Photosensitive Material Conveying System and Image Forming Apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example of implementation

[0069]To begin with, the photosensitive film was prepared in the following manner. That is, the photosensitive film was prepared in a manner similar to that of the sample number 115 in the Implementation Example 1 described in lines [0480] to [0519] of the of the Unexamined Japanese Patent Application Publication No. 2005-107496 applied for by the present applicants. However, the matting agent “3-dimensionally cross-linked polymethyl methacrylate: PMMA, average particle diameter 10 μm, truly spherical shape, degree of monodispersion 10%” was employed in place of the matting agent (3-dimensionally cross-linked polymethyl methacrylate: PMMA, average particle diameter 5 μm) in the “BC layer protective layer coating liquid” described in line [0494].

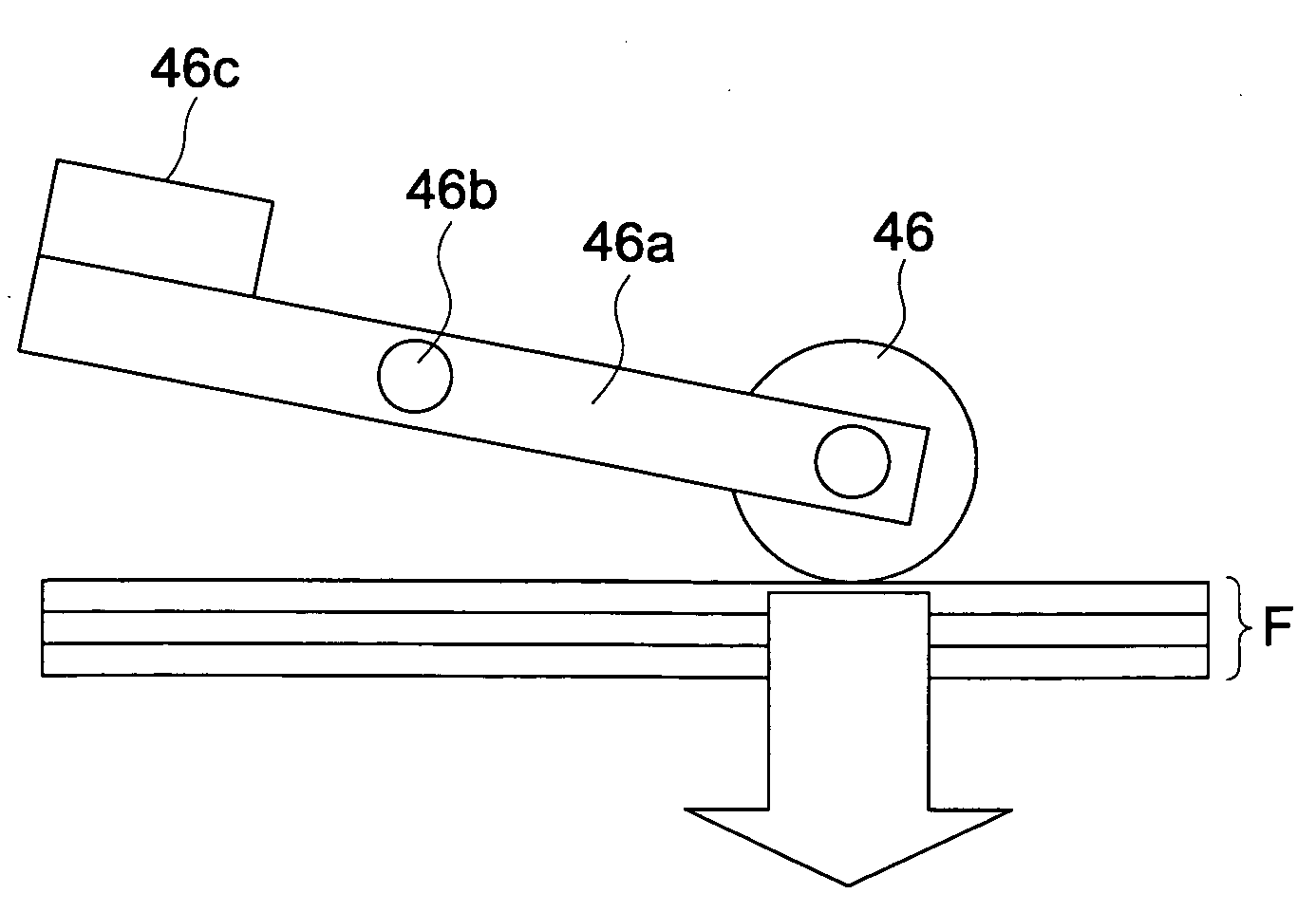

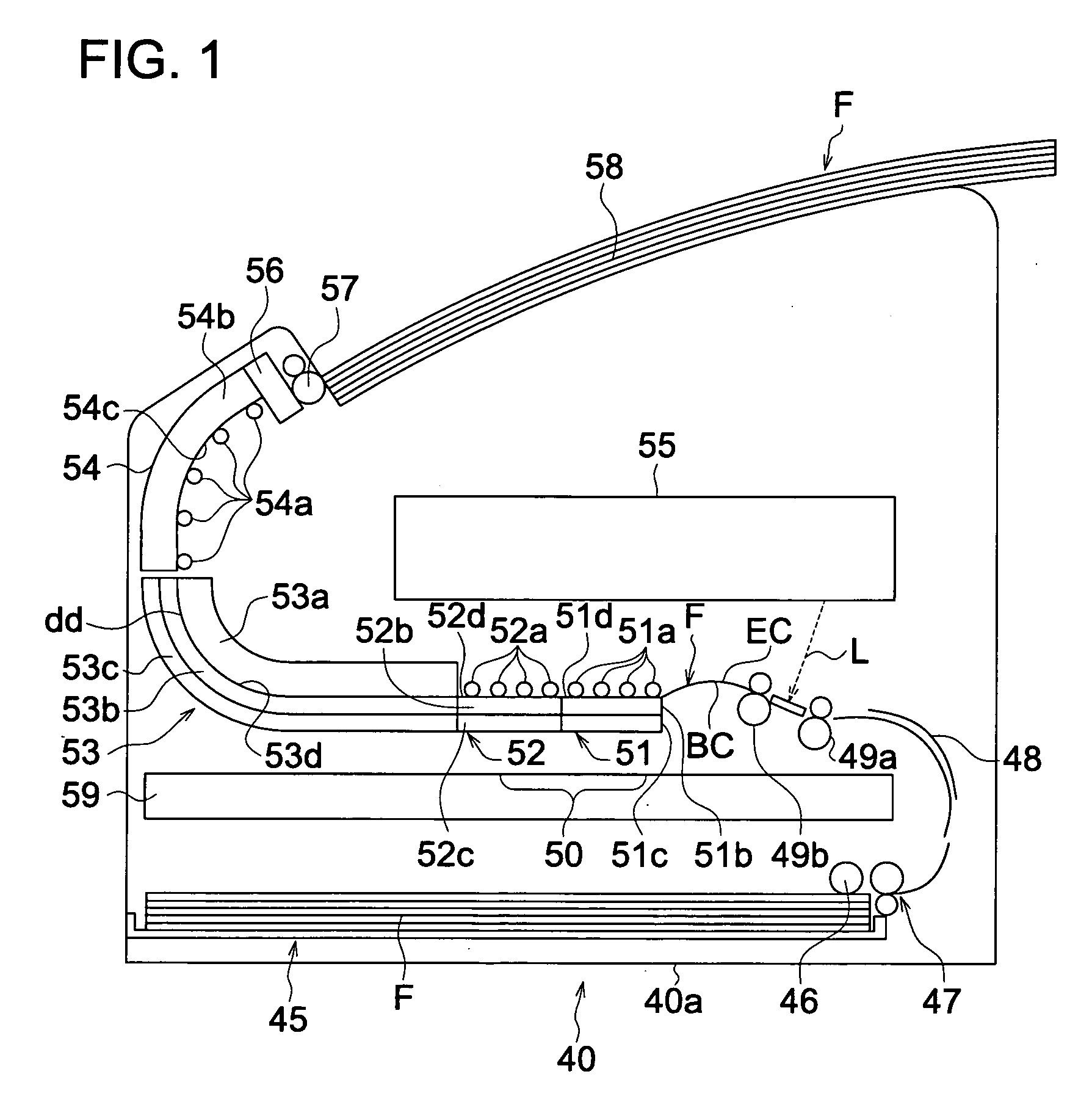

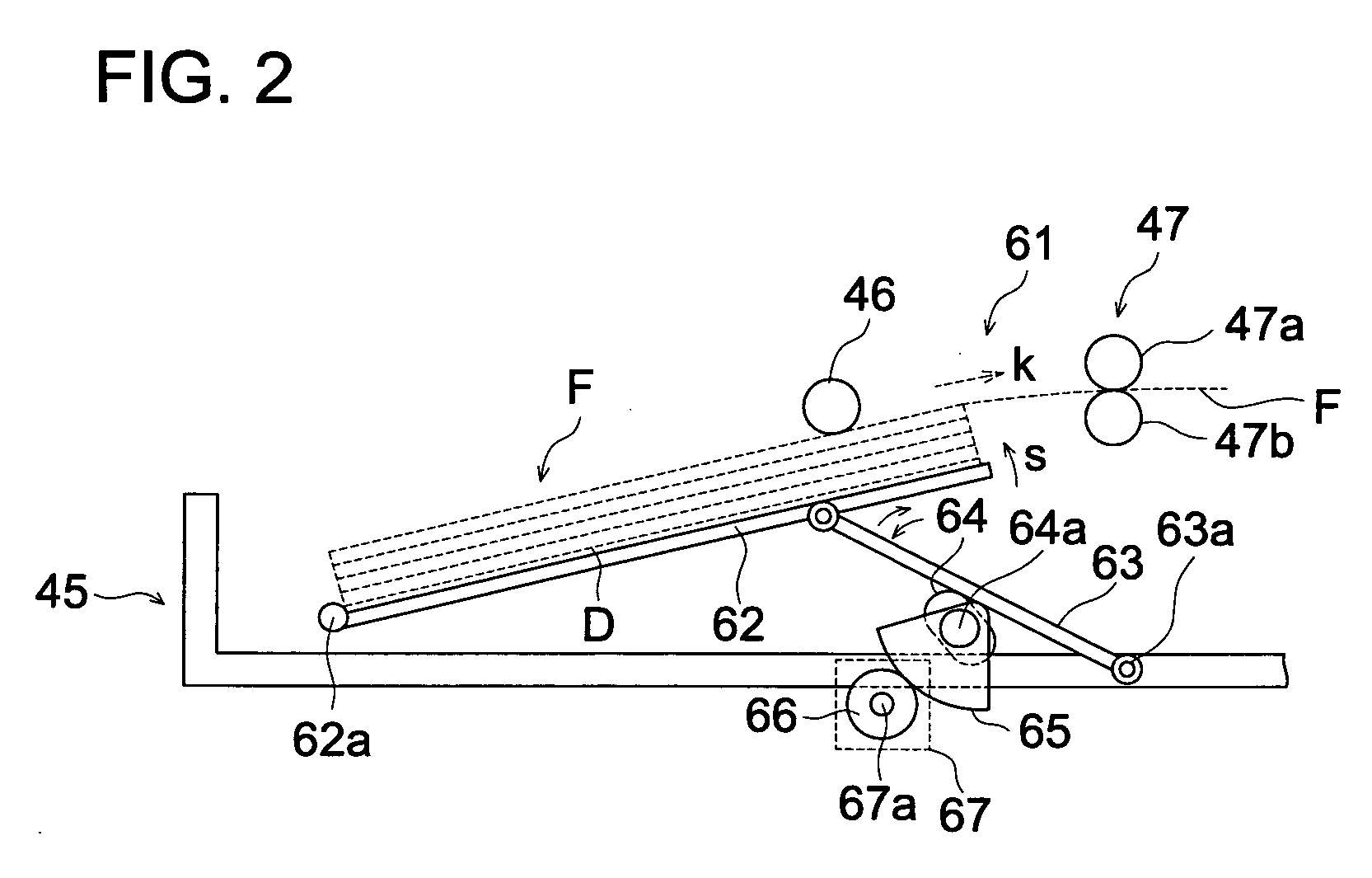

[0070]After feeding out films using the above film as shown in FIG. 1 to FIG. 4, a solid image with a density 2 was formed, developed, and the transmission image scratches were visually measured using a high luminosity X-ray film viewer. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com