Patents

Literature

45 results about "Contact activation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Contact activation pathway. The other pathway that leads to thrombin formation is by the intrinsic pathway, also termed the contact activation pathway; the name derived from its intriguing initiation mechanism where factor XII undergoes auto-activation triggered by the contact with a surface interface.

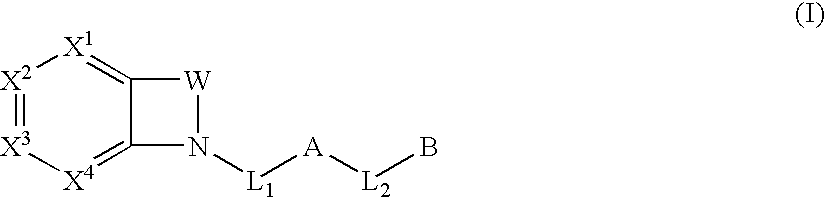

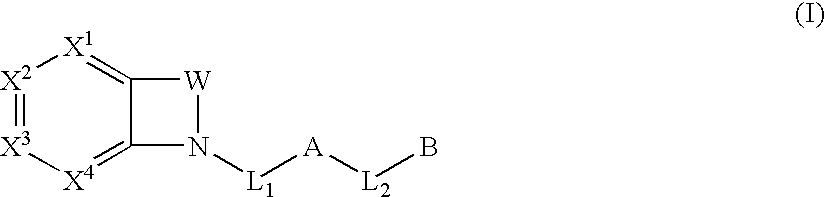

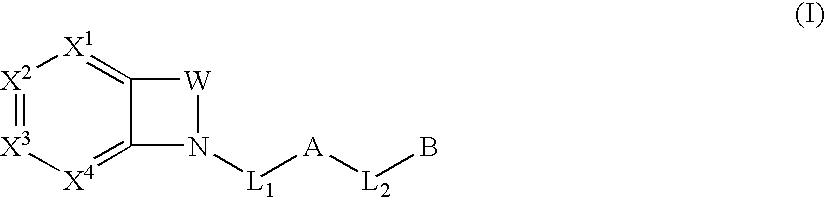

Biarylmethyl indolines and indoles as antithromboembolic agents

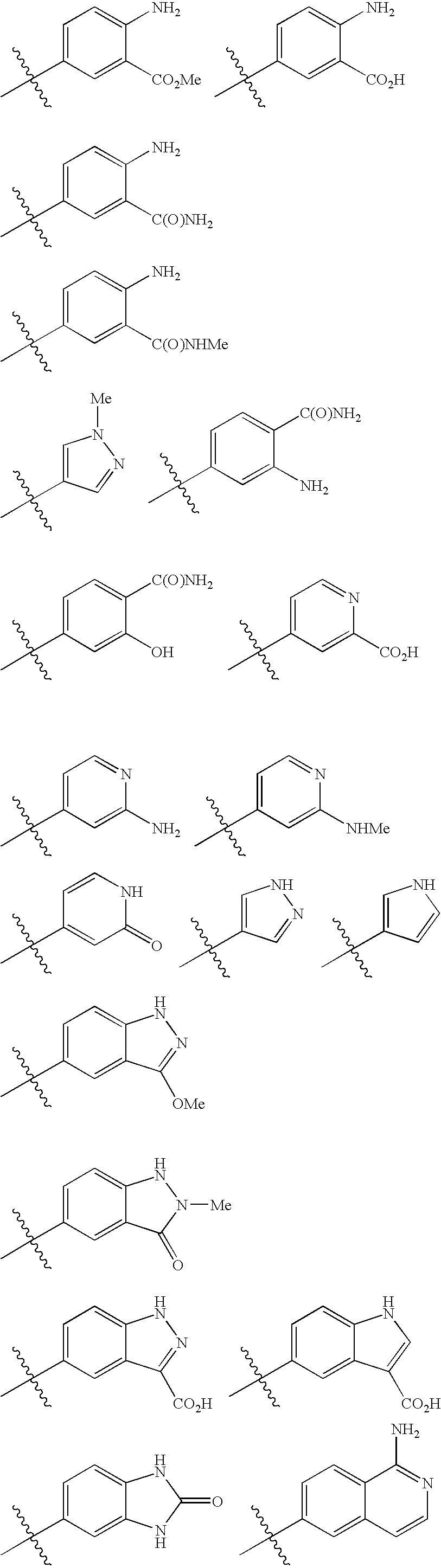

The present invention provides compounds of Formula (I):or a stereoisomer or pharmaceutically acceptable salt or hydrate form thereof, wherein the variables A, B, L1, L2, X1, X2, X3, X4 and W are as defined herein. The compounds of Formula (I) are useful as selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

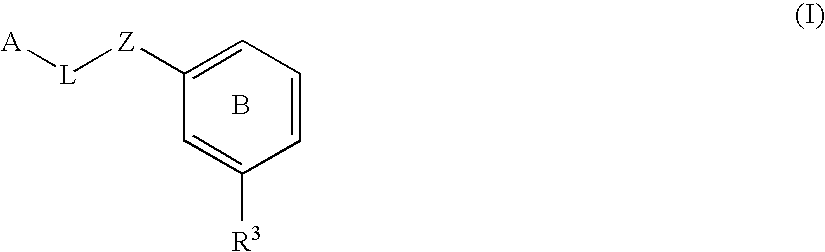

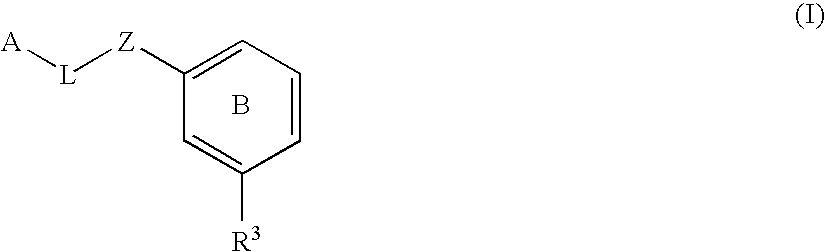

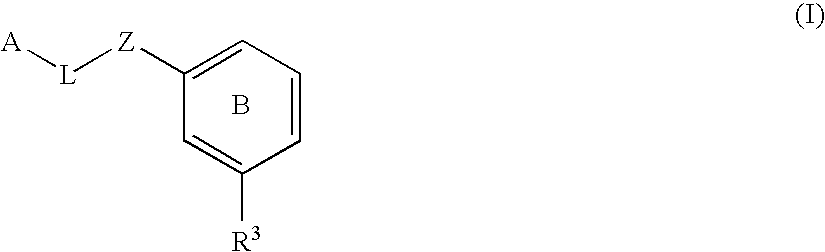

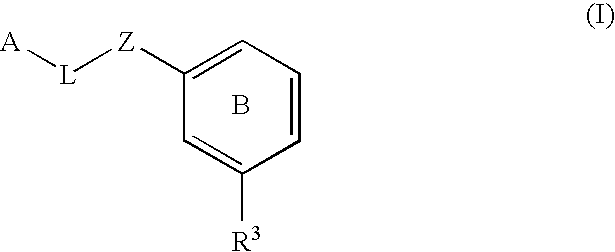

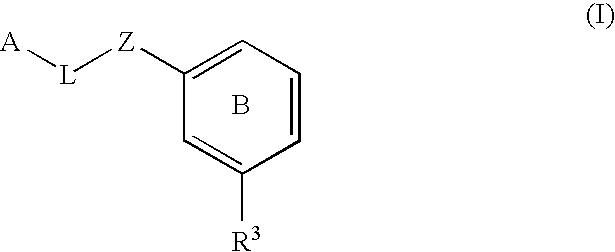

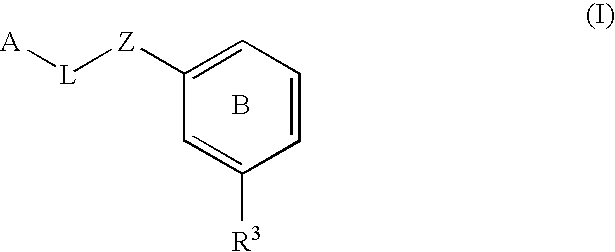

Substituted biaryl compounds as factor XIa inhibitors

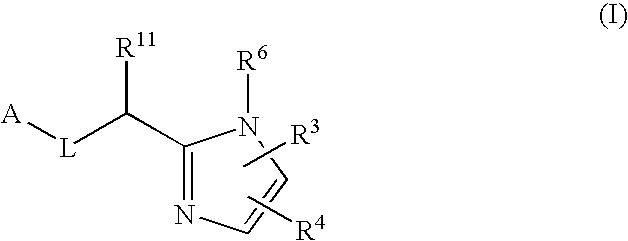

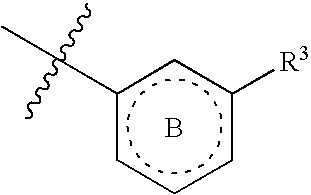

The present invention provides compounds of Formula (I): or a stereoisomer, tautomer, pharmaceutically acceptable salt or solvate form thereof, wherein the variables A, L, Z, R3, and ring B are as defined herein. The compounds of Formula (I) are useful as selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

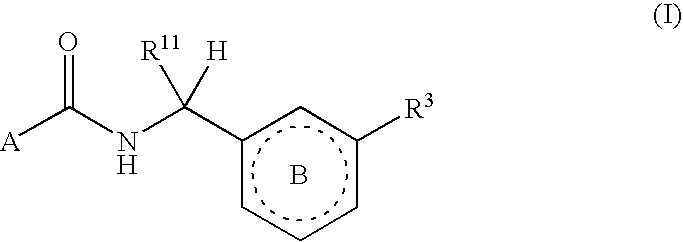

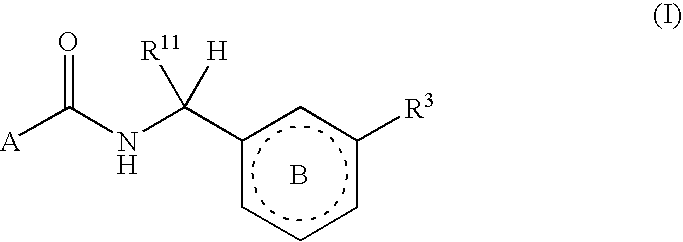

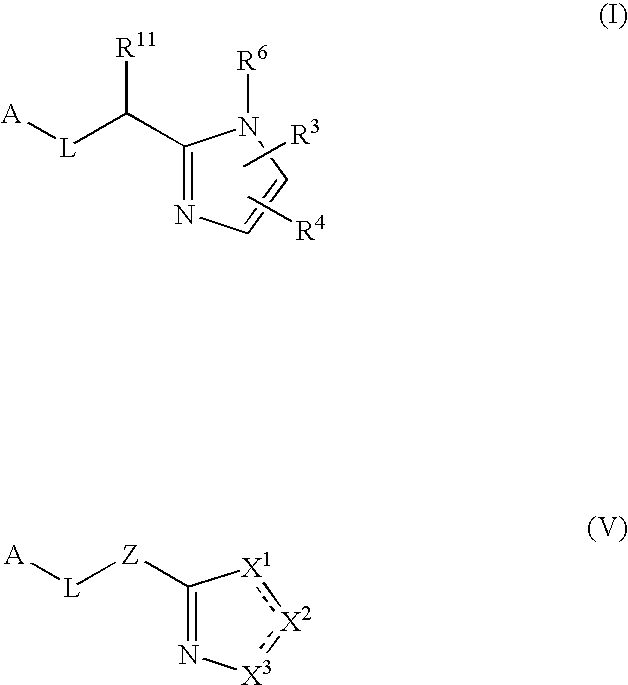

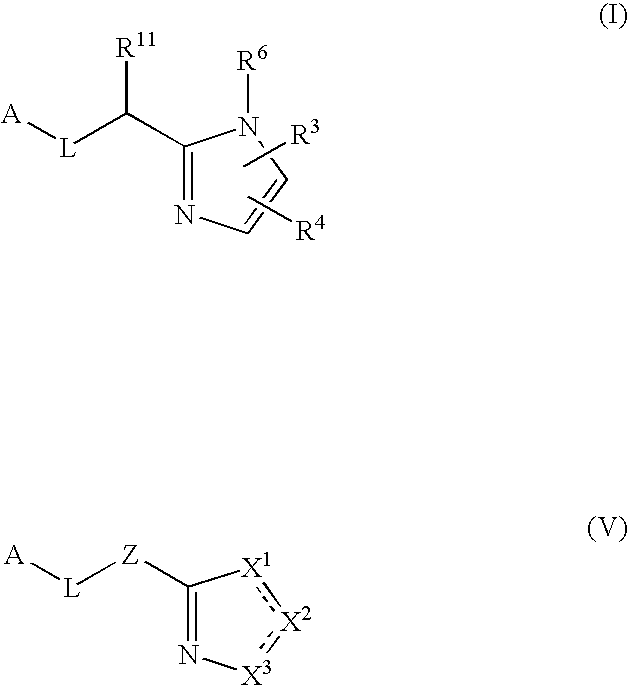

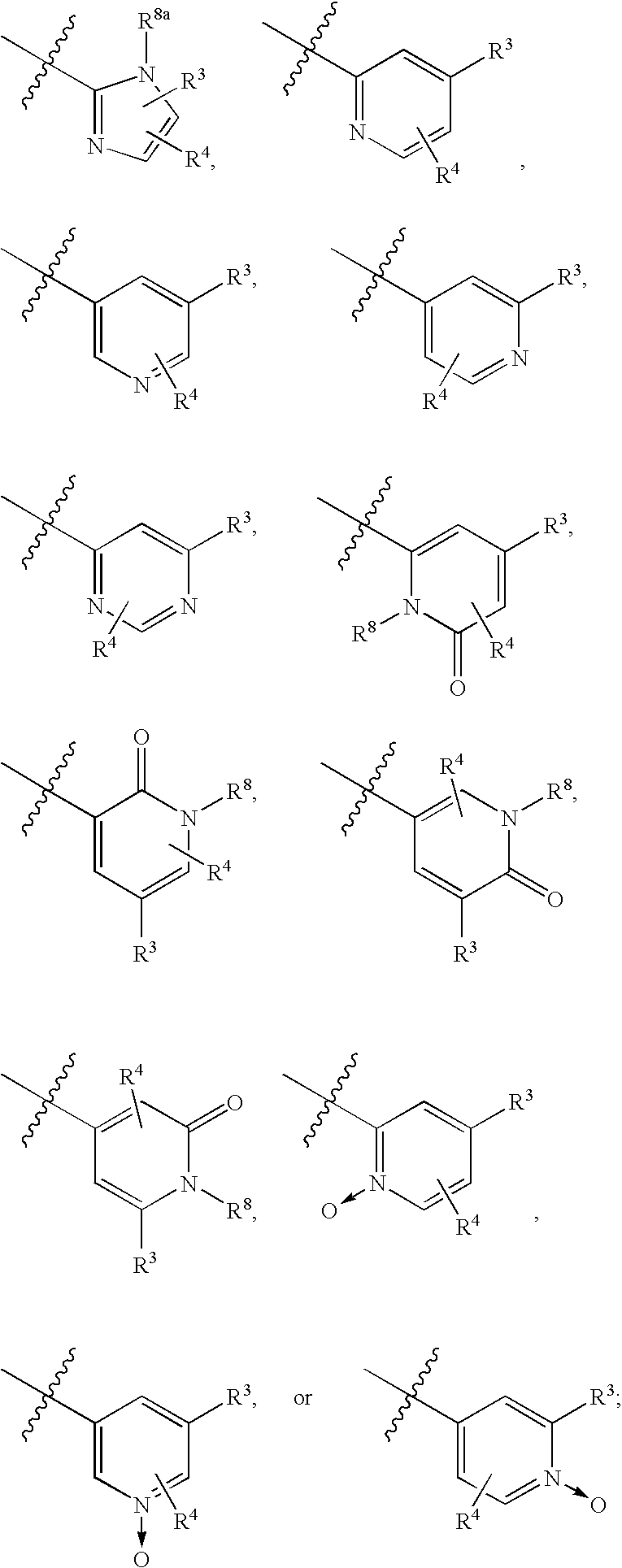

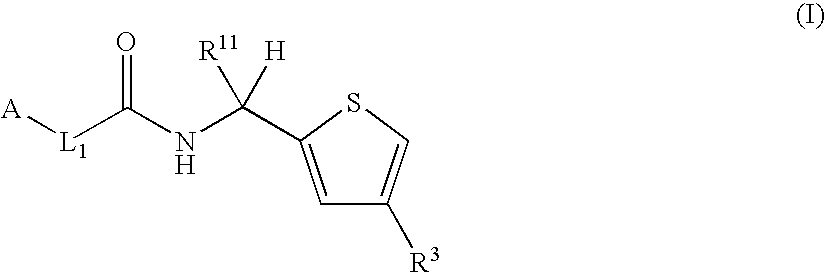

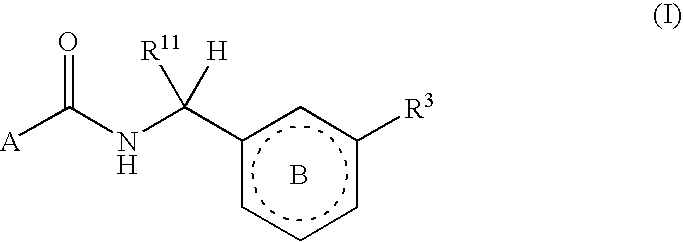

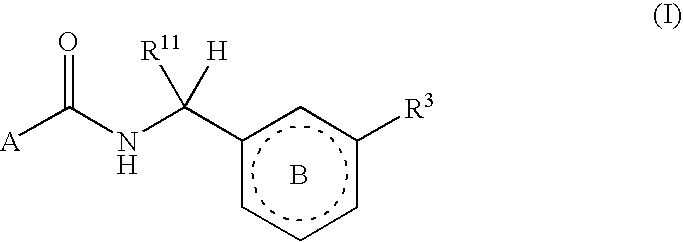

Six-membered heterocycles useful as serine protease inhibitors

The present invention provides compounds of Formula (I):or a stereoisomer, tautomer, pharmaceutically acceptable salt or solvate form thereof, wherein the variables A, B, R3 and R11 are as defined herein. The compounds of Formula (I) are useful as selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors or dual inhibitors of fXIa and plasma kallikrein. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

