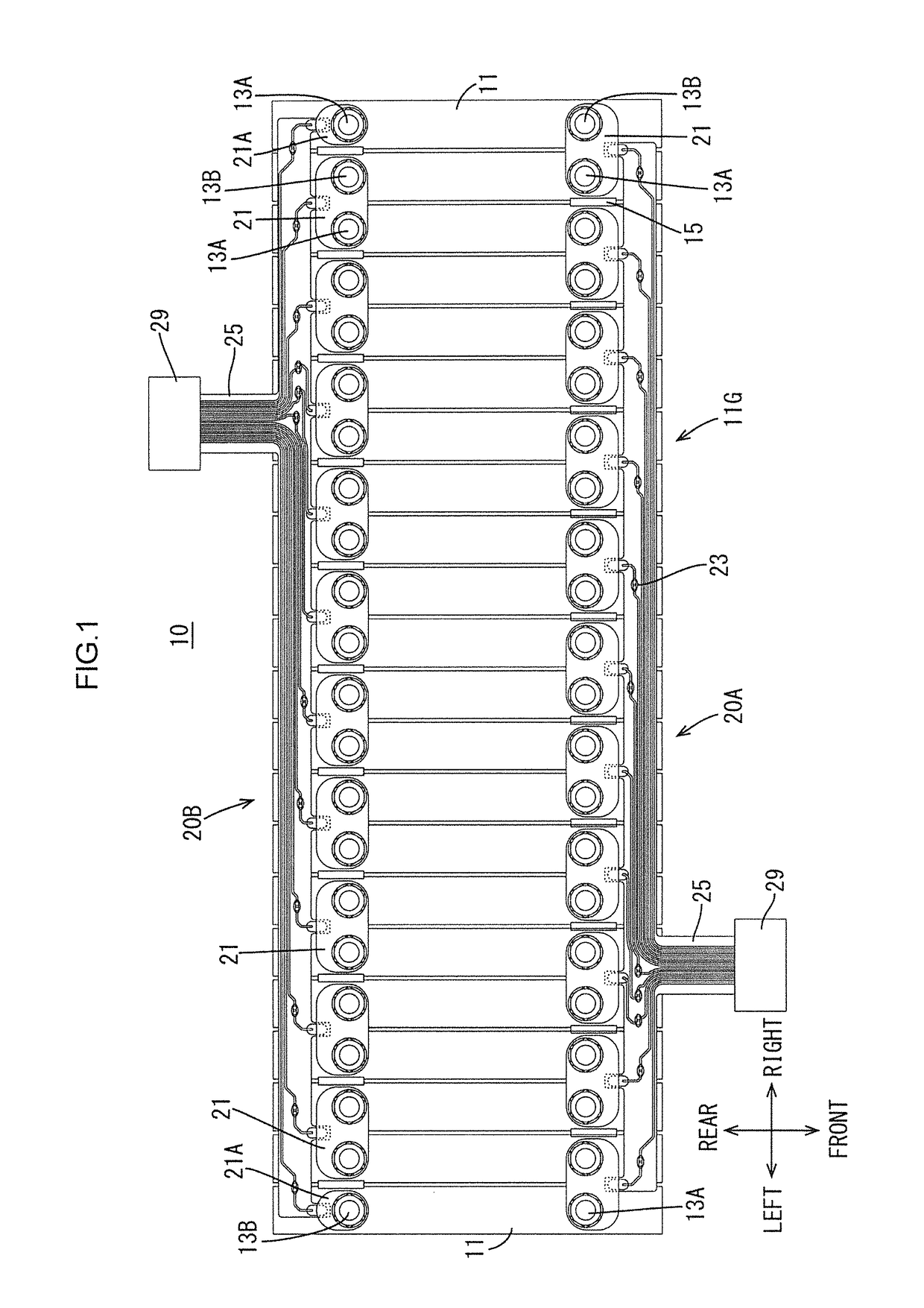

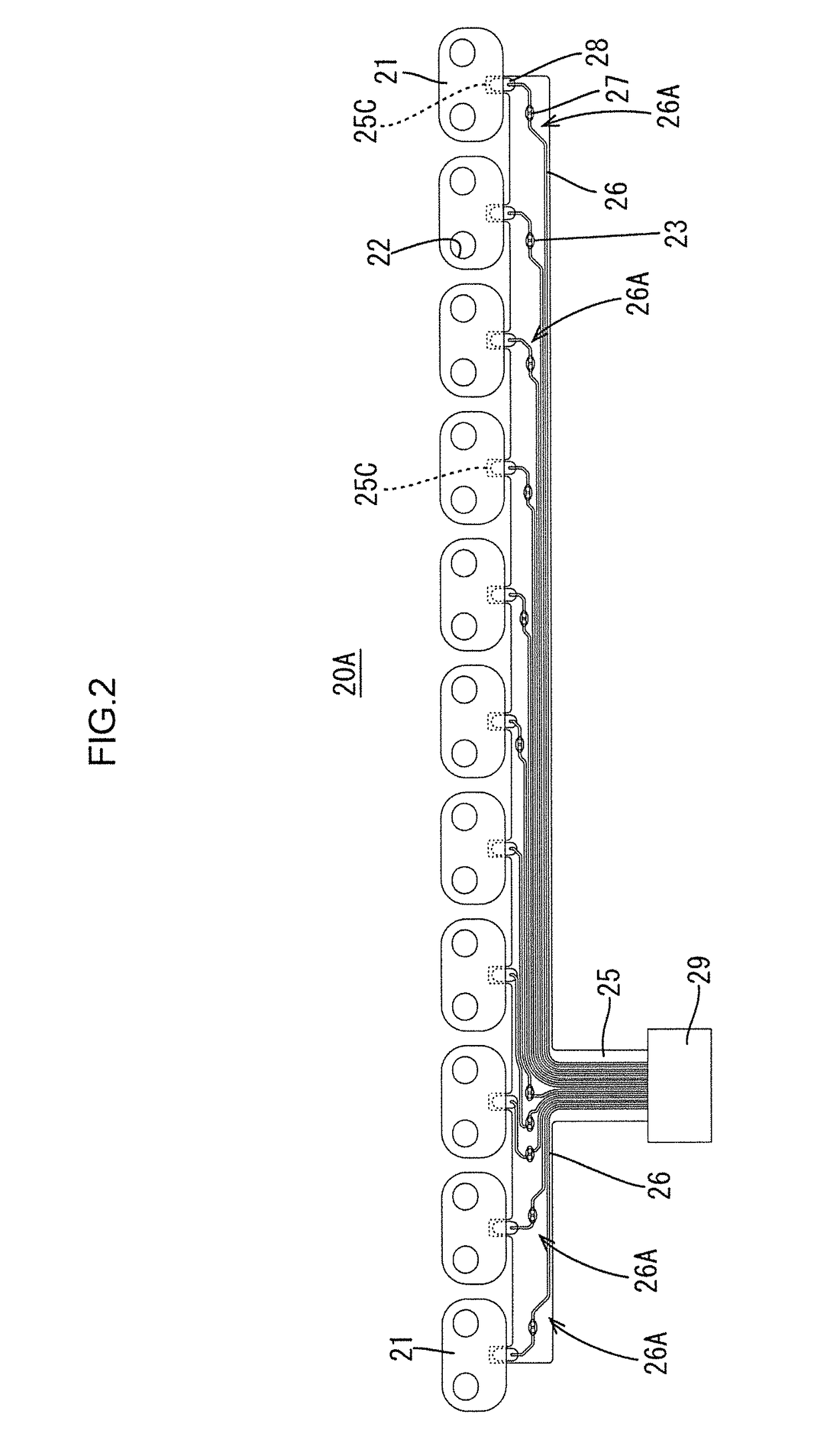

Battery wiring module

ActiveUS20180219204A1Easy to controlLengthCells structural combinationCell component detailsCurrent limitingElectrical battery

A battery wiring module is attached to a cell group including an arrangement of a plurality of cells having positive pole and negative pole electrode terminals. The battery wiring module is provided with: a plurality of connection members connecting the positive pole and negative pole electrode terminals of adjacent cells of the plurality of cells; and a flexible printed board including a plurality of voltage sensing wires for sensing voltages of the plurality of cells via the plurality of connection members. Each of the voltage sensing wires has an electric current limiting element provided somewhere therealong to limit a flow of overcurrent in the voltage sensing wires. The electric current limiting element is connected to the voltage sensing wires at a portion which is overcoated with an insulating resin.

