Extraction composition, extraction system and application thereof

A composition and extraction technology, applied in the directions of lithium compounds, solvent extraction, alkali metal compounds, etc., can solve the problems of long process, complicated operation, insufficient extraction rate and back-extraction performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

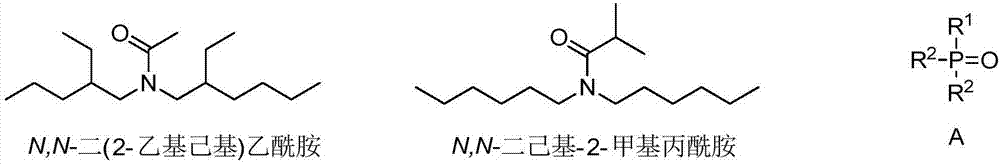

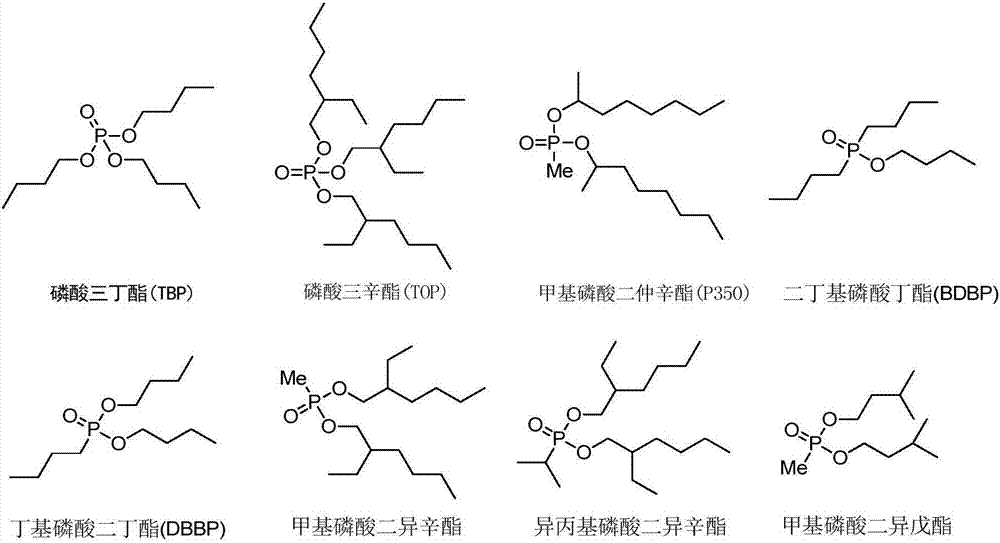

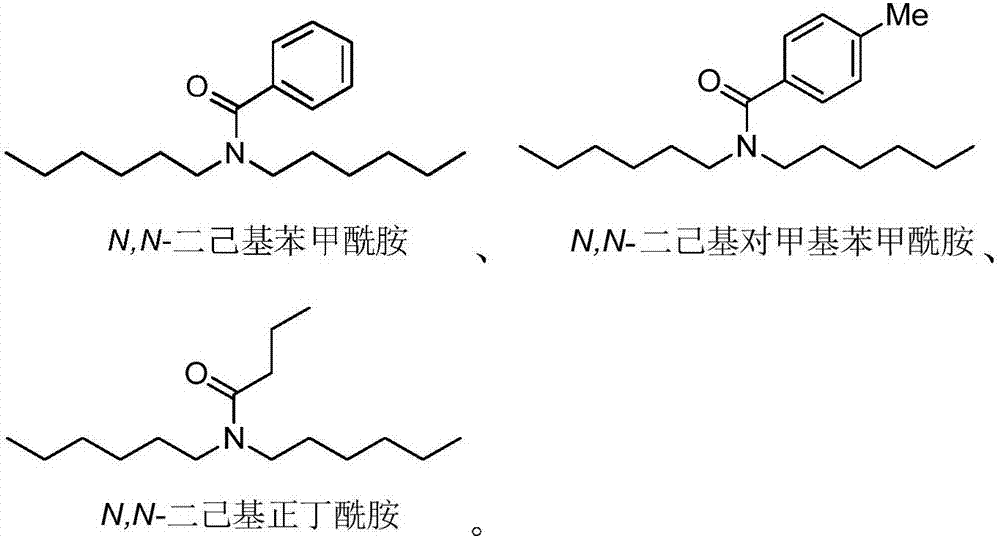

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the extractant involved in the following example is as follows:

[0054] General operation of the experiment: In a 2L three-neck flask equipped with a thermometer, a constant pressure dropping funnel, and a mechanical stirrer, add 1mol of dialkylamine, 400mL of dichloromethane, and 153mL (1.1mol) of triethylamine, and turn on the stirring. And let the system cool down to 0°C, at the same time, put 1.05mol of acid chloride and about 200mL of methylene chloride solution in the dropping funnel and start to add dropwise, keeping the system temperature not exceeding 15°C, and the dropwise addition is completed in about 30 minutes. Remove the ice bath and react overnight at room temperature. Add an equal volume of water to dissolve the resulting solid, separate the layers in a separatory funnel, wash the organic phase with dilute hydrochloric acid and saturated brine, and dry with anhydrous sodium sulfate. After removing the solvent, distill under re...

Embodiment 1-9

[0095] Organic phase: extractant + neutral phosphine oxide + diluent;

[0096] Water phase: Lithium-containing brine;

[0097] Compared (O:A): refers to the volume ratio of organic phase and aqueous phase;

[0098] The specific operation is as follows:

[0099] A certain amount of FeCl 3 (co-extraction agent) is added in lithium-containing brine, shakes to dissolve it, then adds organic phase, oscillates to balance (oscillation time is 5 minutes to 30 minutes), stands and separates, and obtains a balanced water phase and an organic phase containing lithium ions. Mutually. Determination of Li in the equilibrium aqueous phase and organic phase, respectively + 、Na + 、K + and Mg 2+ Concentration, from which to calculate the extraction rate of Li, Li + , Mg 2+ 、Na + and K + The distribution ratio of Li / Mg, Li / Na, and Li / K separation coefficients.

Embodiment 10

[0101] Organic phase: extractant + neutral phosphine oxide;

[0102] Water phase: Lithium-containing brine;

[0103] Compared (O:A): refers to the volume ratio of organic phase and aqueous phase;

[0104] The specific operation is as follows:

[0105] A certain amount of FeCl 3 (Co-extraction agent) was added in the organic phase, then added to the water phase, oscillating to balance (the oscillating time was 30 minutes), and standing to separate layers to obtain a balanced water phase and an organic phase loaded with lithium ions. Determination of Li in the equilibrium aqueous phase and organic phase, respectively + 、Na + 、K + and Mg 2+ Concentration, from which to calculate the extraction rate of Li, Li + , Mg 2+ 、Na + and K + The distribution ratio of Li / Mg, Li / Na, and Li / K separation coefficients.

[0106] The lithium-containing brine parameters in Examples 1-10 are shown in Table 1:

[0107] Table 1. Each component and content (mol / L) in lithium-containing bri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com