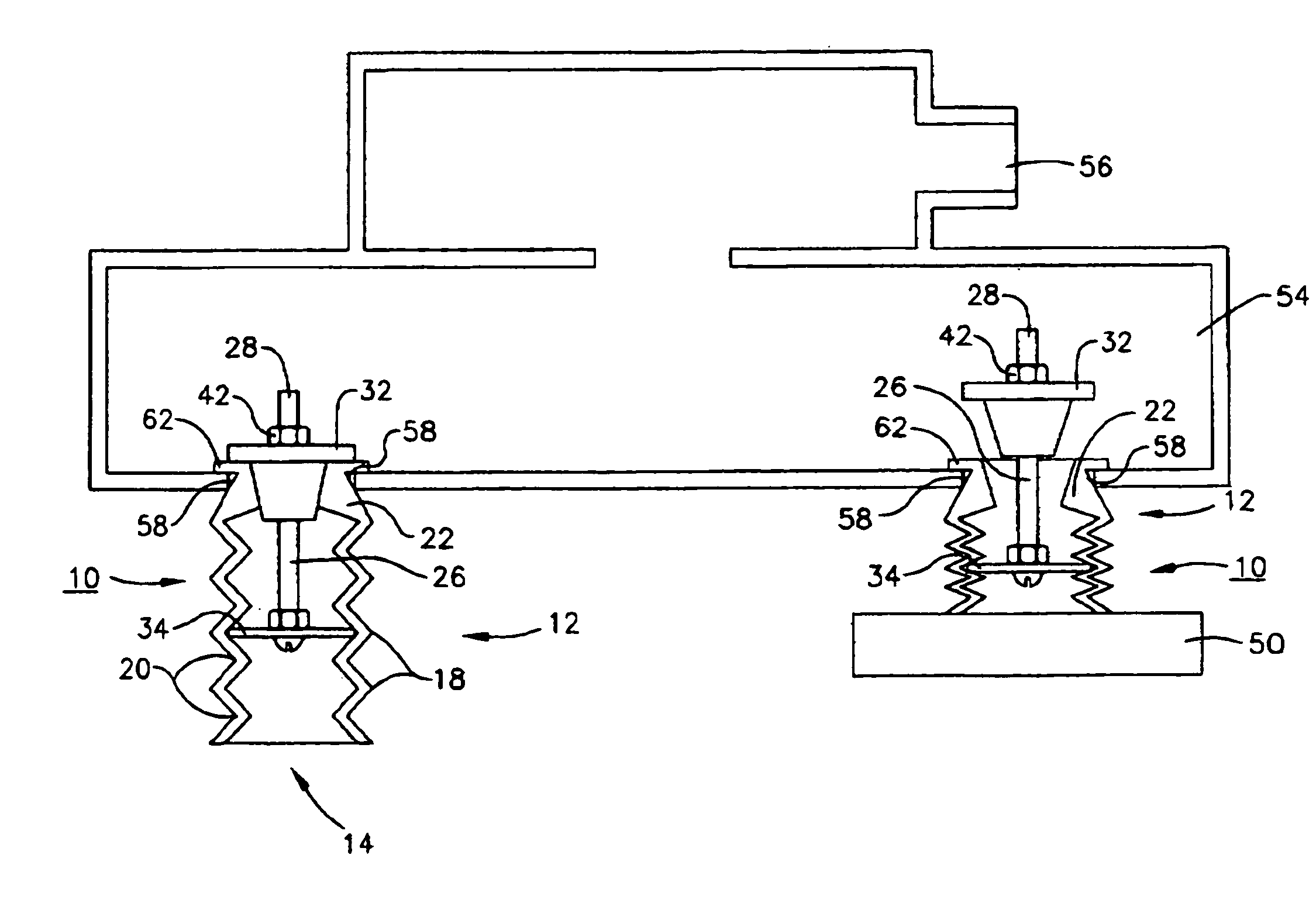

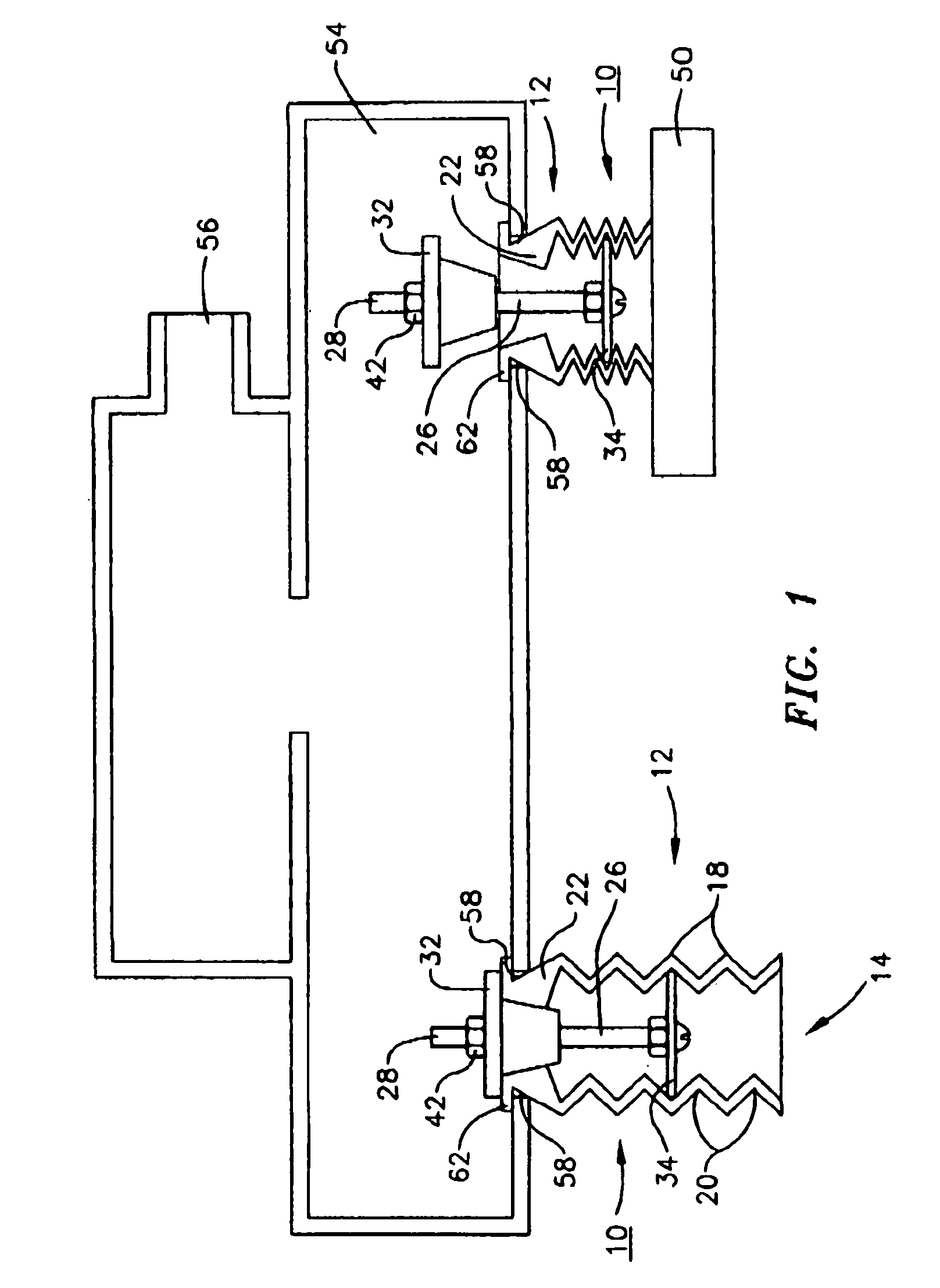

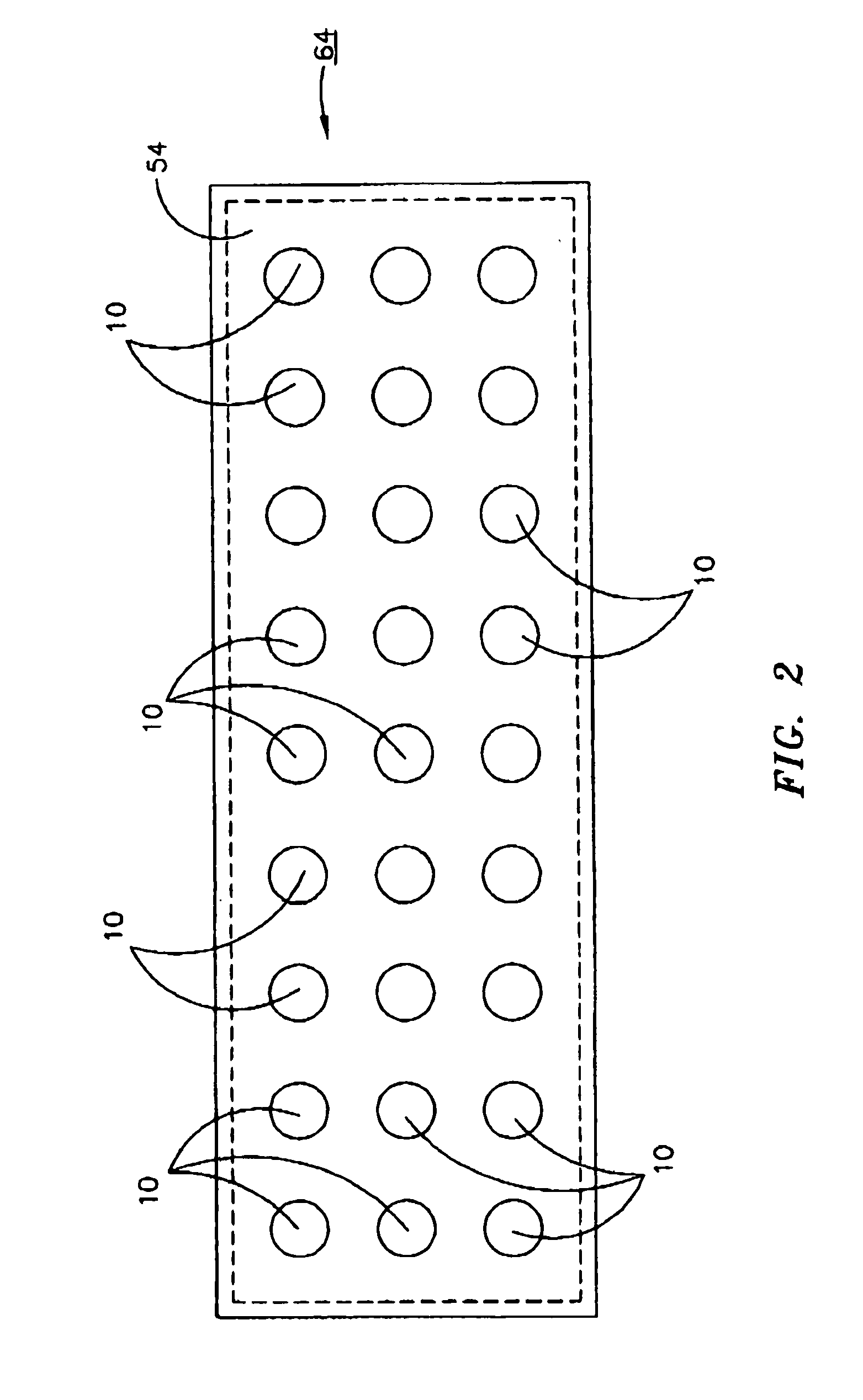

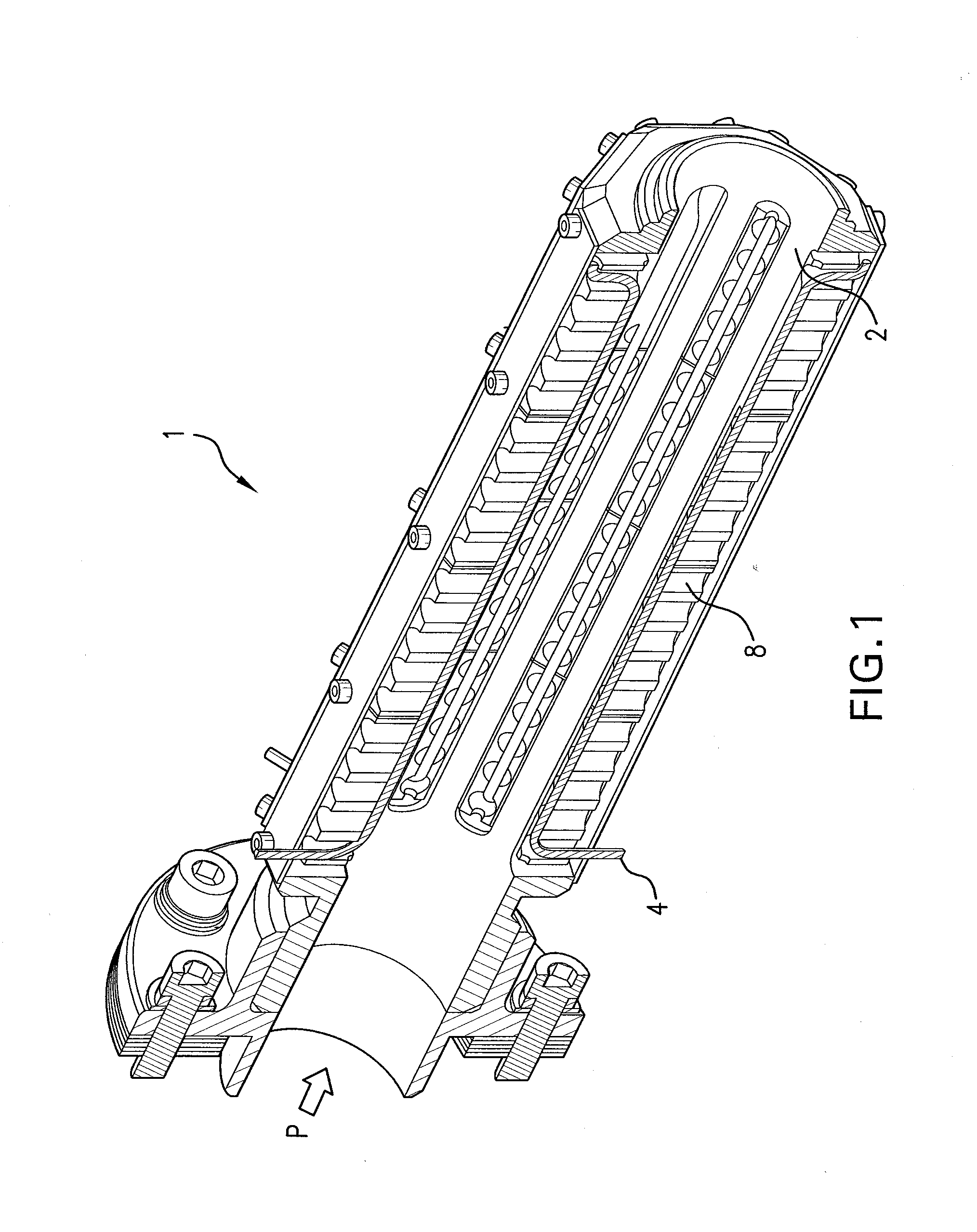

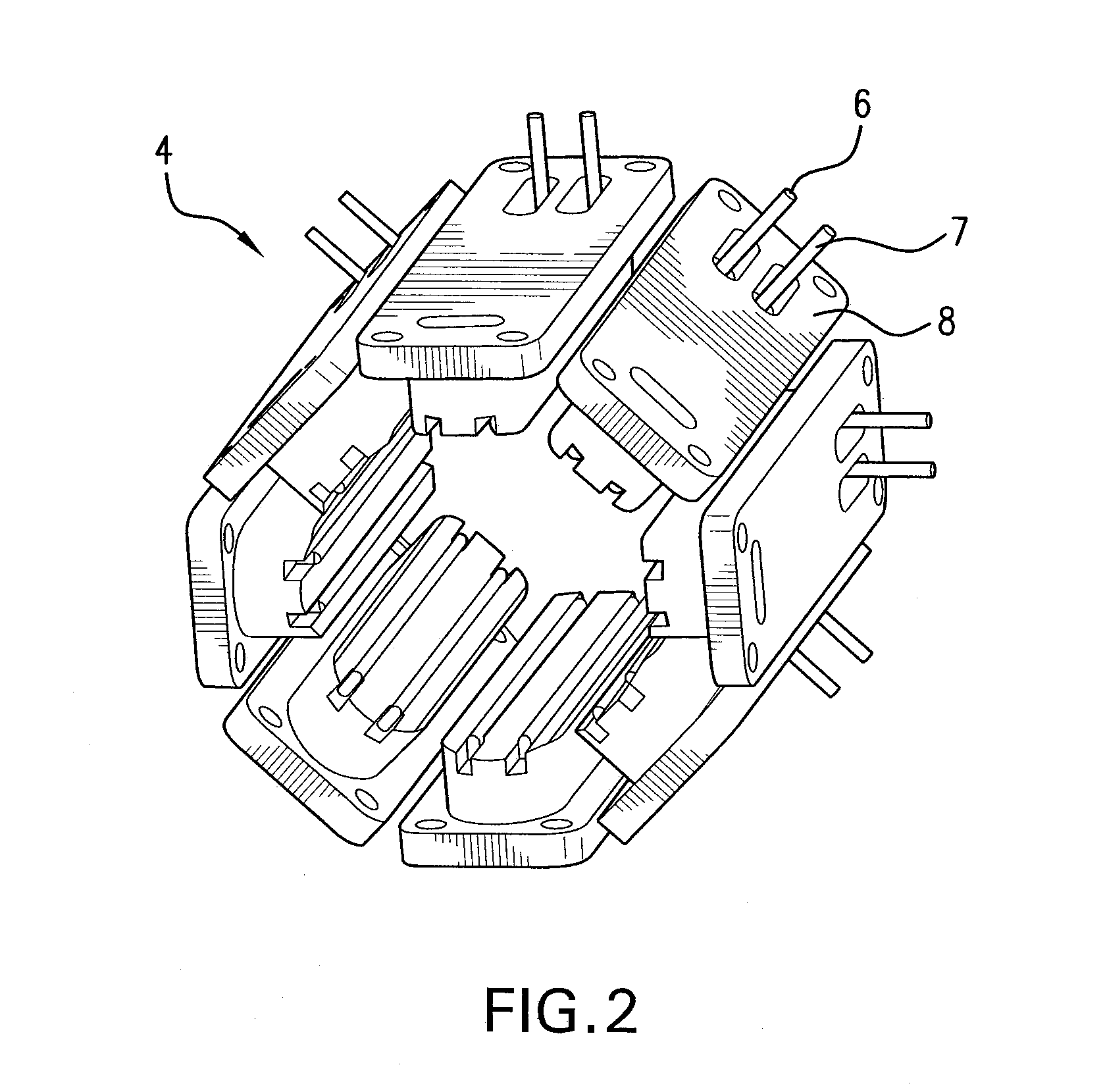

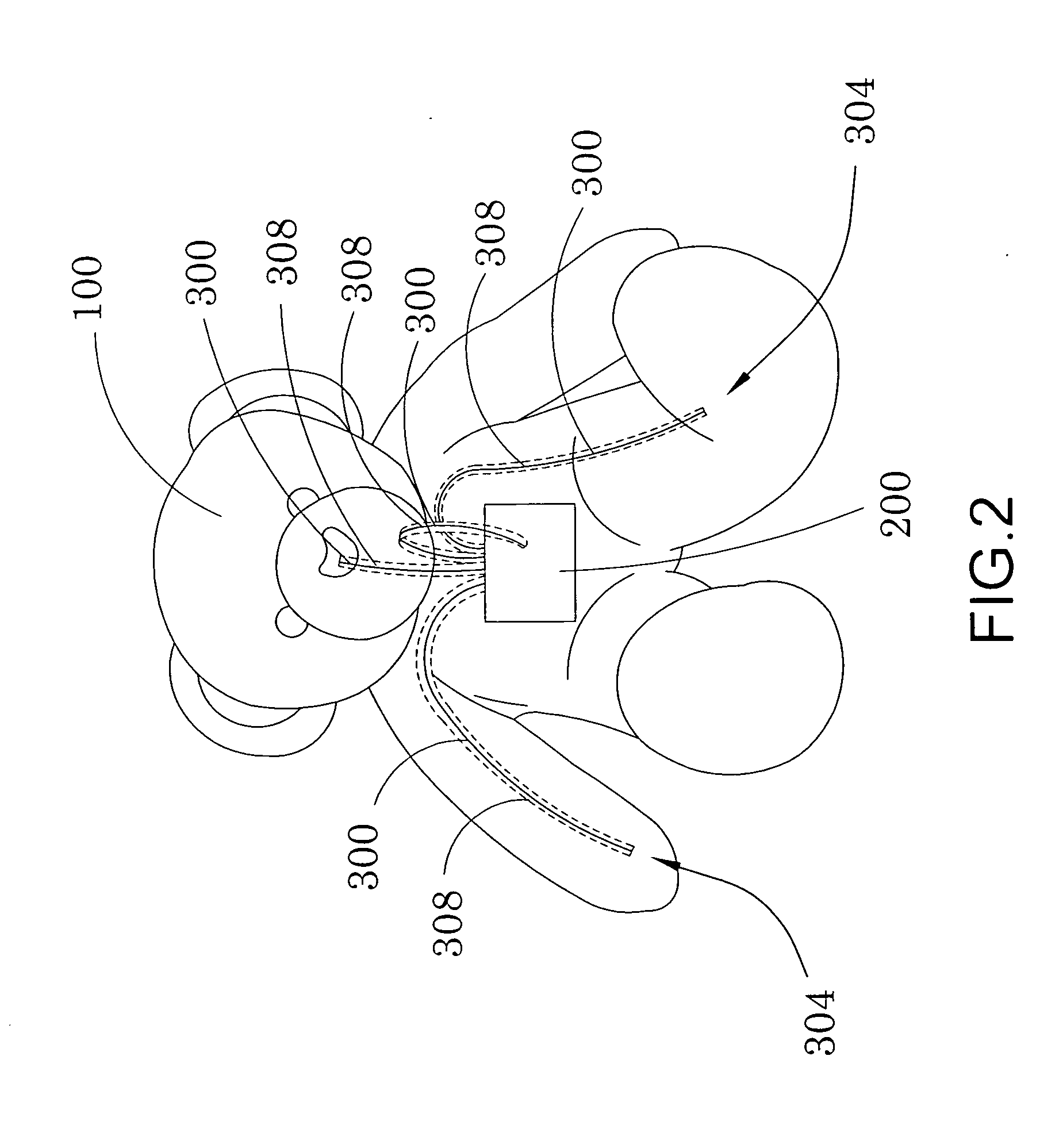

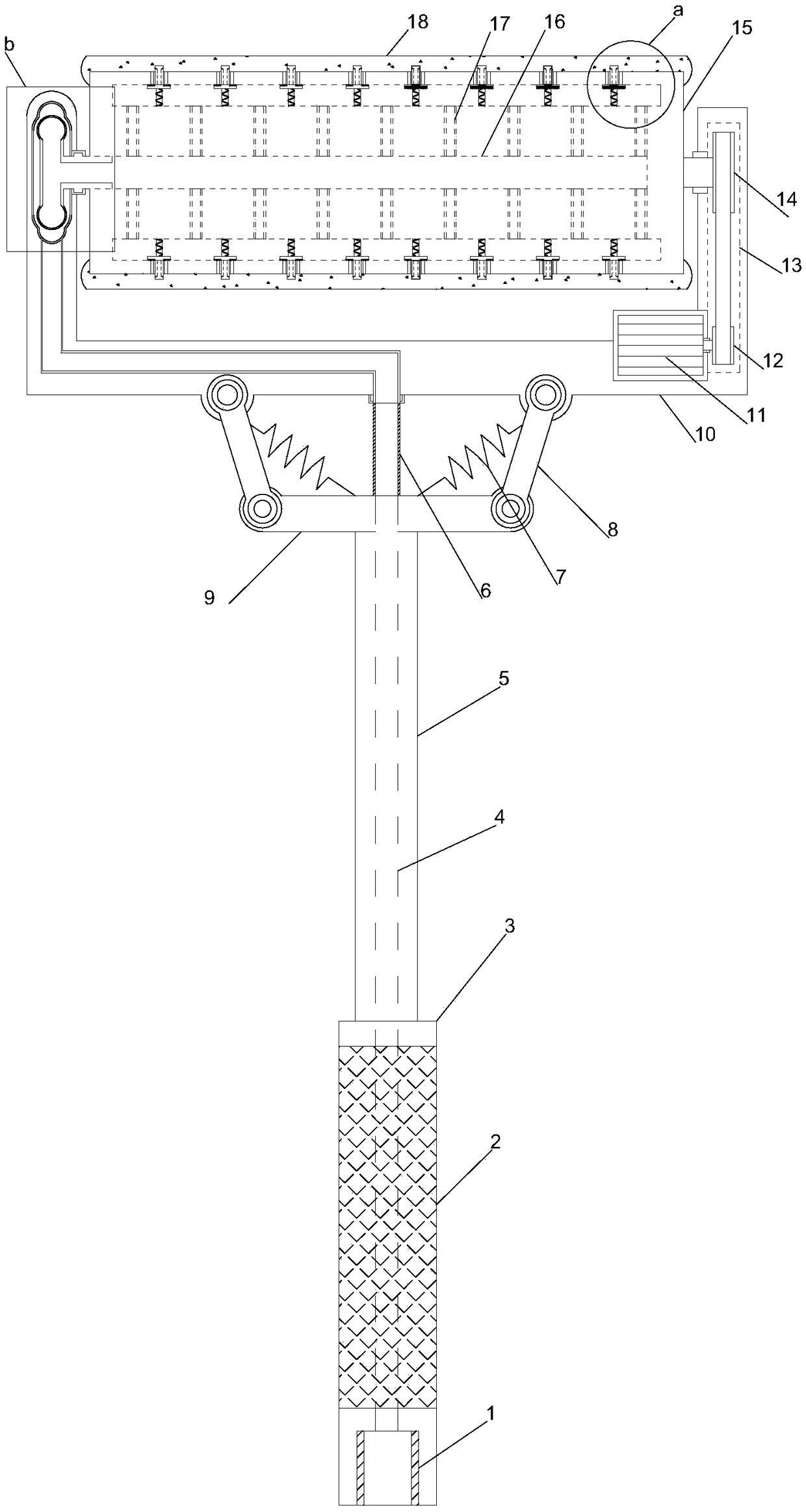

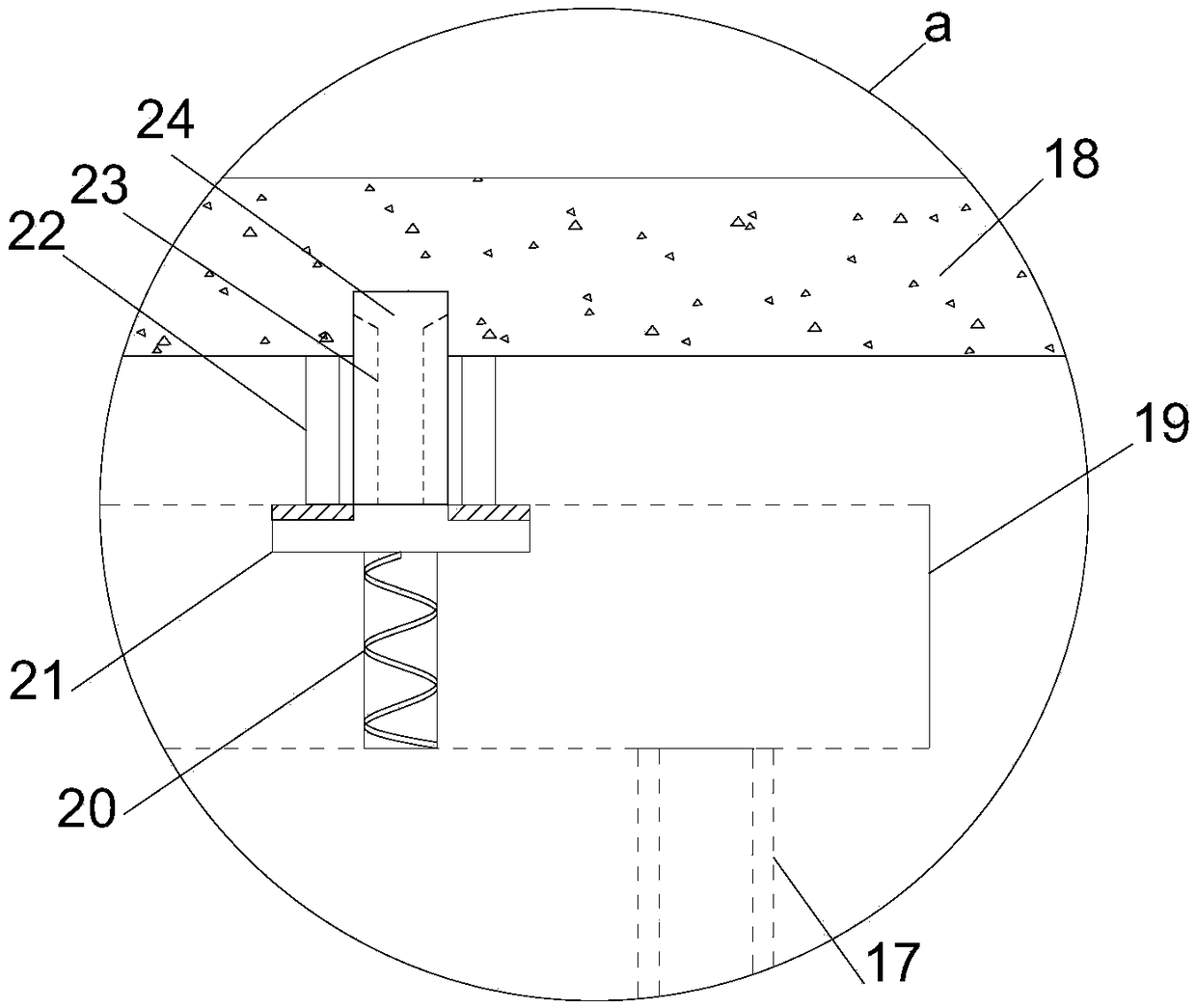

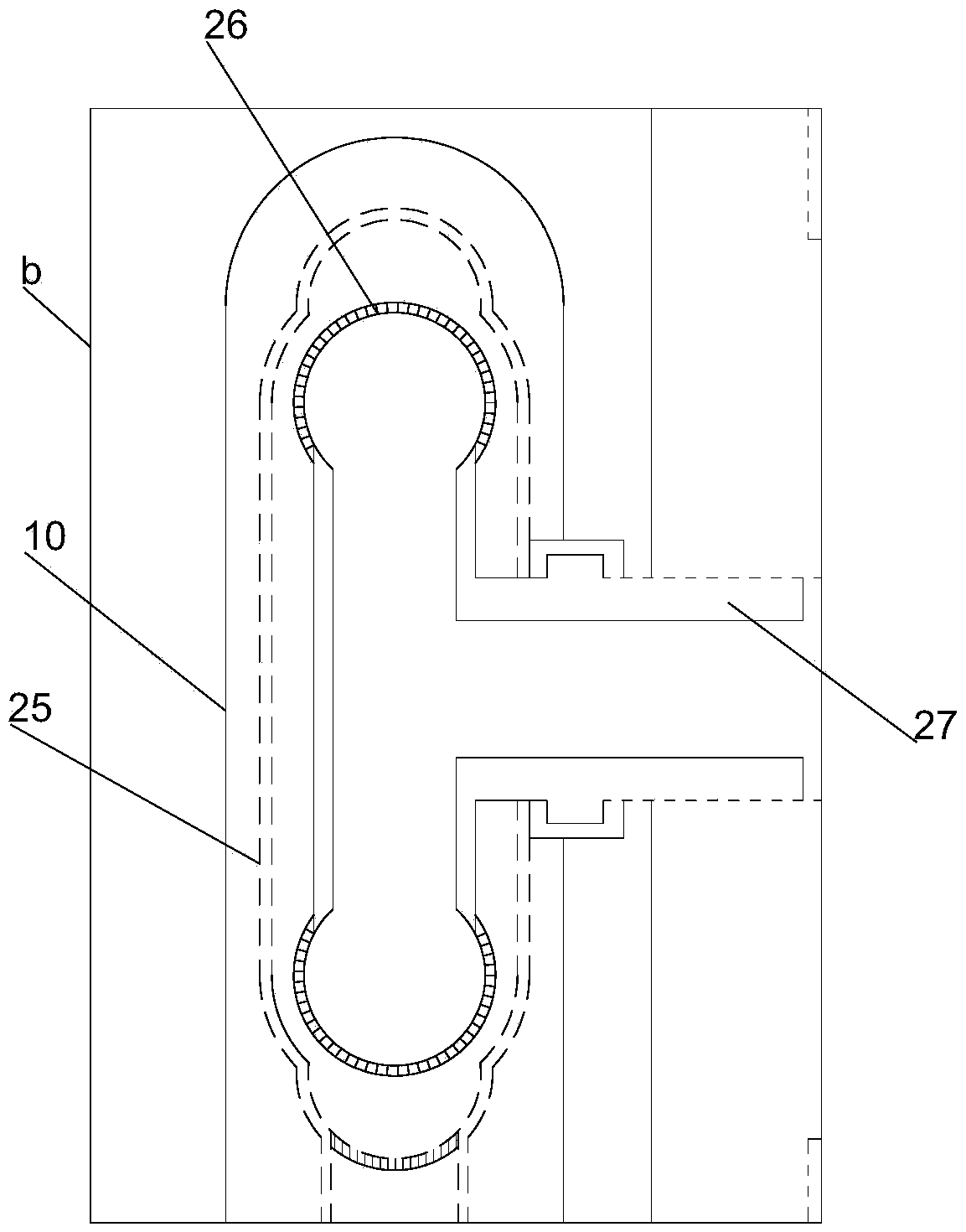

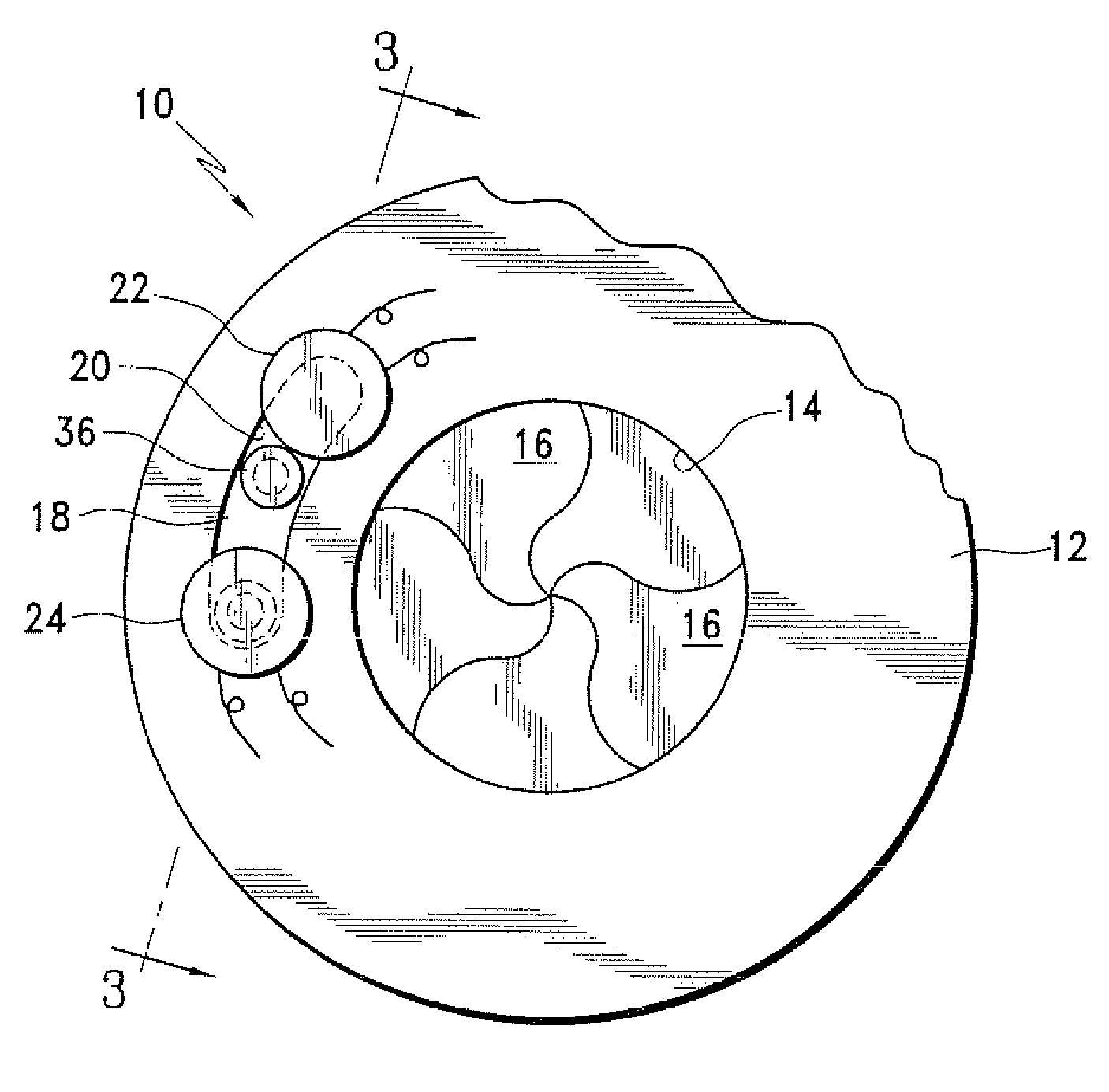

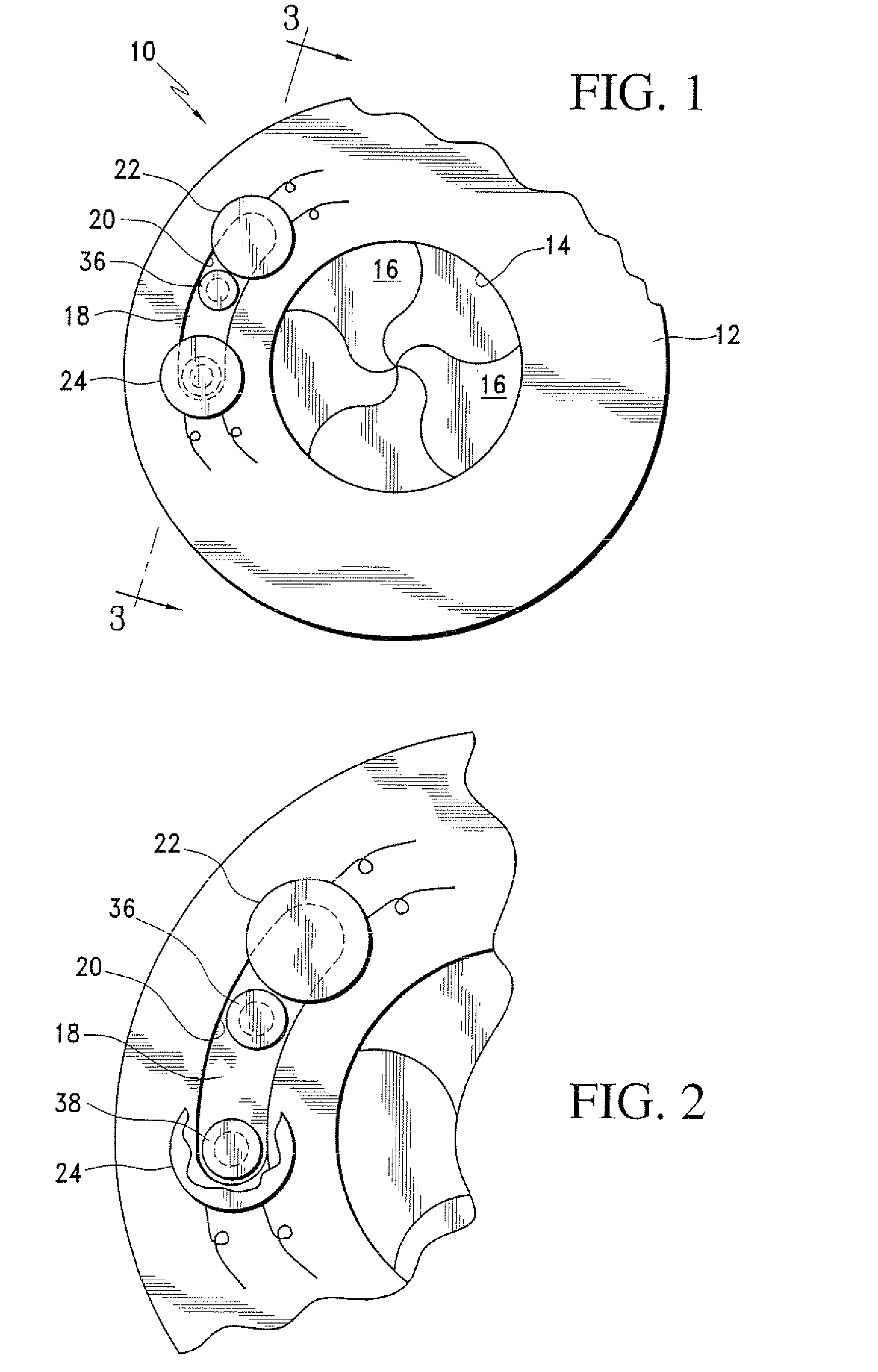

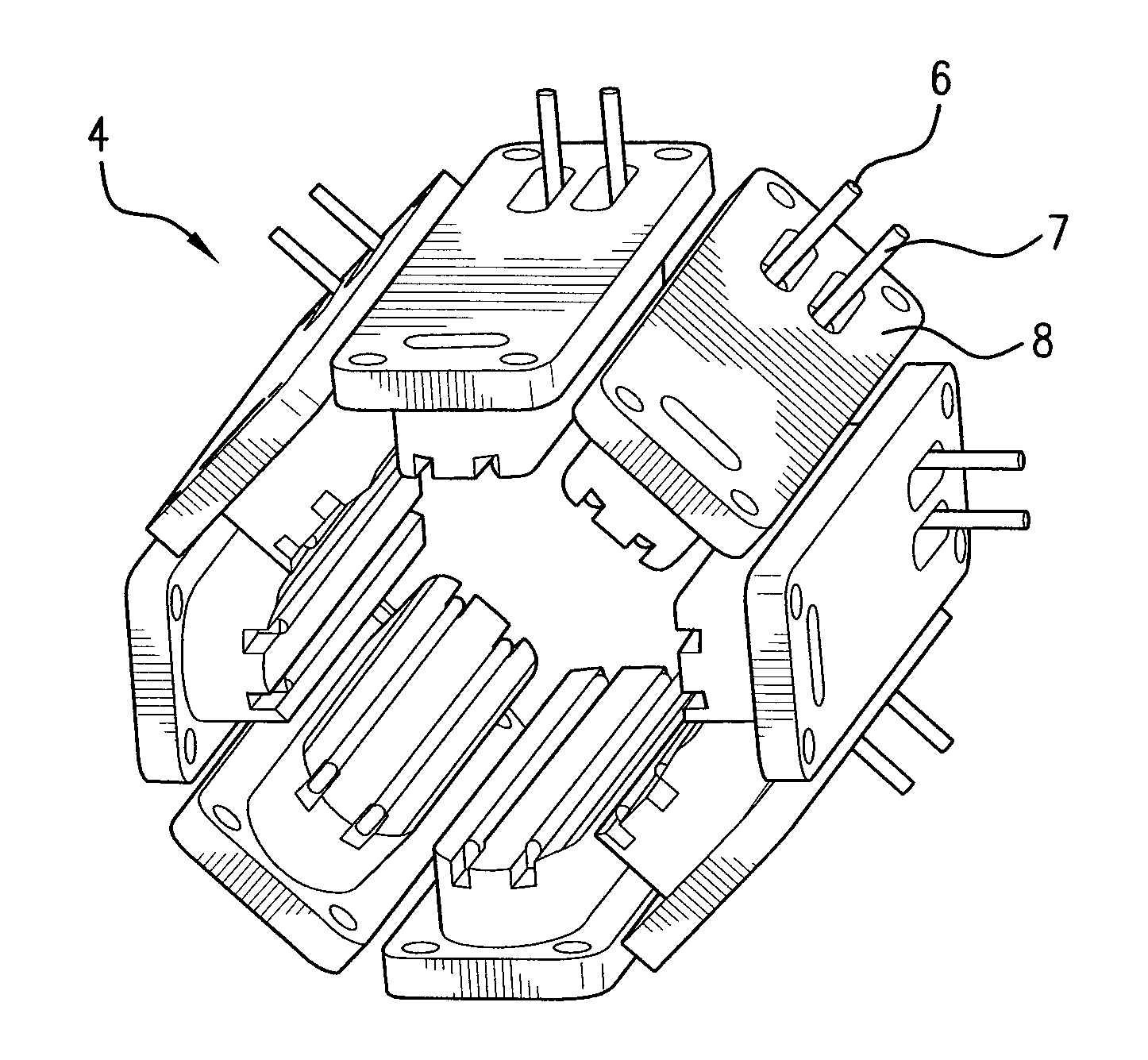

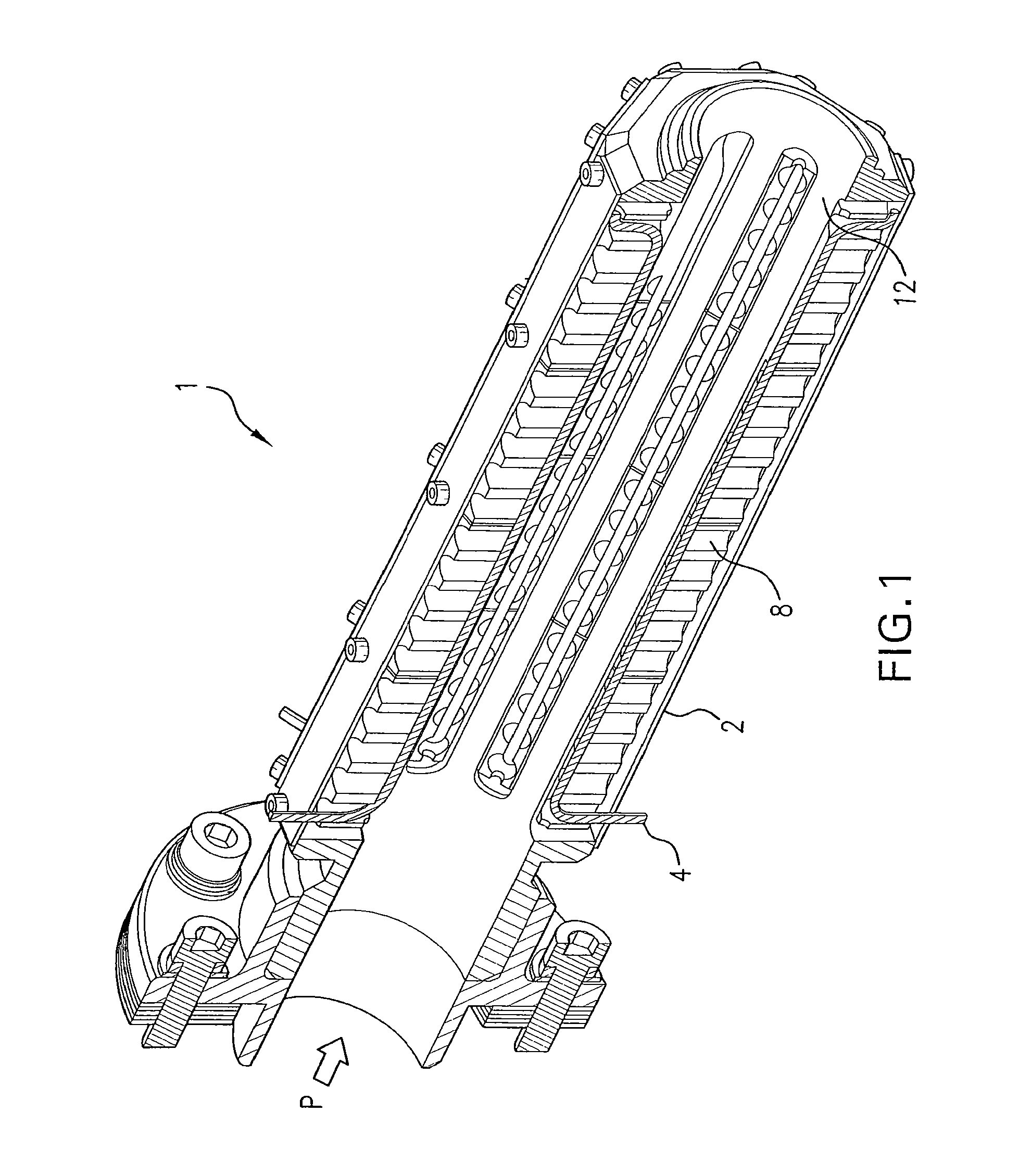

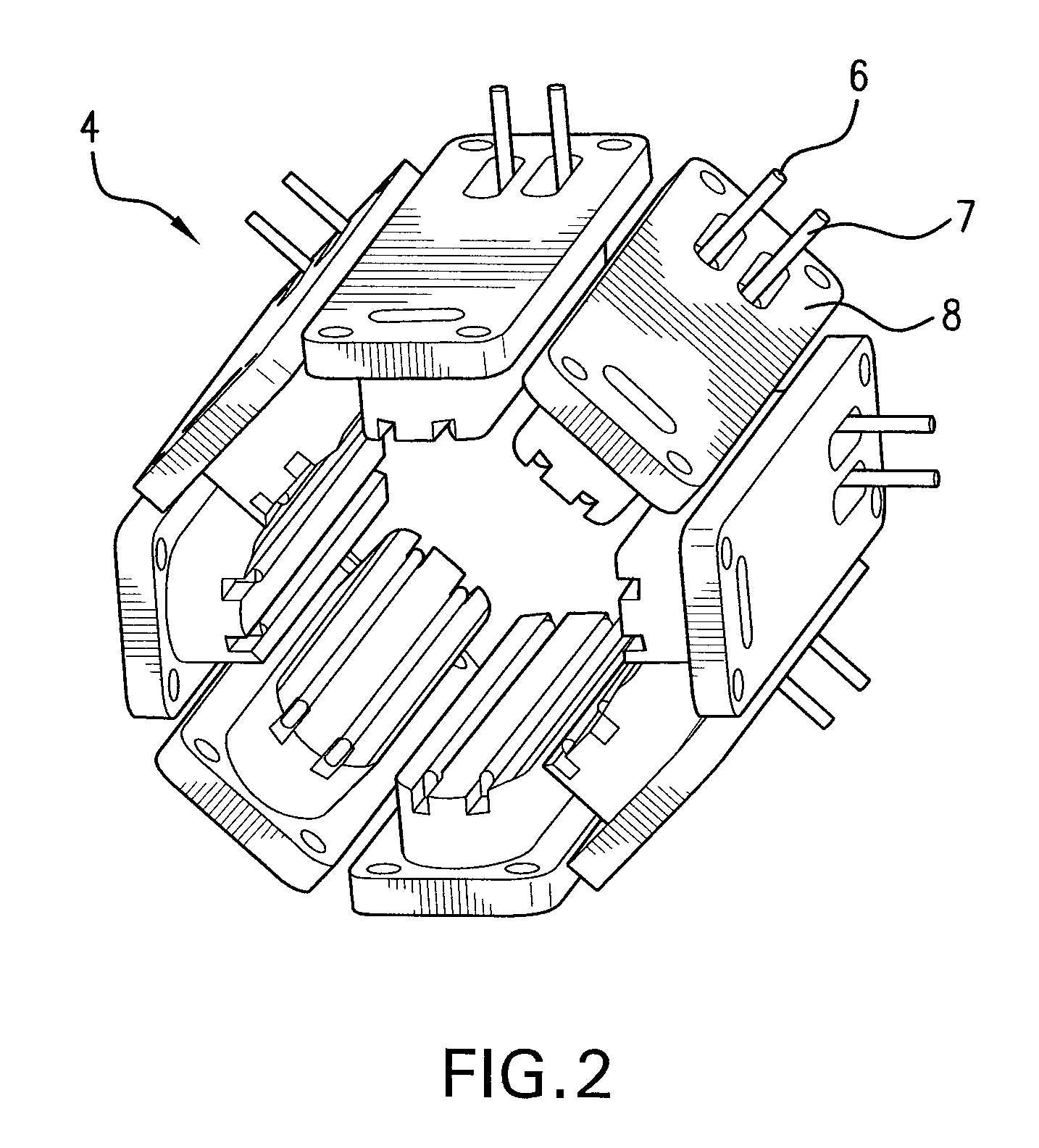

Vacuum flow suction cup assembly

A contact activated vacuum assisted suction cup assembly comprising: 1) a cylindrical bellowed or corrugated cup defining a plurality of interconnected bellows or corrugations of alternating, coaxial large and small diameter areas, hereinafter “bellows”, and having; A) an open contact end; and B) a valve end including a valve seat; 2) a valve stem having first and second extremities; 3) a valve plate intermediate the open contact end and the valve end in one of the large diameter areas attached to the first extremity; and 4) a valve stop attached to the valve stem at the second extremity that can engage the valve seat in the closed position. A picking device comprising a vacuum plenum having a plurality of the previously described contact activated vacuum assisted suction cup assemblies mounted therein in plenum apertures that engage a peripheral flange about the valve end is also described.