Owner:AUTONETWORKS TECH LTD +4

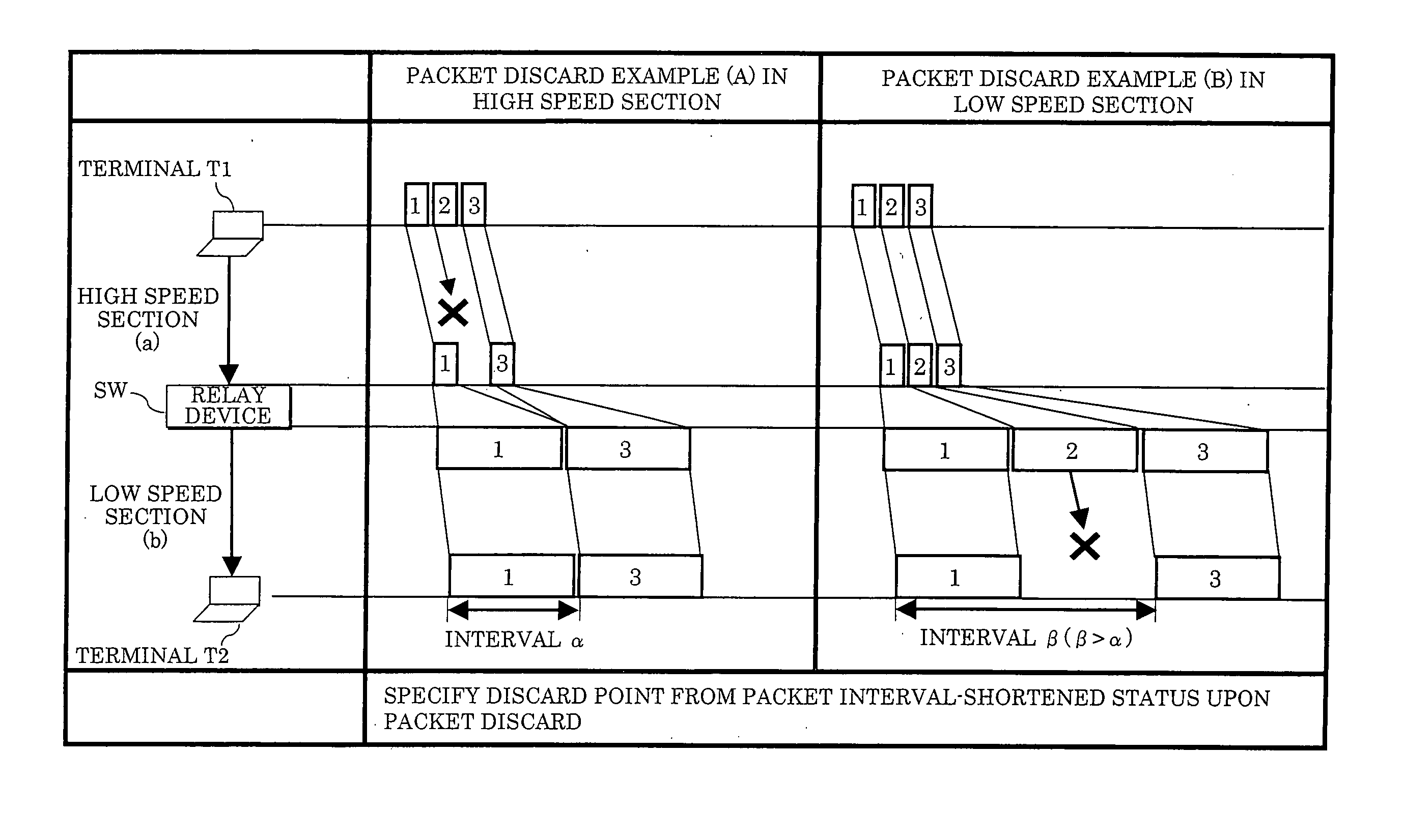

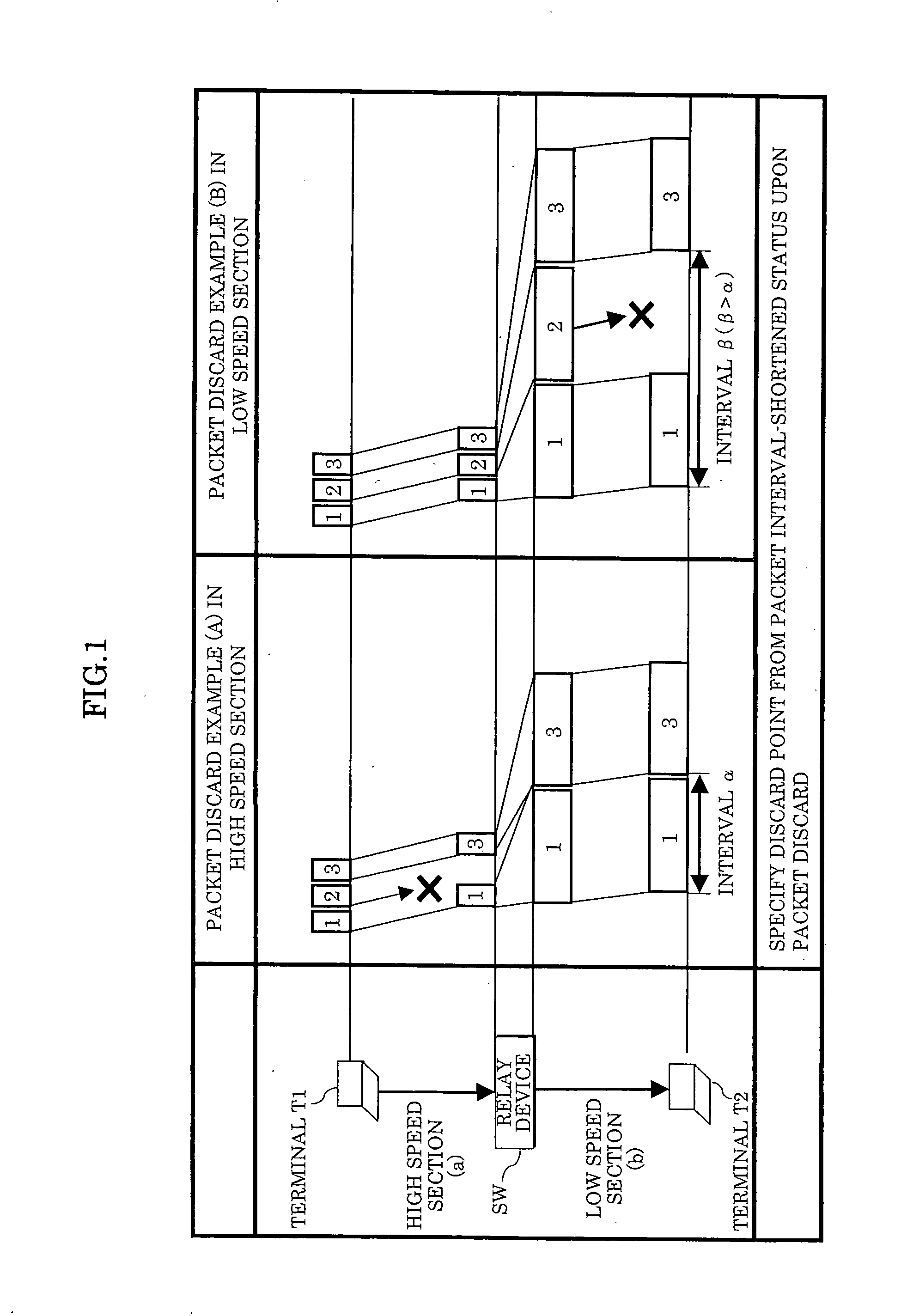

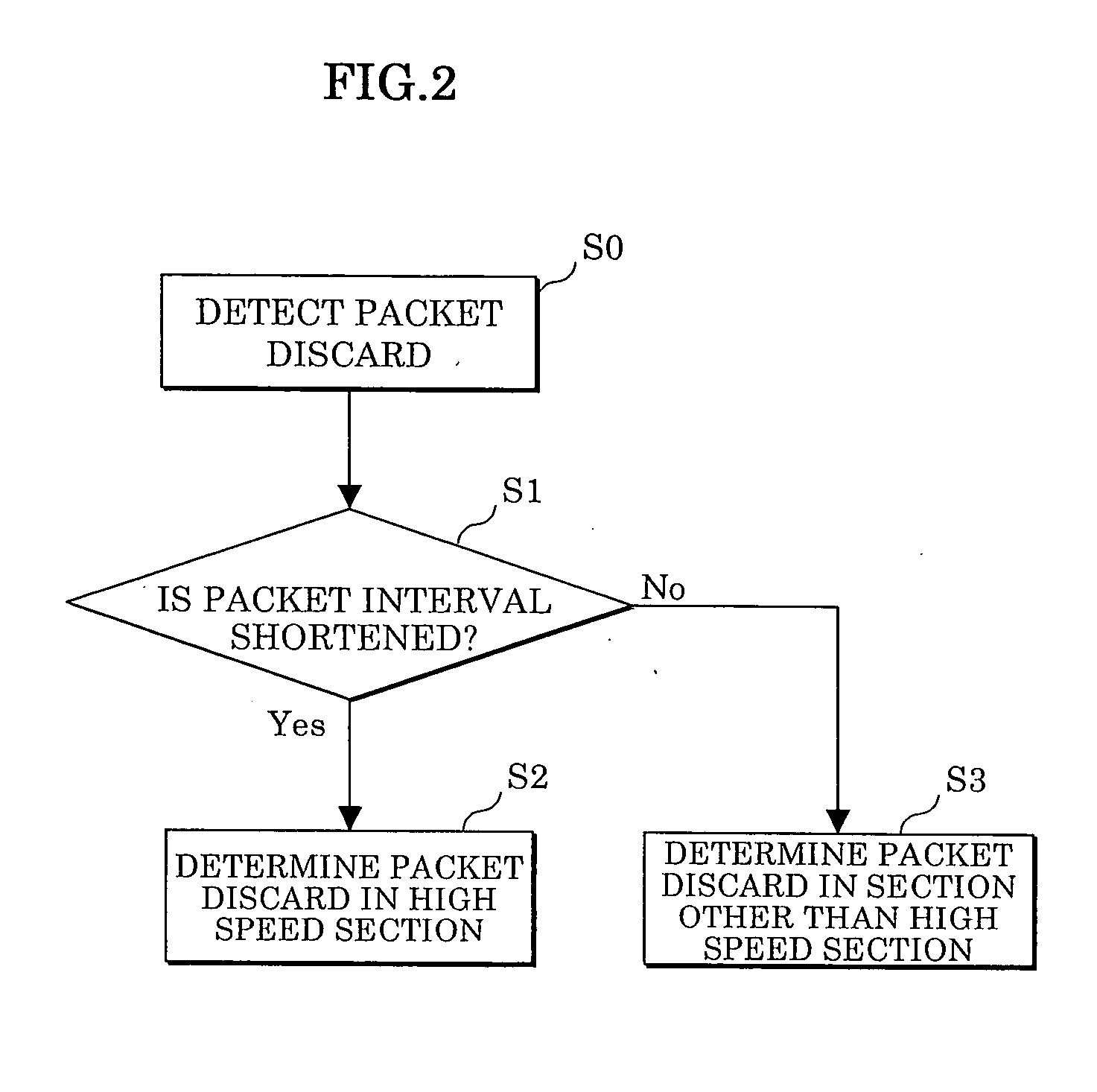

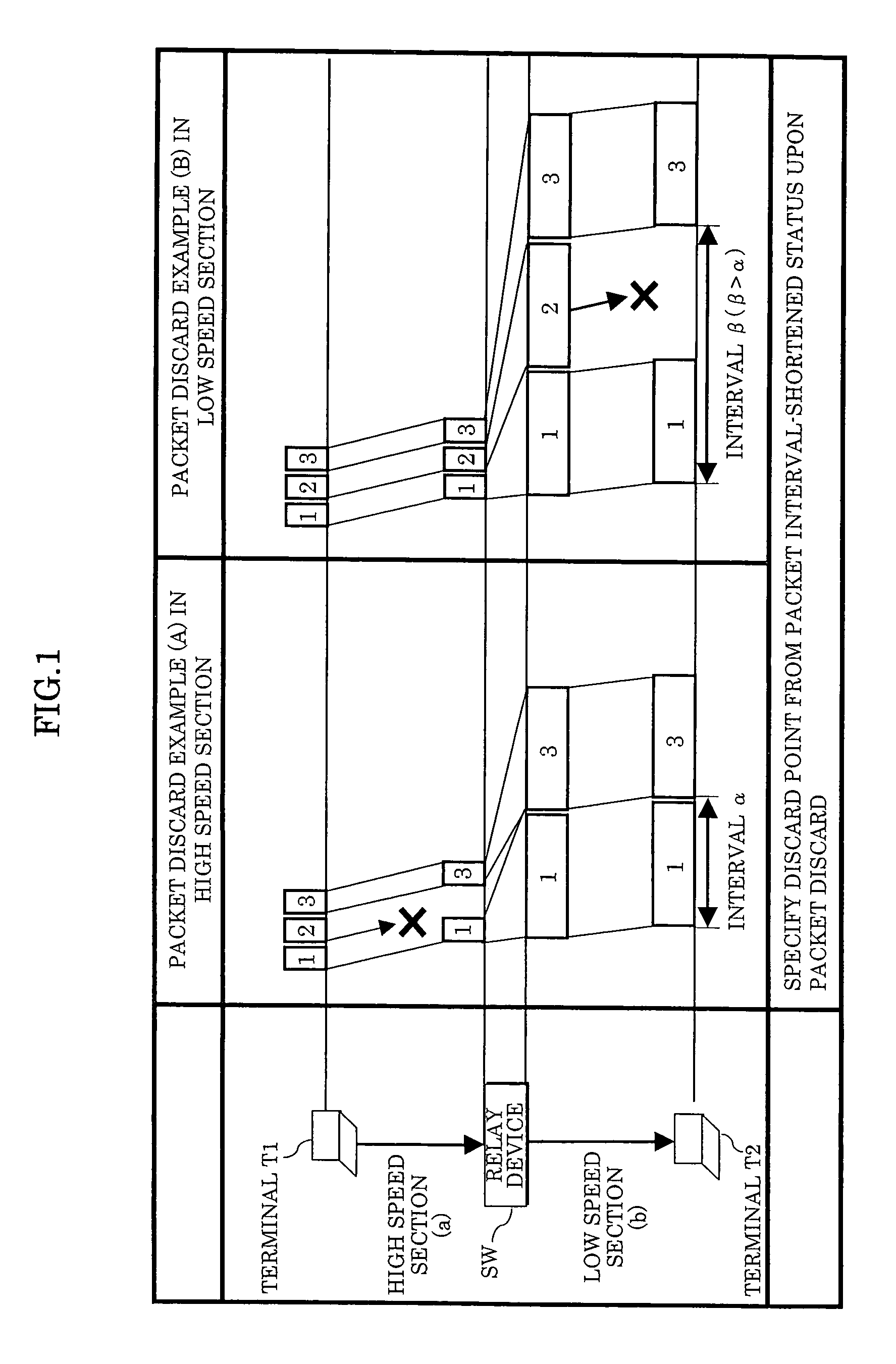

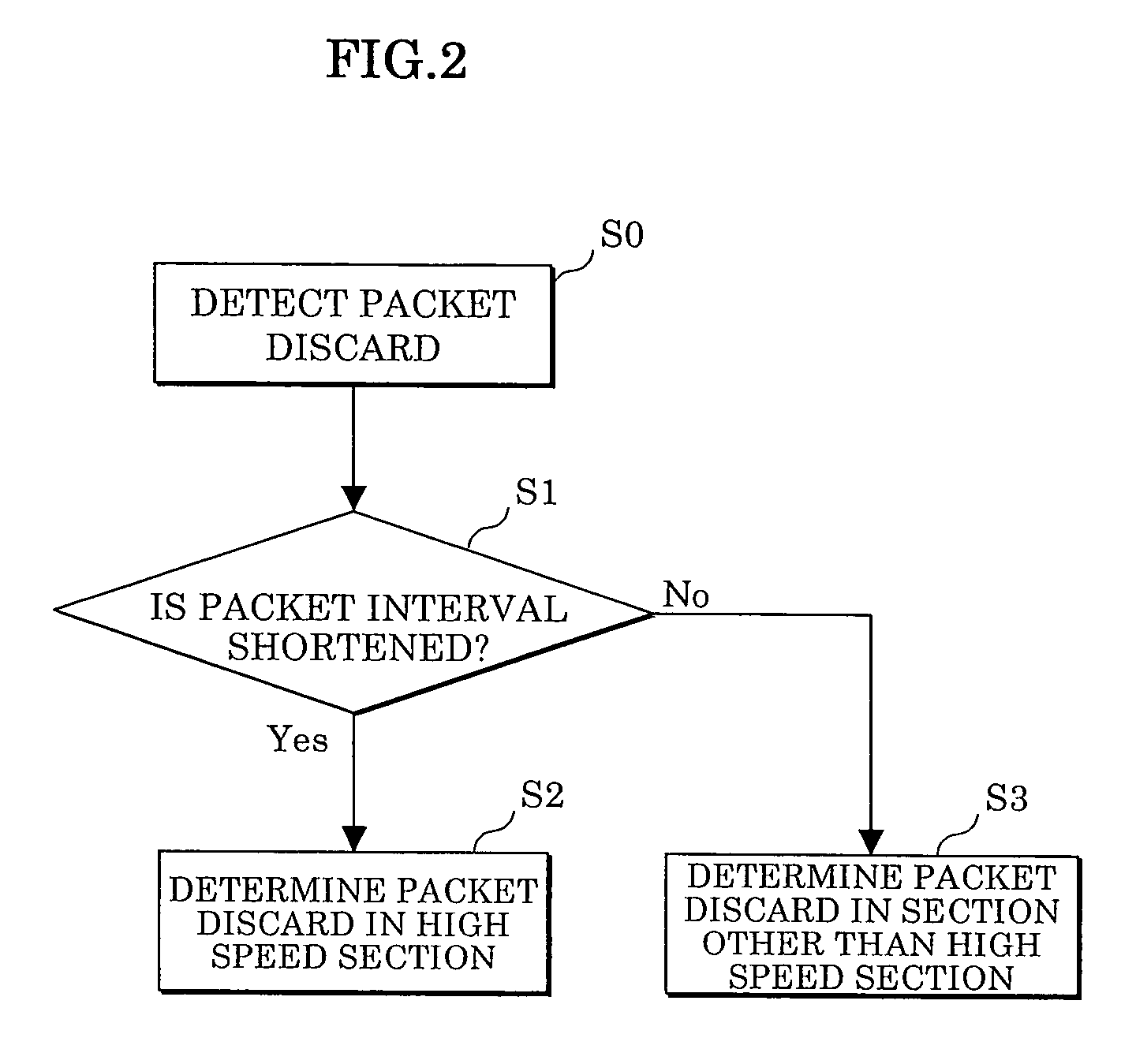

Packet discard point probing method and device

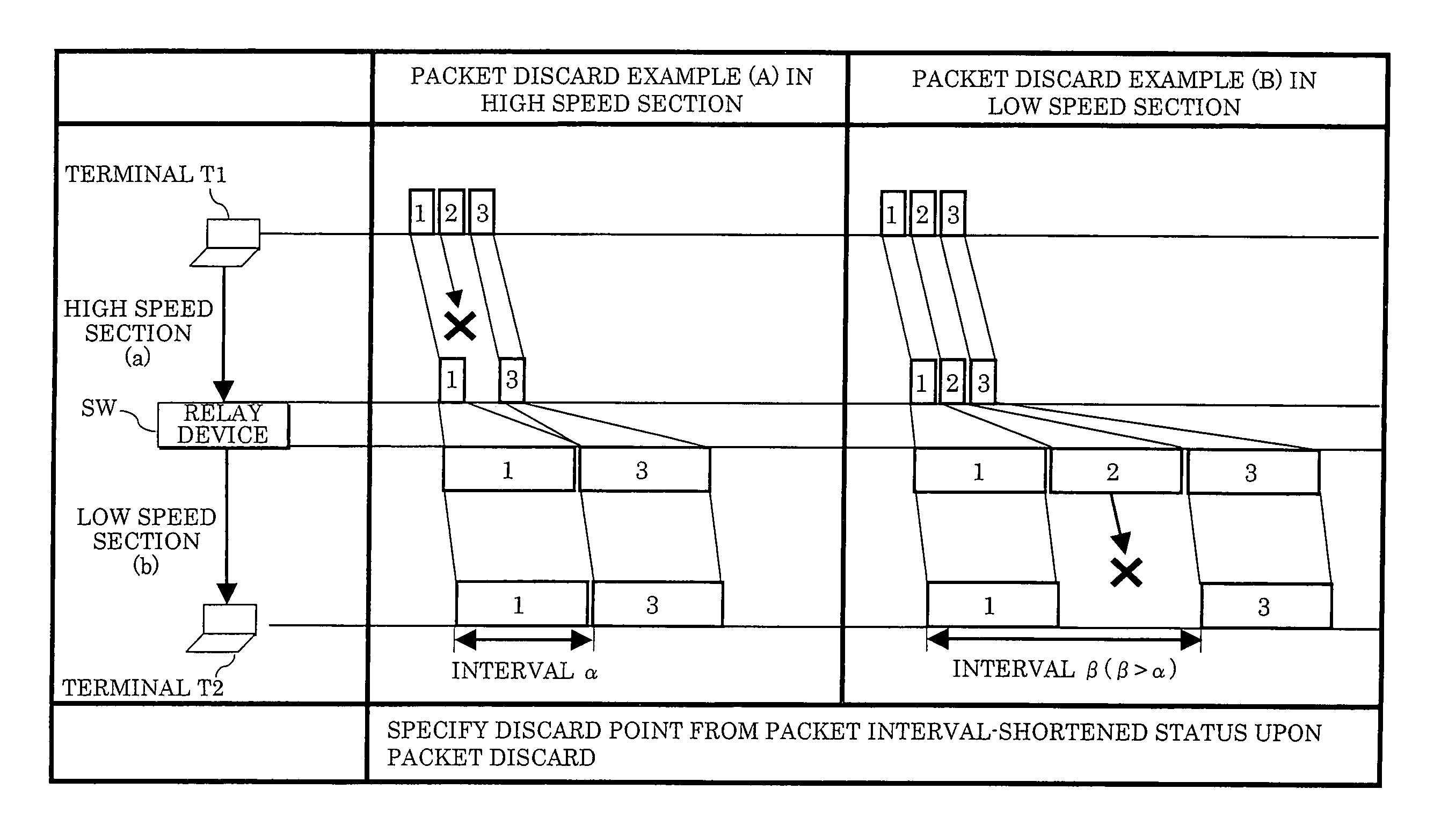

ActiveUS20050286432A1Shorten the timeLow costFrequency-division multiplex detailsTransmission systemsLow speedResidence

In a relay device or the like in which a speed changes from a high speed to a low speed, a packet residence (packet transfer wait) occurs when a packet string in which packet intervals are shortened arrives. When a packet discard occurs before passing through the relay device or the like, a packet interval having been lengthened by the packet discard is shortened by the relay device or the like for transferring packets. When a packet discard occurs after passing through the relay device or the like, a packet interval having been lengthened by the packet discard remains unshortened for transferring packets. Therefore, by observing at terminals the packet discard and the packet interval on the occasion of the packet discard, whether the packet discard has occurred in the high speed section or the low speed section is specified.

Owner:FUJITSU LTD

Information storage device, removable device, developer container, and image forming apparatus

An information storage device installed in a removable device configured to be removably installed in an image forming apparatus body, includes: an information storage unit that stores information communicated between the image forming apparatus body and the removable device; a terminal that comes in contact with a body side terminal; and a substrate that holds the information storage unit and the terminal and includes a hole configured to be engaged with a protruding section installed in the image forming apparatus body. The terminal includes a plurality of terminals each including one of a plurality of metallic plates arranged in a transverse direction thereof. An earth terminal, which comes in contact with a body side earth terminal formed in the protruding section, is formed in the hole. The hole is disposed at a position sandwiched between two metallic plates among the plurality of metallic plates.

Owner:RICOH KK

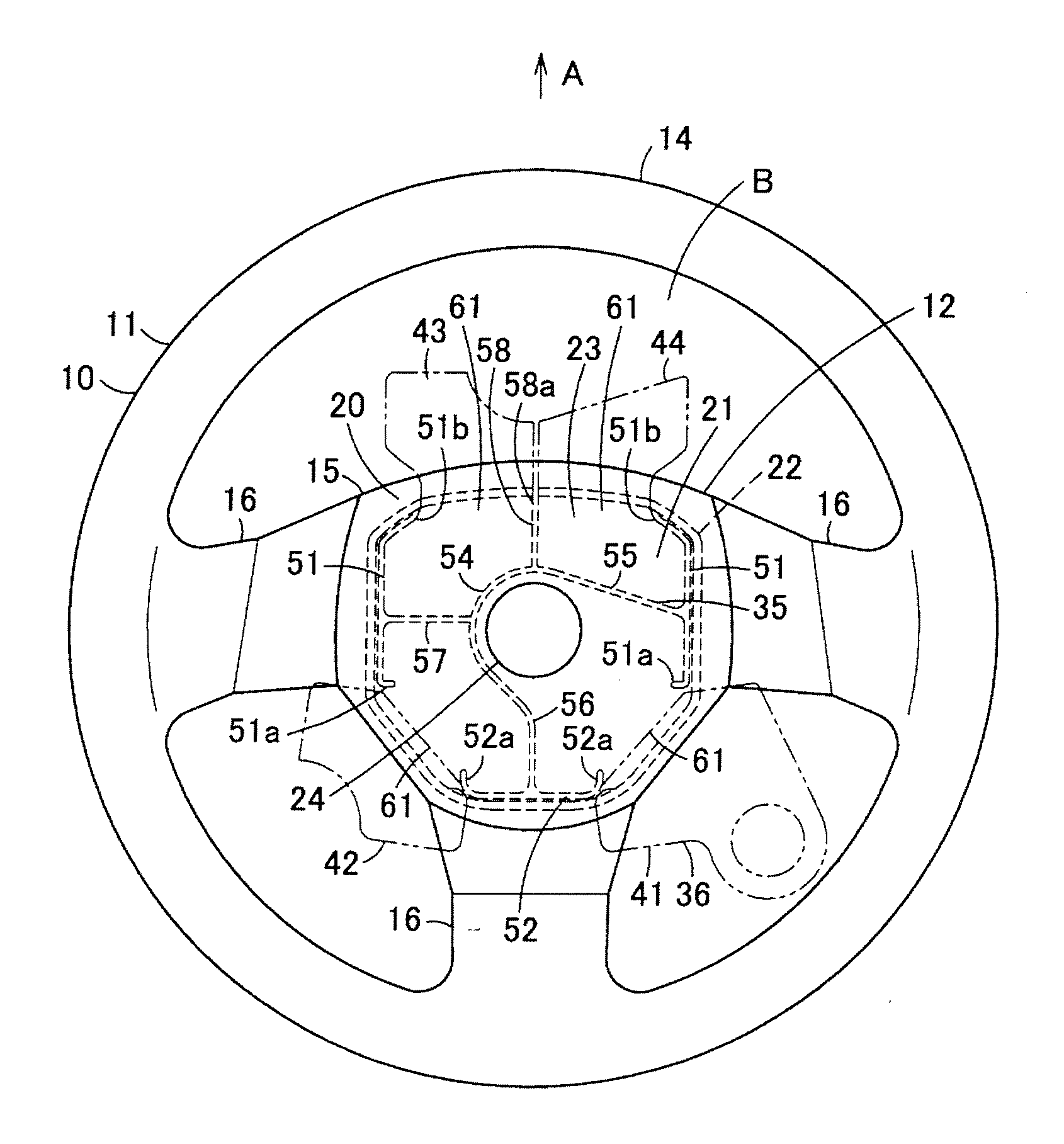

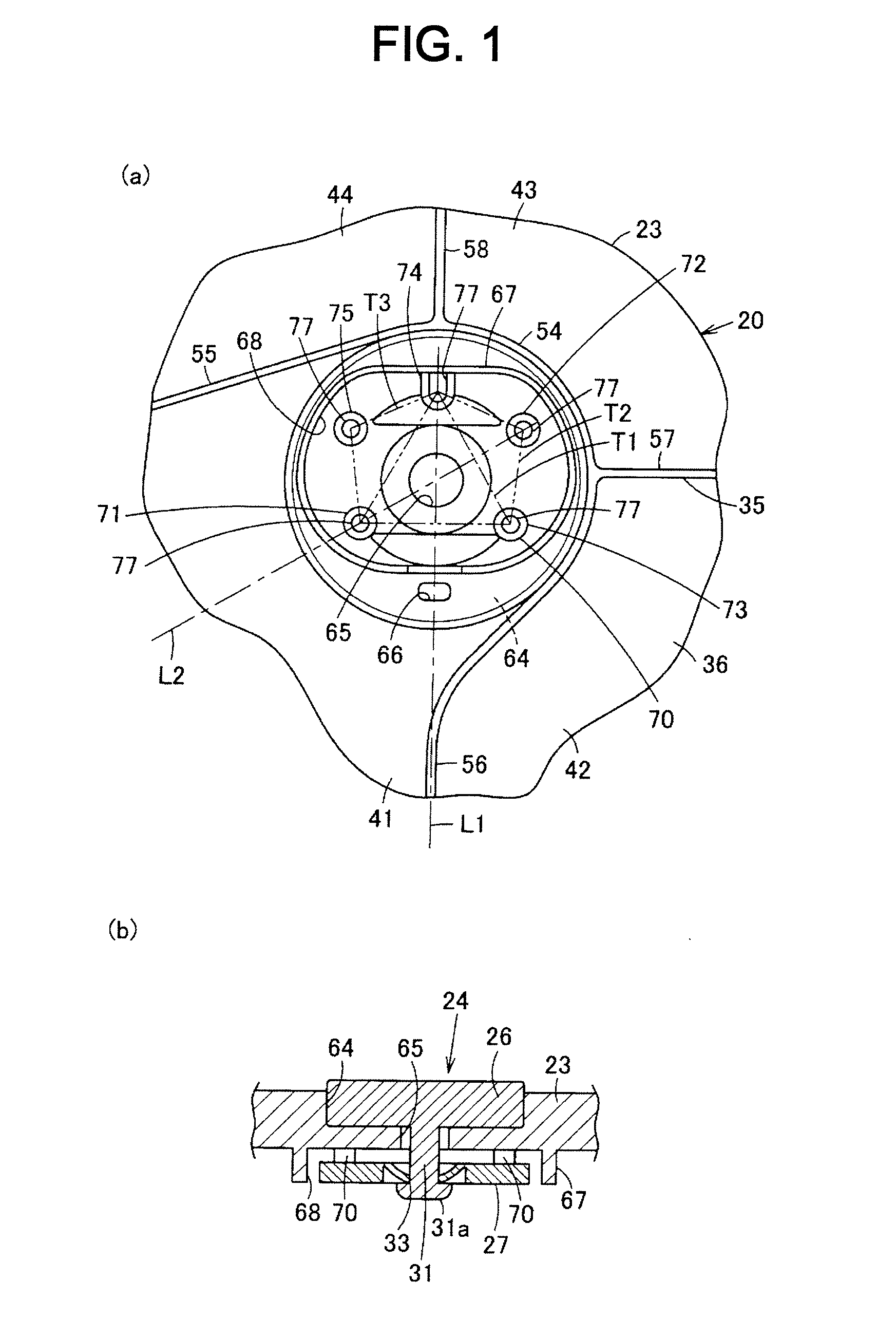

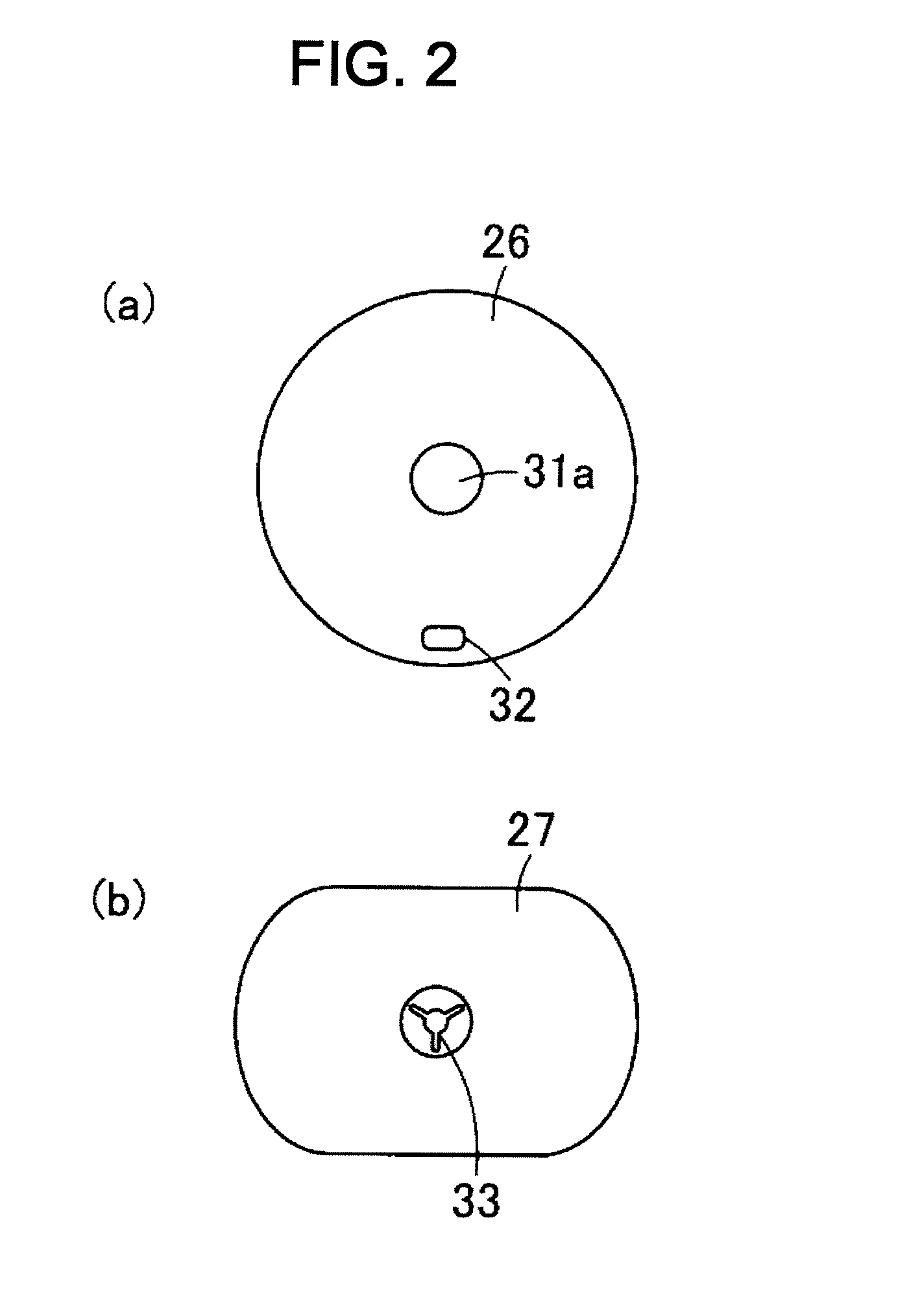

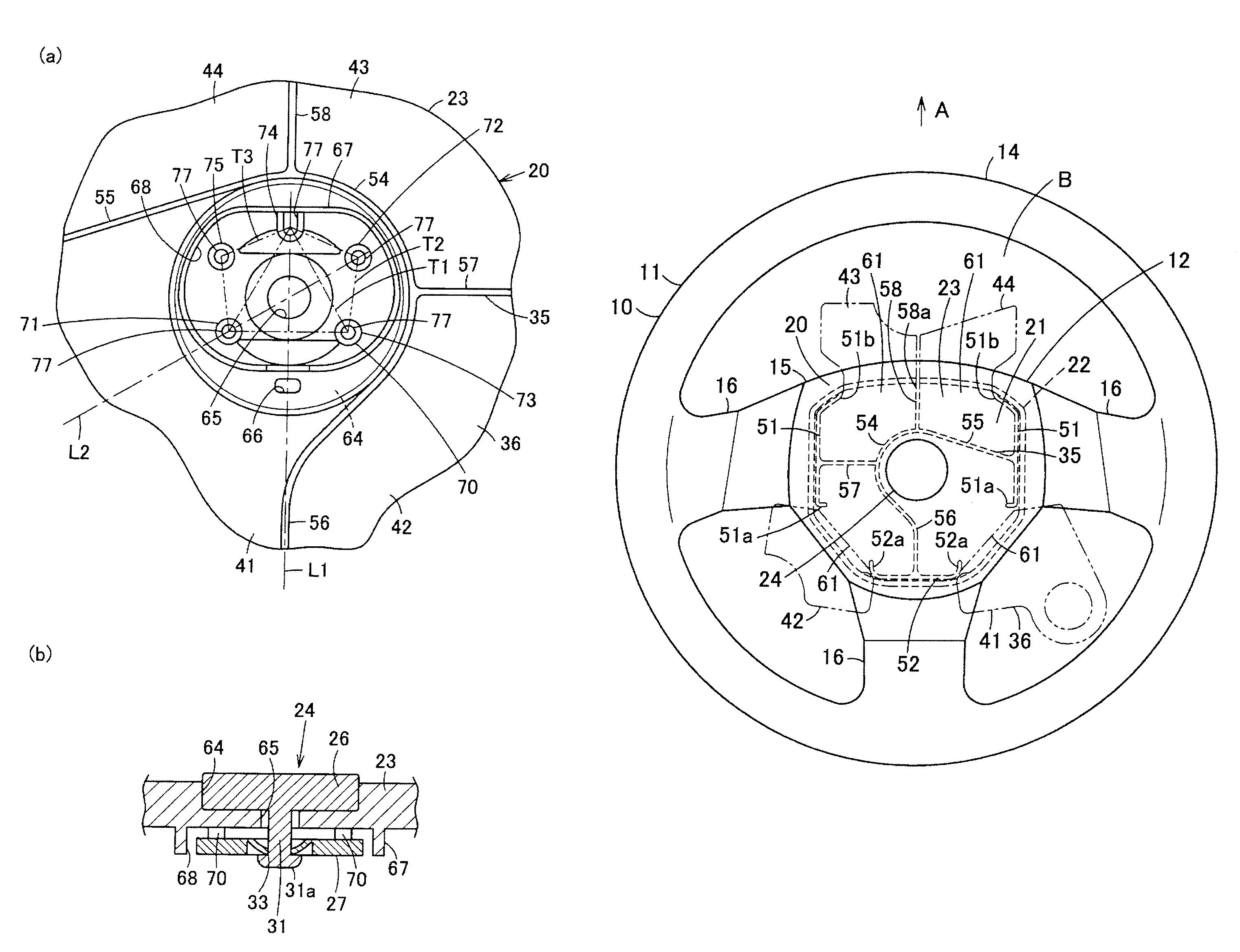

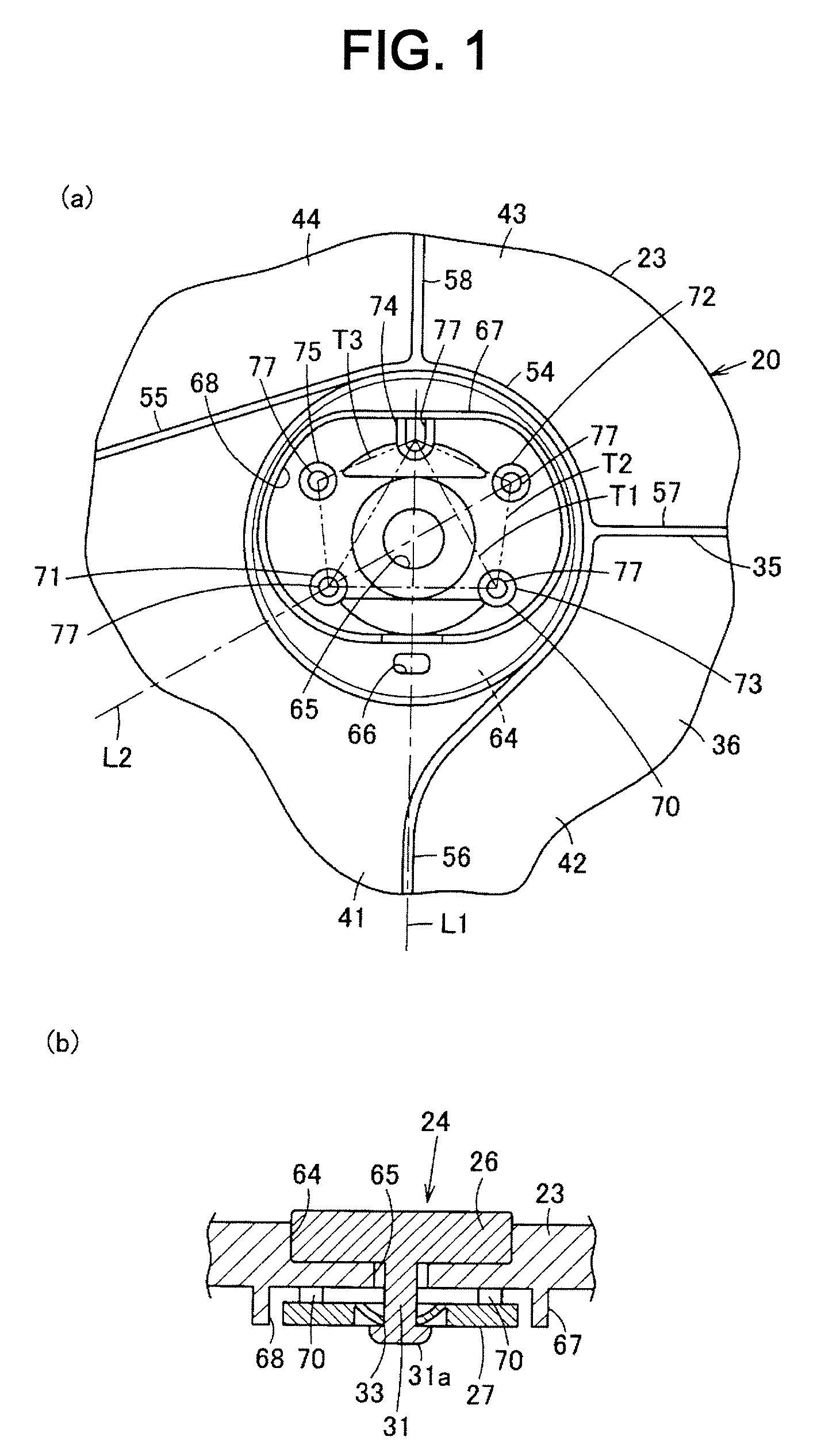

Cover member of airbag device

InactiveUS20130285355A1Improve balanceImprove workabilityPedestrian/occupant safety arrangementEngineeringCentrifugal force

First support portions 71 and 72 positioned on a predetermined straight line L2 approximately perpendicular to a broken line of a hinge portion is set in a support portion 70 that supports a back plate 27 with respect to a back face side of a door portion 36. Second and third support portions 73 and 74 positioned in line symmetry with respect to the straight line L2, are set in the support portion 70. It is possible to receive the centrifugal force, which is applied to the back plate 27 due to the expansion of the door portion 36, with good balance by the first to third support portions 71, 72, 73, and 74. An emblem 24 can be reliably fixed to the door portion 36 with preventing a fixing pin 31 from being excessively locked into a through hole 33 more than necessary.

