Salt-tolerant resistance-reducing agent applied for shale gas reservoir

A shale gas reservoir and drag-reducing agent technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems not mentioned, achieve good salt tolerance, and overcome the effect of insufficient salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

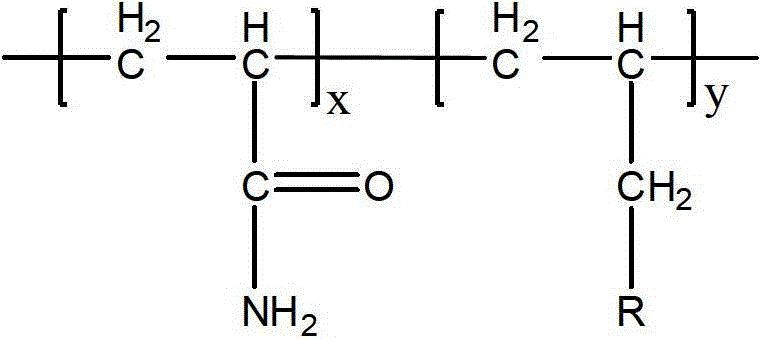

Method used

Image

Examples

Embodiment 1

[0018] Take 500g of the flowback liquid (the main ion content in the flowback liquid is shown in Table 1) and place it in a mixer with a volume of 1000ml, and slowly add 4.875g of the drag reducing agent (the mass percentage concentration of the drag reducing agent is 0.975%), Among them, the drag reducing agent is a binary copolymer composed of 70% acrylamide units and 30% acryltrimethylammonium chloride units, with a molecular weight of 1.6×10 6 , stirred for 10 minutes, and made into a uniform solution. The measured kinematic viscosity of the solution was 1.7mPa.s, and the resistance reduction rate was 68%.

[0019] Table 1 Main ion content in flowback liquid

[0020] Ca 2+ (mg / L)

Embodiment 2

[0022] Take 500g of the flowback liquid (the main ion content in the flowback liquid is shown in Table 2) and place it in a mixer with a volume of 1000ml, slowly add 0.375g of the drag reducer (the mass percentage concentration of the drag reducer is 0.075%), Among them, the drag reducing agent is a binary copolymer composed of 70% acrylamide units and 30% acryltrimethylammonium chloride units, with a molecular weight of 1.6×10 6 , stirred for 10 minutes, and made into a uniform solution. The kinematic viscosity of the solution was measured to be 1.7mPa.s, and the resistance reduction rate was 67%.

[0023] Table 2 Contents of main ions in flowback liquid

[0024] Ca 2+ (mg / L)

Embodiment 3

[0026] Take 500g of the flowback liquid (the content of main ions in the flowback liquid is shown in Table 3) and place it in a mixer with a volume of 1000ml, and slowly add 0.25g of the drag reducing agent (the mass percentage concentration of the drag reducing agent is 0.05%), Among them, the drag reducing agent is a binary copolymer composed of 75% acrylamide units and 25% acrylamidopropyltrimethylammonium chloride units, and its molecular weight is 1.7×10 6 , stirred for 10 minutes, and made into a uniform solution. The kinematic viscosity of the solution was measured to be 1.7mPa.s, and the resistance reduction rate was 66%.

[0027] Table 3 Contents of main ions in flowback liquid

[0028] Ca 2+ (mg / L)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com