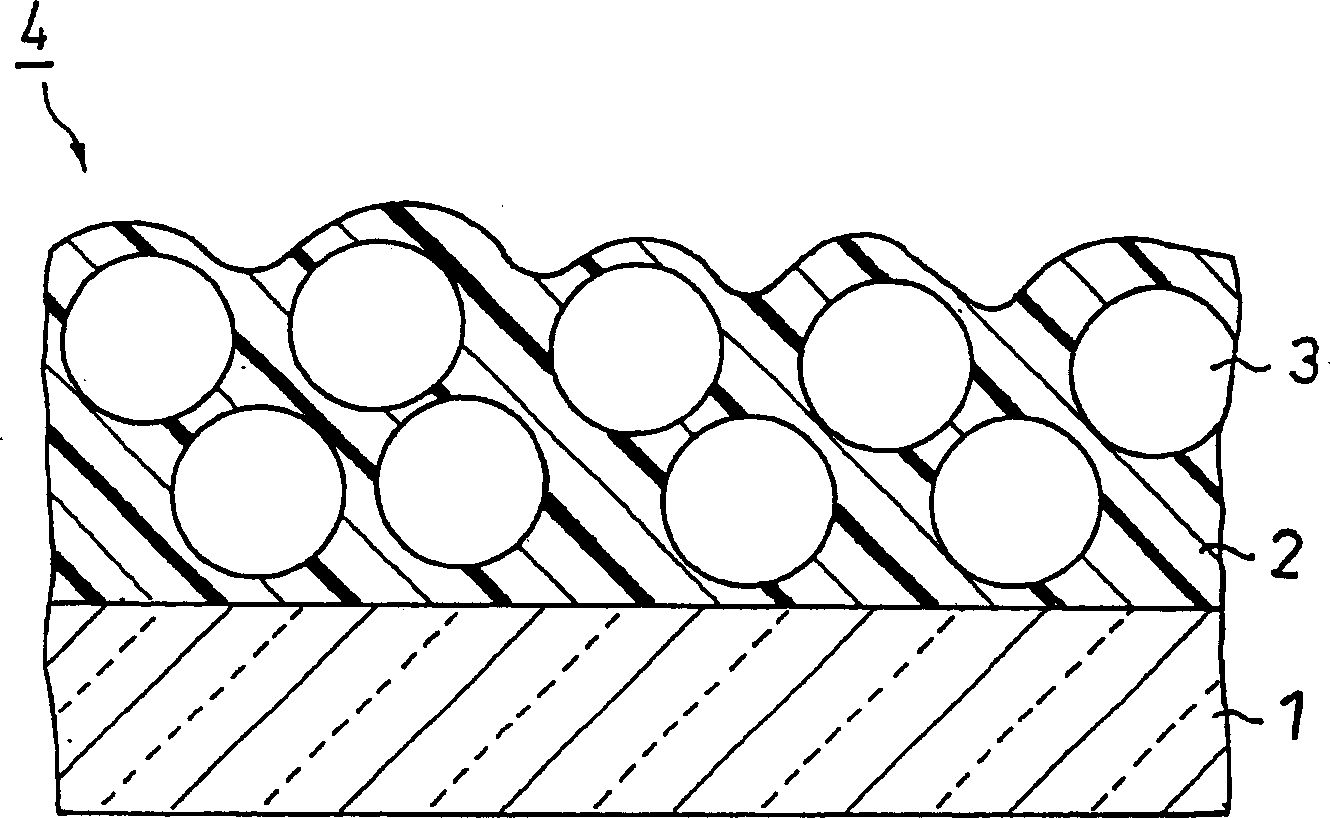

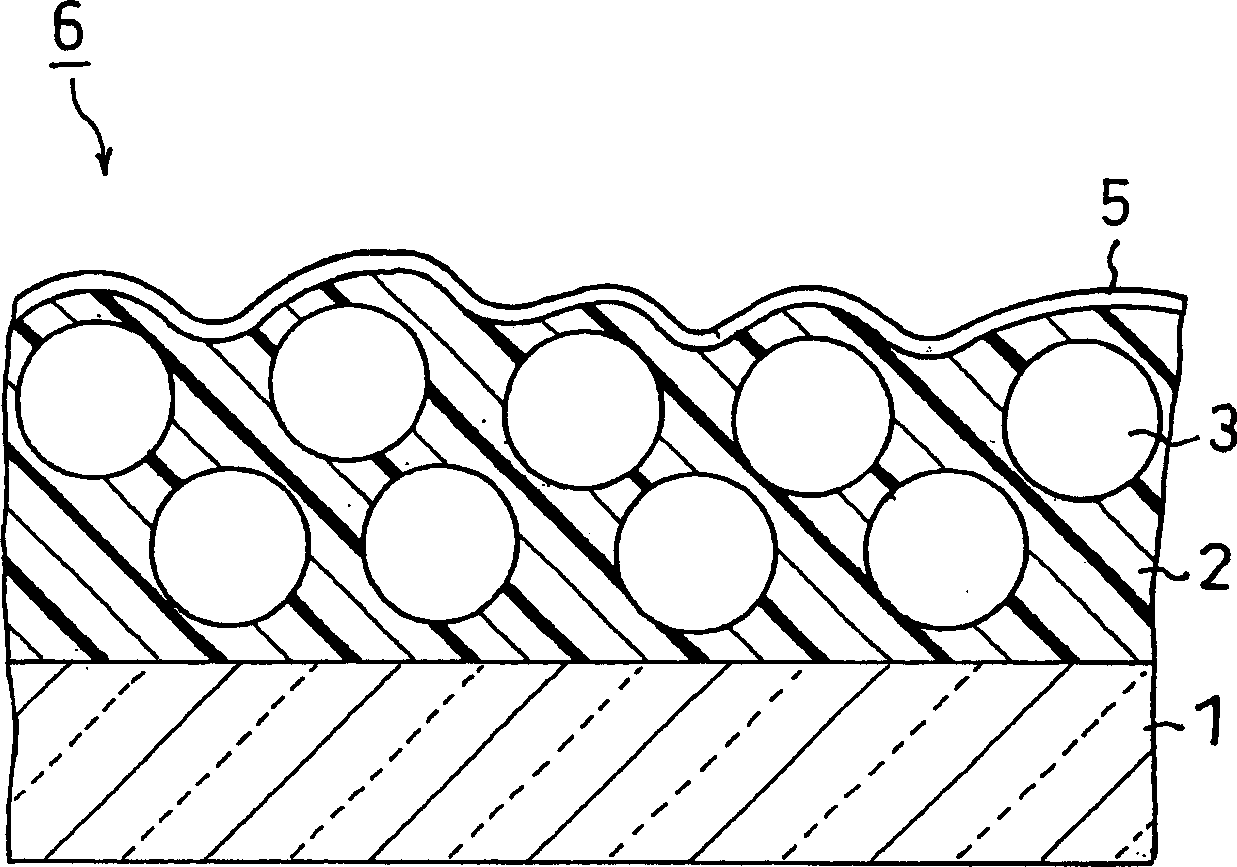

Hard-coated antiglare film and method of manufacturing the same

A manufacturing method and anti-glare technology, applied in the direction of nonlinear optics, optics, instruments, etc., can solve the problem of not being able to obtain sufficient hardness, achieve good anti-glare effect, high hardness, and prevent the reflection of external light, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