Owner:NIHON PLAST CO LTD

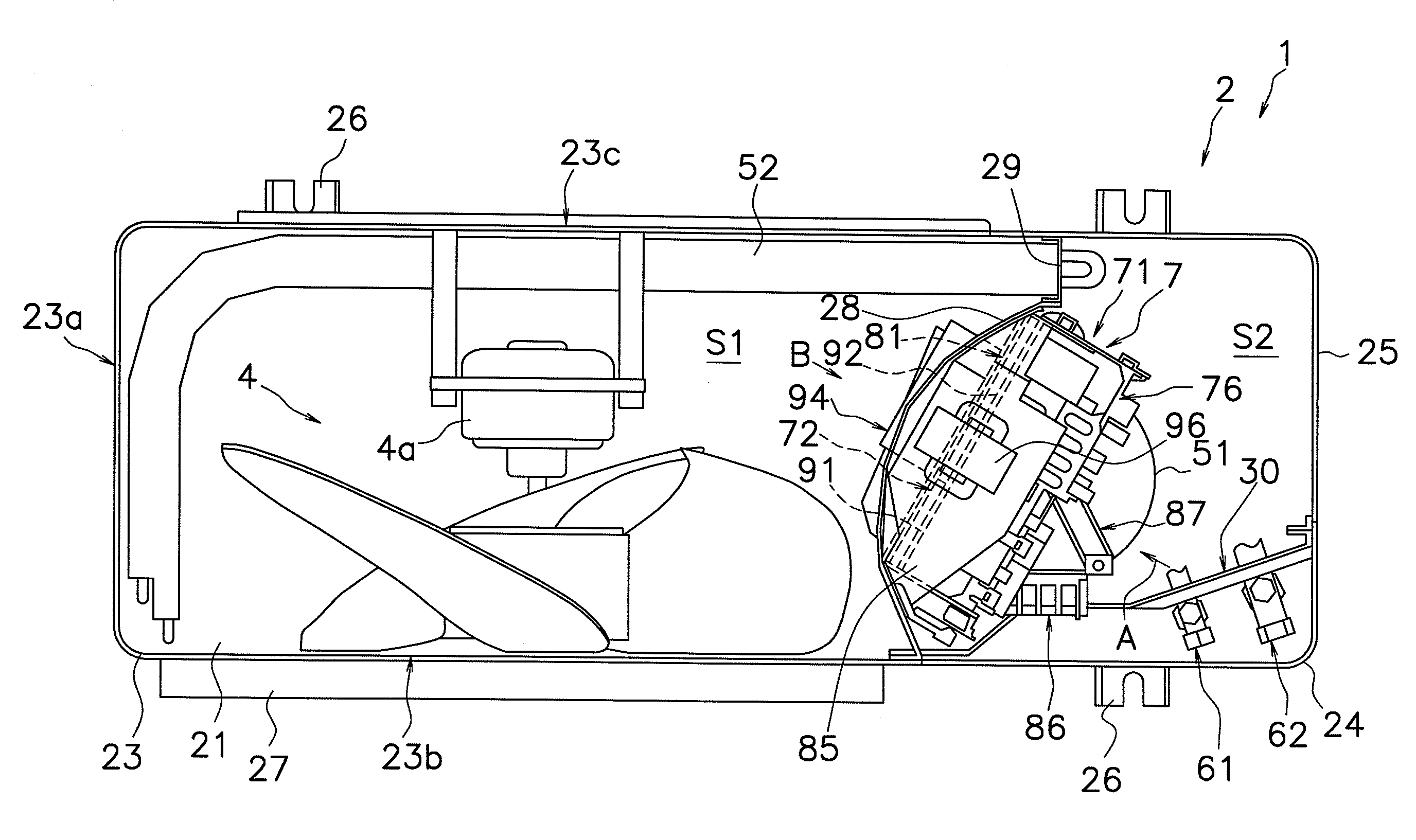

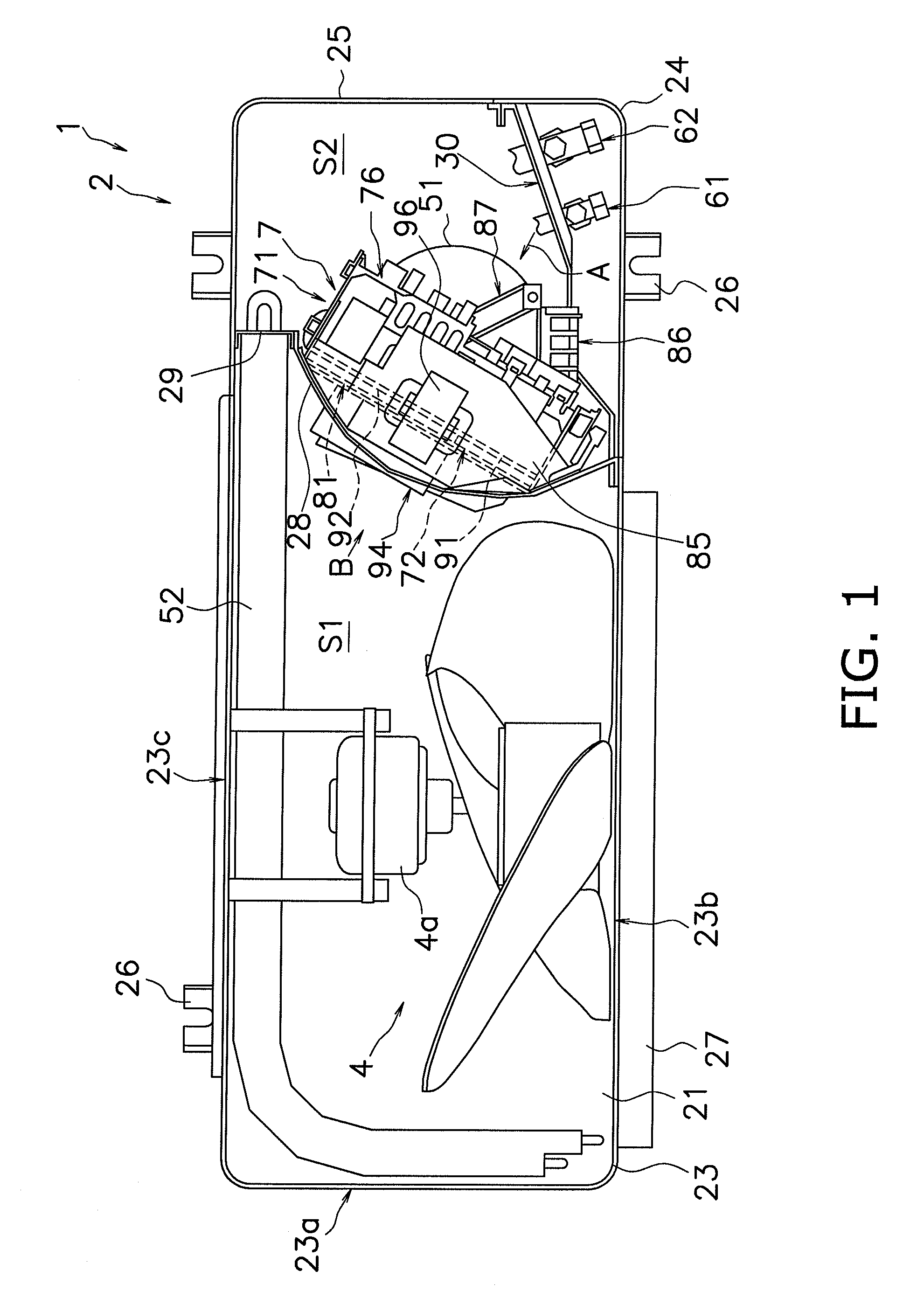

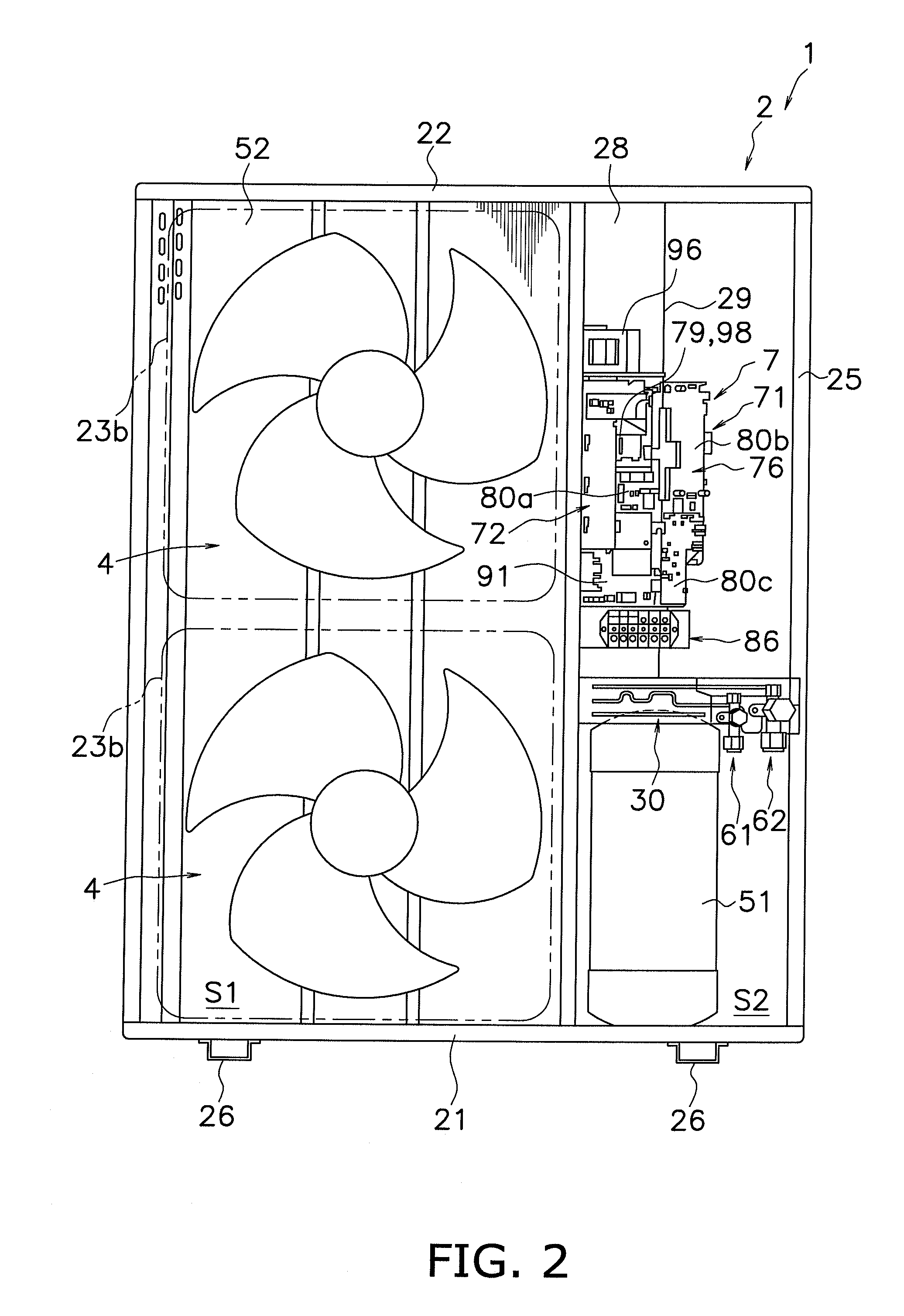

Electrical equipment assembly and outdoor unit of air conditioner disposed with the electrical equipment assembly

InactiveUS20100226104A1Improve reliabilityAvoid accumulationLighting and heating apparatusHeating and ventilation casings/coversElectrical devicesEngineering

An electrical equipment assembly includes a control board and a frame. The control board is disposed lengthwise inside a casing, and various types of electrical parts are mounted on the control board. The frame is a member that holds the control board. Slits that drain water that is present between the frame and the control board are formed in a lower portion of the frame. Water guide paths that guide the water to the slits are formed in a surface of the frame that faces a board surface of the control board.

Owner:DAIKIN IND LTD

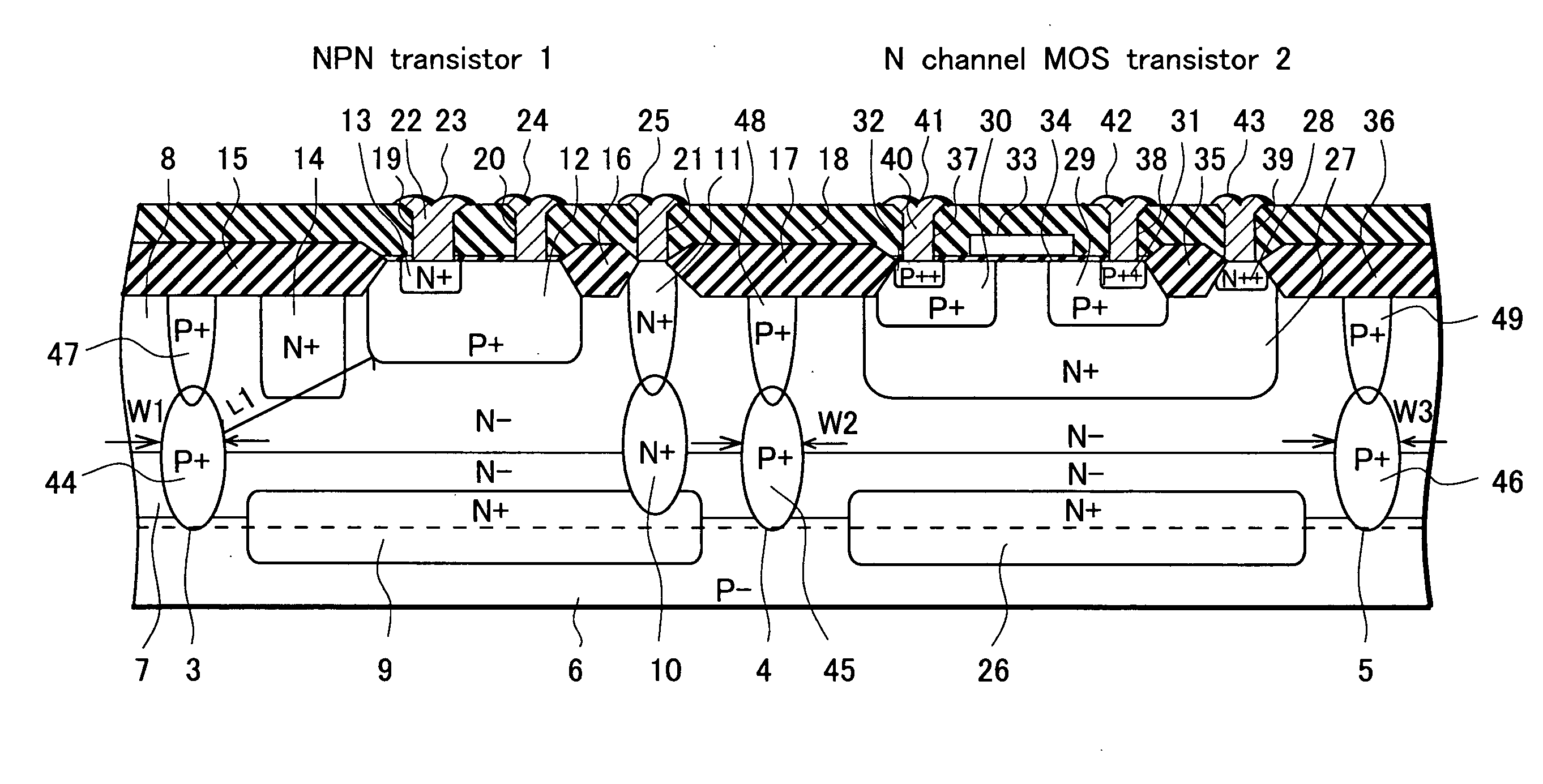

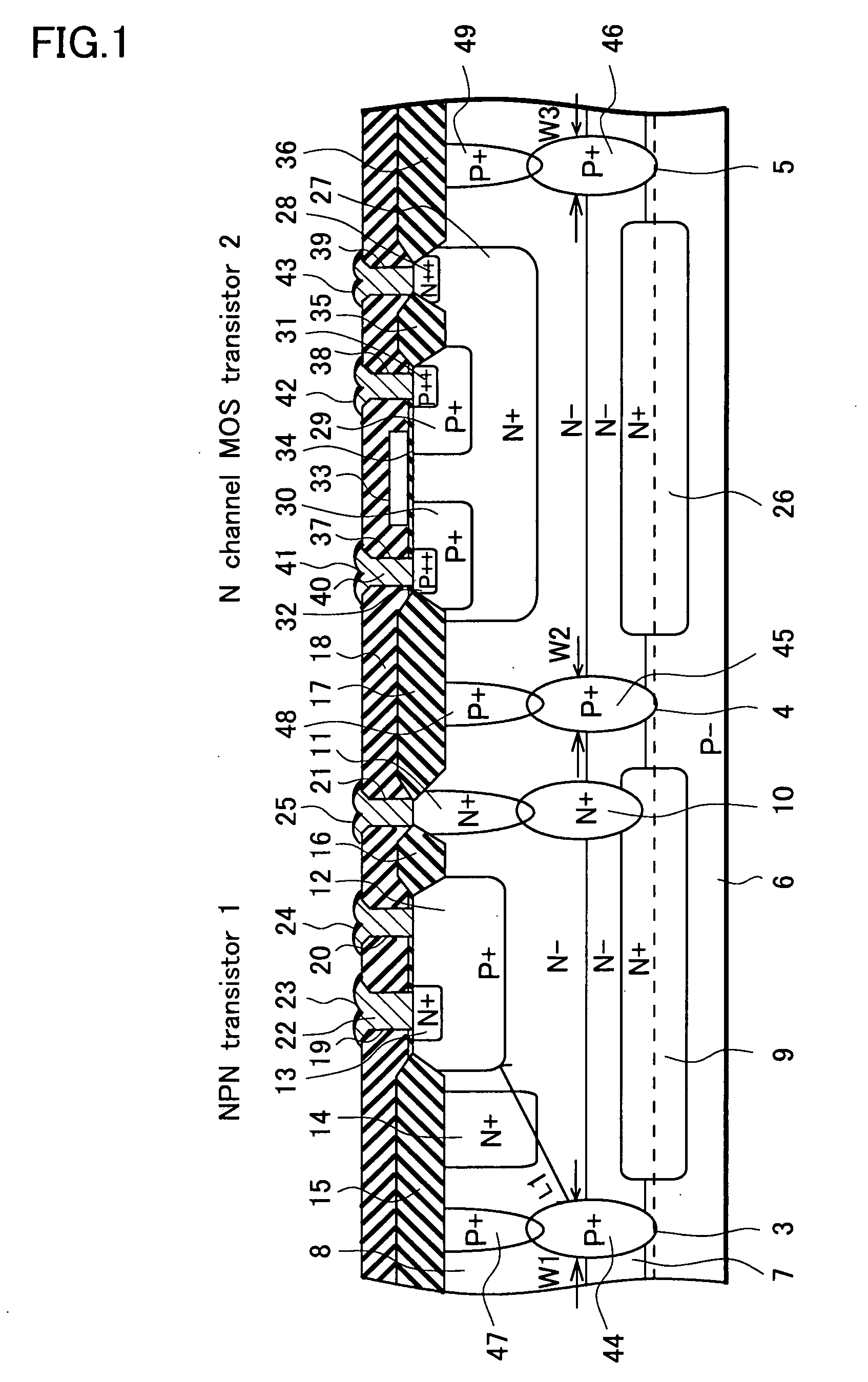

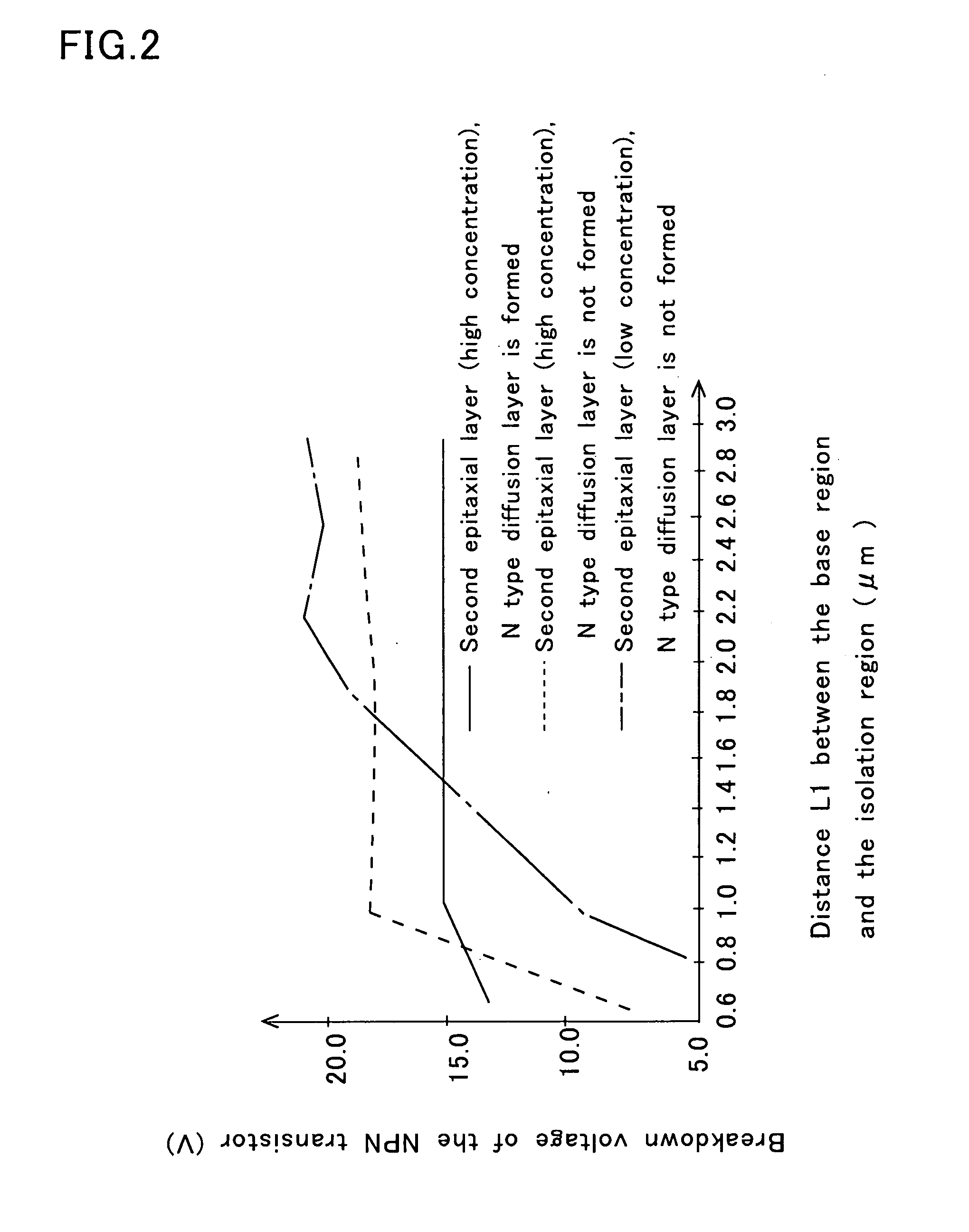

Semiconductor device and manufacturing method of the same

InactiveUS20070145520A1Improved breakdown voltage characteristicsDifficulty occurTransistorSemiconductor/solid-state device manufacturingDevice materialSemiconductor

In a semiconductor device of the present invention, two epitaxial layers are formed on a P type single crystal silicon substrate. One of the epitaxial layers has an impurity concentration higher than that of the other epitaxial layer. The epitaxial layers are divided into a plurality of element formation regions by isolation regions. In one of the element formation regions, an NPN transistor is formed. Moreover, between a P type diffusion layer, which is used as a base region of the NPN transistor, and a P type isolation region, an N type diffusion layer is formed. Use of this structure makes it hard for a short-circuit to occur between the base region and the isolation region. Thus, the breakdown voltage characteristics of the NPN transistor can be improved.

