Synthetic method of parecoxib sodium impurity

A technology for parecoxib sodium and a synthesis method is applied in the field of chemical pharmacy to achieve the effects of cheap raw materials, improved quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

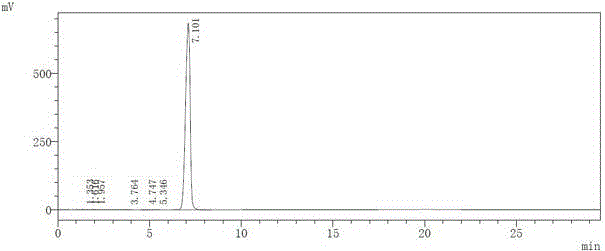

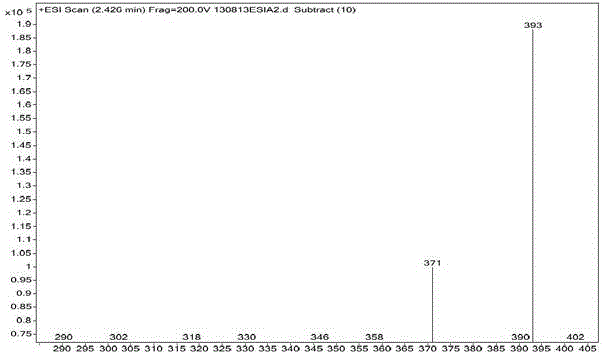

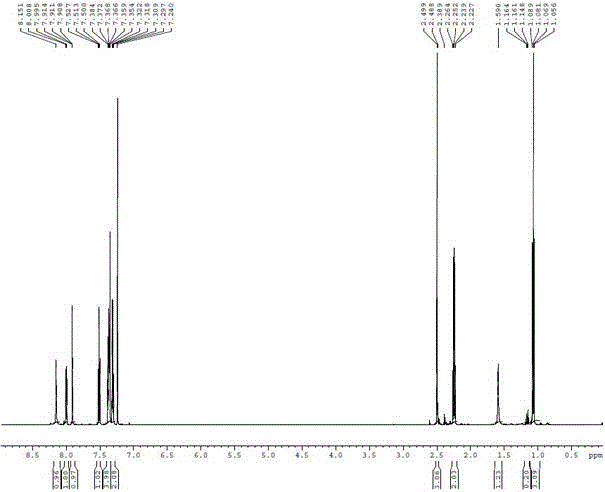

[0021] Embodiment 1: the synthetic method of parecoxib sodium impurity 1 N-[[3-(5-methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl]propionamide

[0022] Add 10g of 5-methyl-3,4-diphenylisoxazole, 7g of zinc chloride, and 20g of chlorosulfonic acid into the reaction flask, and react at 60°C for 2 hours. After the reaction is completed, add dropwise to 100g of ice water, Filtrate, dissolve the filter cake in 10g of ethyl acetate, add 50g of petroleum ether to crystallize, filter, and concentrate the filtrate to dryness under reduced pressure. After the concentration is complete, add 200g of petroleum ether, filter, and dry under normal pressure at 50-60°C for about 8 hours to obtain N- [3-(5-Methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl chloride 5.42 g, yield 38.2%.

[0023] Add 5g of the above N-[3-(5-methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl chloride and 200g of dichloromethane into the reaction flask, after the solid dissolves, add dropwise to 250g of ammonia water , reacted f...

Embodiment 2

[0028] Embodiment 2: the synthetic method of parecoxib sodium impurity 1 N-[[3-(5-methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl]propionamide

[0029] Add 10g of 5-methyl-3,4-diphenylisoxazole, 5g of zinc chloride, and 10g of chlorosulfonic acid into the reaction flask, and react at 60°C for 2 hours. After the reaction is completed, add dropwise to 100g of ice water, Filtrate, dissolve the filter cake in 10g of ethyl acetate, add 50g of petroleum ether to crystallize, filter, and concentrate the filtrate to dryness under reduced pressure. After the concentration is complete, add 200g of petroleum ether, filter, and dry under normal pressure at 50-60°C for about 8 hours to obtain N- [3-(5-Methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl chloride 5.13 g, yield 36.1%.

[0030] Add 5g of the above N-[3-(5-methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl chloride and 200g of dichloromethane into the reaction flask, after the solid dissolves, add dropwise to 200g of ammonia water , reacted f...

Embodiment 3

[0032] Embodiment 3: the synthetic method of parecoxib sodium impurity 1 N-[[3-(5-methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl]propionamide:

[0033] Add 10g of 5-methyl-3,4-diphenylisoxazole, 10g of zinc chloride, and 50g of chlorosulfonic acid into the reaction flask, and react at 60°C for 2 hours. After the reaction is completed, add dropwise to 100g of ice water, Filtrate, dissolve the filter cake in 10g of ethyl acetate, add 50g of petroleum ether to crystallize, filter, and concentrate the filtrate to dryness under reduced pressure. After the concentration is complete, add 200g of petroleum ether, filter, and dry under normal pressure at 50-60°C for about 8 hours to obtain N- [3-(5-Methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl chloride 5.54 g, yield 39.0%.

[0034] Add 5g of the above N-[3-(5-methyl-3-phenyl-4-isoxazolyl)phenyl]sulfonyl chloride and 200g of dichloromethane into the reaction flask, after the solid dissolves, add dropwise to 350g of ammonia water , reacted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com