Owner:AMF AUTOMATION TECH

Substituted biaryl compounds as factor XIa inhibitors

The present invention provides compounds of Formula (I):or a stereoisomer, tautomer, pharmaceutically acceptable salt or solvate form thereof, wherein the variables A, L, Z, R3, and ring B are as defined herein. The compounds of Formula (I) are useful as selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

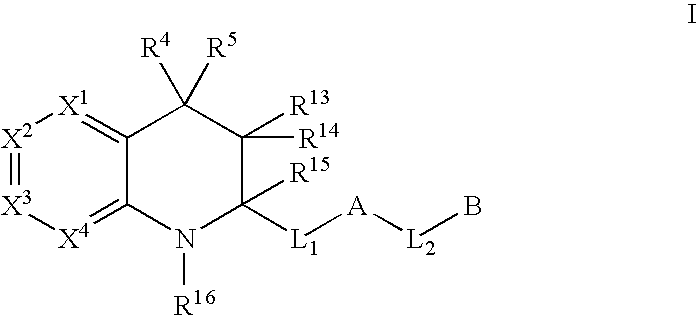

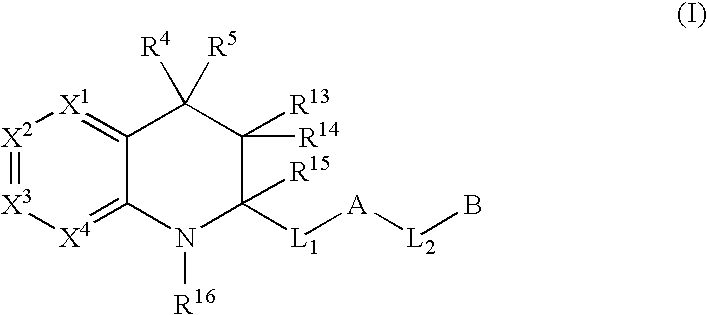

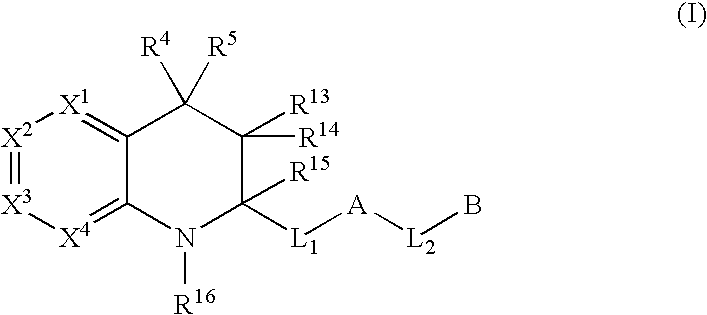

Tetrahydroquinoline derivatives useful as serine protease inhibitors

The present invention provides compounds of Formula (I):or a stereoisomer or pharmaceutically acceptable salt form thereof, wherein the variables A, B, L1, L2, X1, X2, X3, X4, R4, R5, R13, R14, R15 and R16 are as defined herein. The compounds of Formula (I) are useful as selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

Five-membered heterocycles useful as serine protease inhibitors

Owner:BRISTOL MYERS SQUIBB CO

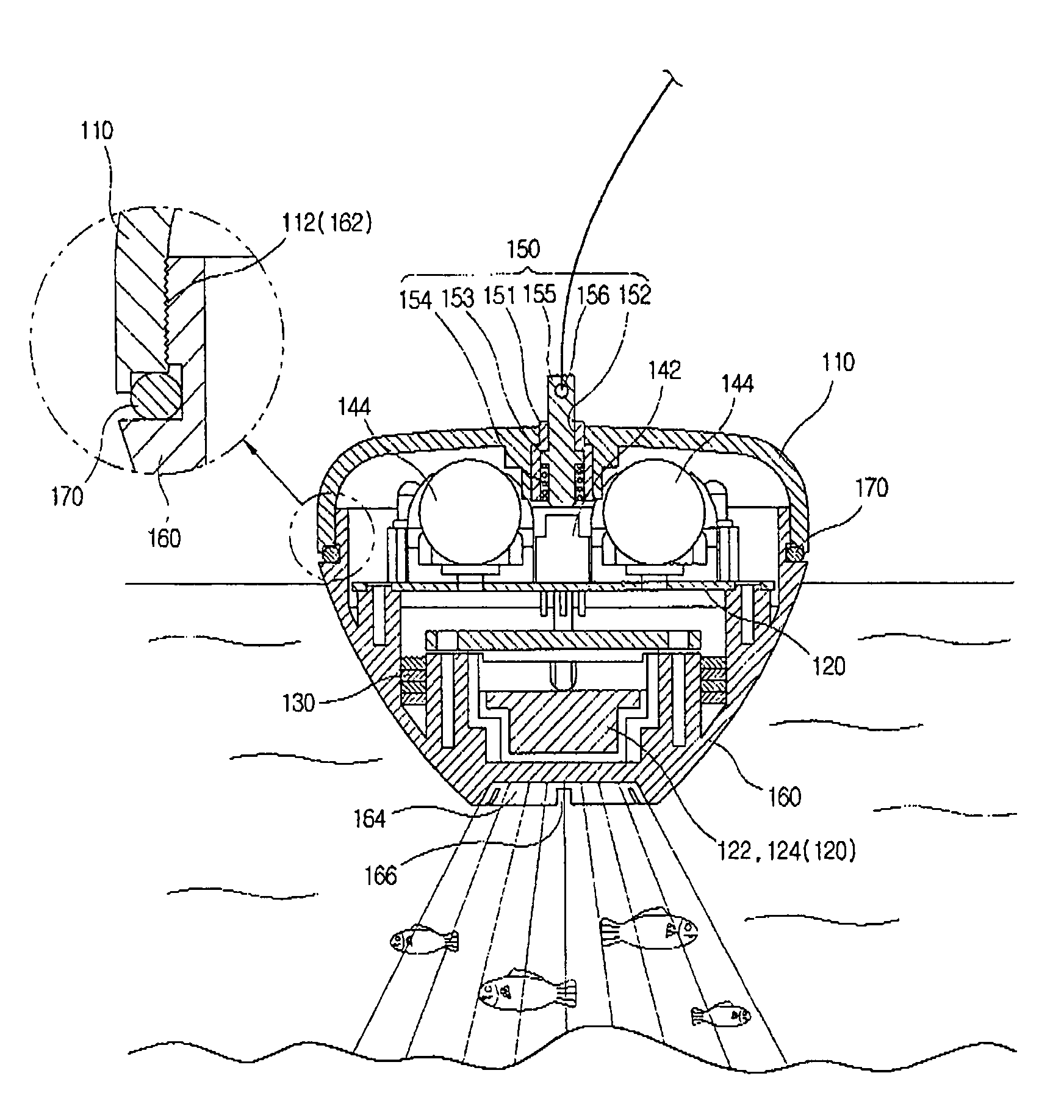

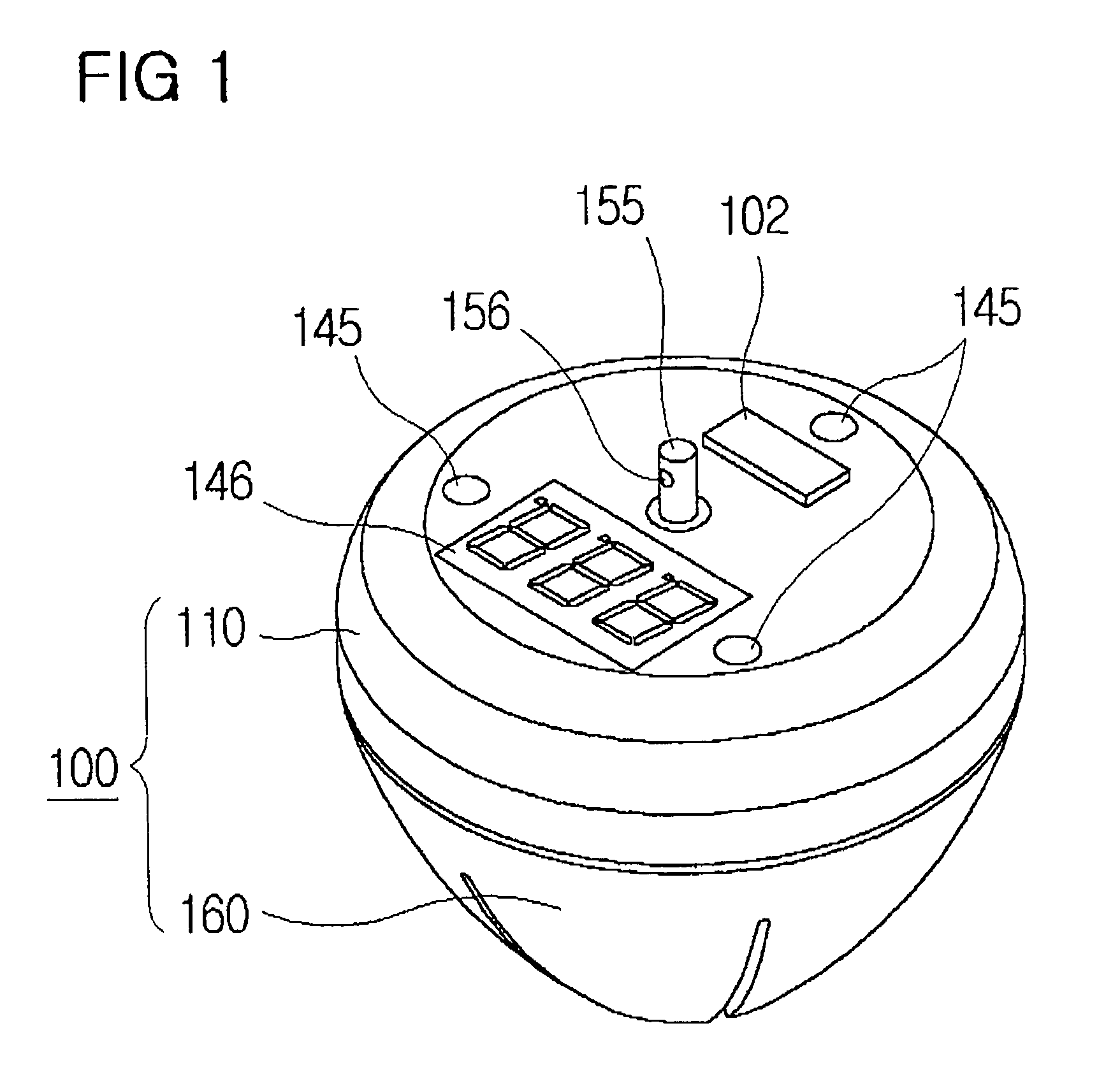

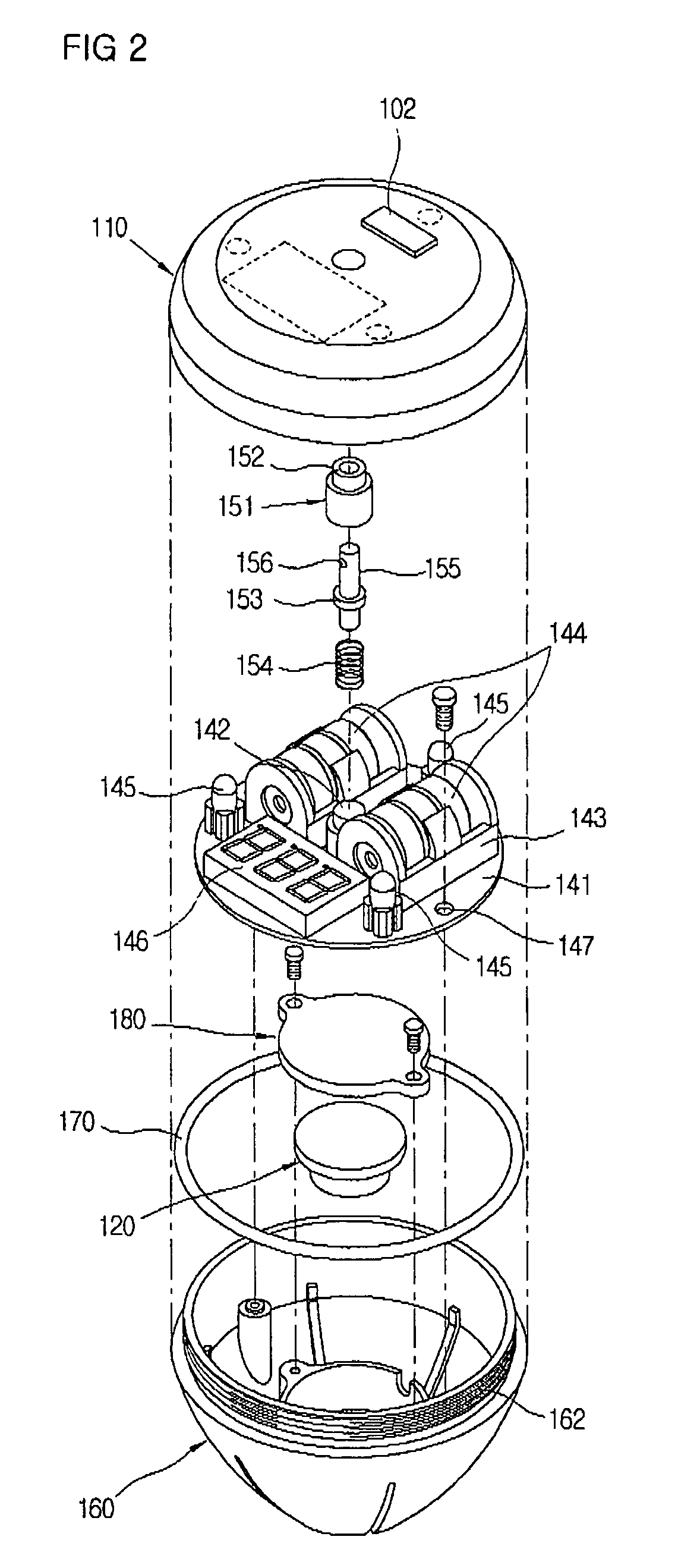

Simplicity sonic depth finder for fishing

Provided is a detector for fishing in order to detect the depth of water, the temperature of water, the distribution of fishes including fishes' migration and / or the length of fishes. The detector includes: a sensor transmitting an ultrasonic signal into the water in a fishing site and receiving a reflective ultrasonic signal reflected from an underwater object; a control unit analyzing / determining the waveform of the reflective ultrasonic signal measured in the sensor to then be indicated on an indication unit including a light-emission indicator, a numeric indicator, and a water depth / temperature indicator; a switching unit having an elevating rod whose lower end contacts an activation switch to turn on / off electric power supplied from a power source and in the upper end of which a fishing line engagement hole is formed in which a fishing line is connected with the fishing line engagement hole and the elevating rod is exposed to the outside to then be elastically pressed to be opened and closed according to the pressure of the elevating rod; and a main body on the upper surface of which a light-emission indicator, a numeric indicator, and a water depth / temperature indicator are formed, and in which the sensor, the control unit, and the switching unit are embedded in a sealed manner with a predetermined structure. The detector further includes a transmitter transmitting a signal representing the analyzed / determined result in the form of a predetermined waveform wirelessly. The wireless signal transmitted from the transmitter in the fishing detector is received and displayed using a predetermined program via a predetermined receiver having a display such as a personal portable communications terminal like a mobile telephone.

Owner:PHARMED MEDICARE PVT LTD

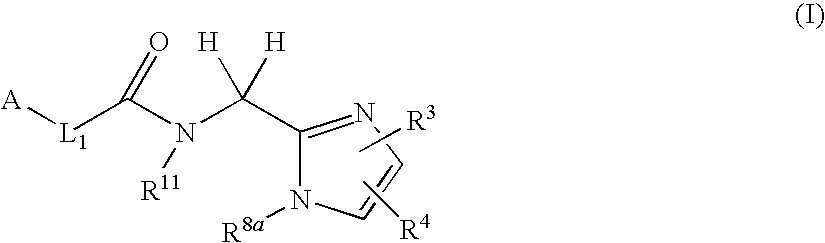

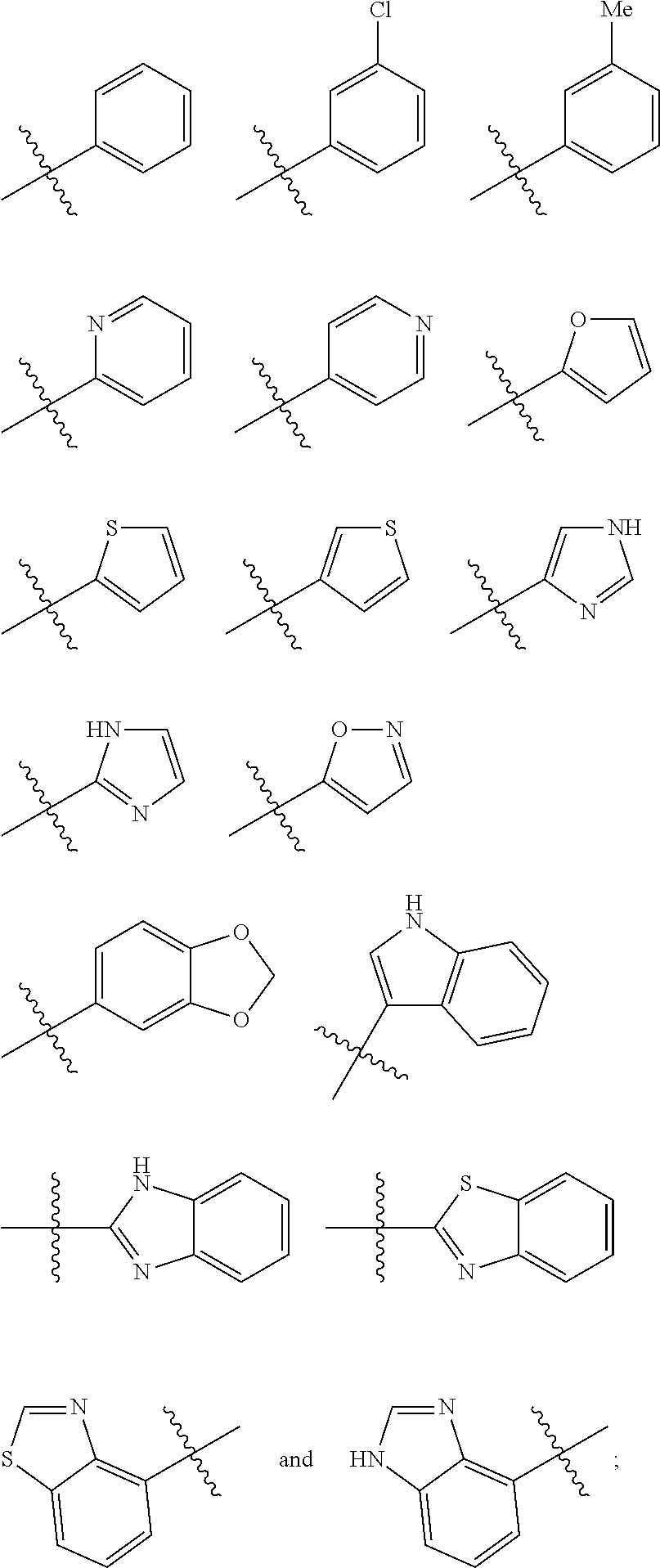

Arylpropionamide, arylacrylamide, ayrlpropynamide, or arylmethylurea analogs as factor XIa inhibitors

The present invention provides compounds of Formula (I):or a stereoisomer, tautomer, pharmaceutically acceptable salt or solvate form thereof, wherein the variables A, L1, M and R11 are as defined herein. The compounds of Formula (I) are selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors or dual inhibitors of fXIa and plasma kallikrein. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

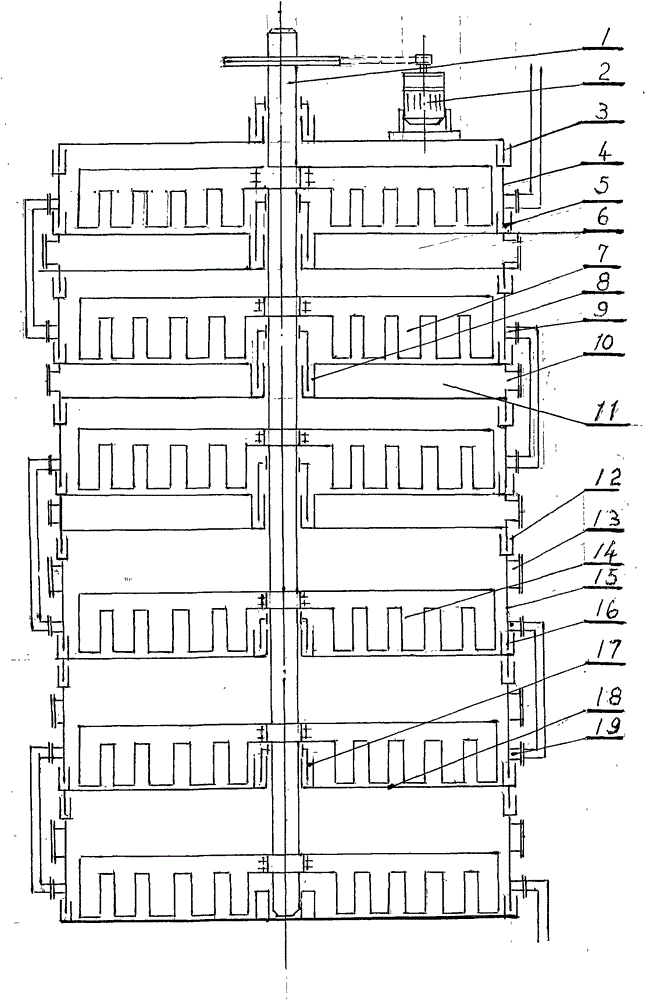

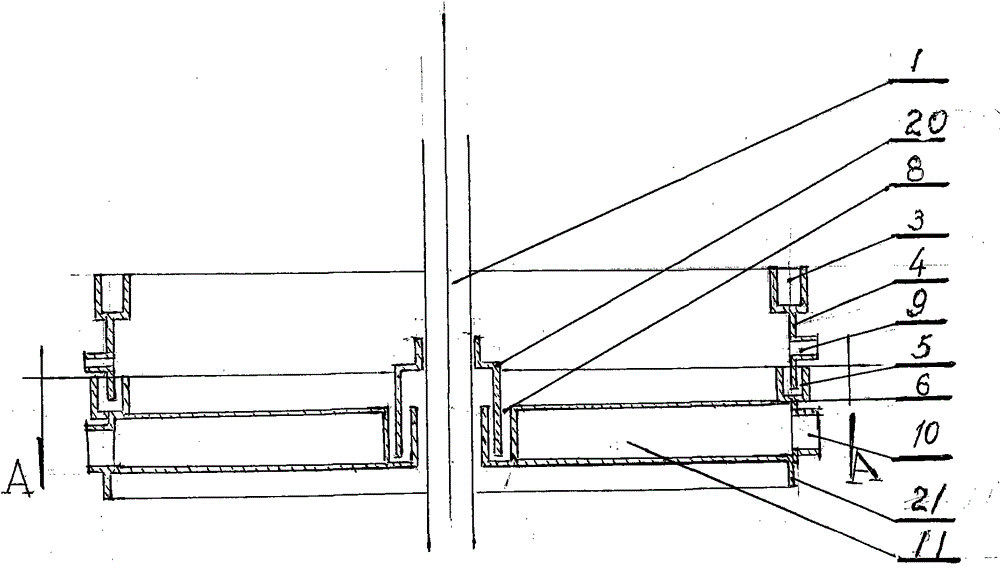

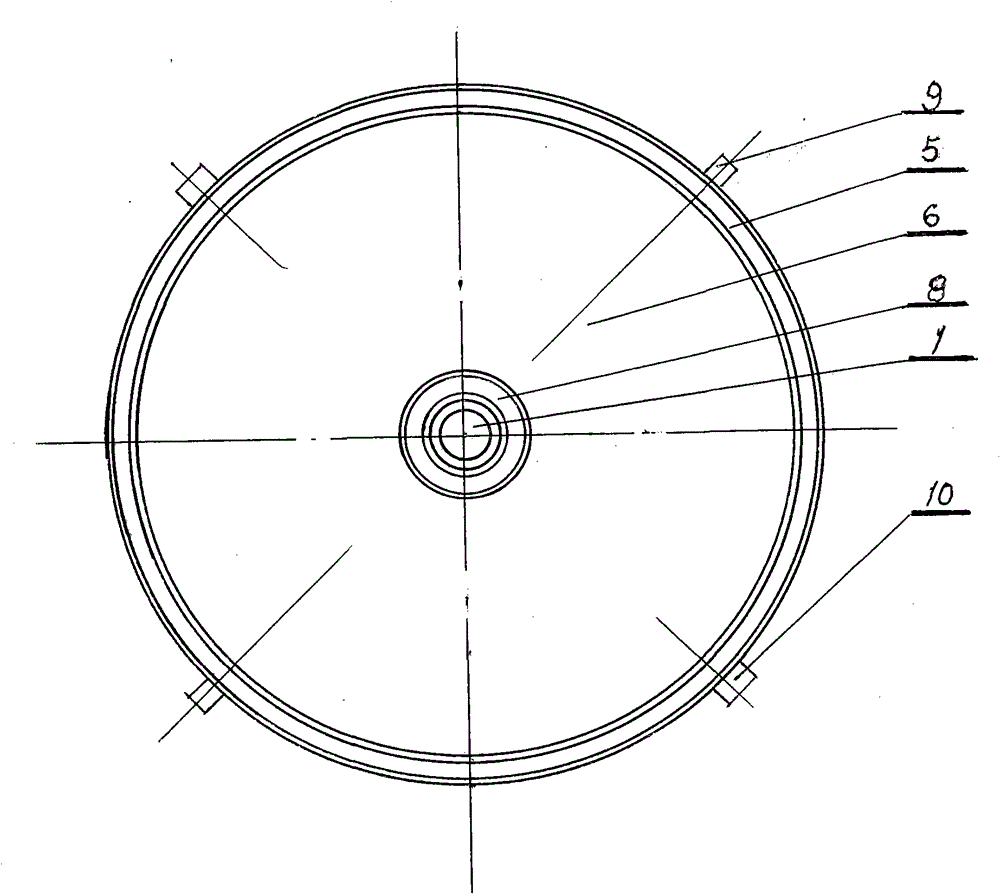

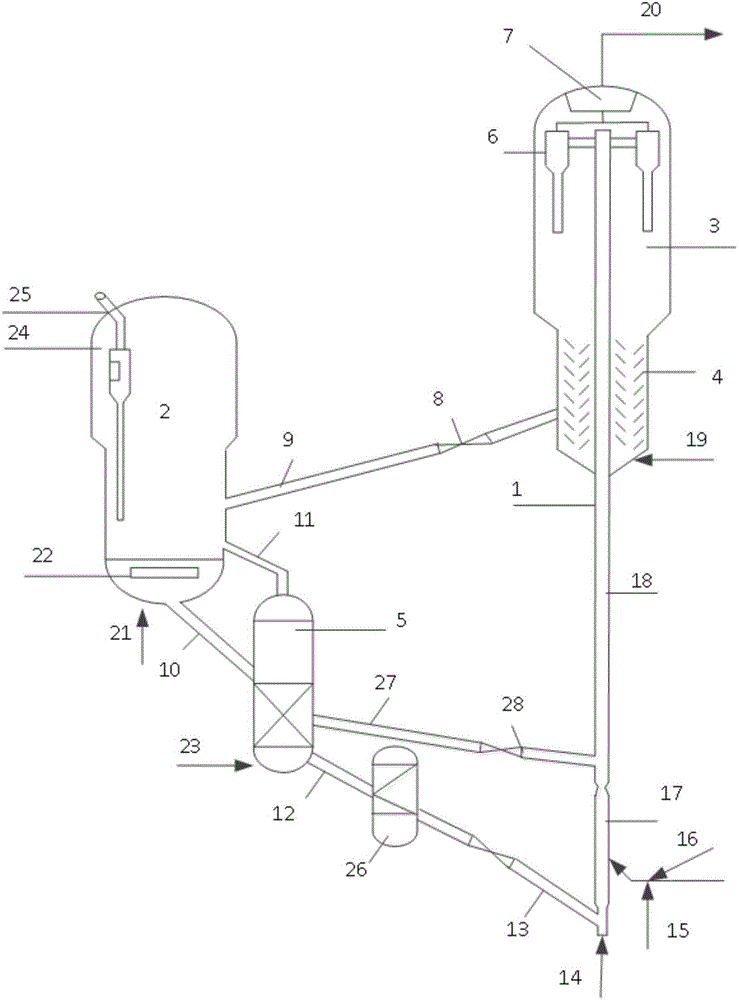

Thermal regeneration furnace for waste powdered activated carbon

InactiveCN102794163AIncrease temperatureEasy loadingOther chemical processesCombustible gas purificationChemical industryContact activation

The invention relates to a thermal regeneration furnace for waste powdered activated carbon, and belongs to the technical field of chemical industry. The thermal regeneration furnace is used for the thermal regeneration (100 to 850 DEG C) of waste powdered activated carbon obtained by refining and decolorizing medicines and fine chemicals. The thermal regeneration furnace is formed by serially connecting a plurality of dry distillation trays and activation trays, which are provided with rotary stirrers, wherein the dry distillation trays are vertically arranged on the activation trays; and waste powdered carbon is continuously and quantificationally added, indirect heating is adopted for dry distillation, the activation is that high-temperature activation gas is generated by using water gas generated in the thermal regeneration process and an oxygen-enriched combustion improver, and over-heated water vapor is doped and taken as activation gas for direct contact activation, organic matter in the waste carbon can be completely decomposed and removed through dry distillation and activation in an innocent manner, the waste powdered carbon can be generated, and the original adsorption performance and the original adsorption indexes are restored. The thermal regeneration of the waste powdered carbon is a most effective technical means for realizing the cyclic utilization of industrial waste powdered carbon, environmental pollution caused by inappropriately disposing the waste powdered carbon which is taken as garbage, and also ensures that powdered carbon resources are recycled; and the thermal regeneration also has a relatively high economic benefit.