Owner:SEMICON COMPONENTS IND LLC

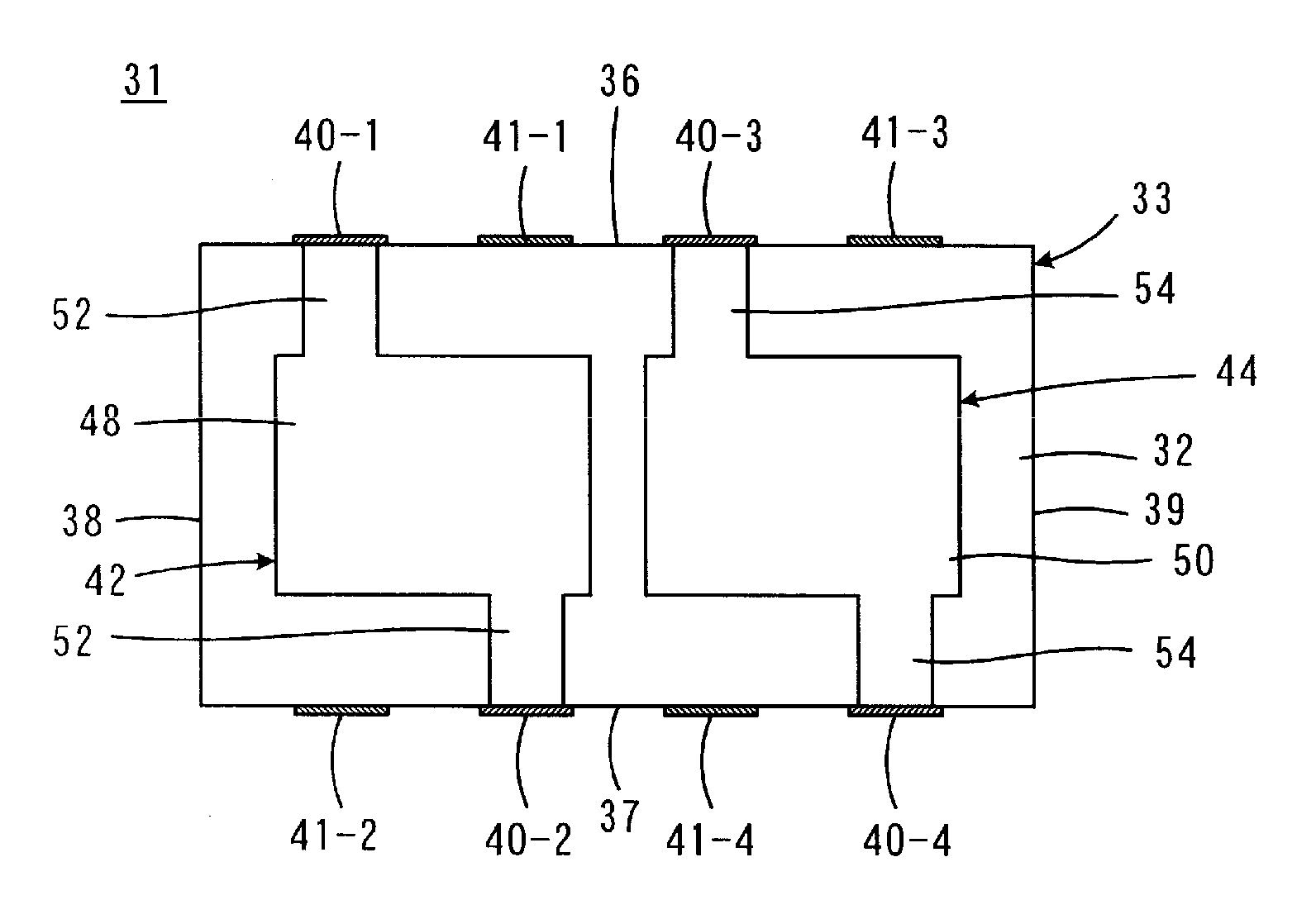

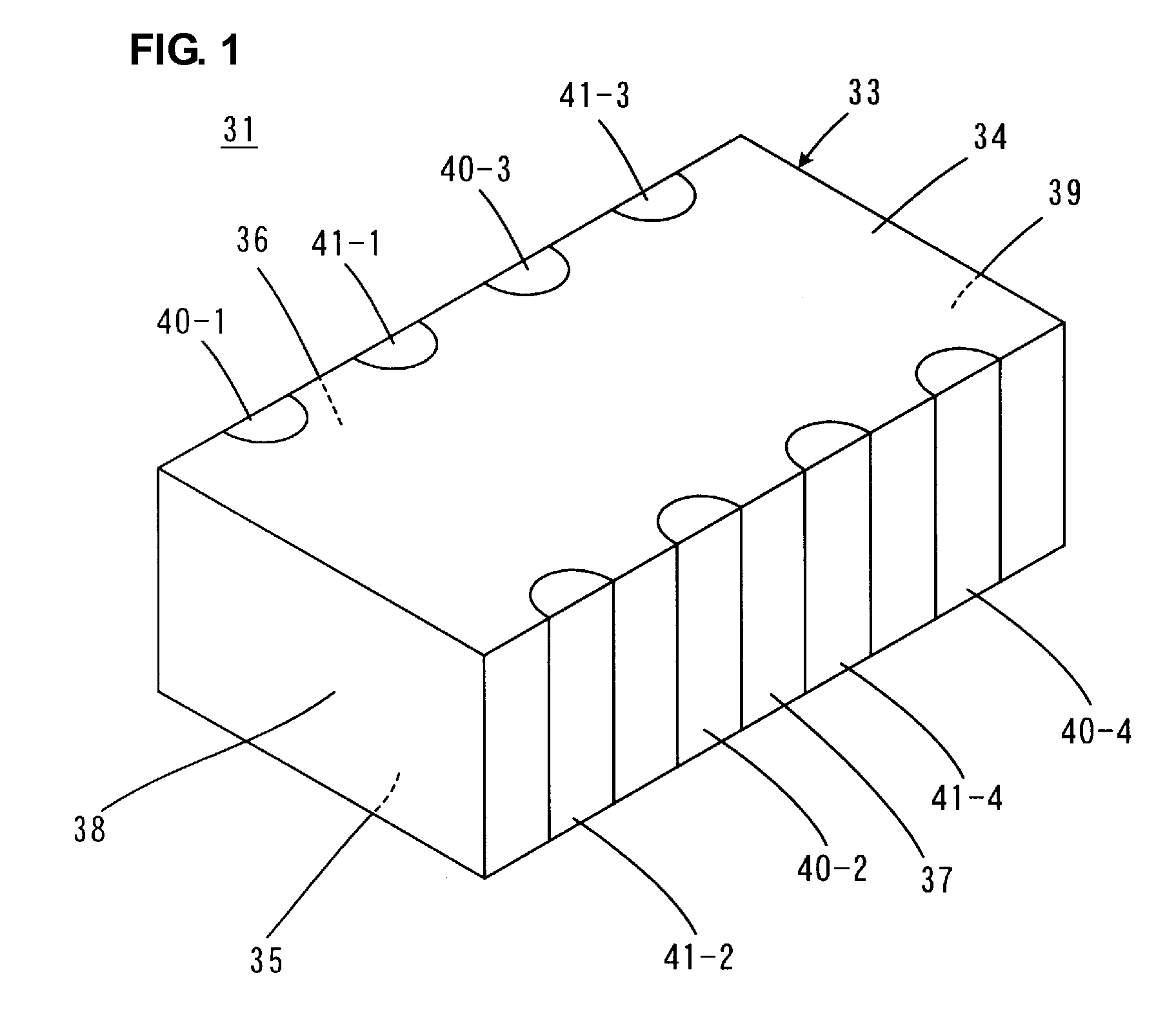

Multilayer capacitor

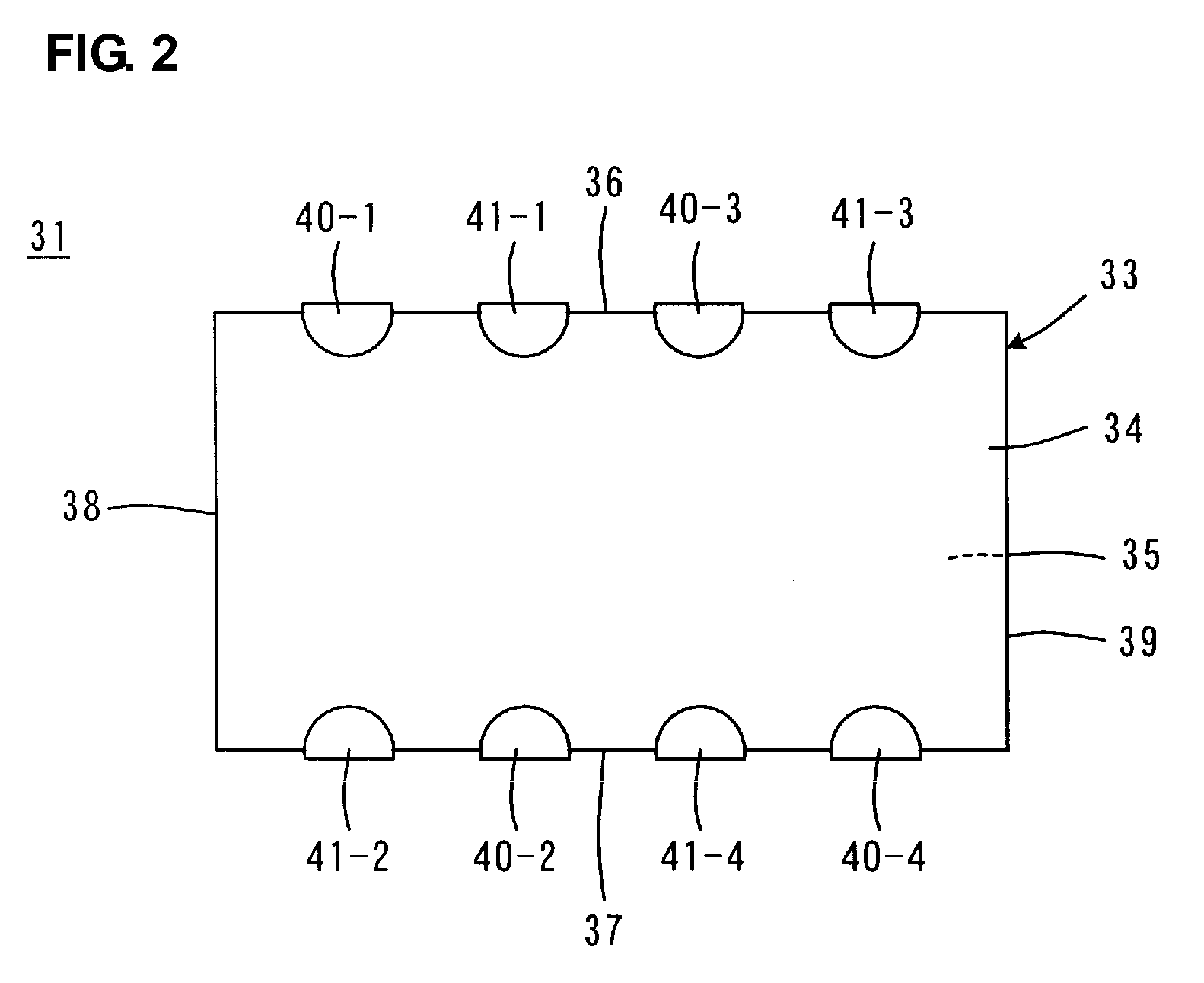

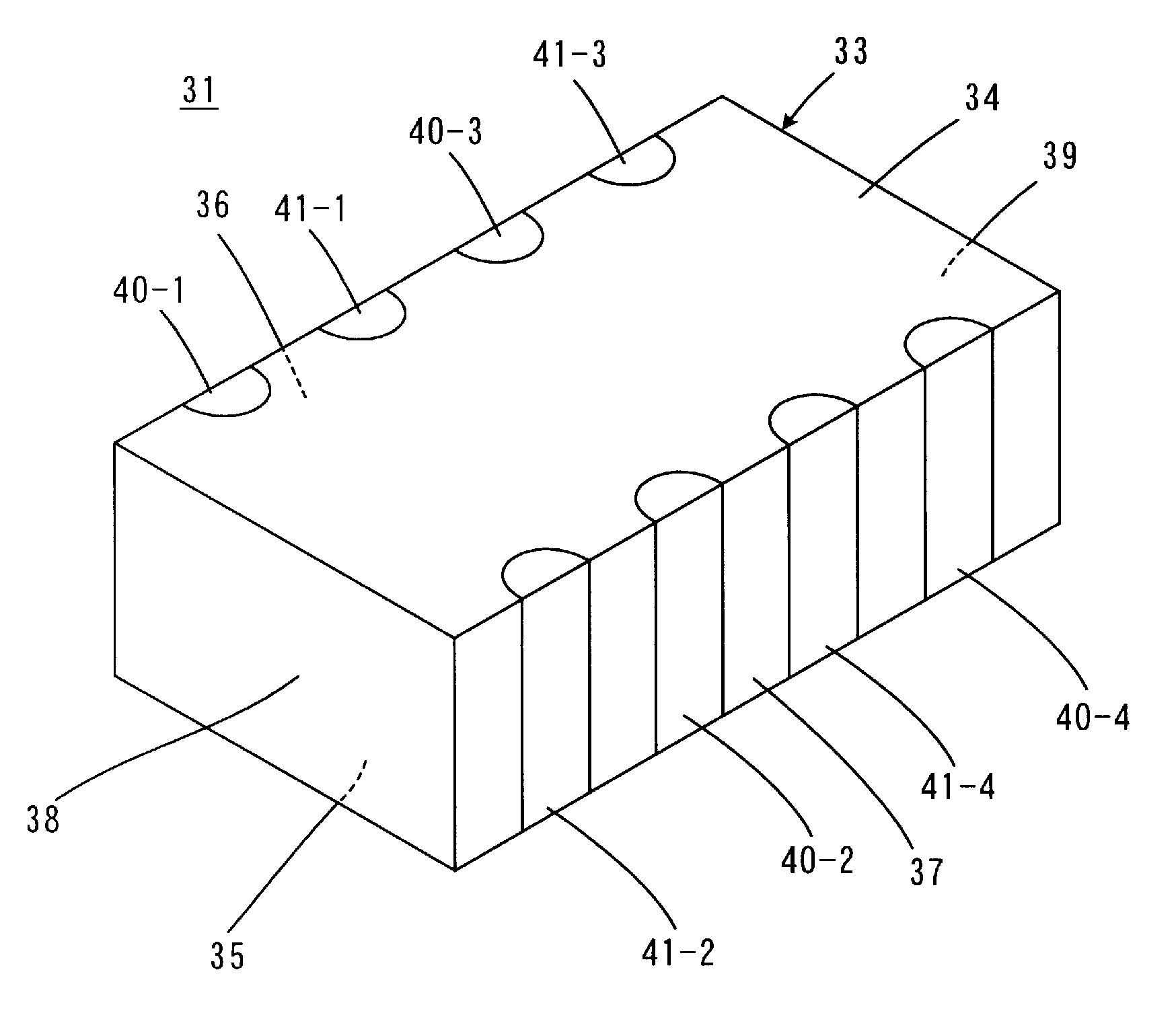

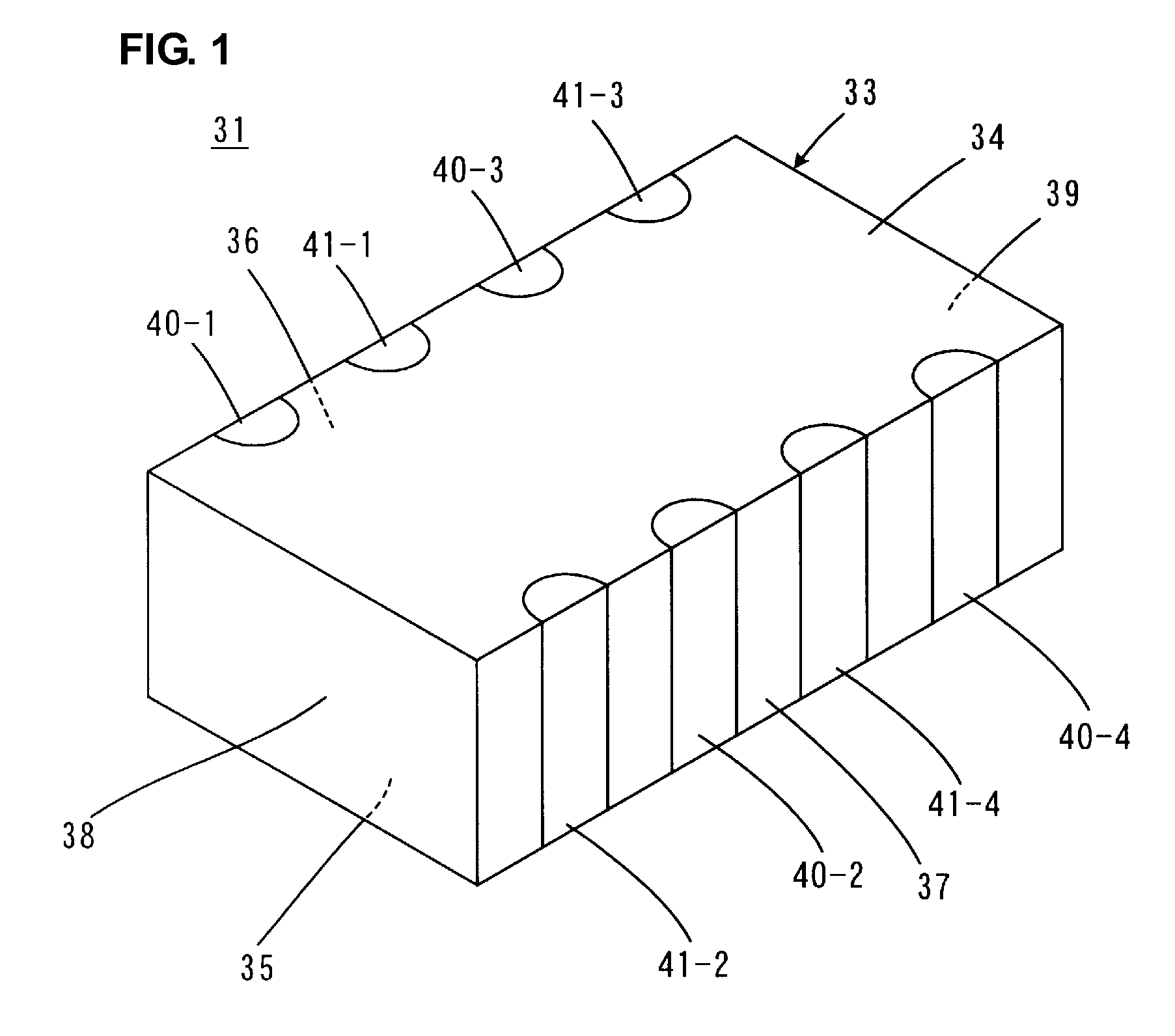

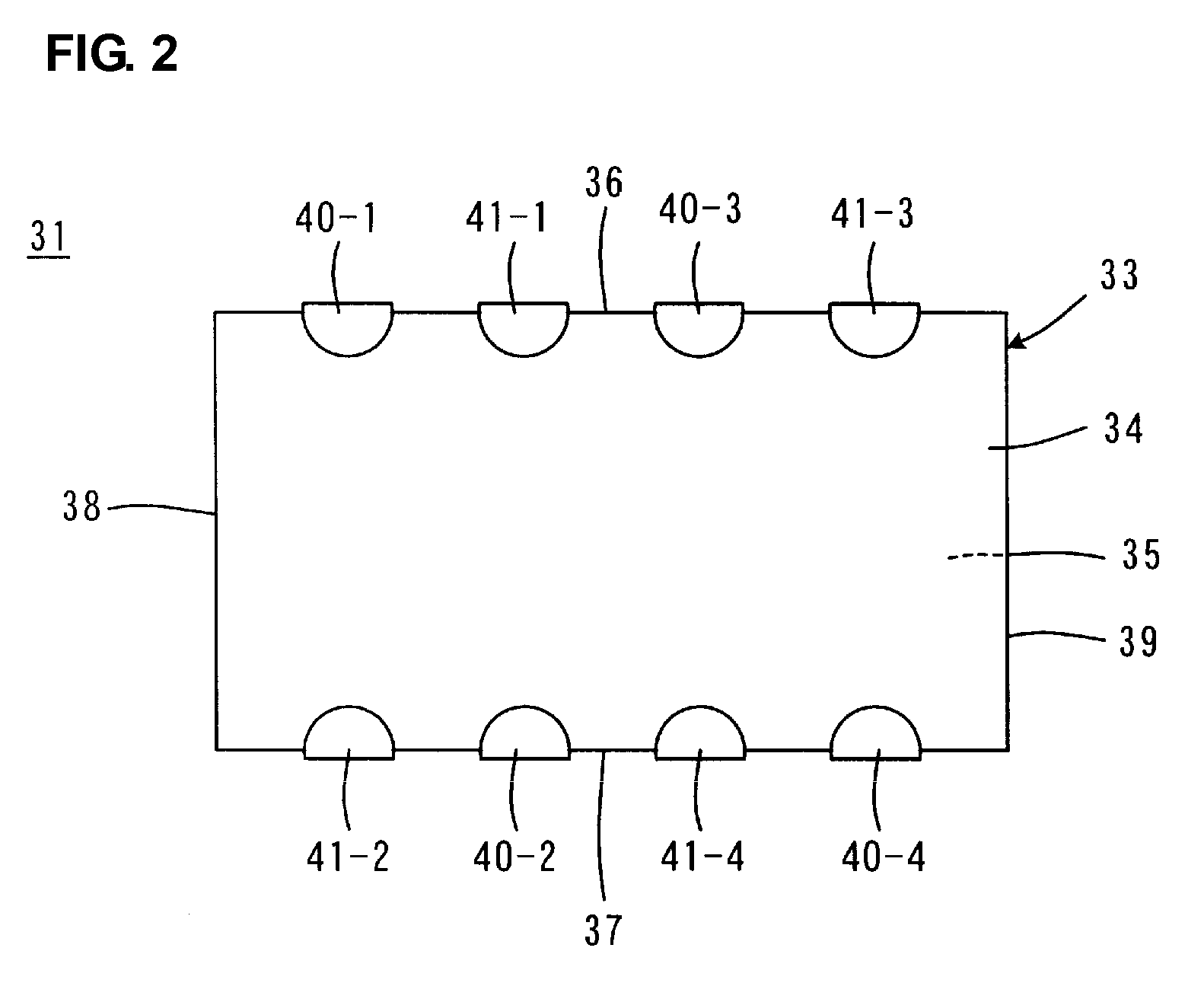

ActiveUS20080106847A1Improve design flexibilityLow costFixed capacitor electrodesFixed capacitor dielectricEquivalent series inductanceDielectric layer

A multi-terminal multilayer capacitor reducing an equivalent series inductance (ESL), whose design flexibility is high, in which cost of electrode material is low, and in which a structural defect hardly occurs includes lead portions of first and second internal electrodes and lead portions of third and fourth internal electrodes that are disposed along the length of each of two side surfaces so as to be alternately exposed. Preferably, the first and third internal electrodes, and the second and fourth internal electrodes are disposed so as to be arranged along the length of each side surface in a coplanar manner, with a predetermined distance provided between two internal electrodes. When viewed in a laminating direction of dielectric layers, a capacitor-forming portion of the first internal electrode does not overlap with a capacitor-forming portion of the fourth internal electrode, and a capacitor-forming portion of the second internal electrode does not overlap with a capacitor-forming portion of the third internal electrode.

Owner:MURATA MFG CO LTD

Multilayer capacitor

ActiveUS7420796B2Improve design flexibilityLow costFixed capacitor electrodesFixed capacitor dielectricEquivalent series inductanceEngineering

Owner:MURATA MFG CO LTD

Cover member of airbag device

InactiveUS9027955B2Improve manufacturabilityIncrease productivityStampsPedestrian/occupant safety arrangementAirbagCentrifugal force

First support portions 71 and 72 positioned on a predetermined straight line L2 approximately perpendicular to a broken line of a hinge portion is set in a support portion 70 that supports a back plate 27 with respect to a back face side of a door portion 36. Second and third support portions 73 and 74 positioned in line symmetry with respect to the straight line L2, are set in the support portion 70. It is possible to receive the centrifugal force, which is applied to the back plate 27 due to the expansion of the door portion 36, with good balance by the first to third support portions 71, 72, 73, and 74. An emblem 24 can be reliably fixed to the door portion 36 with preventing a fixing pin 31 from being excessively locked into a through hole 33 more than necessary.