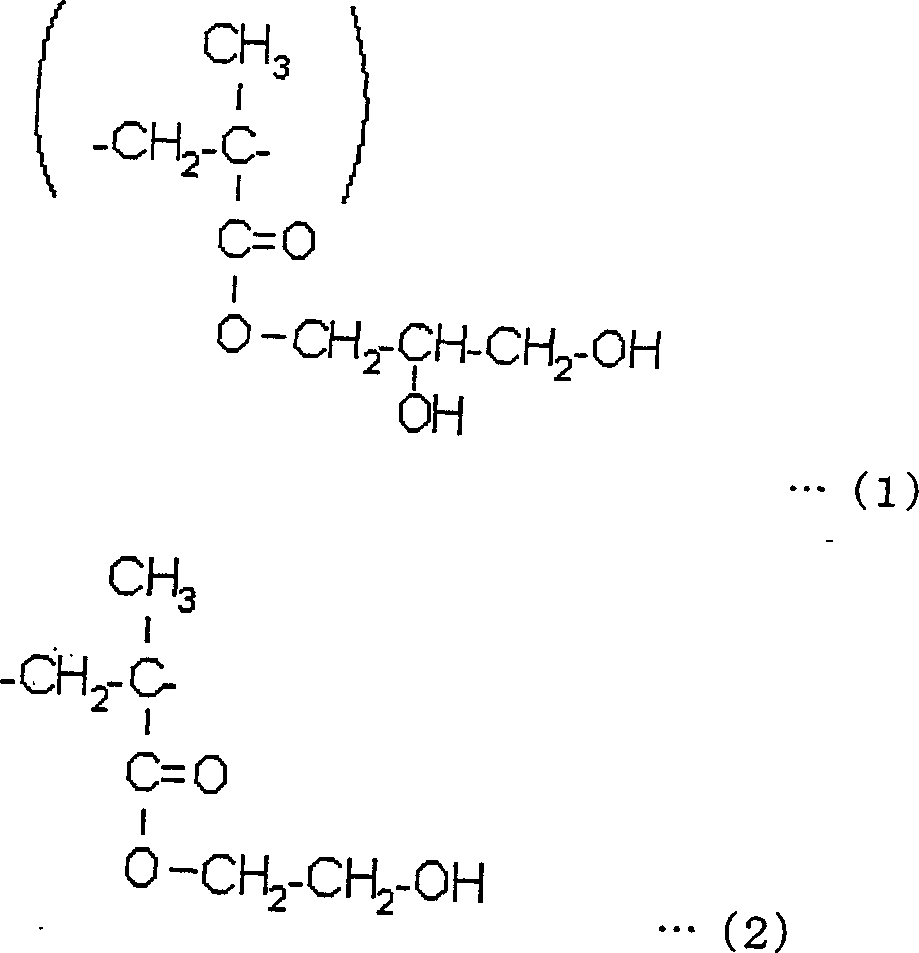

Embodiment 1

[0173] 100 parts of urethane acrylate composed of pentaerythritol-based acrylate and hydrogenated xylene diisocyanate are blended as urethane acrylate (hereinafter, component A), as polyol (meth)acrylate (hereinafter, B) Component) 49 parts of dipentaerythritol hexaacrylate (hereinafter, component B1 (monomer)), 24 parts of pentaerythritol triacrylate (hereinafter, component B2 (monomer)), and pentaerythritol tetraacrylate (hereinafter, component B3 (monomer) )) 41 parts, as a (meth)acrylic polymer having an alkyl group containing 2 or more hydroxyl groups (hereinafter, component C) (methyl) having 2-hydroxyethyl and 2,3-dihydroxypropyl 59 parts of acrylic polymer (manufactured by Dainippon Ink Chemical Industry Co., Ltd., trade name: PC1097). Furthermore, through a mixed solvent with a mixing ratio of butyl acetate and ethyl acetate of 55:45 (the ratio of ethyl acetate to the total solvent is 45%), the PMMA particles with an average particle size of 10 μm relative to the total re...

Embodiment 2

[0176] In this example, except that the addition amount of PMMA particles was changed to 15 parts, the same method as in Example 1 was used to produce an anti-glare hard coating film.

Embodiment 3

[0178] In this example, 30 parts of PMMA particles (refractive index: 1.49) with an average particle diameter of 15 μm were added, and the solid content concentration was changed to 35%. The same method as in Example 1 was used except that Glare hard coating film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com