Owner:沈善明

Historical information retrieval system

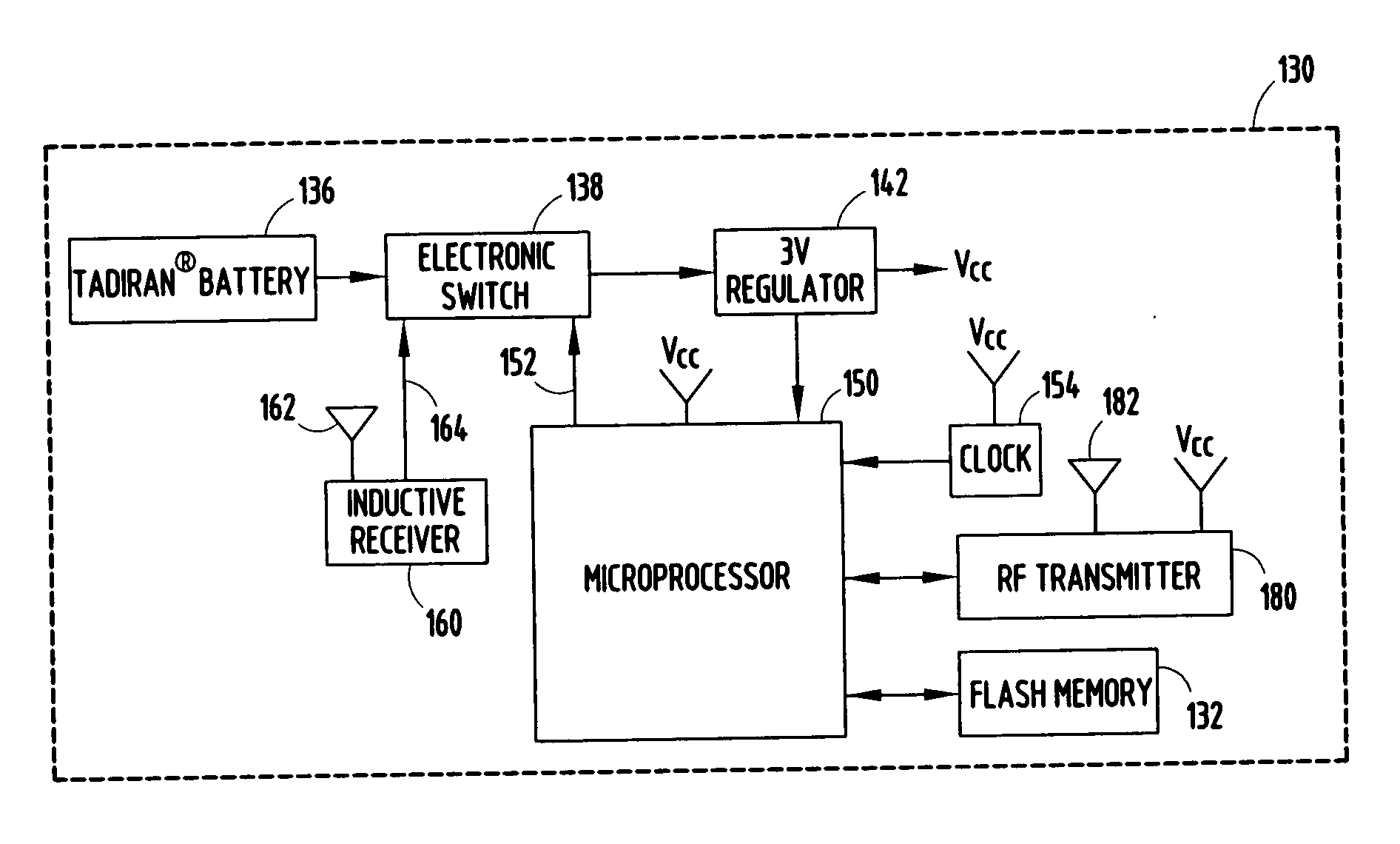

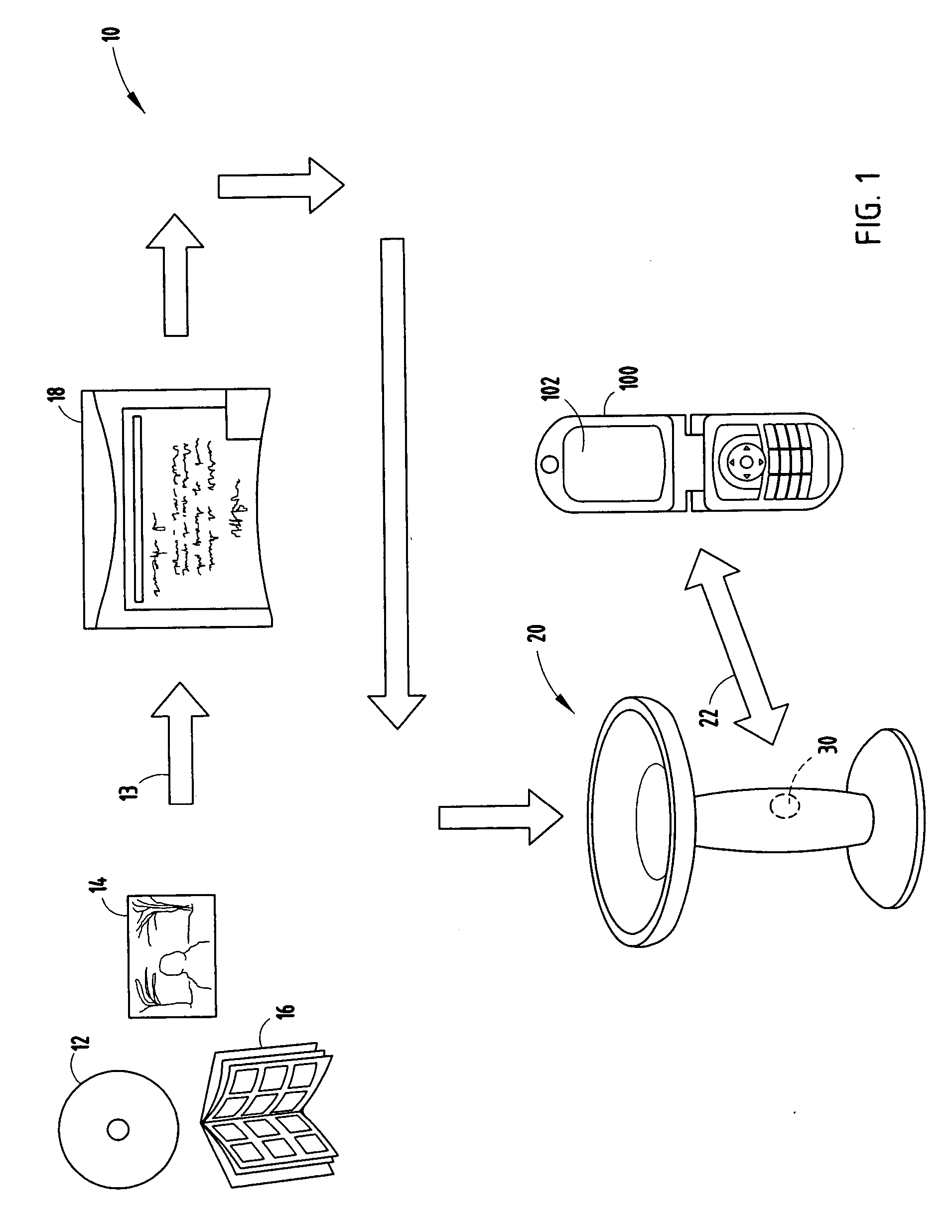

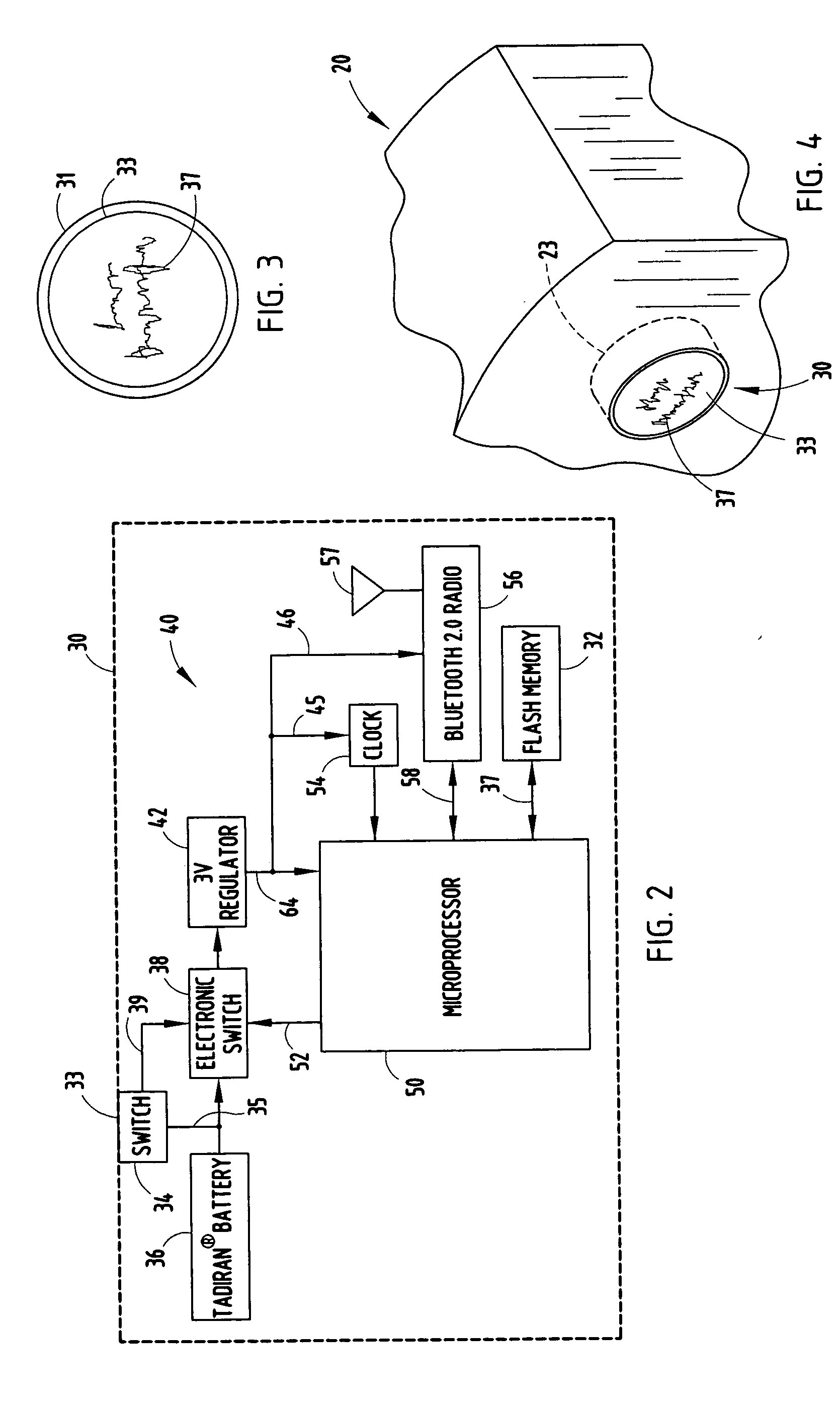

InactiveUS20060155783A1Easy accessLower unit costUser identity/authority verificationSensing record carriersDigital dataElectric power transmission

An embedded unit contains a microprocessor and memory for storing video, audio, photograph, and written digital data pertaining to a monument. The microprocessor, when actuated by a visitor, communicates through a two-way radio transceiver to a visitor carried transceiver. The embedded unit includes a long-life battery and is activated only upon a visitor approaching the marker and momentarily contacting an activation switch or passing an activating dongle adjacent the embedded unit for initiating power to the embedded unit for the transfer of data. A Bluetooth® receiver, such as a cellular phone having Bluetooth® capability, a PDA with Bluetooth®, or other Bluetooth® device, is employed for reading and / or storing information contained in the embedded unit.

Owner:FOREVER REMEMBERED

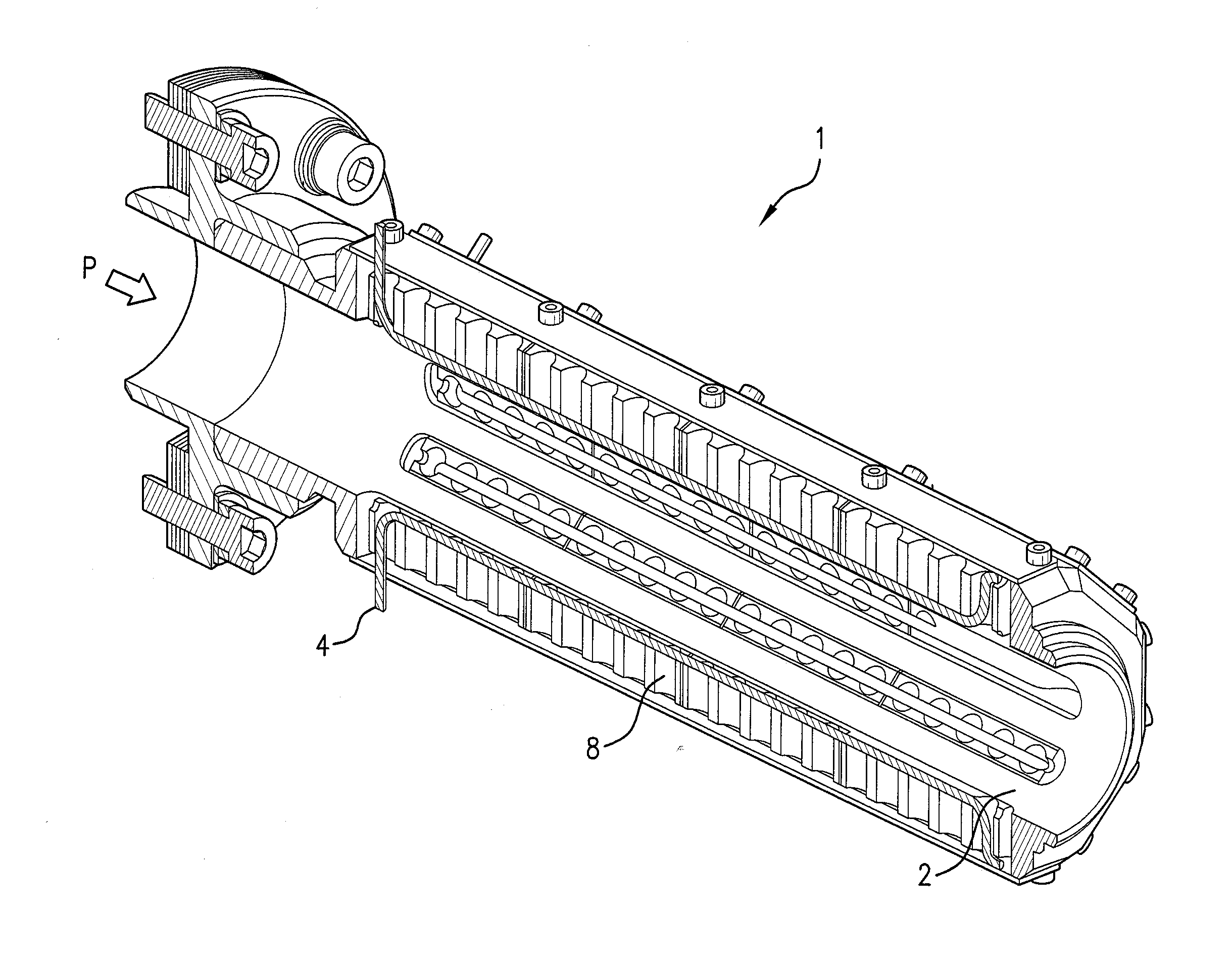

Activation unit for explosive masses or explosive bodies

InactiveUS20120137913A1Low level of lossIncrease contactFirework flares/torchesBlasting cartridgesThermal energyContact activation

An activation unit for explosive masses or explosive bodies includes an ejector tube and high-performance heating elements mounted around the ejector tube, each made of at least one heating wire supplied with electrical power by a control unit. Each heating wire is enclosed in a casing and embedded in a material minimizing heat loss. When the explosive body is passed through the activation unit, the jacket surface of the explosive body contacts the individual elements of the activation unit in a direct or non-contact manner. Thermal energy is transferred to the explosive body by means of the heating wires, and the body ignites at the contact points. A further activation unit includes heating elements in the ejector tube, at least partially fed longitudinally through the ejector tube, made of heating wire clad with CrNi steel and contact plates soldered thereto.