Owner:NIHON PLAST CO LTD

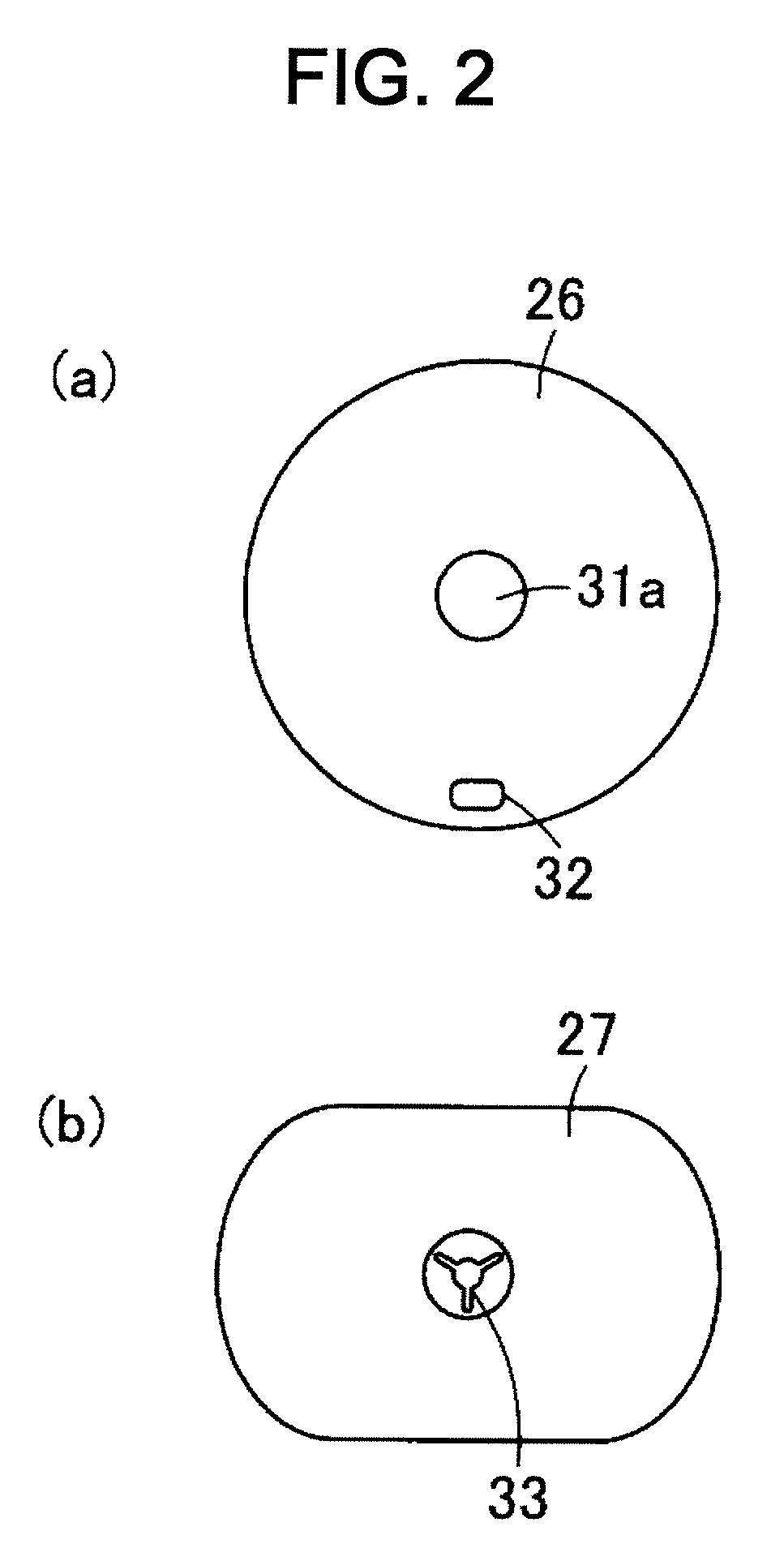

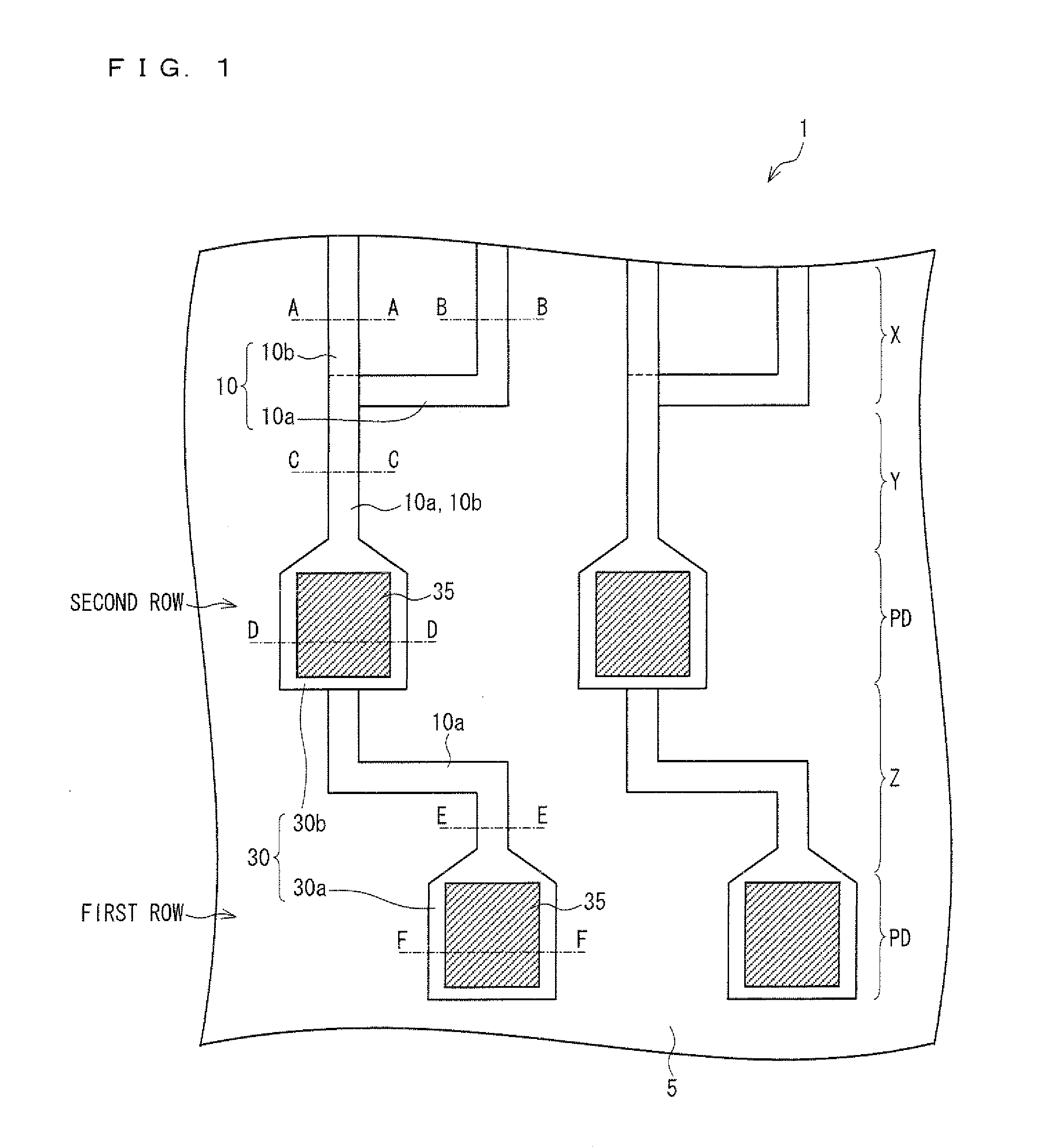

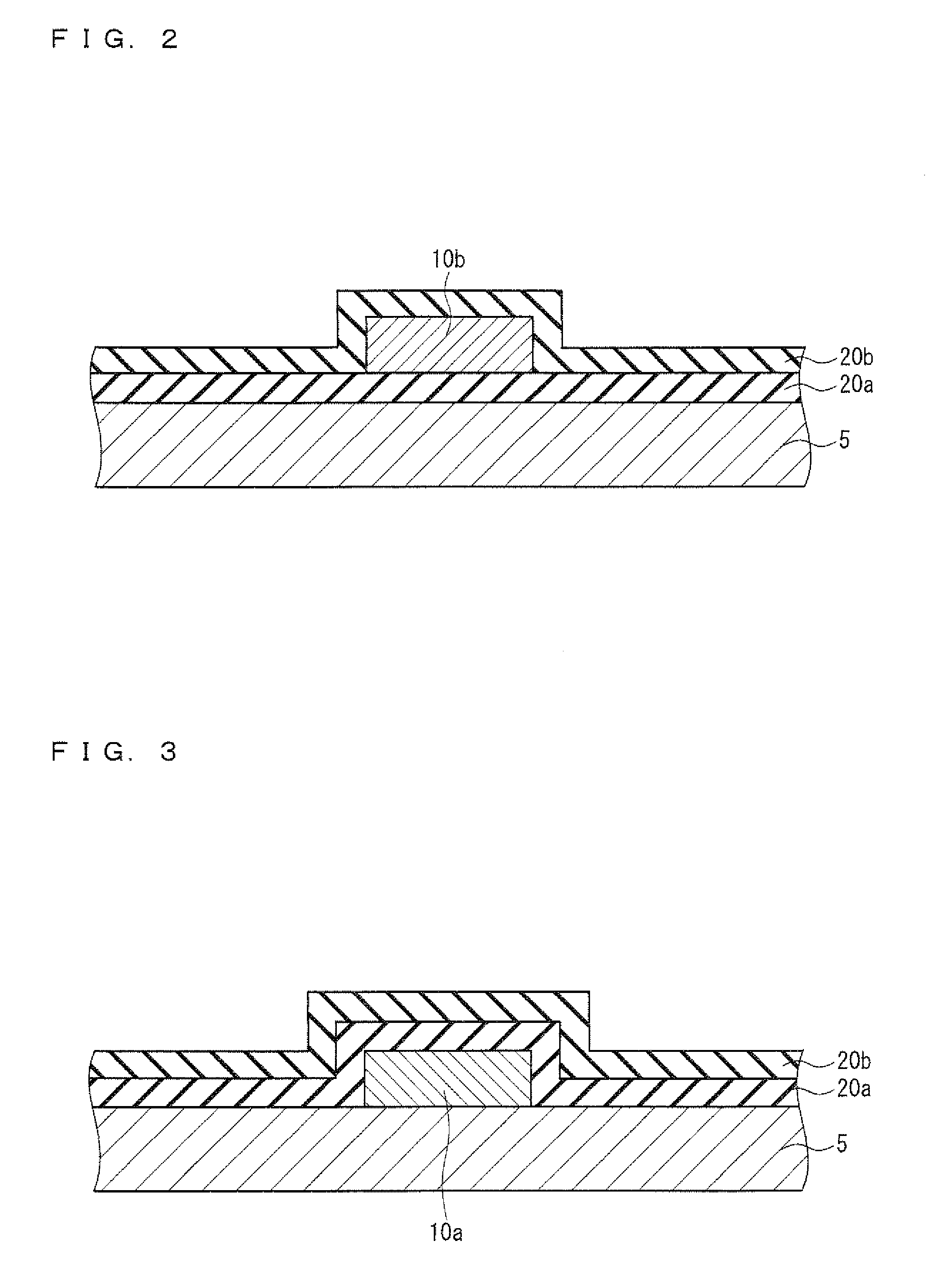

Wiring board and liquid crystal display device

InactiveUS20120006584A1Narrower pad pitchDifficulty occurFinal product manufacturePrinted electric component incorporationLiquid-crystal displayMetal

A wiring board of the present invention (1) is arranged so that: pads (30) arranged in a plurality of rows include: first-row pads (30a) connected to first metal wires (10a) among metal wires (10); and second-row pads (30b) connected to second metal wires (10b) among the metal wires (10), the first metal wires (10a) being longer than the second metal wires (10b); and that each of the first connecting lines (10a) is formed so as to be separated from a corresponding one of the second-row pads (30b) by at least an insulating layer, and so as to extend not through a region between the corresponding second-row pad (30b) and a second-row pad (30b) adjacent to the corresponding second-row pad (30b), but through a region below the corresponding second-row pad (30b).

Owner:SHARP KK

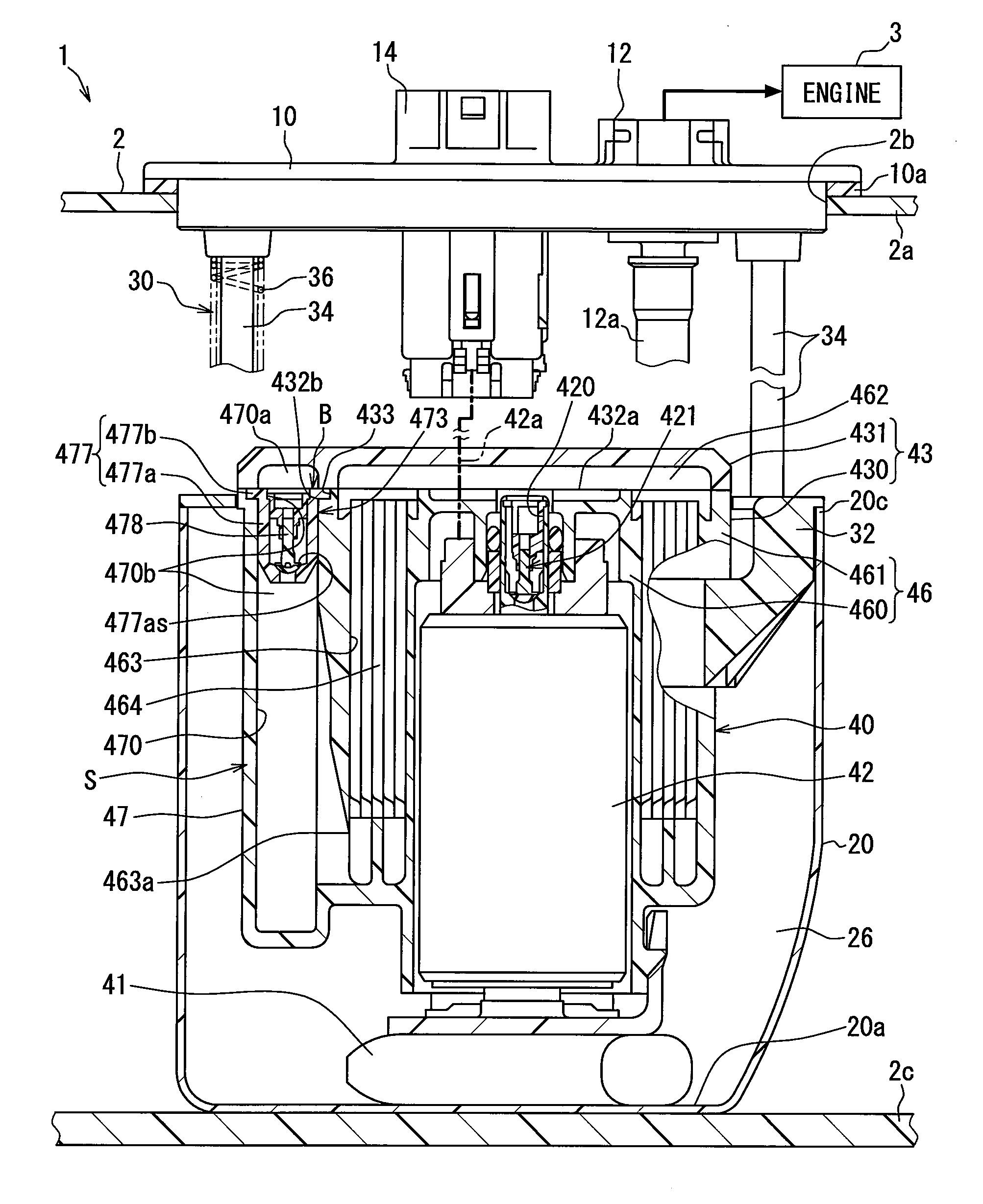

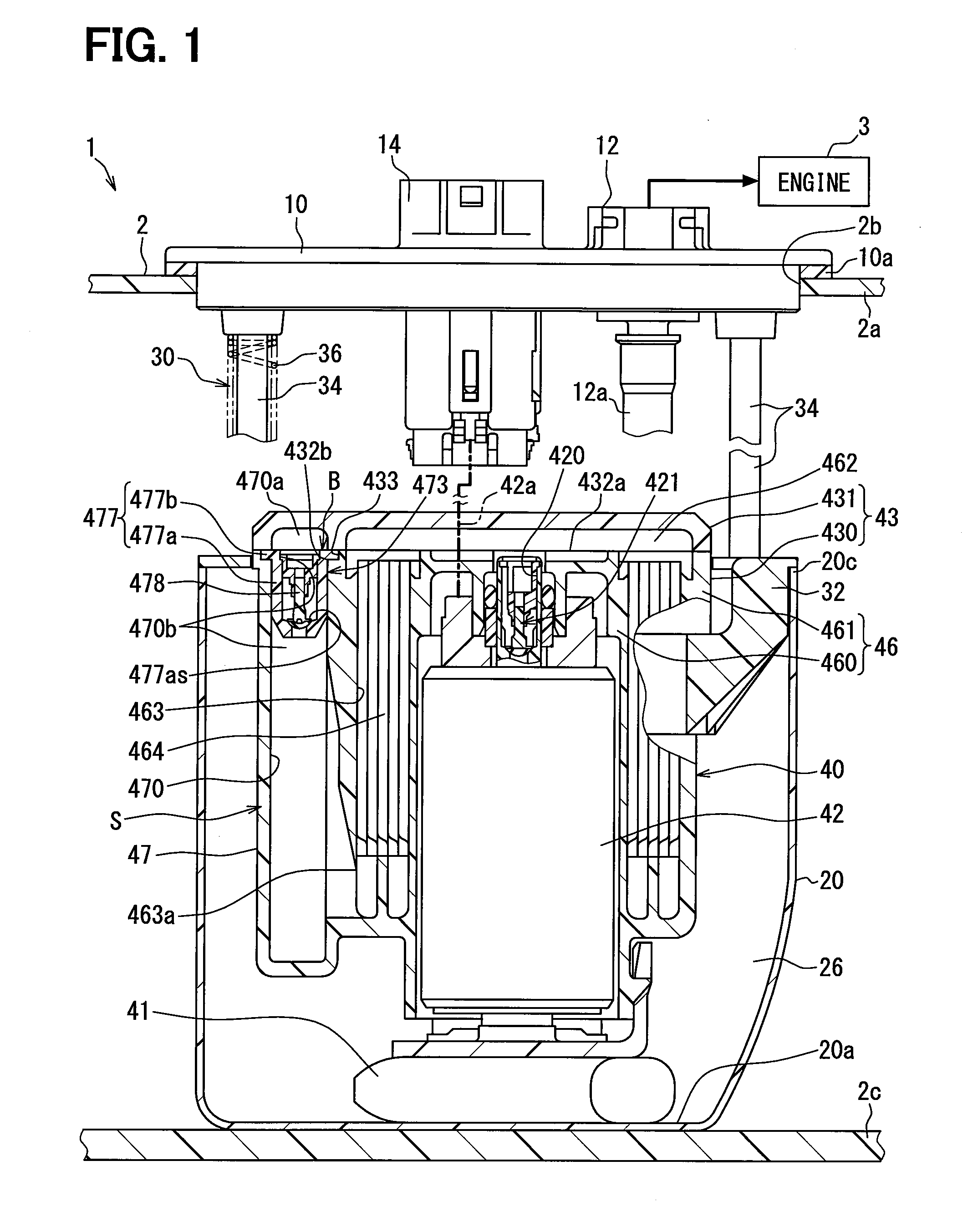

Fuel supply device

InactiveUS20160245246A1Pressure oscillation can be suppressedReduce noiseMachines/enginesLiquid fuel feedersExternal combustion engineFuel tank

A fuel supply device includes a fuel pump and a filter case that houses a fuel filter, a fuel pumped by the fuel pump from inside a fuel tank is filtered by the fuel filter and supplied from inside the filter case toward an internal combustion engine, and the filter case includes a case body having a closed bottom shape that forms a housing chamber of the fuel filter, a case cap that covers an aperture of the case body by being joined to the case body, and a residual pressure retention valve that, when the fuel pump is stopped, retains a pressure of the fuel supplied from inside the filter case toward the internal combustion engine, the residual pressure retention valve being disposed at a joint boundary of the case body and the case cap.

Owner:DENSO CORP +1

Storage device with protection against inadvertent writing

InactiveUS20050237355A1Reducing erroneous writingLower potentialMemory loss protectionDigital storageElectrical resistance and conductanceData signal

The present invention provides a storage device. The storage device includes a reset signal terminal, a clock signal terminal, a non-volatile memory, and a pull down resistance. The reset signal terminal is electrically connected to external equipment at a contact point, for receiving a reset signal. The clock signal terminal is electrically connected to the external equipment at a contact point, for receiving a clock signal. The data signal terminal is electrically connected to the external equipment at a contact point, for sending and receiving a data signal. The pull down resistance is connected to a lower side of electric potentials used by the storage device, at one terminal of the pull down resistance. The controller is initialized in response to the reset signal. The controller also writes to and reads from the non-volatile memory according to the clock signals and the data signals. The data signal includes a signal configured to raise a voltage of the data signal terminal to a higher side of the electric potentials, for instructing to write to the non-volatile memory. The data signal terminal is connected to the other terminal of the pull down resistance.

Owner:SEIKO EPSON CORP

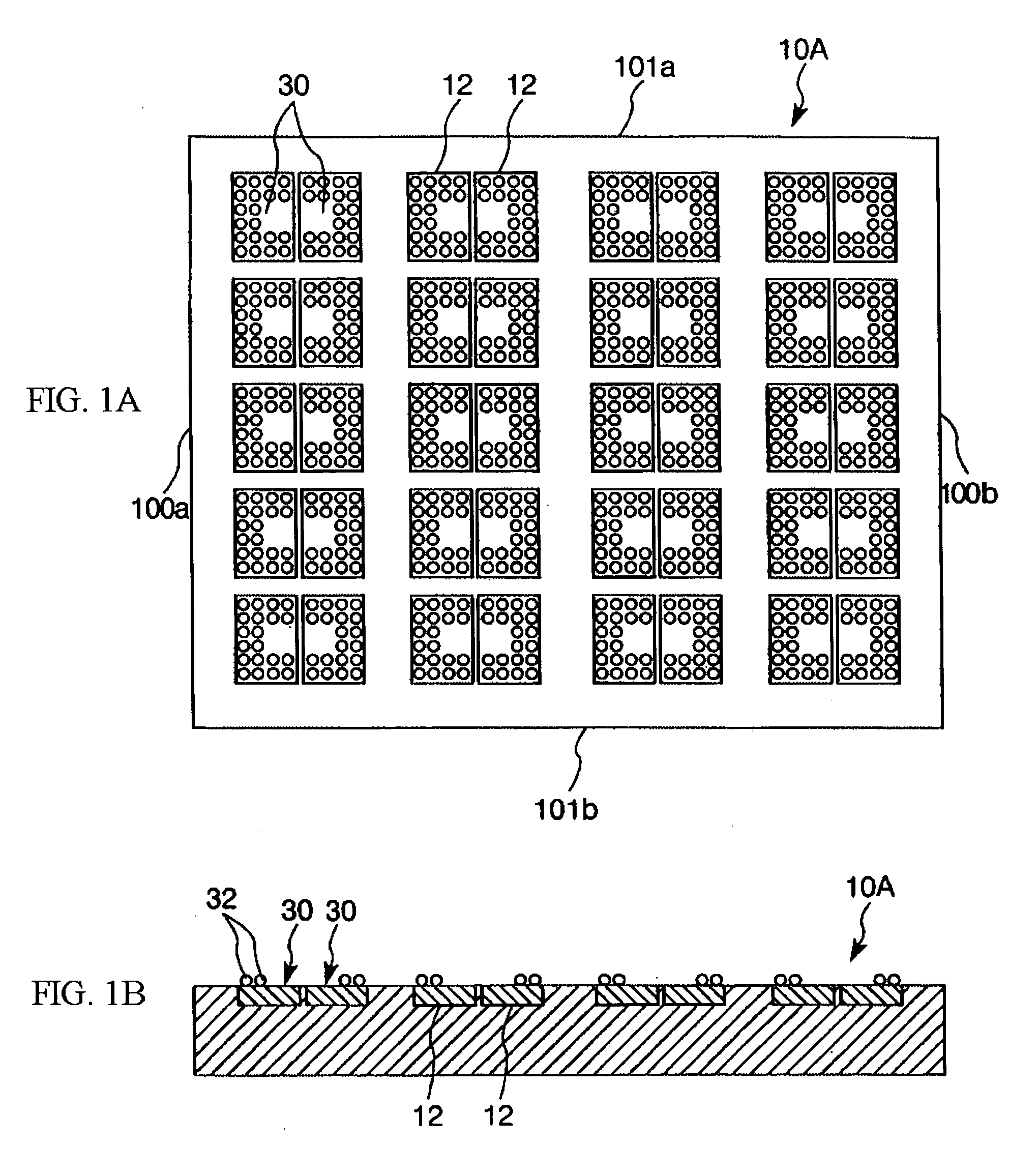

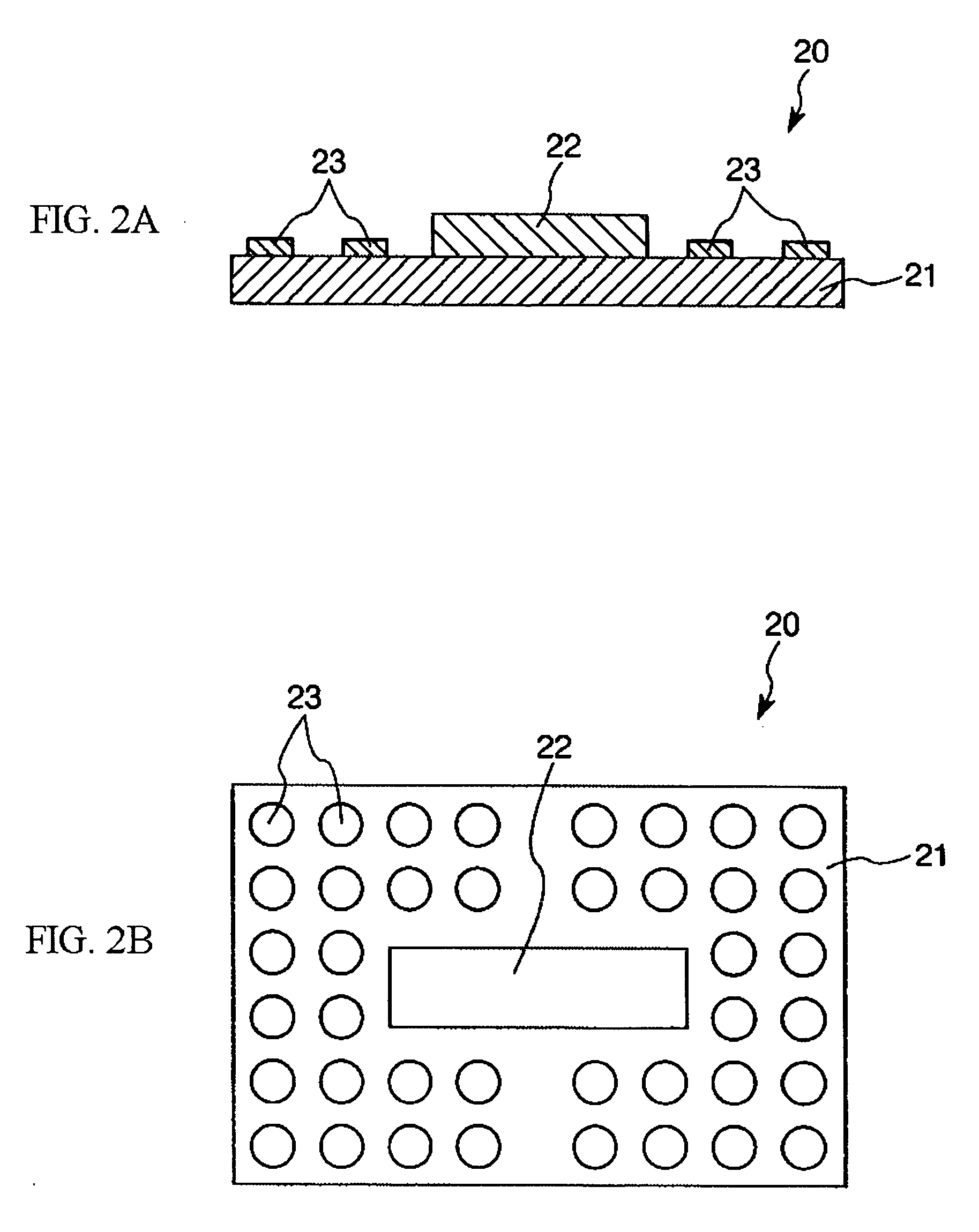

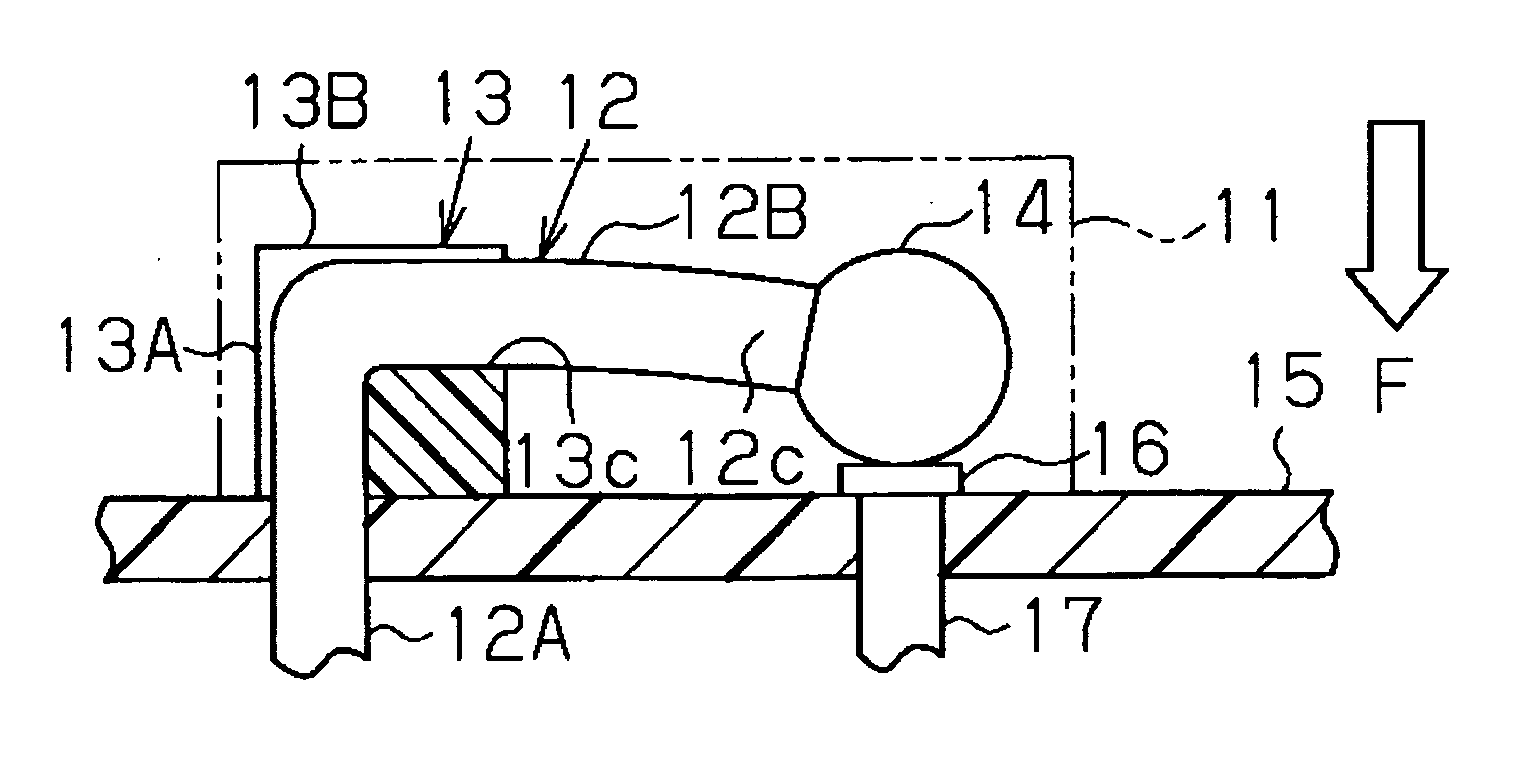

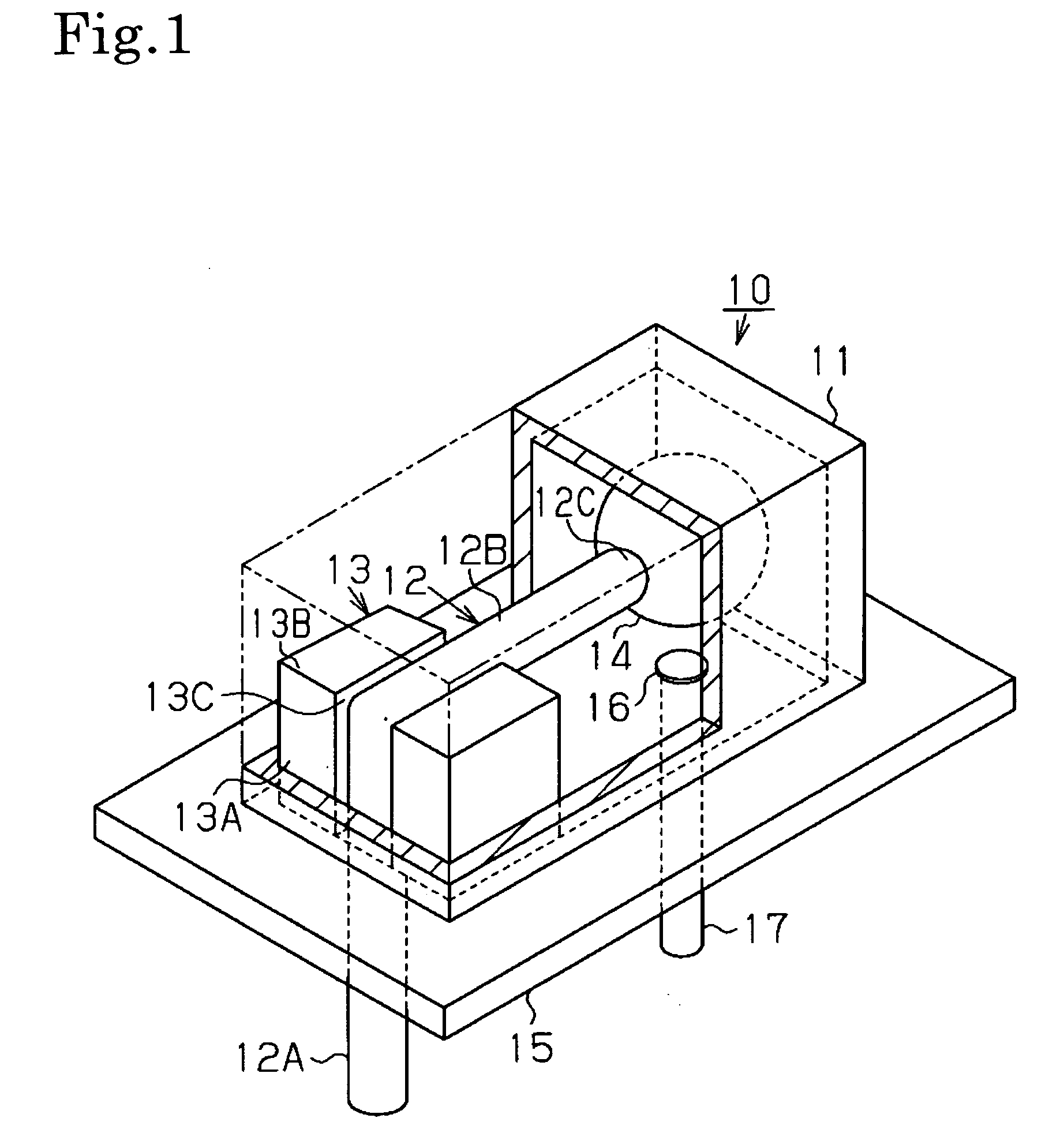

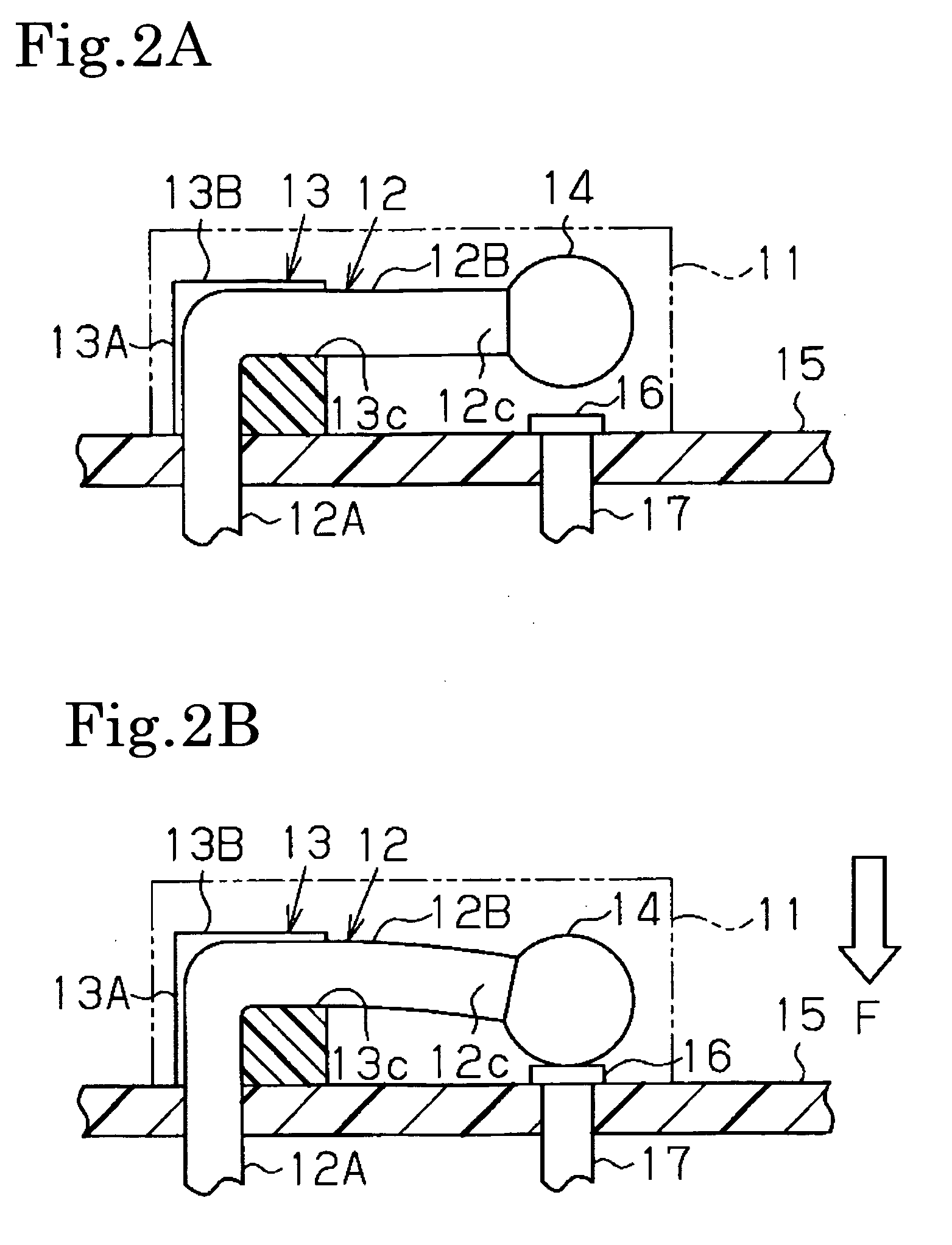

Apparatus used for manufacturing semiconductor device, method of manufacturing the semiconductor devices, and semiconductor device manufactured by the apparatus and method

InactiveUS20050071989A1Avoid it happening againSuppress manufacturing costTransistorSolid-state devicesManufacturing cost reductionSemiconductor package

An apparatus for manufacturing semiconductor devices having a roughly rectangular parallelepiped box-shape includes an internal insertion space for semiconductor packages, first guide grooves and arranged along the longitudinal direction in both side surfaces facing the insertion space and second guide grooves and arranged parallel to the first guide grooves and respectively. Edge portions of an upper semiconductor package (a semiconductor component) are loosely fitted into the second guide grooves so that the movement of the upper semiconductor package in the left and right direction is restricted. Further, edge portions of a lower semiconductor package (a substrate for mounting semiconductor components) are loosely fitted into the first guide grooves so that the movement of the lower semiconductor package in the left and right direction is restricted. By using the apparatus, it becomes possible to provide a semiconductor device in which poor connections are difficult to occur, and further to provide an apparatus for manufacturing semiconductor devices and a method of manufacturing semiconductor devices that enable to prevent the occurrence of such poor connections in the obtained semiconductor devices and also enable to reduce manufacturing costs.

Owner:SEIKO EPSON CORP

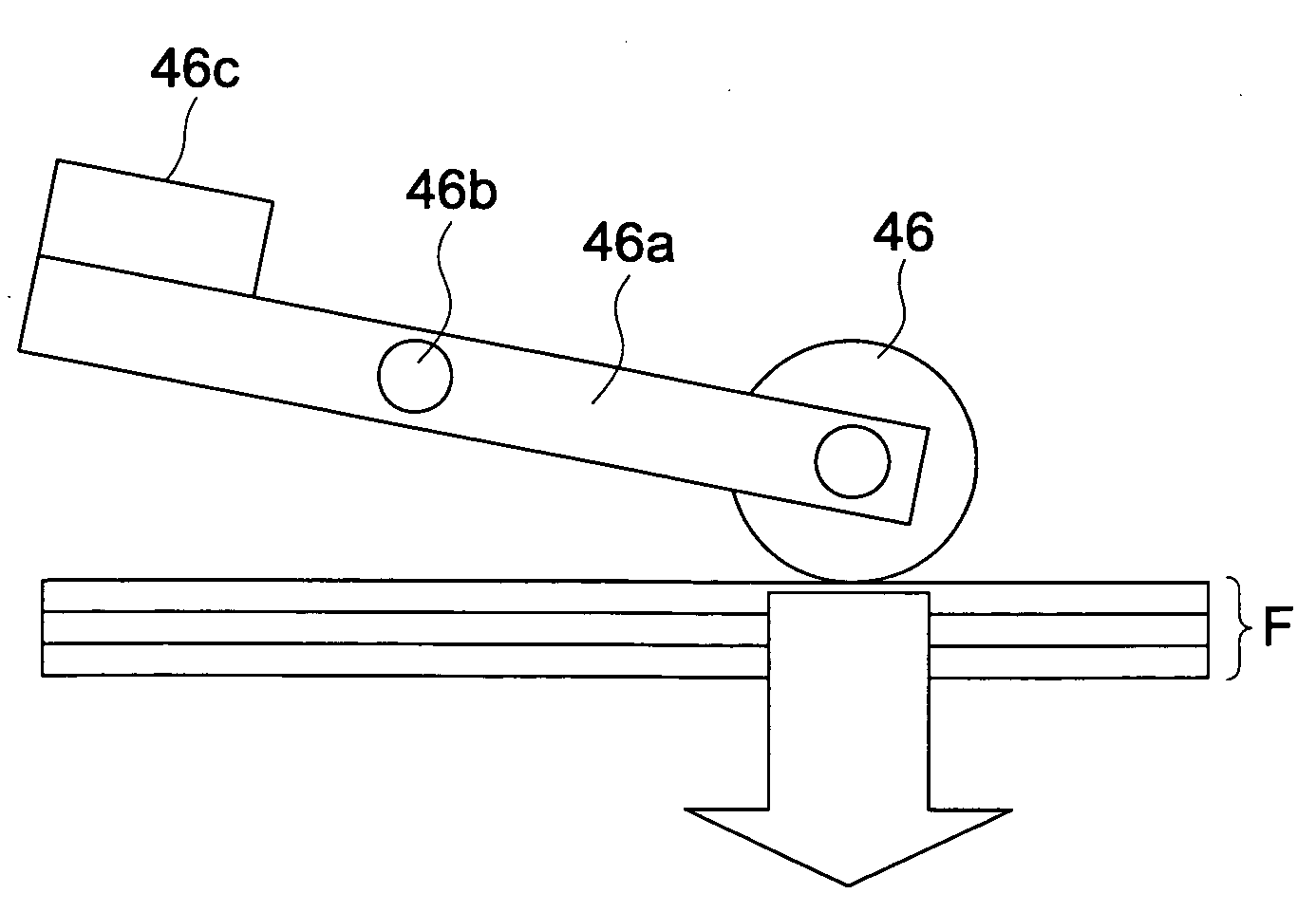

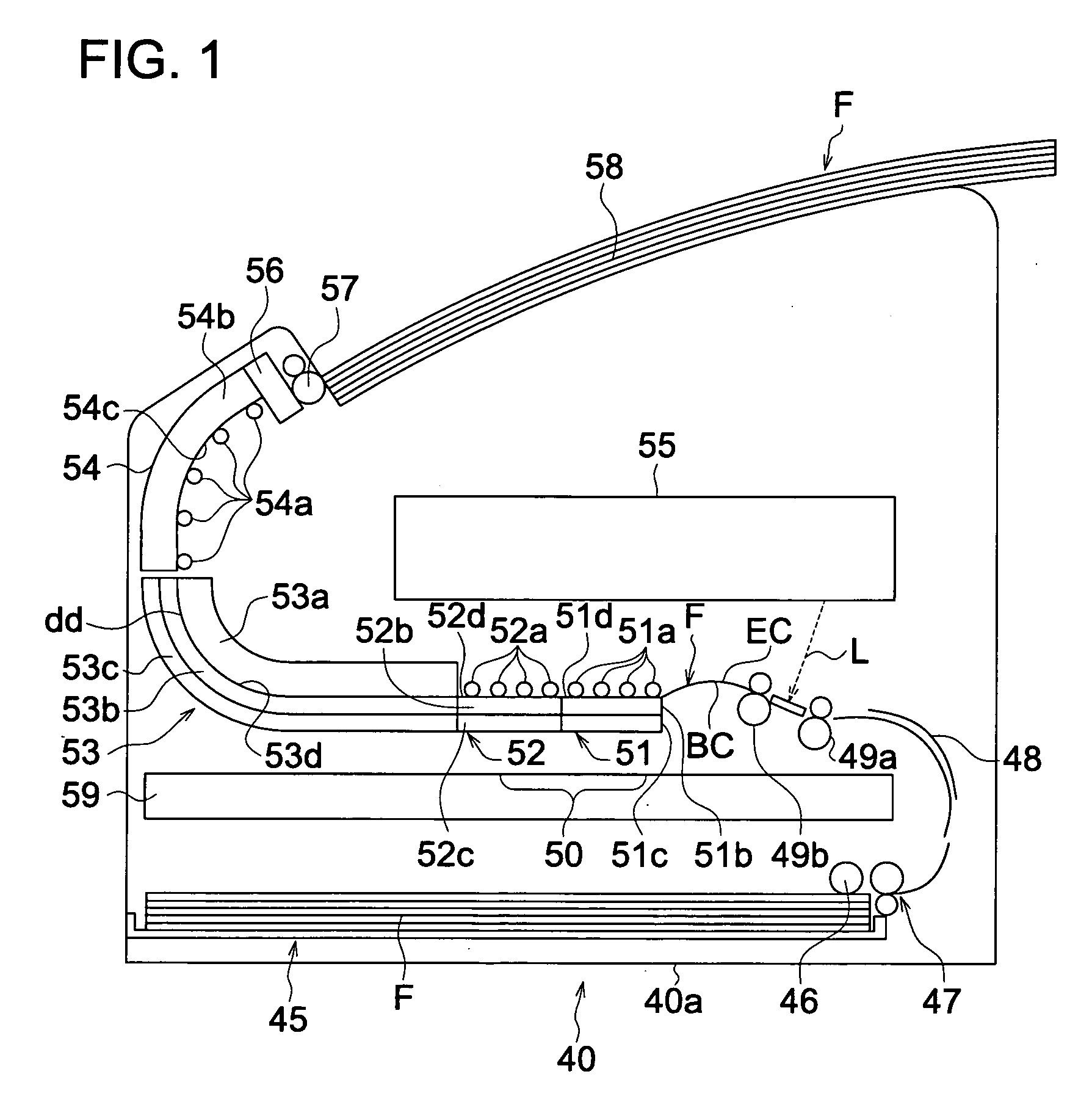

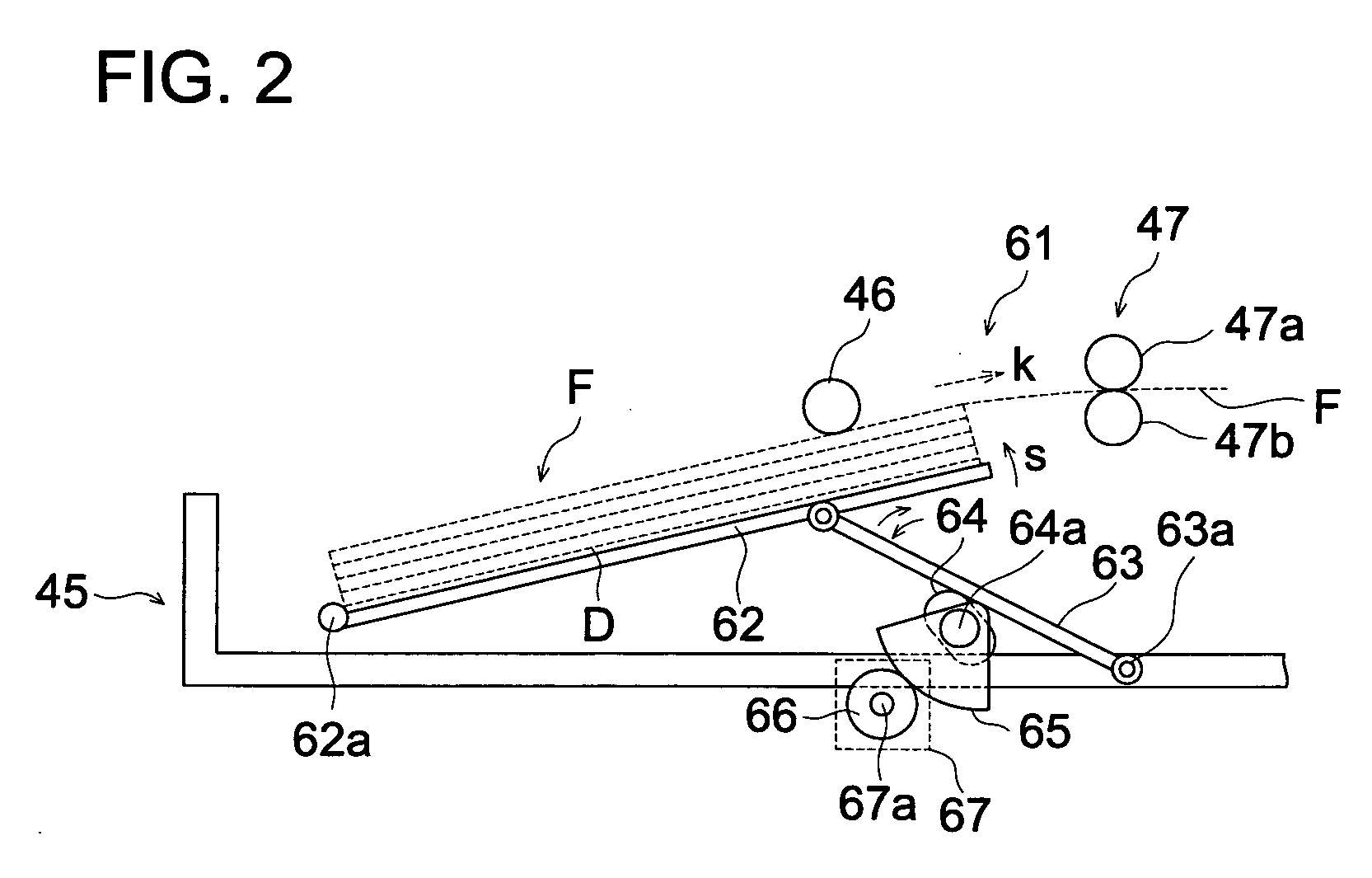

Photosensitive Material Conveying System and Image Forming Apparatus

InactiveUS20090134566A1High qualityQuality improvementTypewritersOther printing apparatusEmulsionEngineering