Owner:RHEINMETALL WAFFE MUNITION GMBH

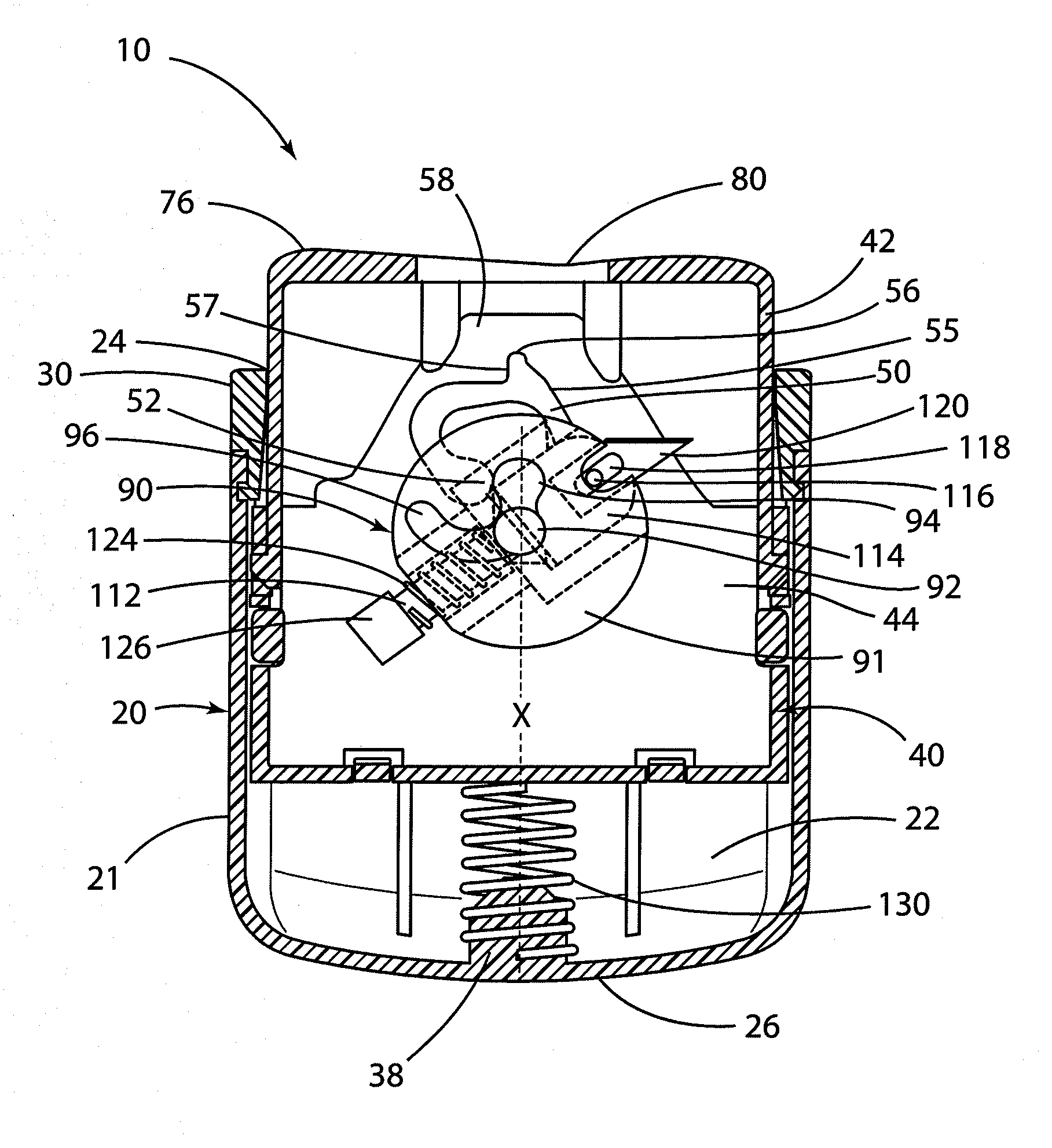

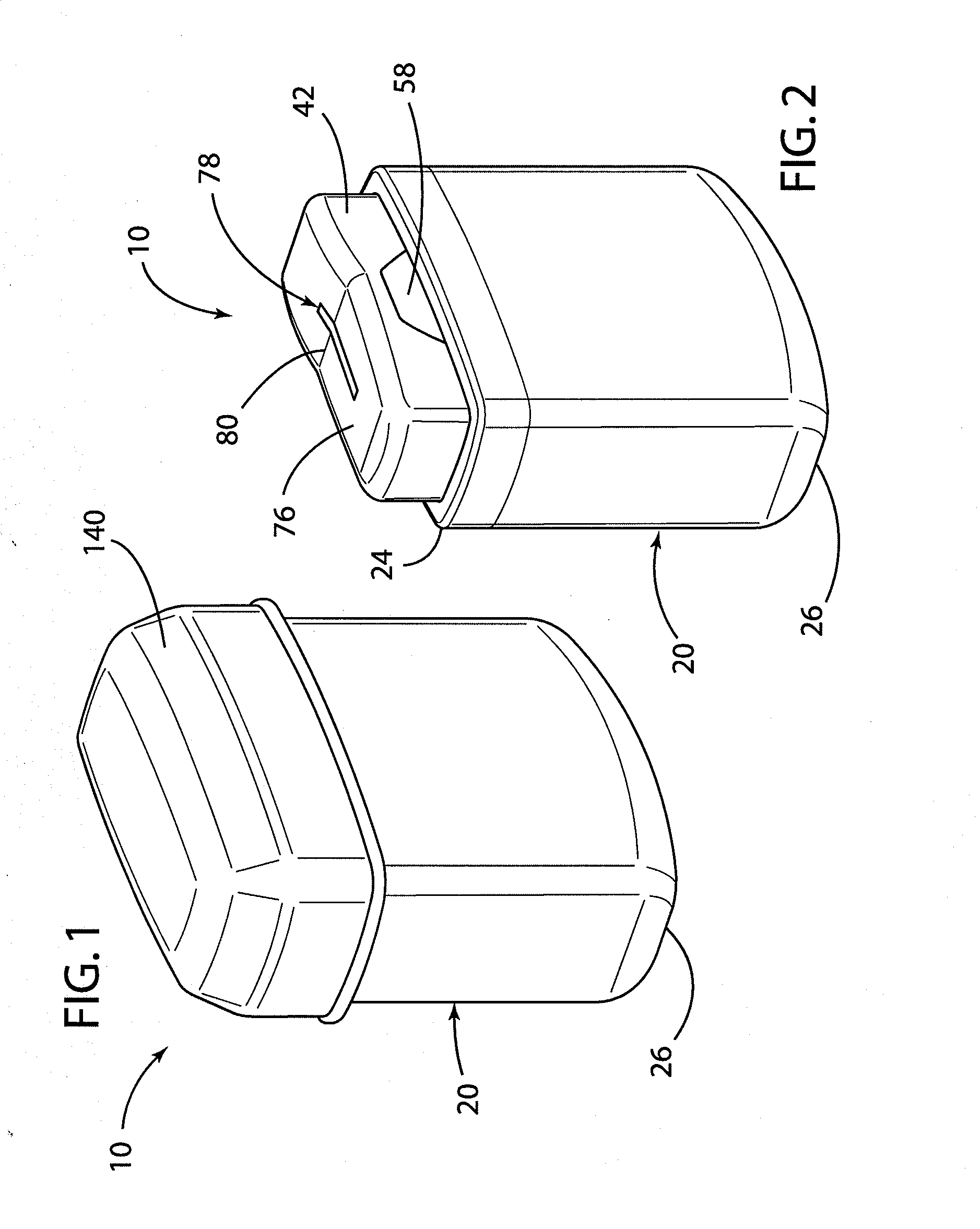

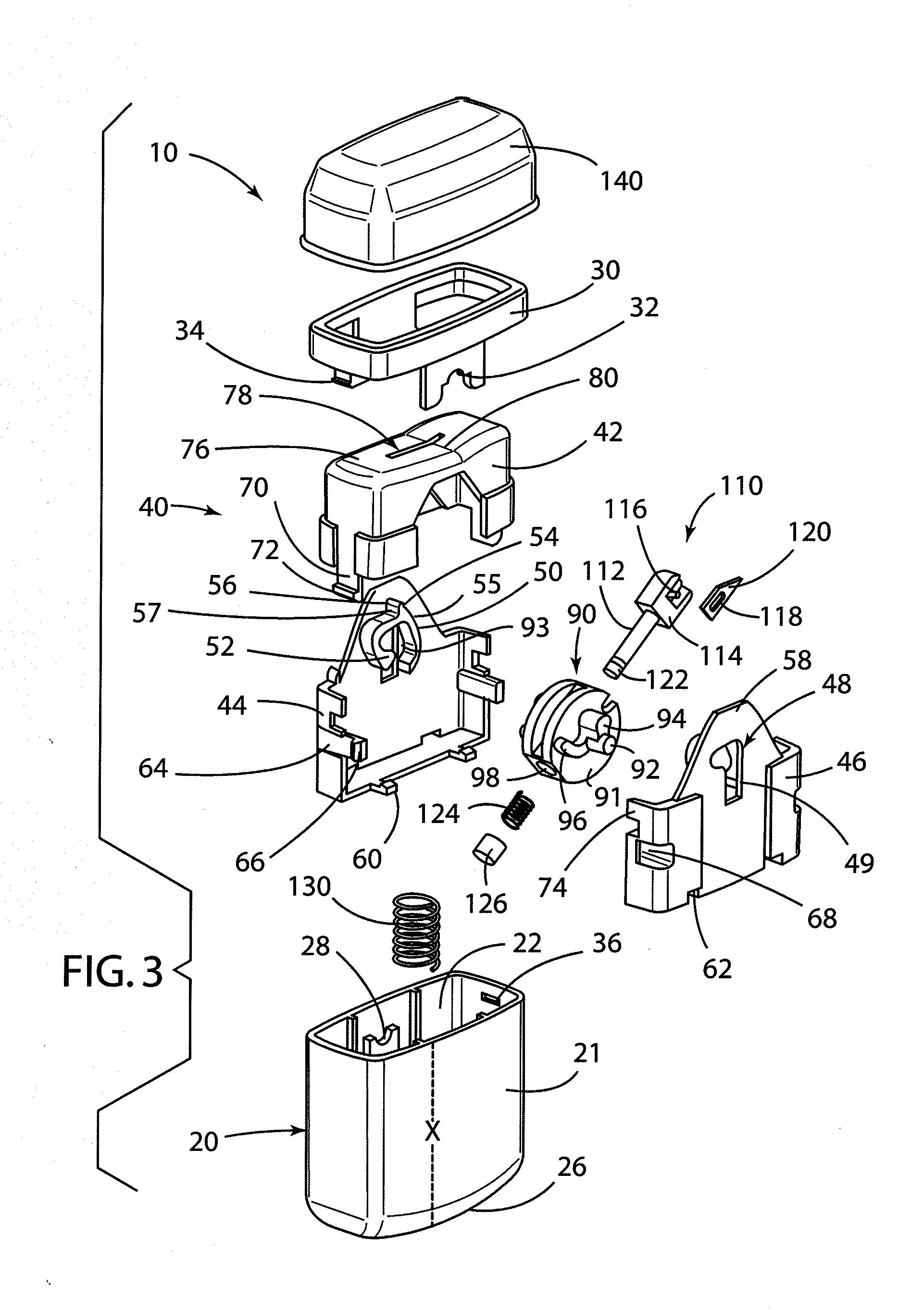

Contact activated incision device

A contact activated incision device, comprises a housing defining a cavity, and a longitudinal axis extends between a proximal end and a distal end of the housing. A slider is slidable with respect to the housing along the longitudinal axis and at least partially positioned outside of the housing. A roller is mounted on the housing and rotatable about an axis perpendicular to the longitudinal axis. A blade assembly is mounted on the roller and has a blade, wherein the blade is movable from a retracted position to an extended position and to a final position, at the retracted position the blade is positioned in the cavity, at the extended position the blade extends at least partially beyond the proximal end of the housing, and at the final position the blade is positioned in the cavity.

Owner:NSP TECH PTE LTD

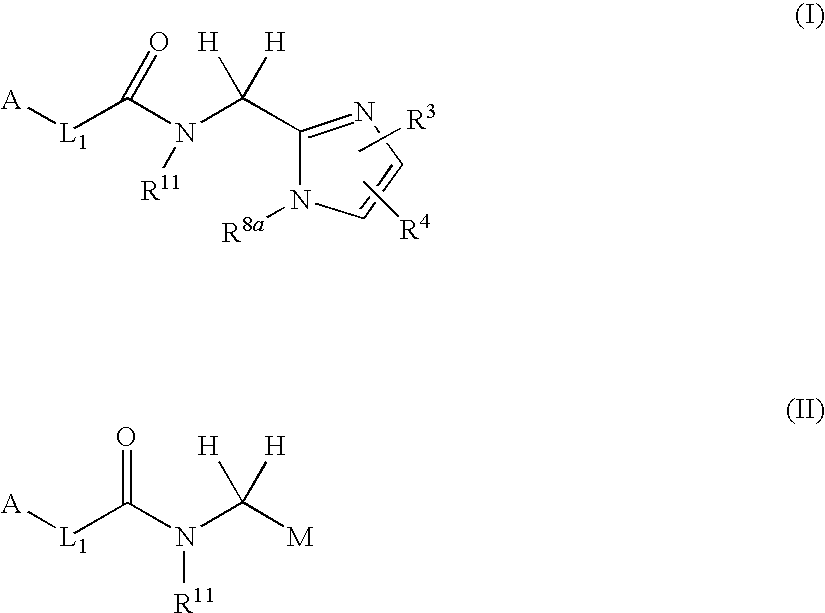

Arylpropionamide, arylacrylamide, arylpropynamide, or arylmethylurea analogs as factor xia inhibitors

The present invention provides compounds of Formula (I) or (II):or a stereoisomer, tautomer, pharmaceutically acceptable salt or solvate form thereof, wherein the variables A, L1, R3, R4, R8a, R11 and M are as defined herein. The compounds of Formula (I) or (II) are selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors or dual inhibitors of fXIa and plasma kallikrein. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

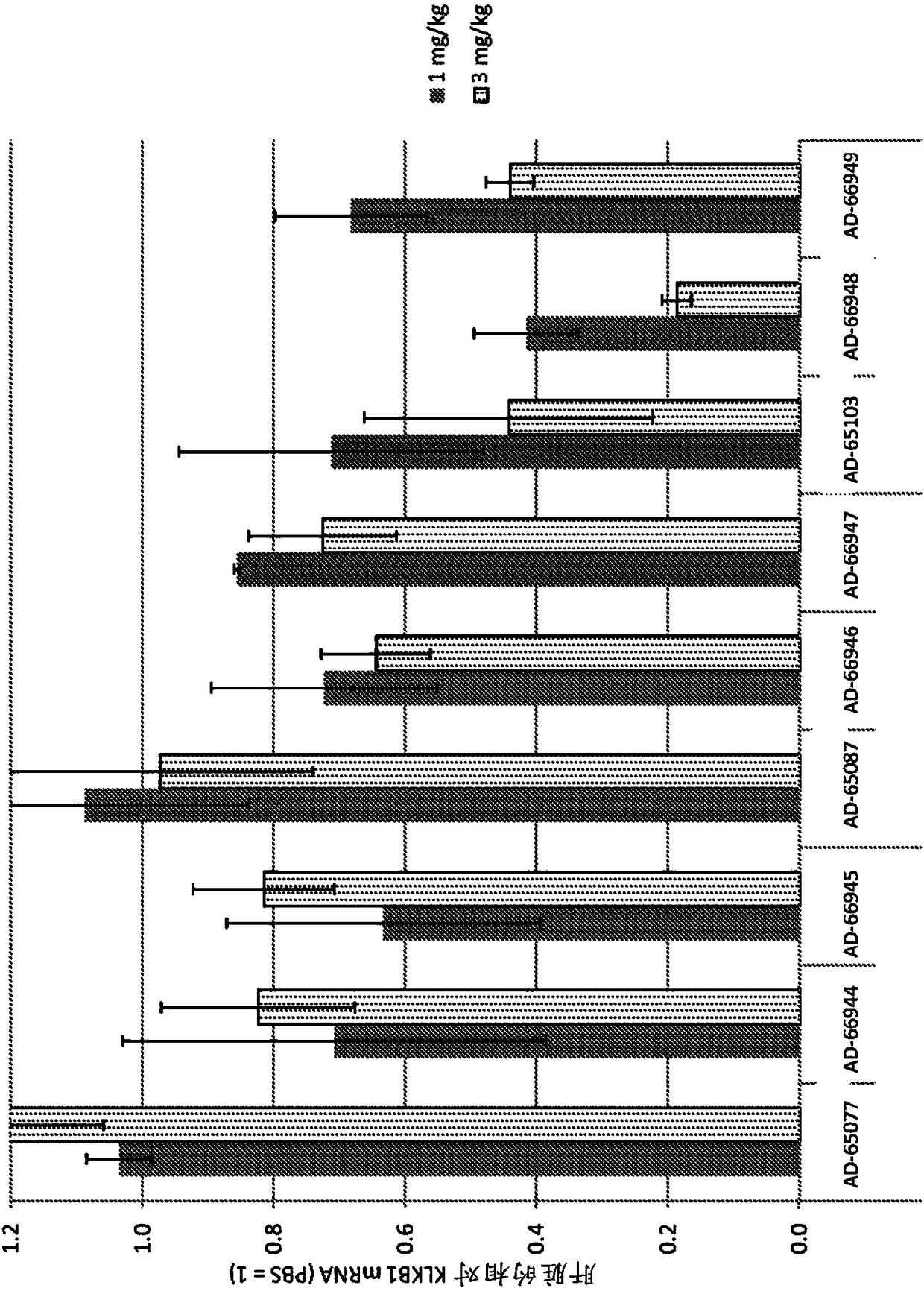

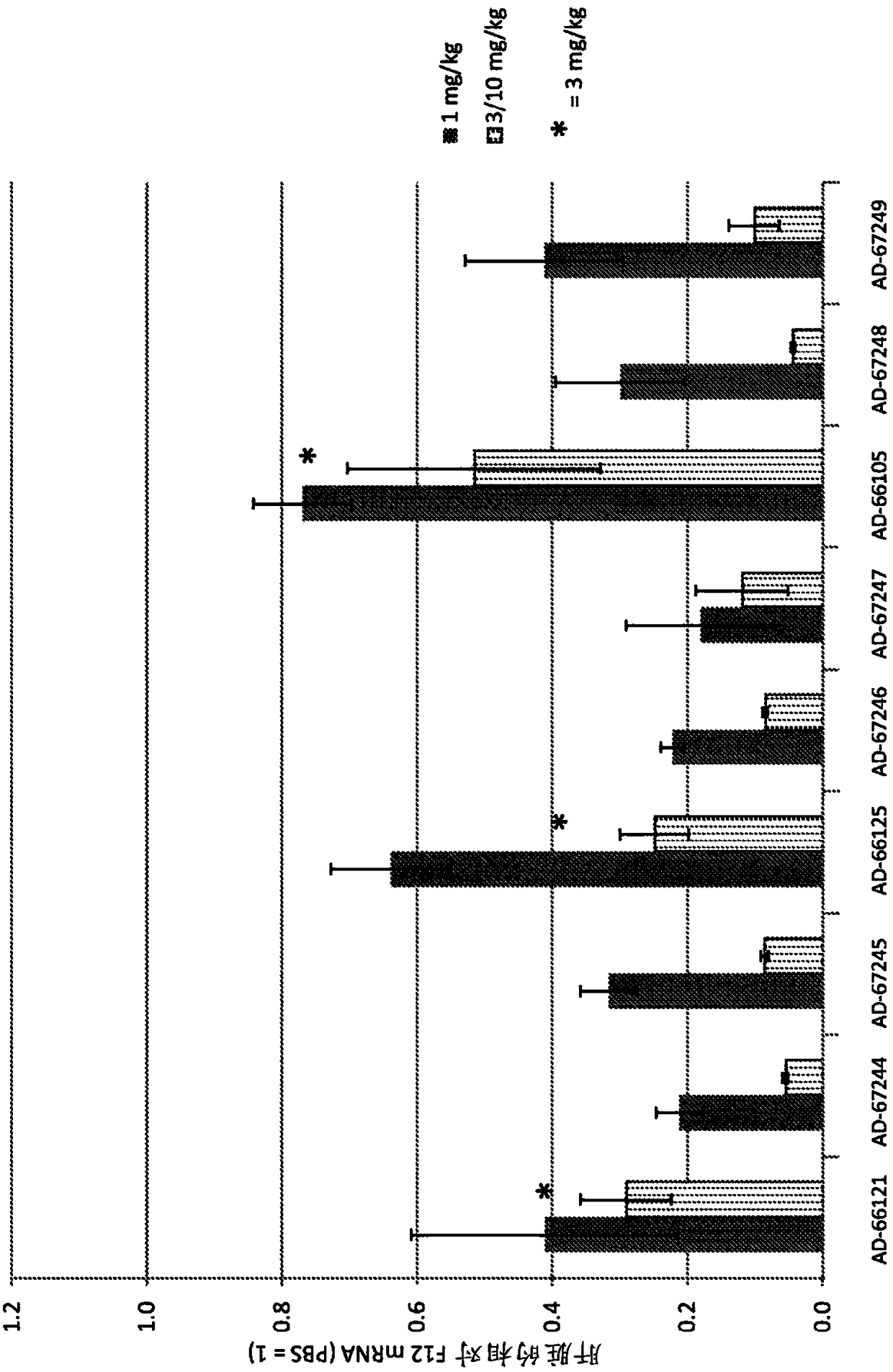

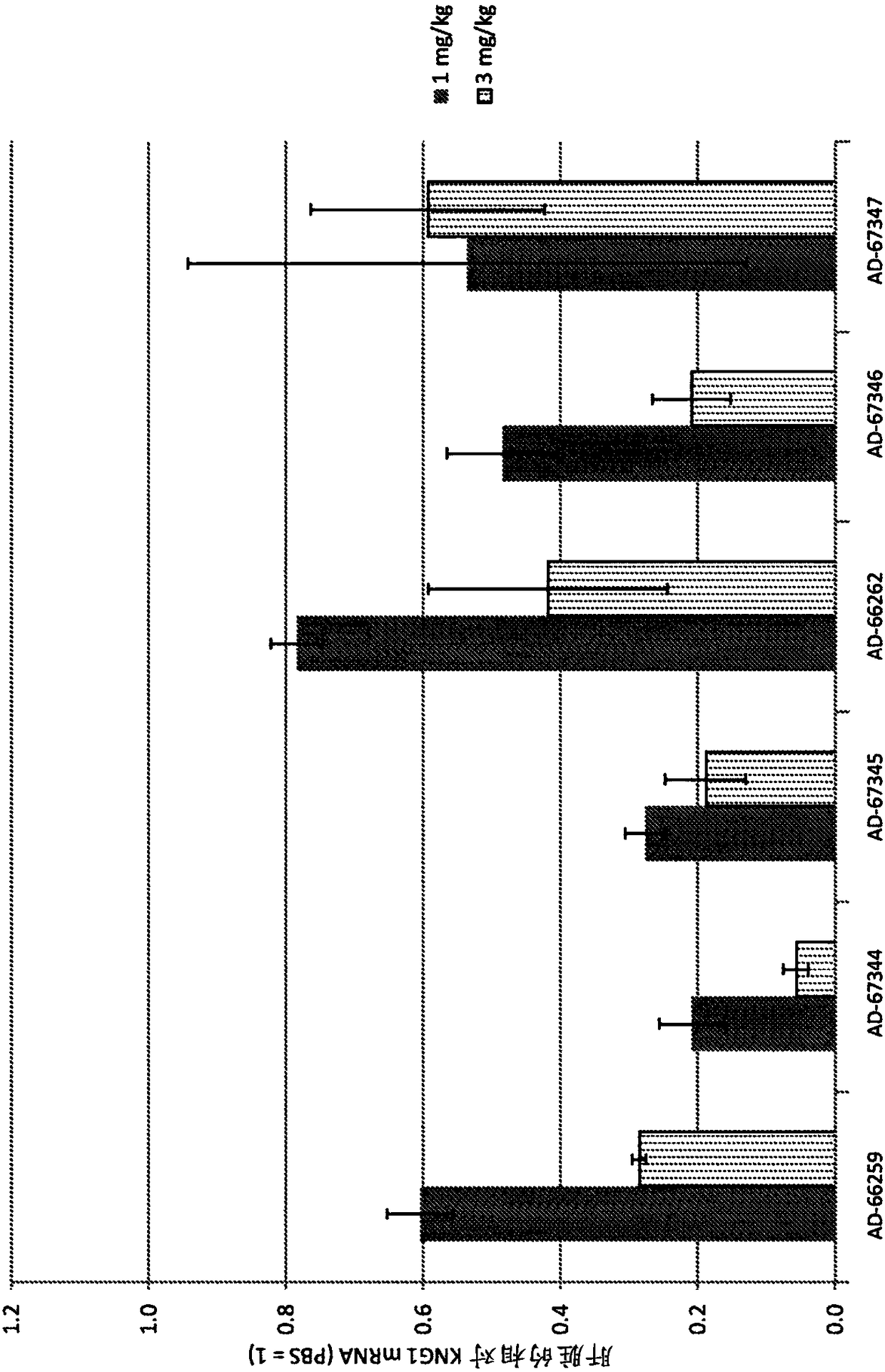

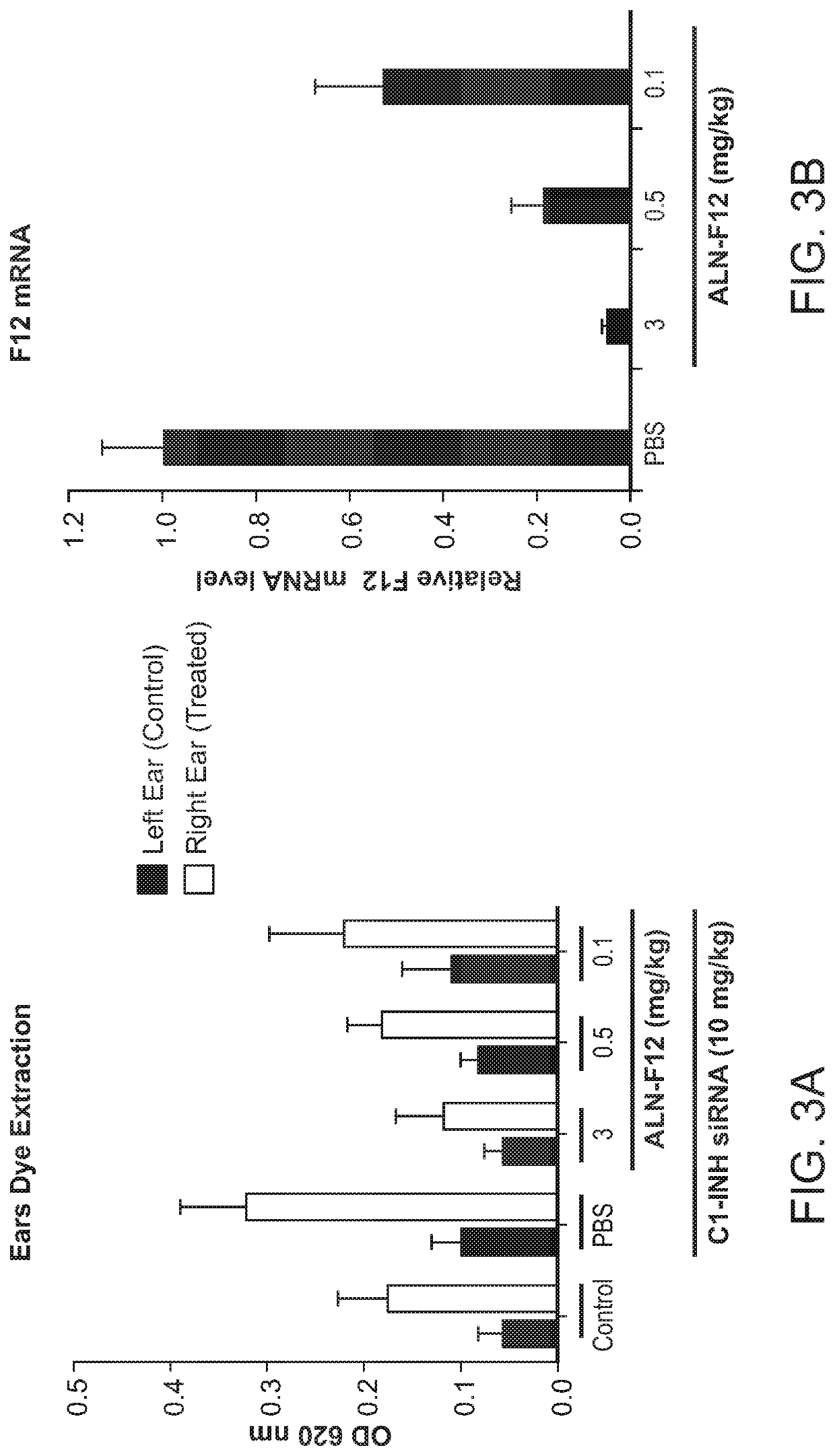

Factor xii (hageman factor) (F12), kallikrein b, plasma (fletcher factor) 1 (KLKB1), and kininogen 1 (KNG1) irna compositions and methods of use thereof

ActiveCN108271386AOrganic active ingredientsMicrobiological testing/measurementContact activationKinin

The present invention relates to RNAi agents, e.g., double stranded RNAi agents, targeting the Kallikrein B, Plasma (Fletcher Factor) 1 (KLKB1) gene, the Factor XII (Hageman Factor (F12) gene, or theKininogen 1 (KNG1) gene, and methods of using such RNAi agents to inhibit expression of a KLKB1 gene, an F12 gene, and / or a KNG1 gene, and methods of treating subjects having an hereditary angioedema(HAE) and / or a contact activation pathway-associated disorder.

Owner:ALNYLAM PHARM INC

Preparation method and application of time temperature indicator based on lipase reaction diffusion

ActiveCN102175677ALower pH valueObvious color changeThermometers using mean/integrated valuesMaterial analysis by observing effect on chemical indicatorContact activationActivation energy

The invention relates to a preparation method and application of a time temperature indicator based on lipase reaction diffusion. The preparation method comprises the following steps of: preparing an upper cover containing a gel reaction substrate and a bottom board containing a gel enzyme substrate; before activation, separating the upper cover containing the gel reaction substrate from the bottom board containing the gel enzyme substrate and refrigerating at the temperature of 4 DEG C; during use, pressing the upper cover containing the gel reaction substrate on the bottom board containing the gel enzyme substrate, so that substrate gel of the gel reaction substrate is contacted with the gel enzyme substrate for activation; performing an enzymatic reaction after the substrate gel is contacted with the gel enzyme substrate to form a yellow belt; judging and determining the accumulation effect of the yellow belt on time and temperatures according to the diffusion length of the yellow belt; and performing the matching of activation energy with food to be predicted according to the relation between the activation energy of an established time temperature indicator (TTI) and influence factors, so that the quality condition of the food during production, storage and transportation and sale can be monitored conveniently and reliably.

Owner:JIANGNAN UNIV

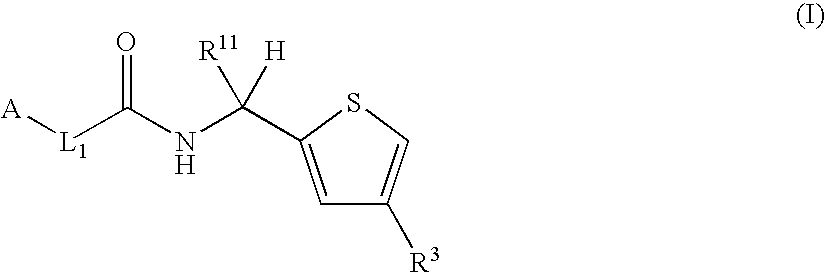

Thiophene derivatives as factor xia inhibitors

The present invention provides compounds of Formula (I):or stereoisomers, tautomers, pharmaceutically acceptable salts, solvates, or prodrugs thereof, wherein the variables A, L1, R3, and R11 are as defined herein. The compounds of Formula (I) are useful as selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

Six-membered heterocycles useful as serine protease inhibitors

The present invention provides compounds of Formula (I):or a stereoisomer, tautomer, pharmaceutically acceptable salt or solvate form thereof, wherein the variables A, B, R3 and R11 are as defined herein. The compounds of Formula (I) are useful as selective inhibitors of serine protease enzymes of the coagulation cascade and / or contact activation system; for example thrombin, factor Xa, factor XIa, factor IXa, factor VIIa and / or plasma kallikrein. In particular, it relates to compounds that are selective factor XIa inhibitors or dual inhibitors of fXIa and plasma kallikrein. This invention also relates to pharmaceutical compositions comprising these compounds and methods of treating thromboembolic and / or inflammatory disorders using the same.