The photosensitive material conveying system is configured so that a feed out roller is contacted on a stack of sheets having a plurality of stacked photosensitive sheet films each of which is provided with an emulsion layer and a first protective layer provided on one side of a supporting base and a second protective layer provided on the other side with matting agent dispersed in the second protective layer, and the topmost sheet film in the stack of sheets is fed out by the rotation of the feeding out roller, wherein the matting agent has a spherical shape, a hardness softer than the first protective layer, and particle diameter in the range of 8 to 12 μm, and the contact pressure of the feeding out roller is 0.49 N / cm or less.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

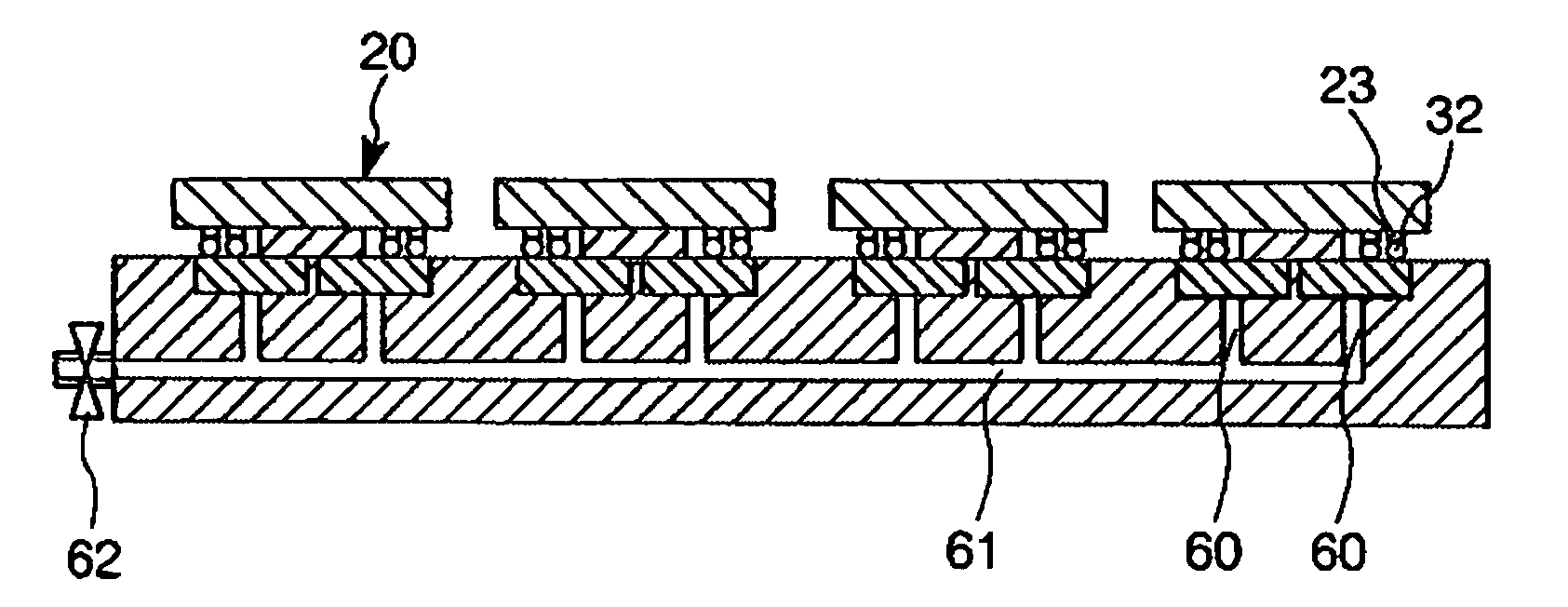

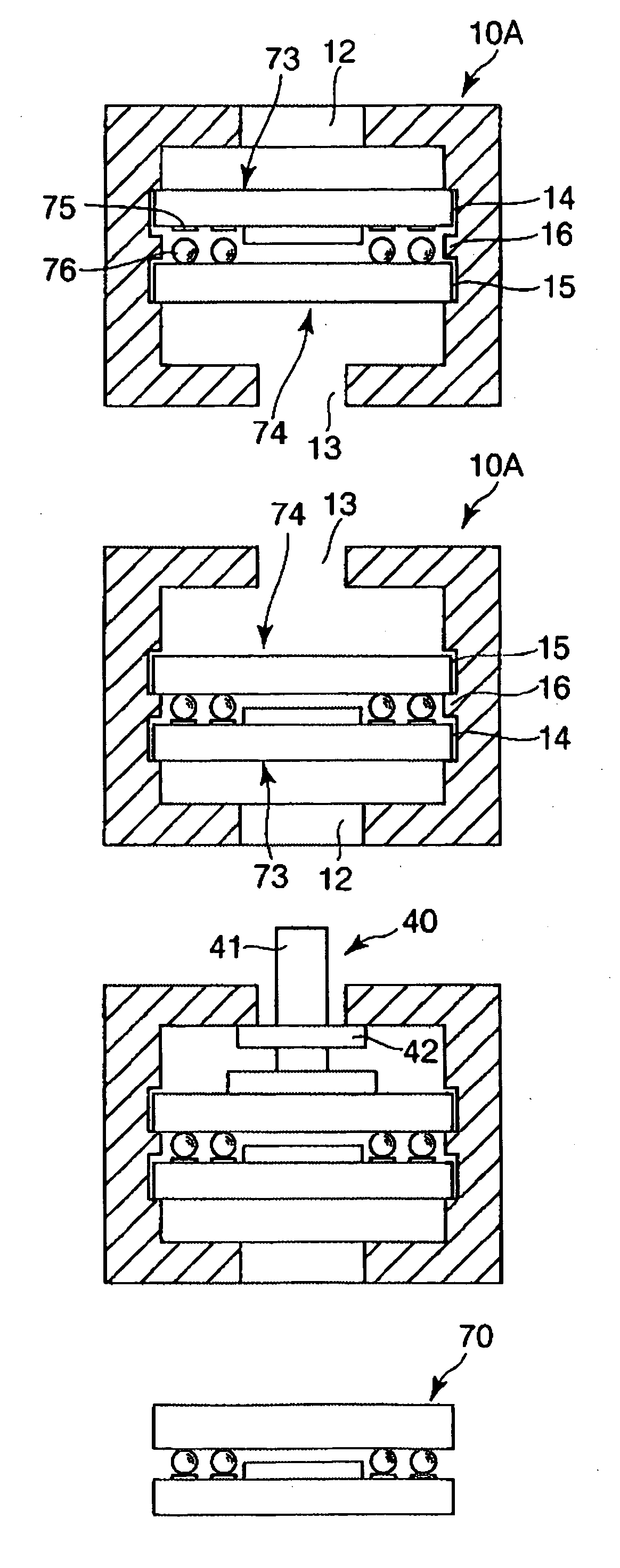

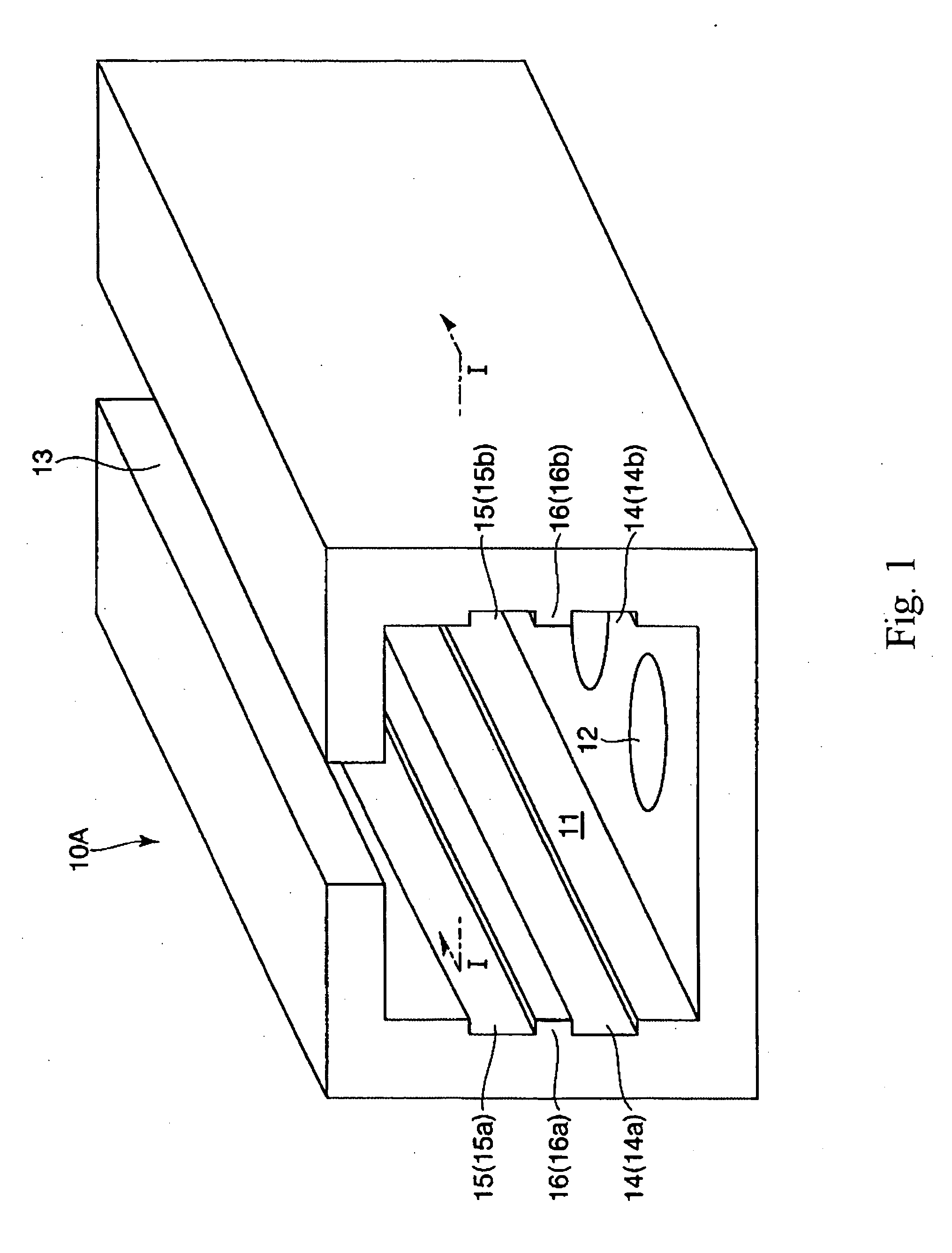

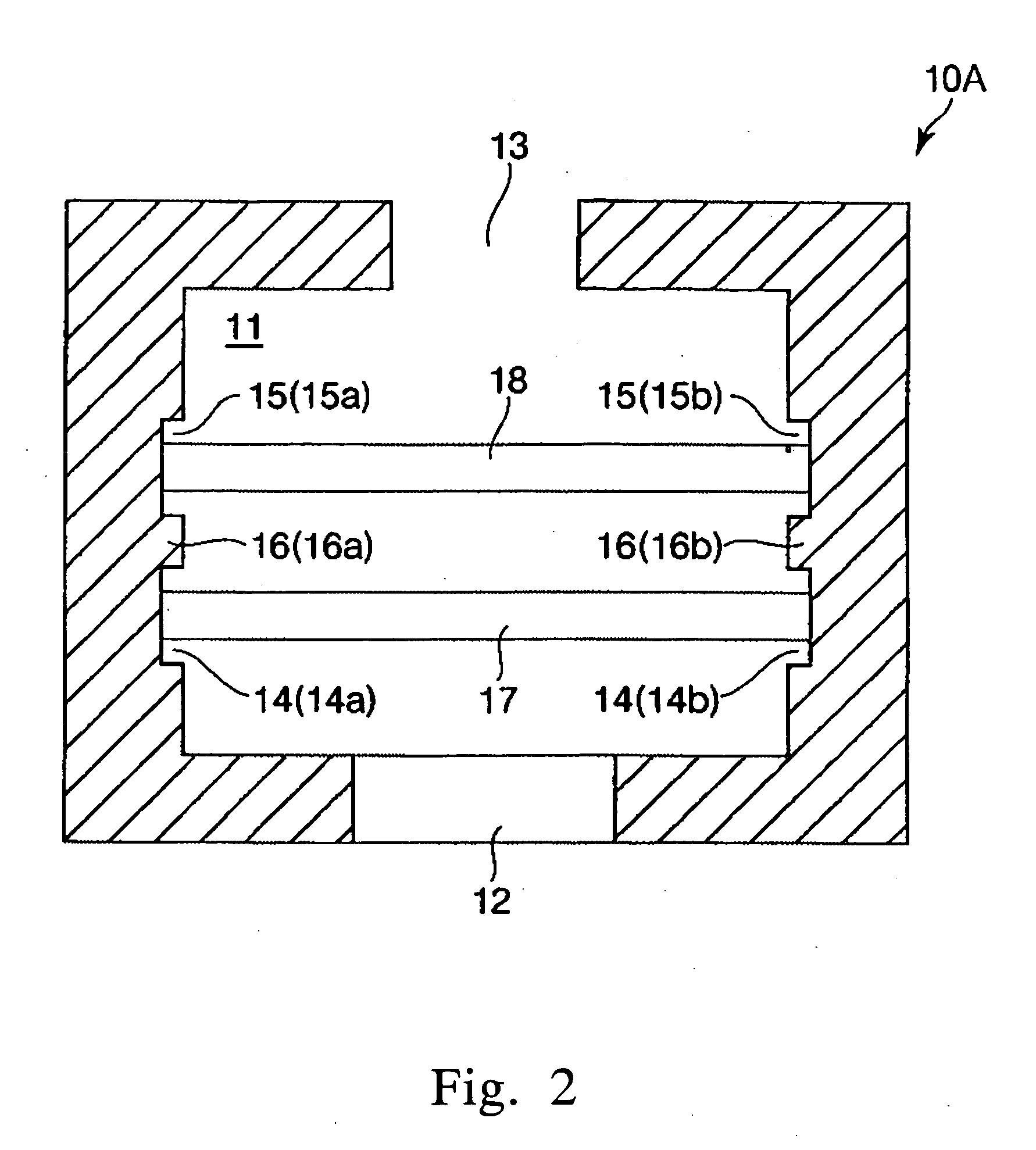

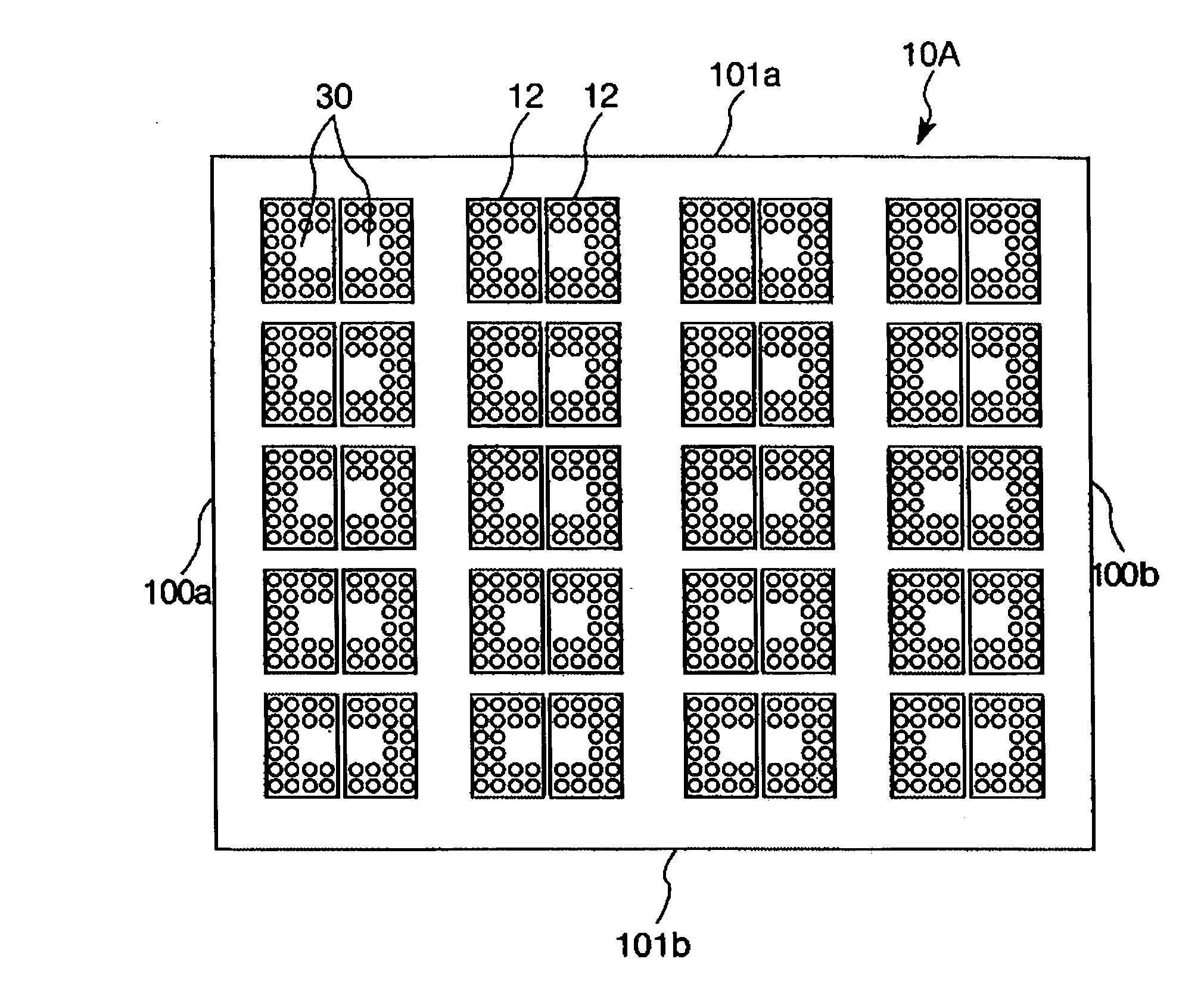

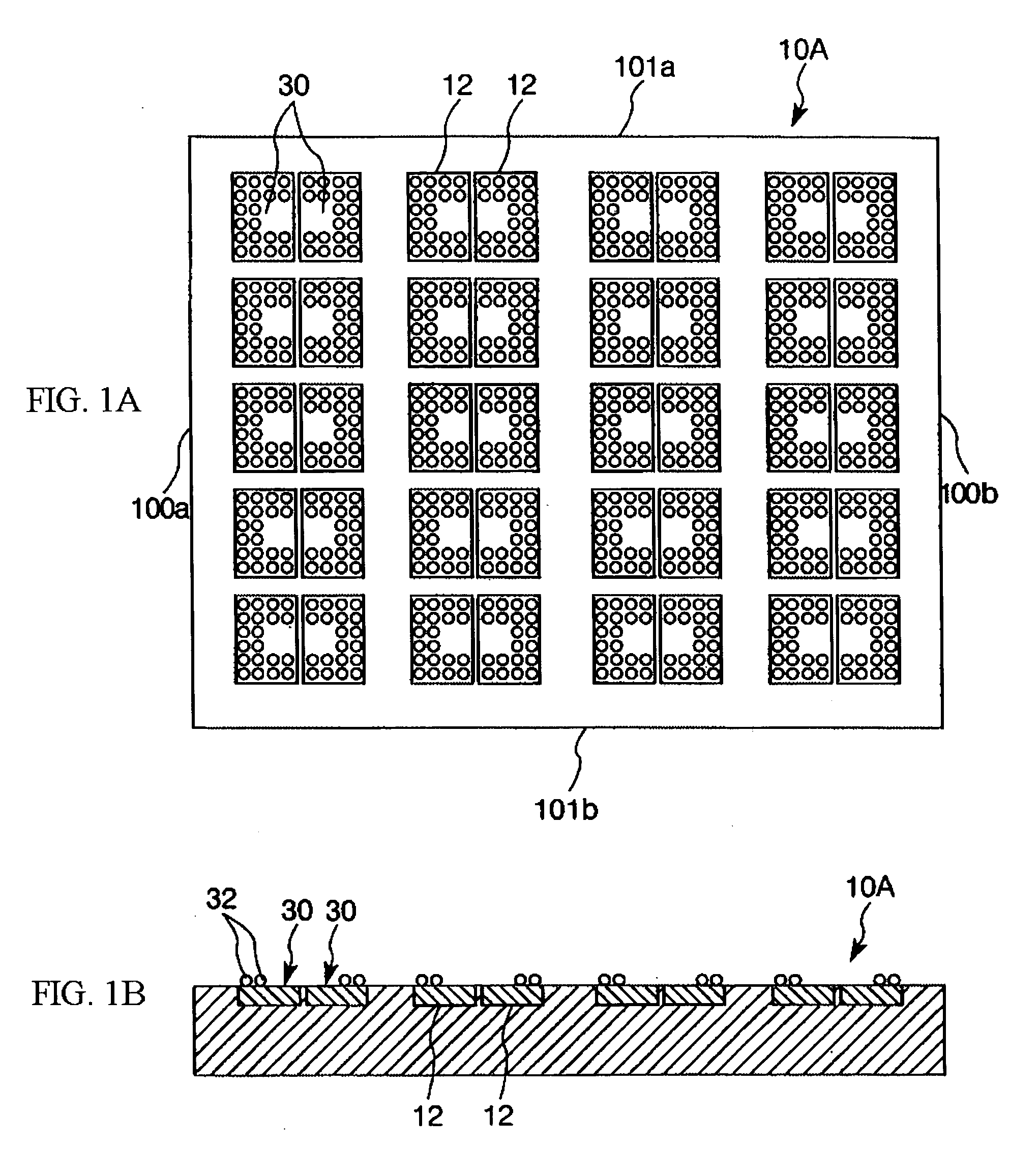

Apparatus for manufacturing semiconductor devices, method of manufacturing the semiconductor devices, and semiconductor device manufactured by the apparatus and method

InactiveUS20050112844A1Suppress manufacturing costAvoid it happening againSoldering apparatusSolid-state devicesDevice materialSemiconductor package

An apparatus 10A for manufacturing semiconductor devices includes a plurality of receiving portions 12 for receiving an upper semiconductor package 30 on a top surface of the receiving portion 12. The receiving portion has a function of restricting the movement of the upper semiconductor package 30 in a direction parallel to a top surface of the upper semiconductor package 30. The receiving portion 12 is a concave portion in which the upper semiconductor package 30 is adapted to be received. An adhesive material having a function of immovably holding the upper semiconductor package 30 to the receiving portion 12 may be provided within the receiving portion 12, for example.

Owner:SEIKO EPSON CORP

Motion switch

InactiveUS20090008226A1Well formedConvenience to workContact materialsAcceleration measurementCeramicHigh heat

There is provided a mechanical motion switch whose structure is simple, which is a microminiature, which can be used for a long time even in a such a severe environment as a high temperature state, and whose reliability is high. A ceramic-made pedestal of an approximately rectangular shape is fixed to a board and, in the pedestal, there is formed a reverse L-letter shape groove continuous with a base end face and an upside face. A high elasticity wire having an electrical conductivity is fitted and fixed to the groove while being bent, and has a lead penetrating through the board and an arm part extended in a direction horizontal to the board, and a tip part of the arm part is made an action end. In the action end, there is formed, in a position separated from the board, a metal-made deadweight movable by a swing by an elasticity of the arm part. On the board just below the deadweight, there is provided a contact having the electrical conductivity, which is support-fixed to the board by a lead. And, the pedestal, the arm part, the deadweight and the contact are covered by a case.

Owner:SEIKO INSTR INC

Protective film for polarizing plate

ActiveUS7998563B2High color reproductionLess occurrenceLiquid crystal compositionsPrismsTectorial membraneLiquid-crystal display

A protective film for polarizing plate comprising k layers (k is an integer of 2 or more) of thermoplastic resin layer laminated, whereina refractive index ni(380) at a wavelength of 380 nm and a refractive index ni(780) at a wavelength of 780 nm in the i th thermoplastic resin layer as well as a refractive index ni+1(380) at a wavelength of 380 nm and a refractive index ni+1(780) at a wavelength of 780 nm in the i+1 th thermoplastic resin layer have a relationship in∥ni(380)−ni+1(380)|−|ni(780)−ni+1(780)∥≦0.02(where, i is an integer of 1 to k−1). A polarizing plate is obtained by bonding the protective film for the polarizing plate and a polarizer. And a liquid crystal display comprising the polarizing plate and a liquid crystal panel.

Owner:ZEON CORP

Packet discard point probing method and device

ActiveUS7385930B2Low costReduce laborFrequency-division multiplex detailsTransmission systemsLow speedResidence

In a relay device or the like in which a speed changes from a high speed to a low speed, a packet residence (packet transfer wait) occurs when a packet string in which packet intervals are shortened arrives. When a packet discard occurs before passing through the relay device or the like, a packet interval having been lengthened by the packet discard is shortened by the relay device or the like for transferring packets. When a packet discard occurs after passing through the relay device or the like, a packet interval having been lengthened by the packet discard remains unshortened for transferring packets. Therefore, by observing at terminals the packet discard and the packet interval on the occasion of the packet discard, whether the packet discard has occurred in the high speed section or the low speed section is specified.

Owner:FUJITSU LTD

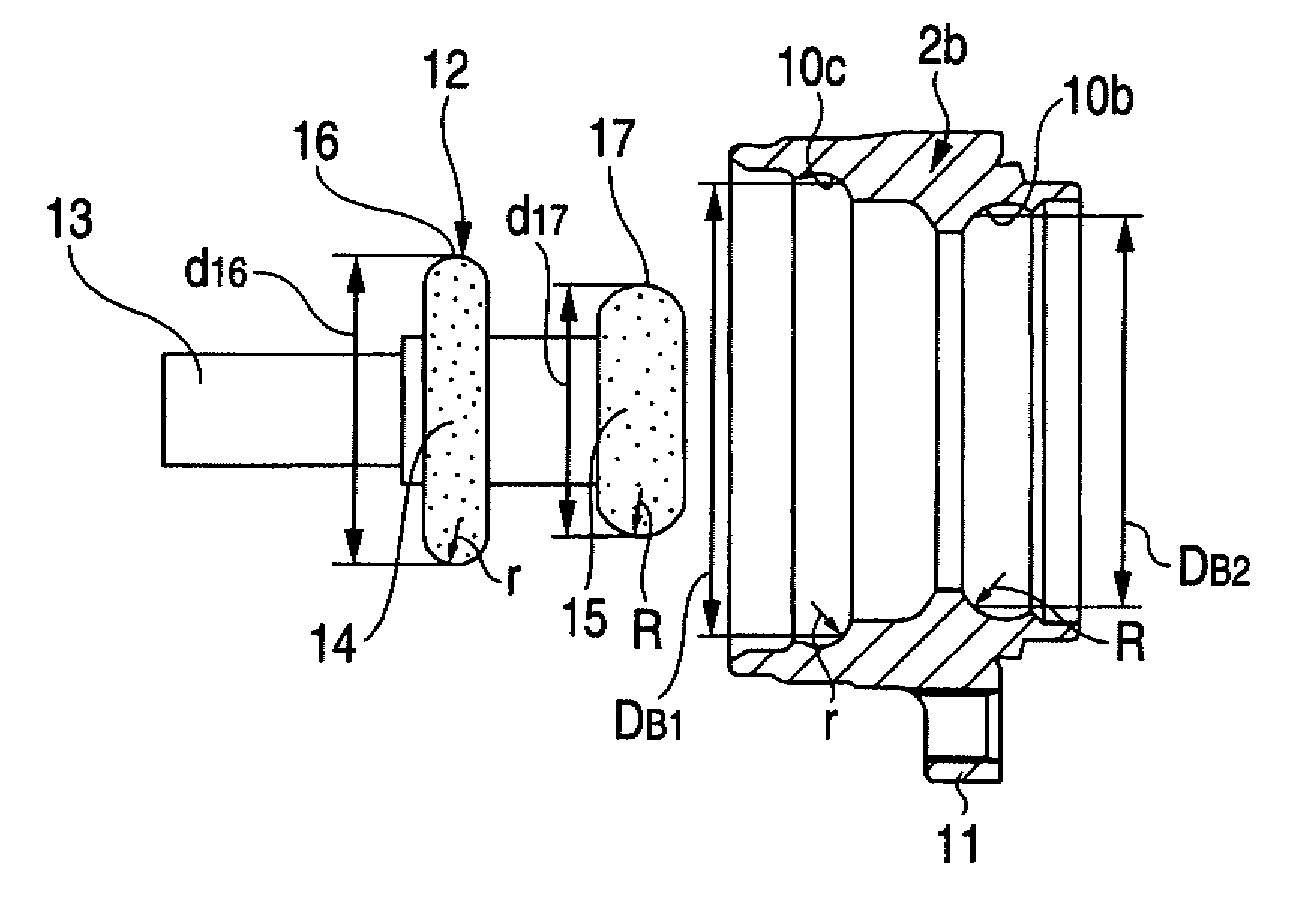

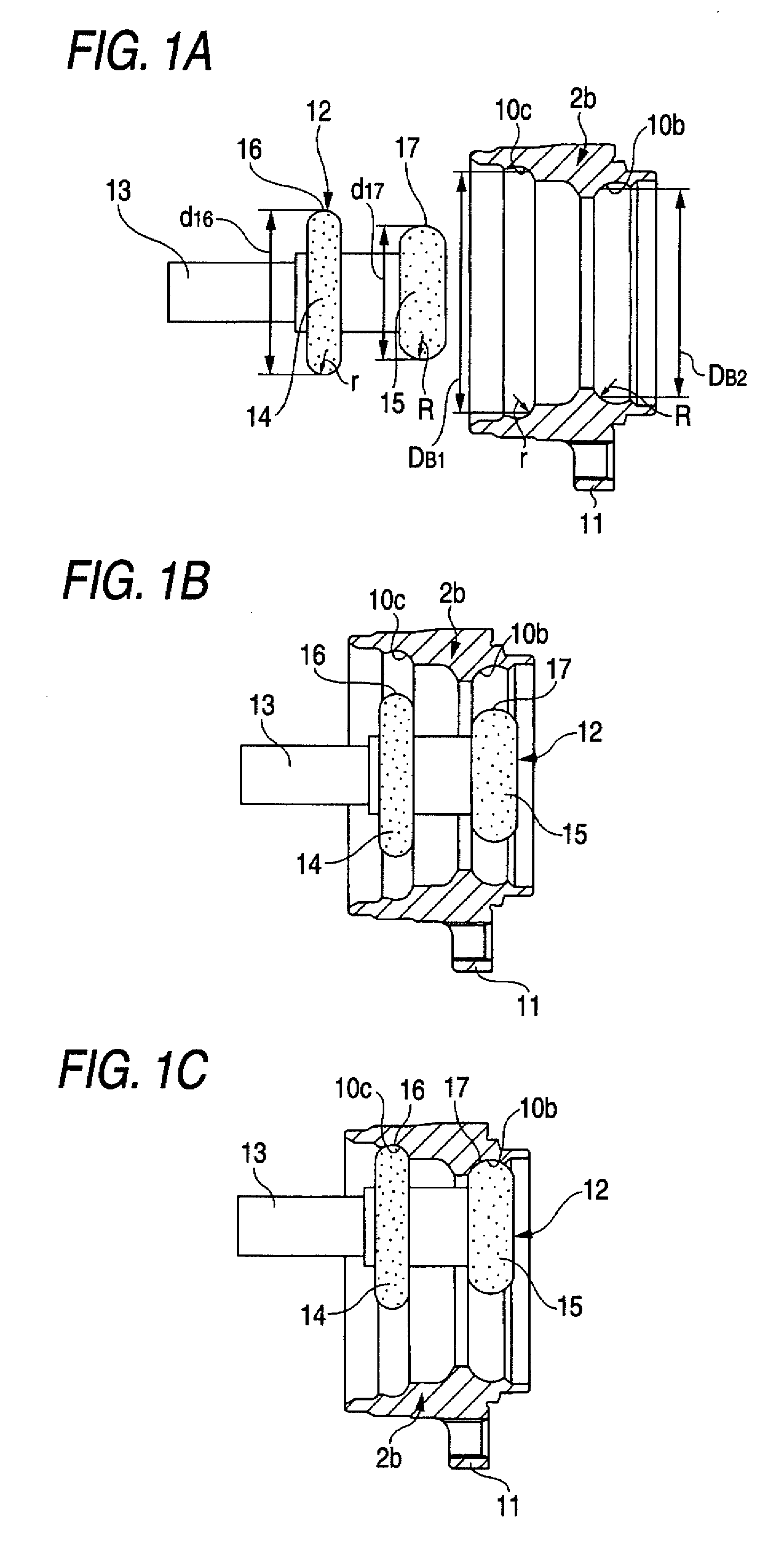

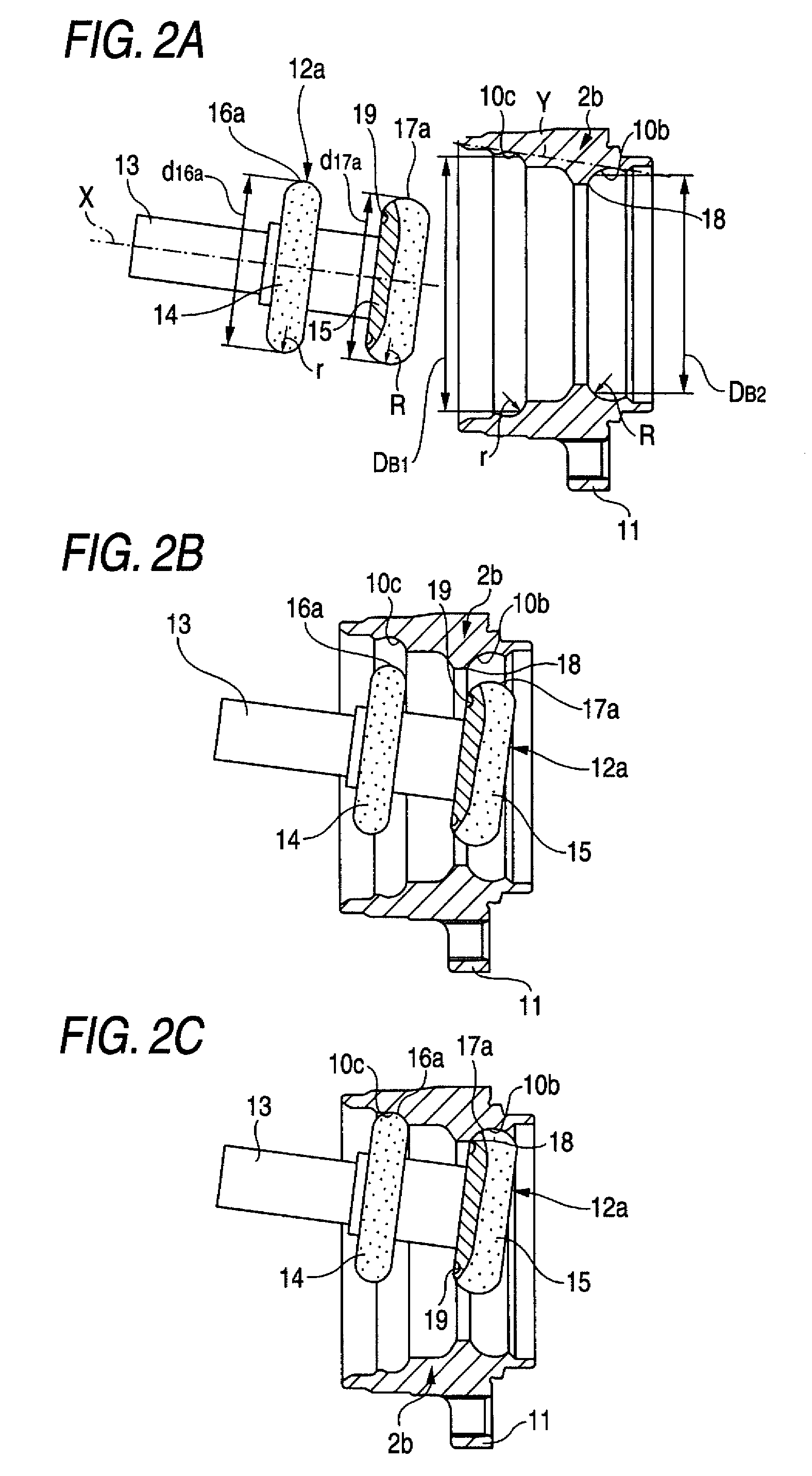

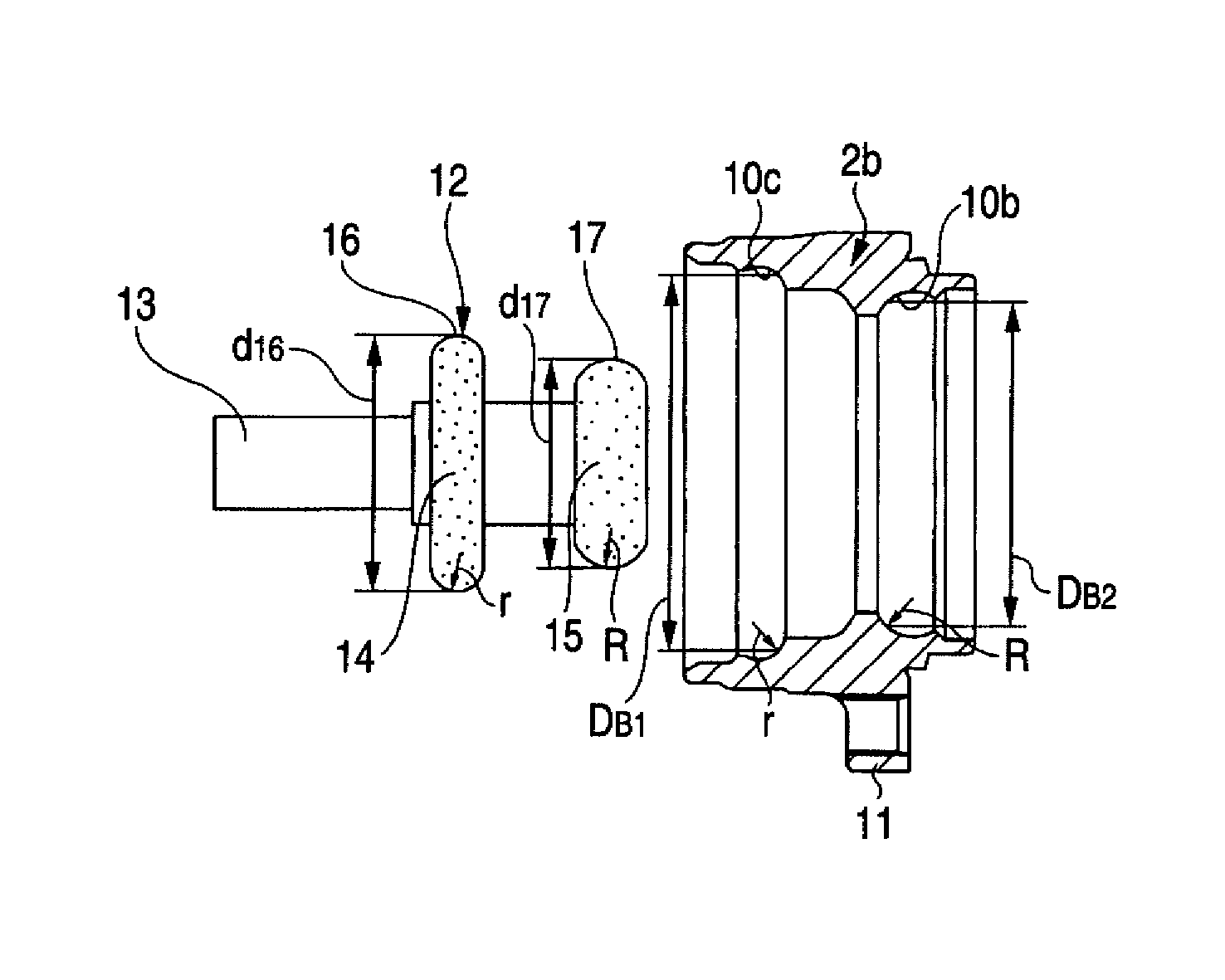

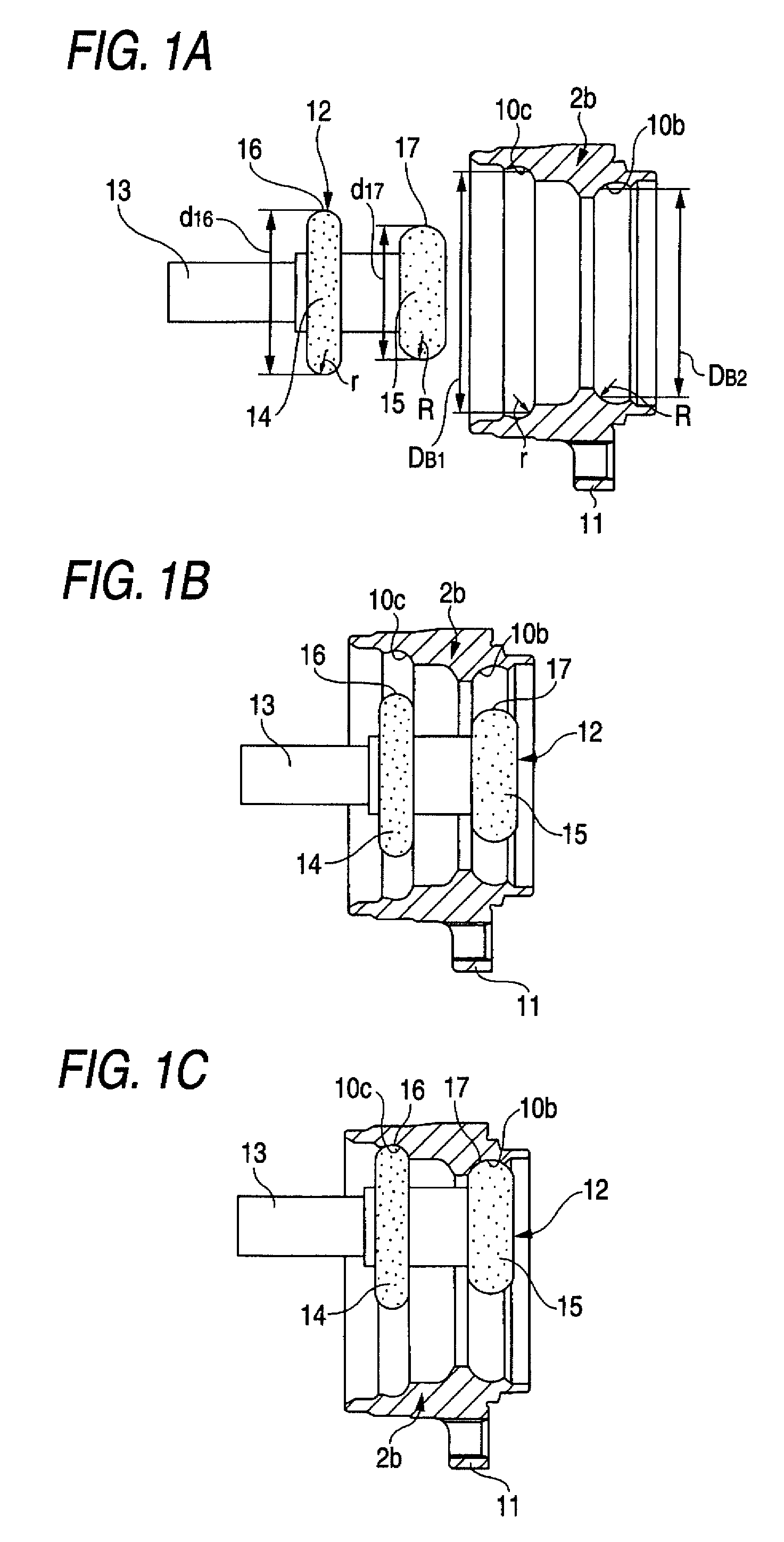

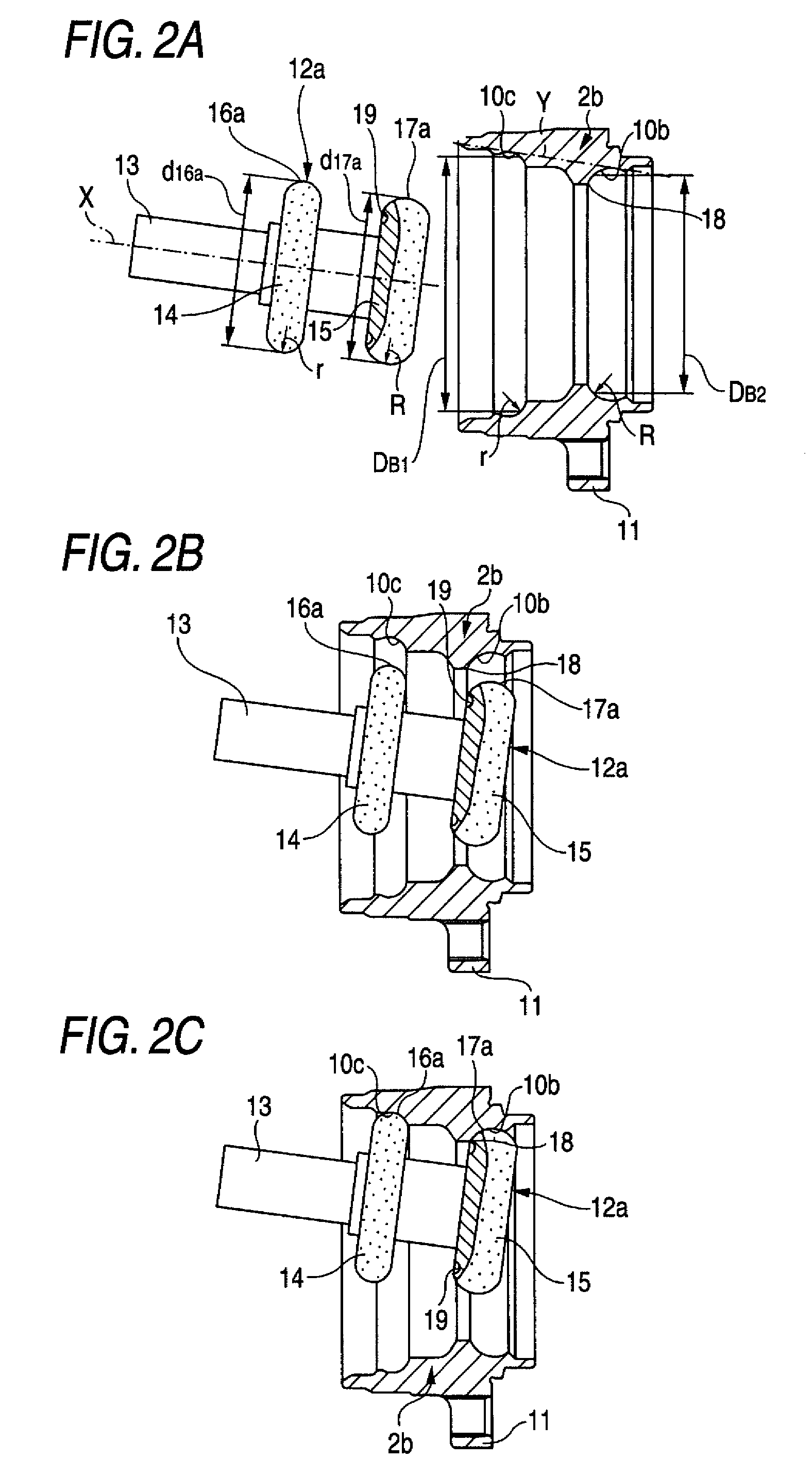

Manufacturing method of an outer ring for a bearing unit

InactiveUS20090199404A1Increase freedomEfficient executionRolling contact bearingsRevolution surface grinding machinesEngineeringMechanical engineering

With respect to an outer ring 2b in which a diameter DB1 of a first outer ring raceway 10c is greater than a diameter of a second outer ring raceway 10b (DB1>DB2), a method is realized which facilitates the entry of a grinding tool 12 into an inner side of the outer ring when these both outer ring raceways 10c and 10b are subjected to a grinding process. As shown in (A) to (B), the grinding tool 12 is made to enter the inner side of the outer ring 2b through an opening on a side close to the first outer ring raceway 10c between the openings at both ends of this outer ring 2b. This resolves the above-described problem.

Owner:NSK LTD

Plasma display panel and method for manufacturing the same

InactiveUS20100171420A1Guaranteed StrengthAvoid crackingSustain/scan electrodesGas discharge vessels/containersNanocrystalProtection layer

A plasma display panel has a plurality of pairs of display electrodes, dielectric layer, and protective layer disposed on front glass substrate. Protective layer is formed of nano crystal particles, and the average particle diameter of the nano crystal particles is in the range of 10 nm to 100 nm. With this structure, in the plasma display panel, front glass substrate has a sufficient strength and occurrence of panel cracks is reduced.

Owner:PANASONIC CORP

Manufacturing method of an outer ring for a bearing unit

InactiveUS8341844B2Increase freedomEfficient executionRolling contact bearingsRevolution surface grinding machinesEngineeringMechanical engineering

With respect to an outer ring 2b in which a diameter DB1 of a first outer ring raceway 10c is greater than a diameter DB2 of a second outer ring raceway 10b (DB1>DB2), a method is realized which facilitates the entry of a grinding tool 12 into an inner side of the outer ring when these both outer ring raceways 10c and 10b are subjected to a grinding process.The grinding tool 12 is made to enter the inner side of the outer ring 2b through an opening on a side close to the first outer ring raceway 10c.

Owner:NSK LTD

Permanent magnet for motor, and method for manufacturing the permanent magnet for motor

InactiveUS9093218B2Total current dropDifficulty occurMagnetic circuit rotating partsSynchronous machinesSlurryMaterials science

A method for producing a permanent magnet for a motor, including a step of producing a slurry of a magnet powder, a step of molding the slurry into a sheet form to prepare green sheets of the magnet powder, and a step of alternately laminating the green sheets of the magnet powder and an insulating layer and sintering the laminated plural layers.

Owner:NITTO DENKO CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com