Owner:BRISTOL MYERS SQUIBB CO

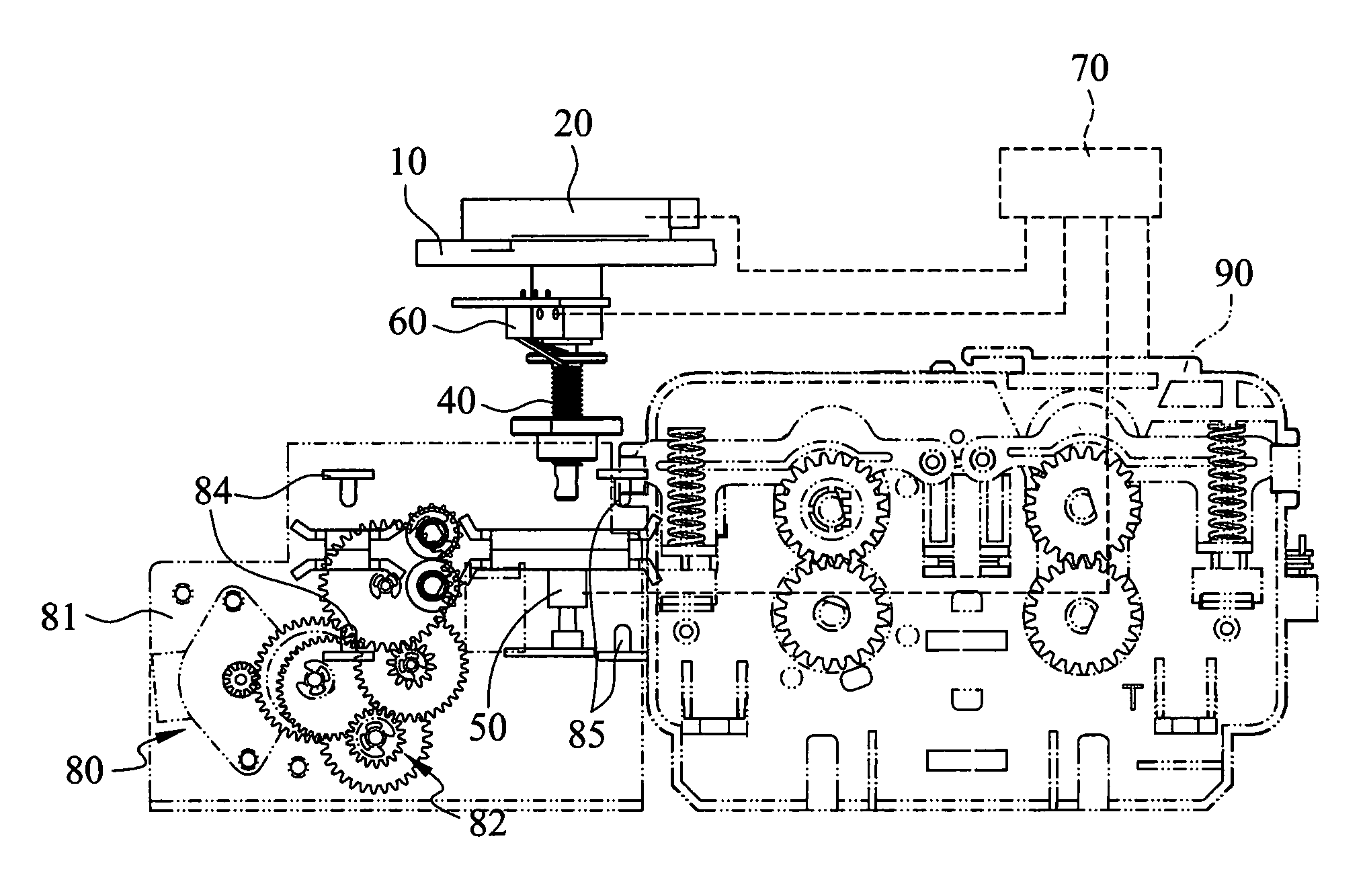

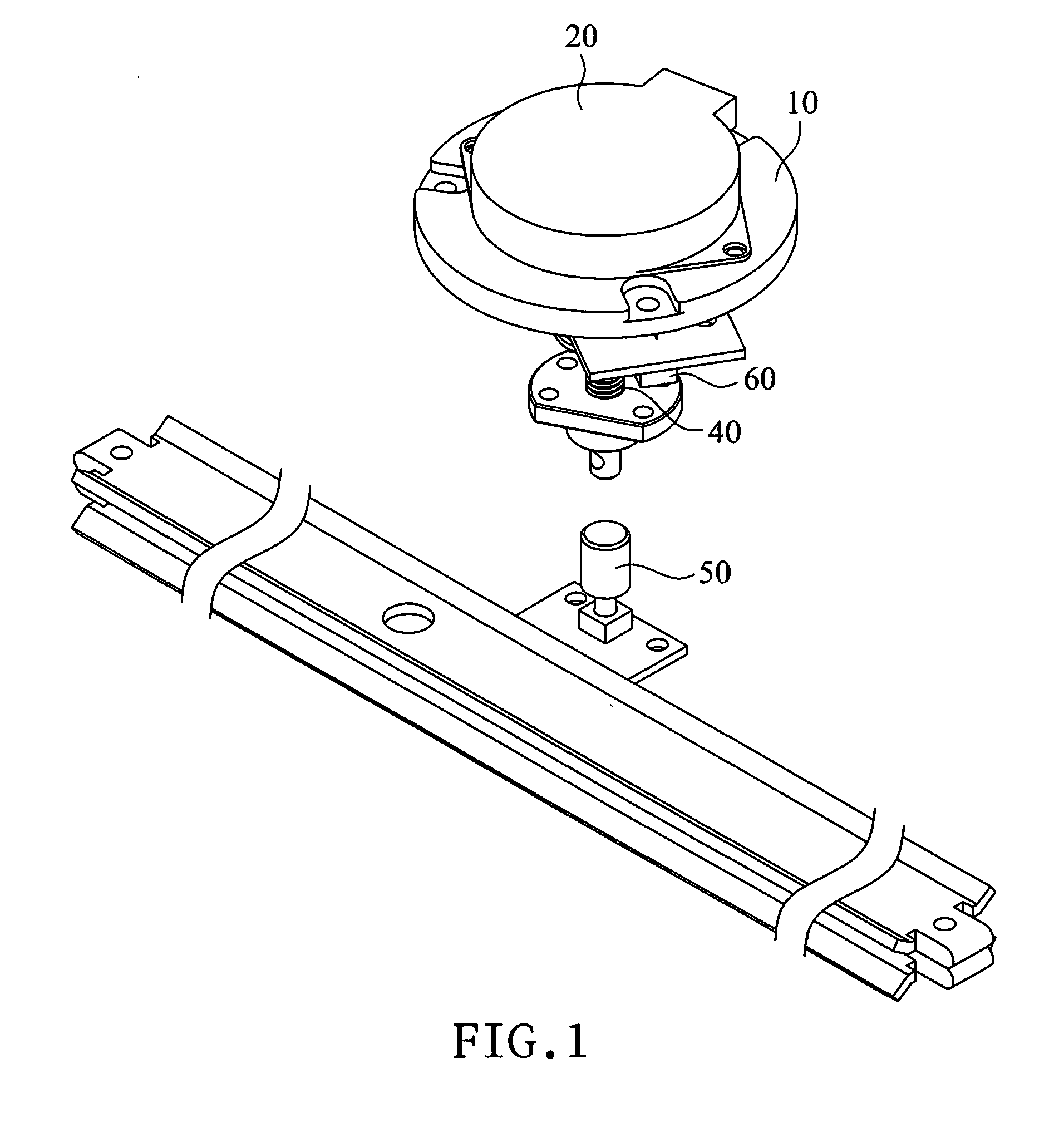

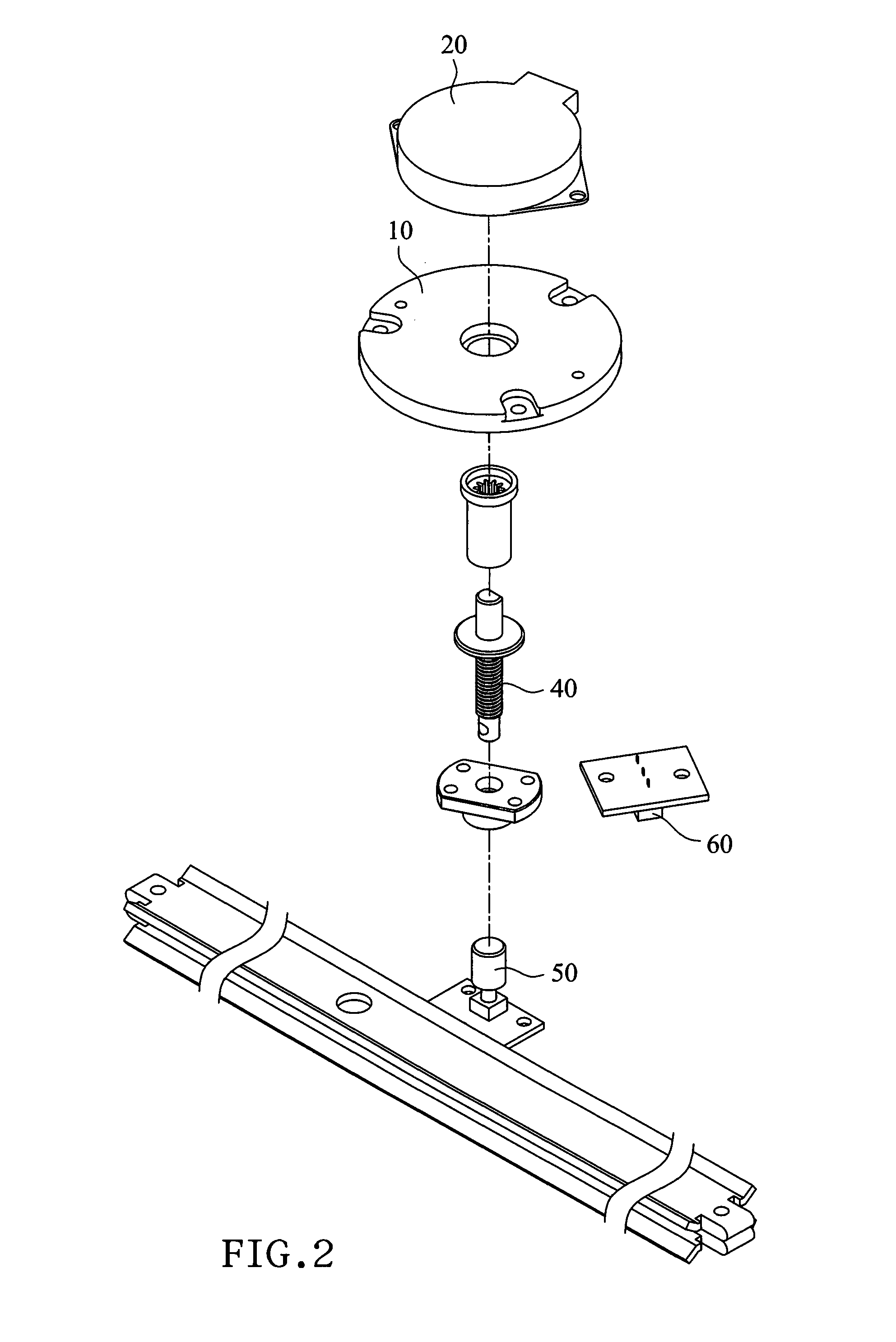

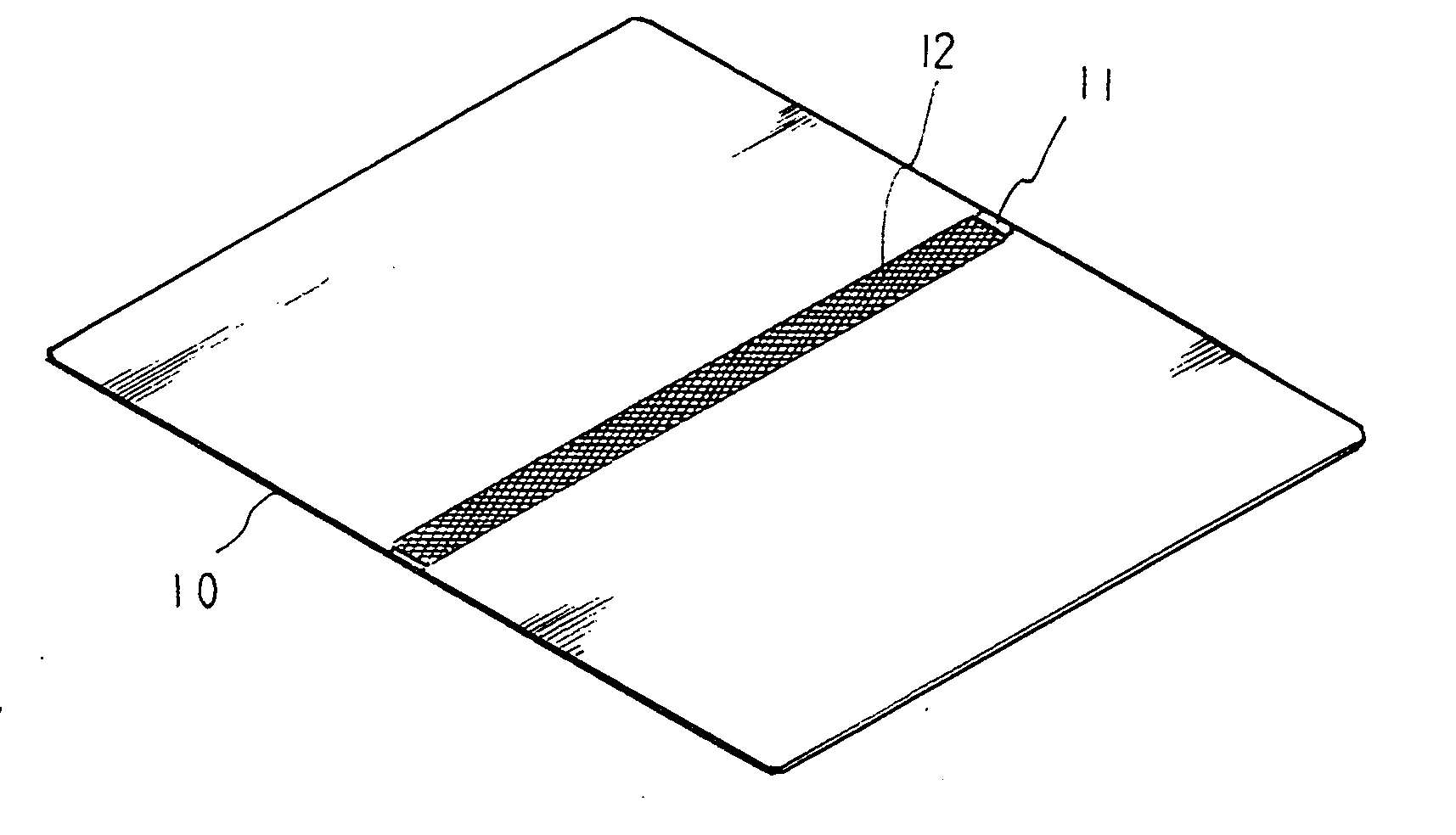

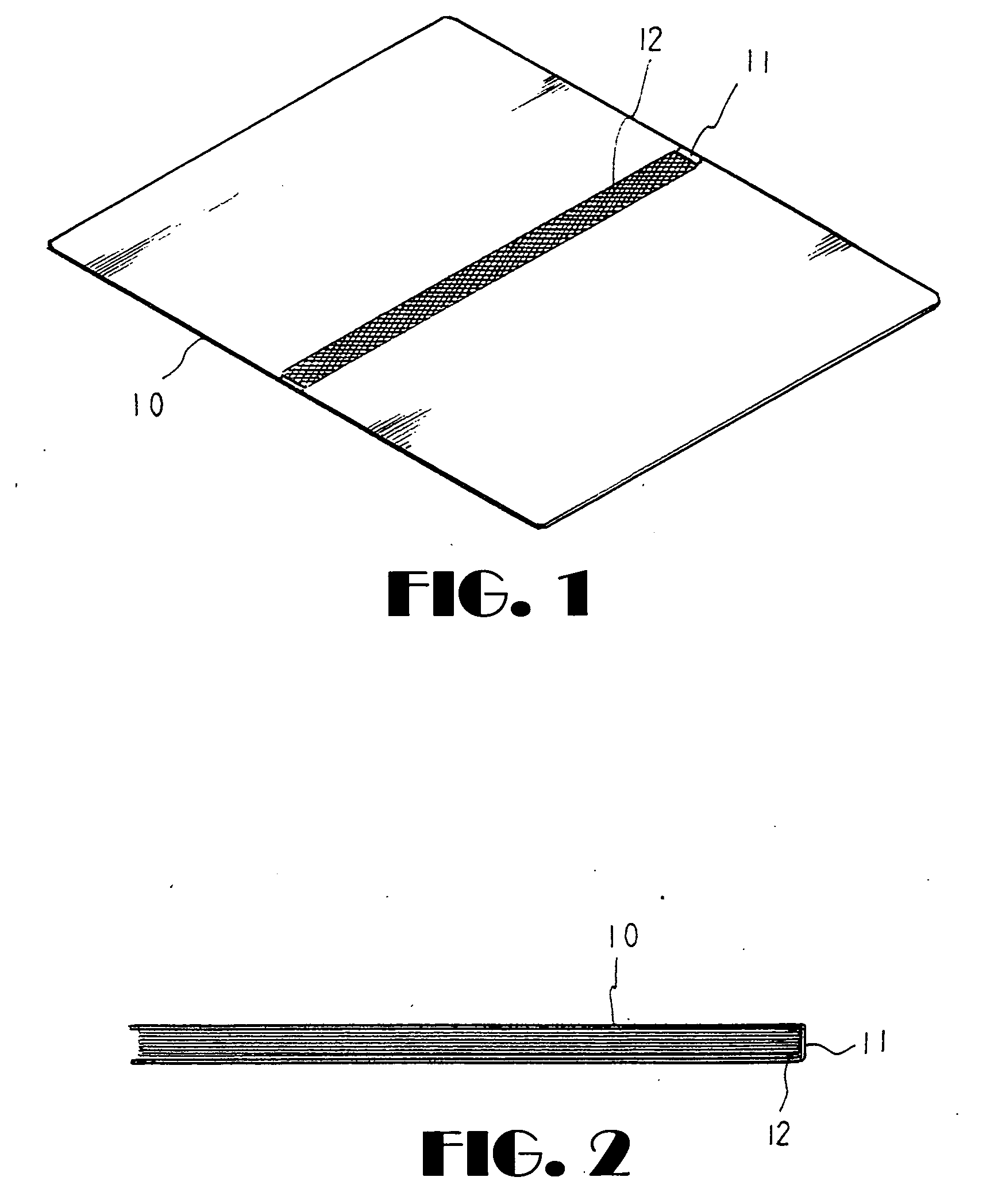

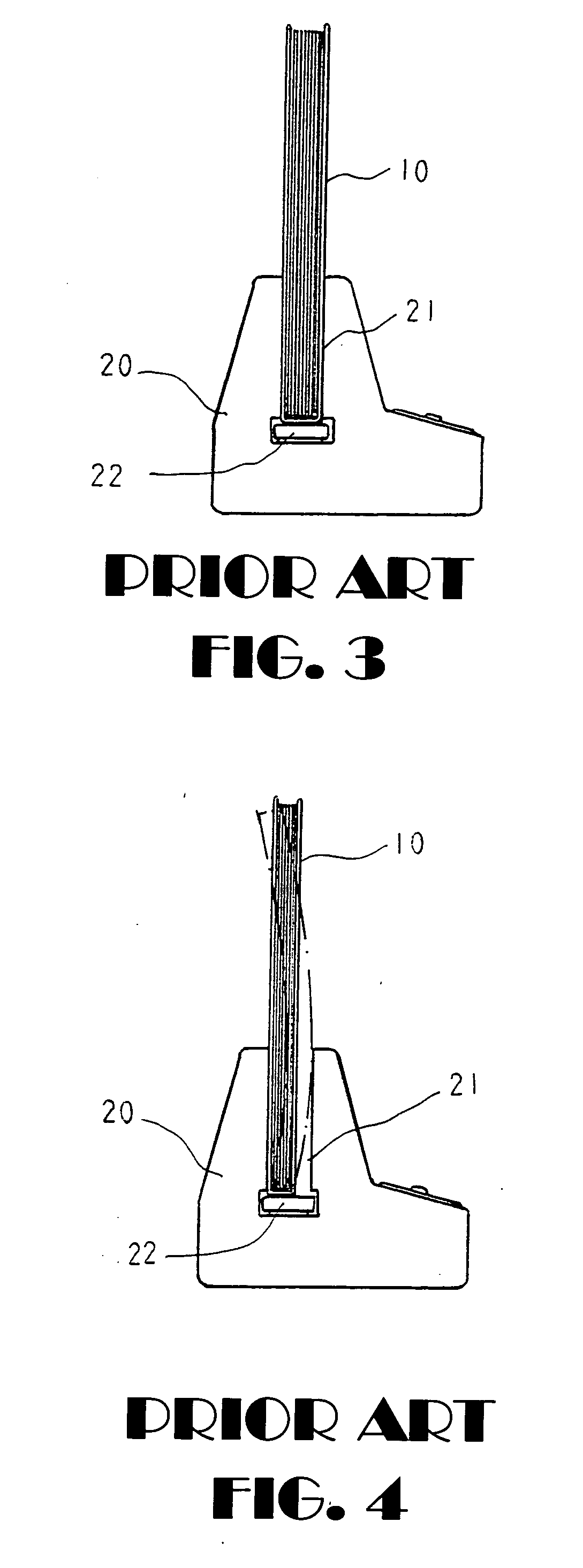

Thickness measuring device of laminating machine

InactiveUS20110132545A1Easy to operateImprove the usefulnessControlling laminationLaminationMicrocontrollerElectricity

A thickness measuring device of a laminating machine includes a mount, a stepper motor, a screw rod, a first contact-activated element, a second contact-activated element, and a microcontroller unit. The stepper motor is coupled to the mount. The screw rod is interlocked with the stepper motor. The first contact-activated element is provided at a position corresponding to and some distance below the screw rod. The second contact-activated element is provided at a position corresponding to and some distance above the screw rod. The microcontroller unit is electrically connected to the stepper motor, the first contact-activated element, and the second contact-activated element so as to provide initialization setting and exercise judgment and control after receiving a thickness measurement. Thus, the thickness of an object to be detected can be conveniently measured.

Owner:TEX YEAR INDS

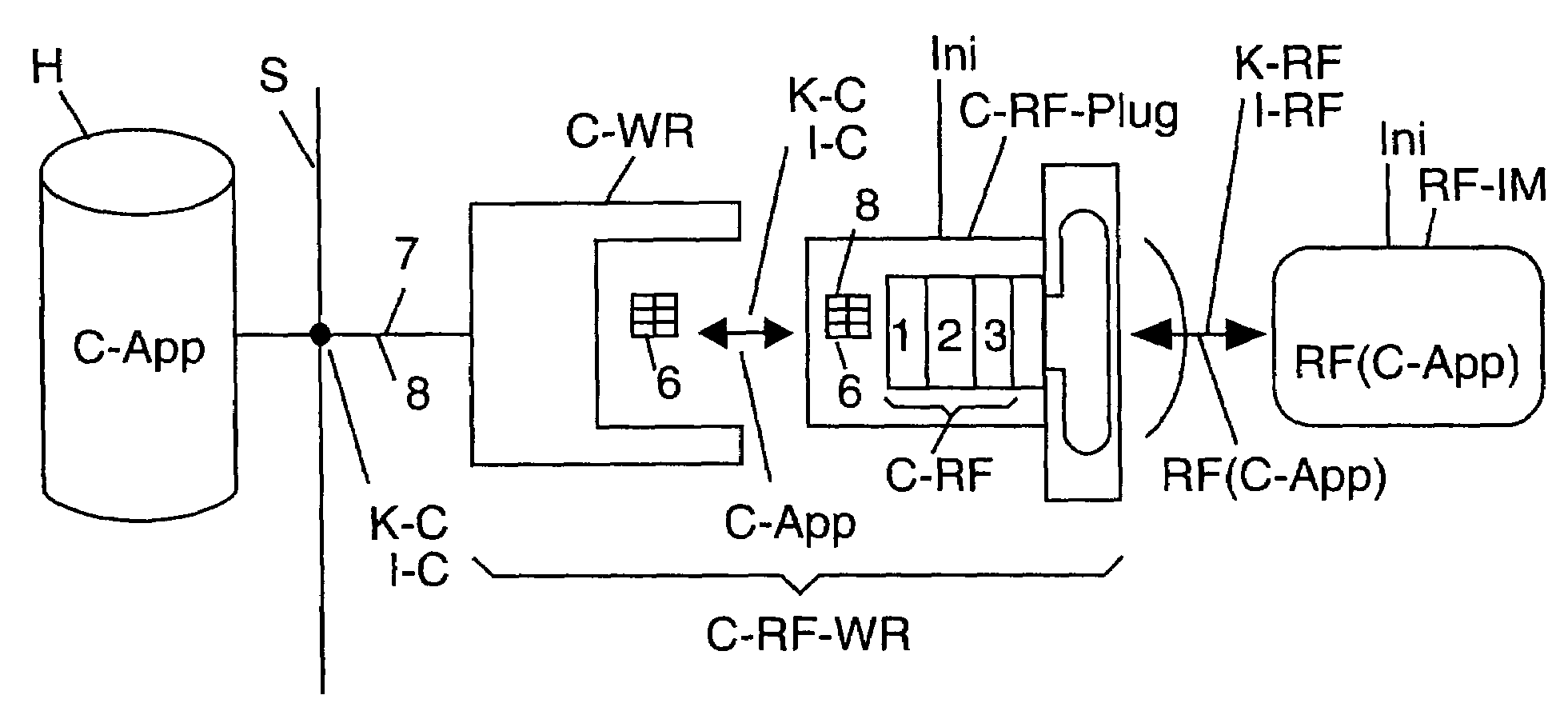

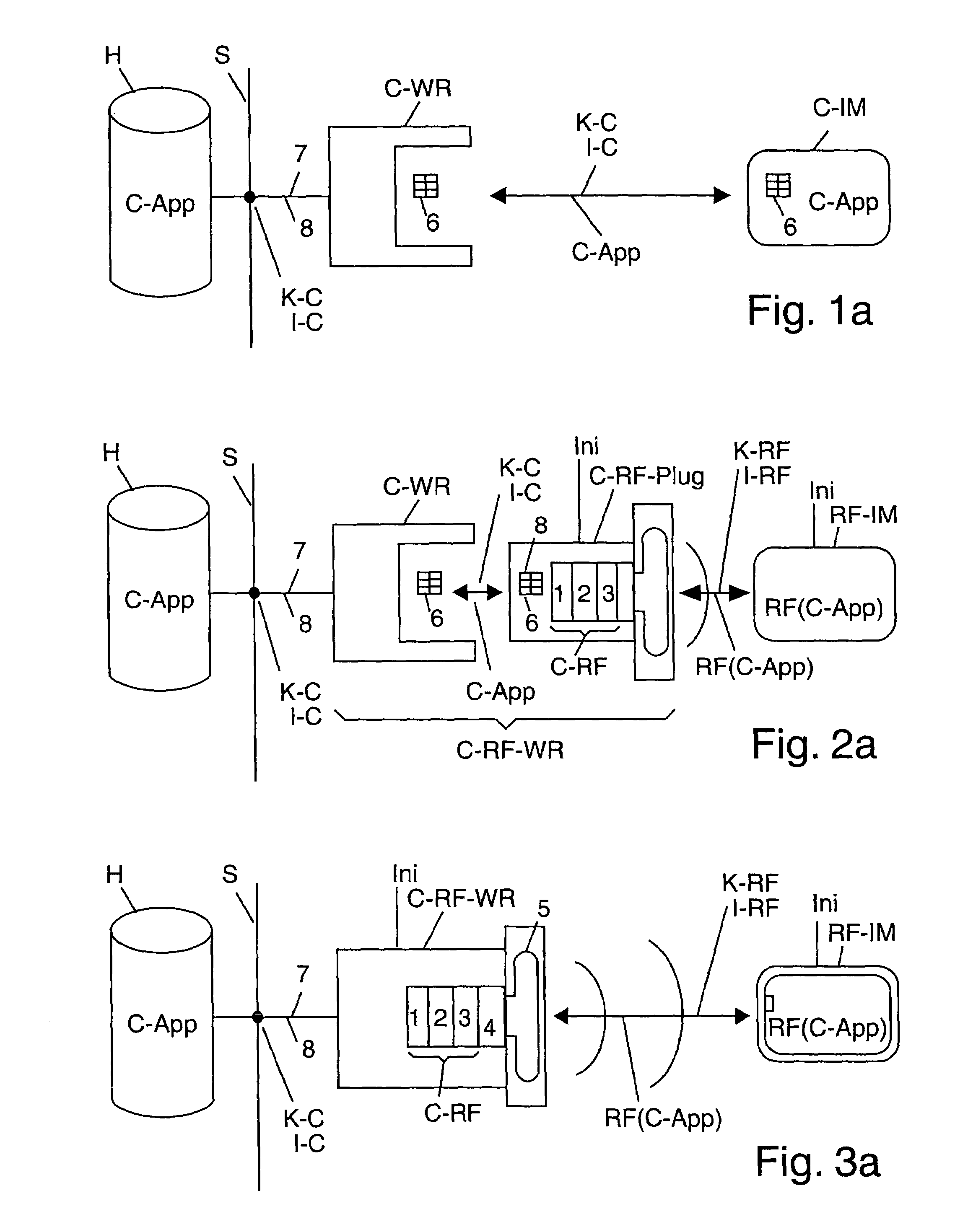

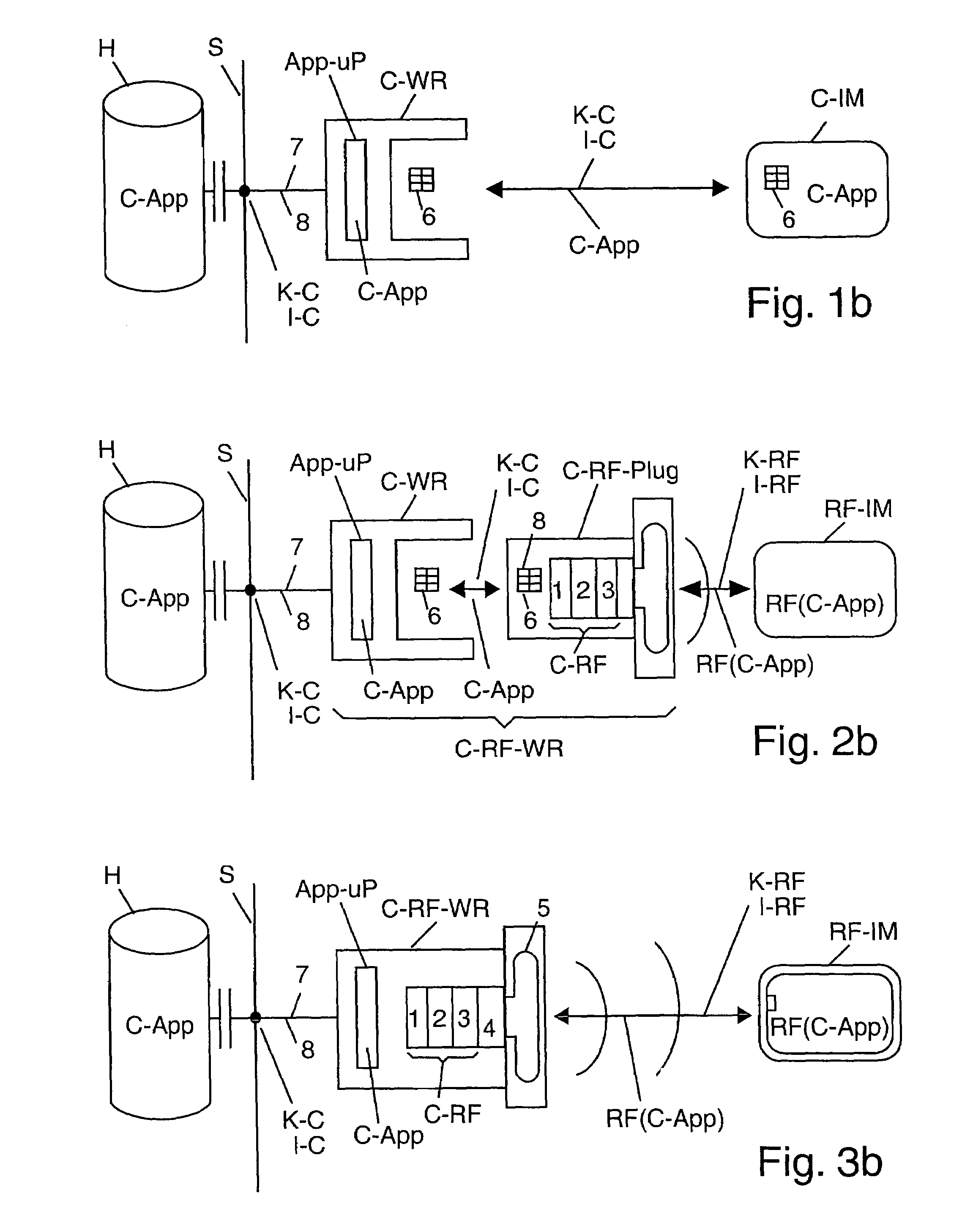

Method for operating non-contact identification media

InactiveUS7172128B2Simpler and cheap complementLess effortComplete banking machinesInput/output to record carriersContact activationApplication computers

For operation of contact-less identification media in a system with contact applications for contact cards, an initialized converter module is connected in series as a read / write station. This converter module, on the one hand, executes a contact-less communication with initialized contact-less identification media and, on the other hand, a contact communication at a contact card interface to a host computer or to an application computer for the communication with a contact application of the system and the converter module translates the contact-less communication with respect to communication rules and information into a contact communication with contact information and vice versa and the initialization of the converter module is defined in a hierarchic authorization system. This makes possible a particularly simple and efficient introduction of contact-less identification media into existing contact card systems and—installations.

Owner:LEGIC IDENTSYSTEMS AG

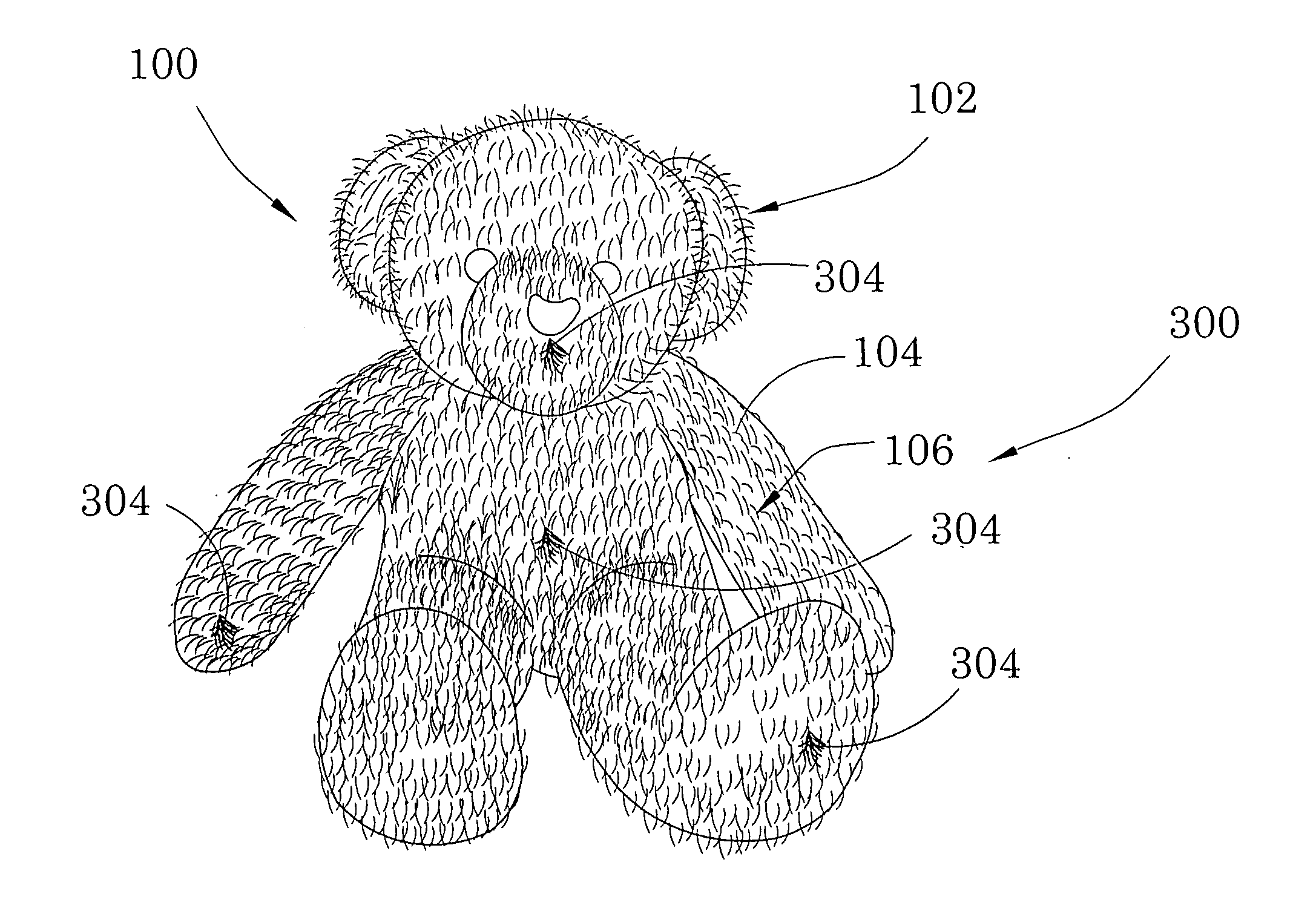

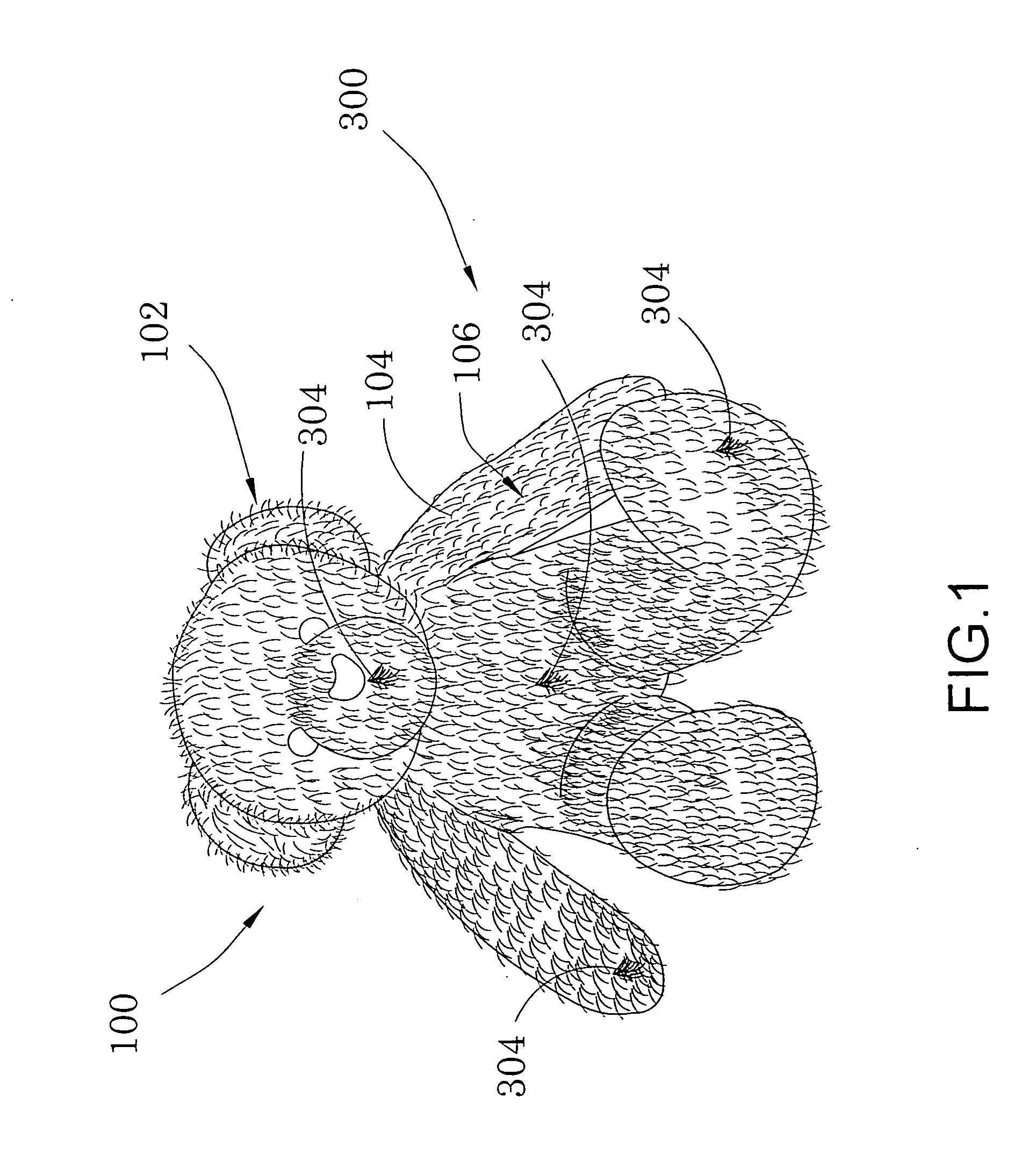

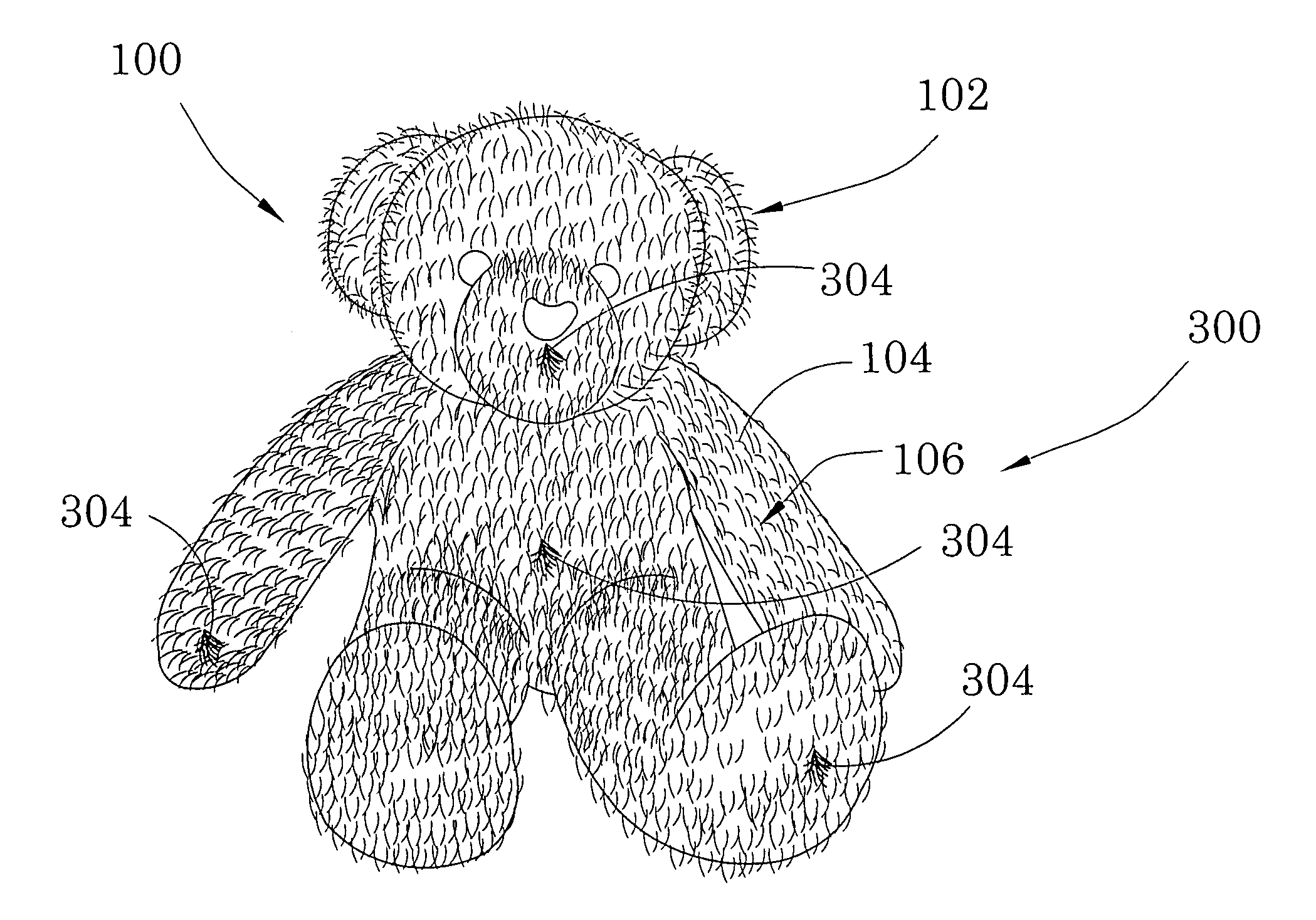

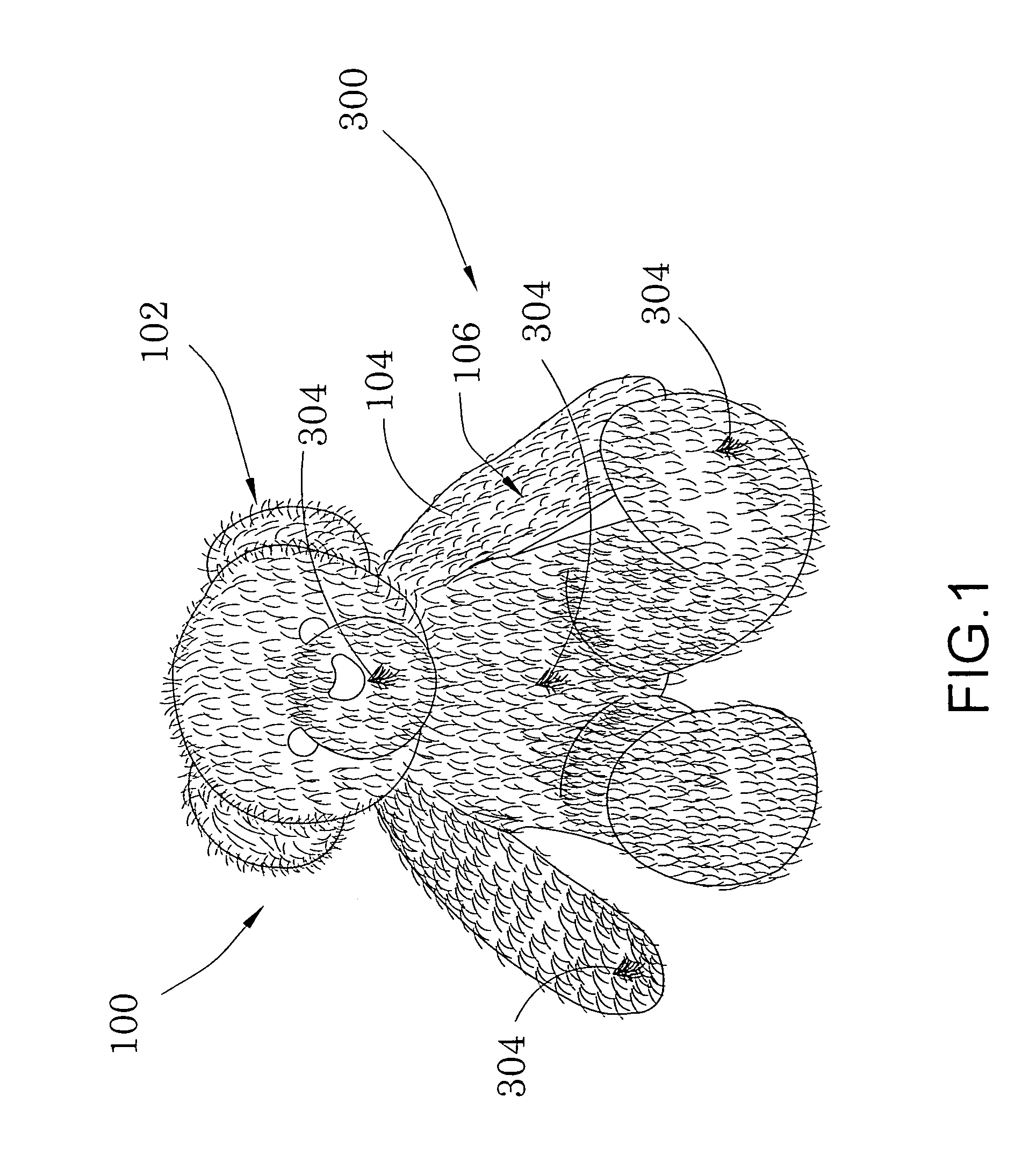

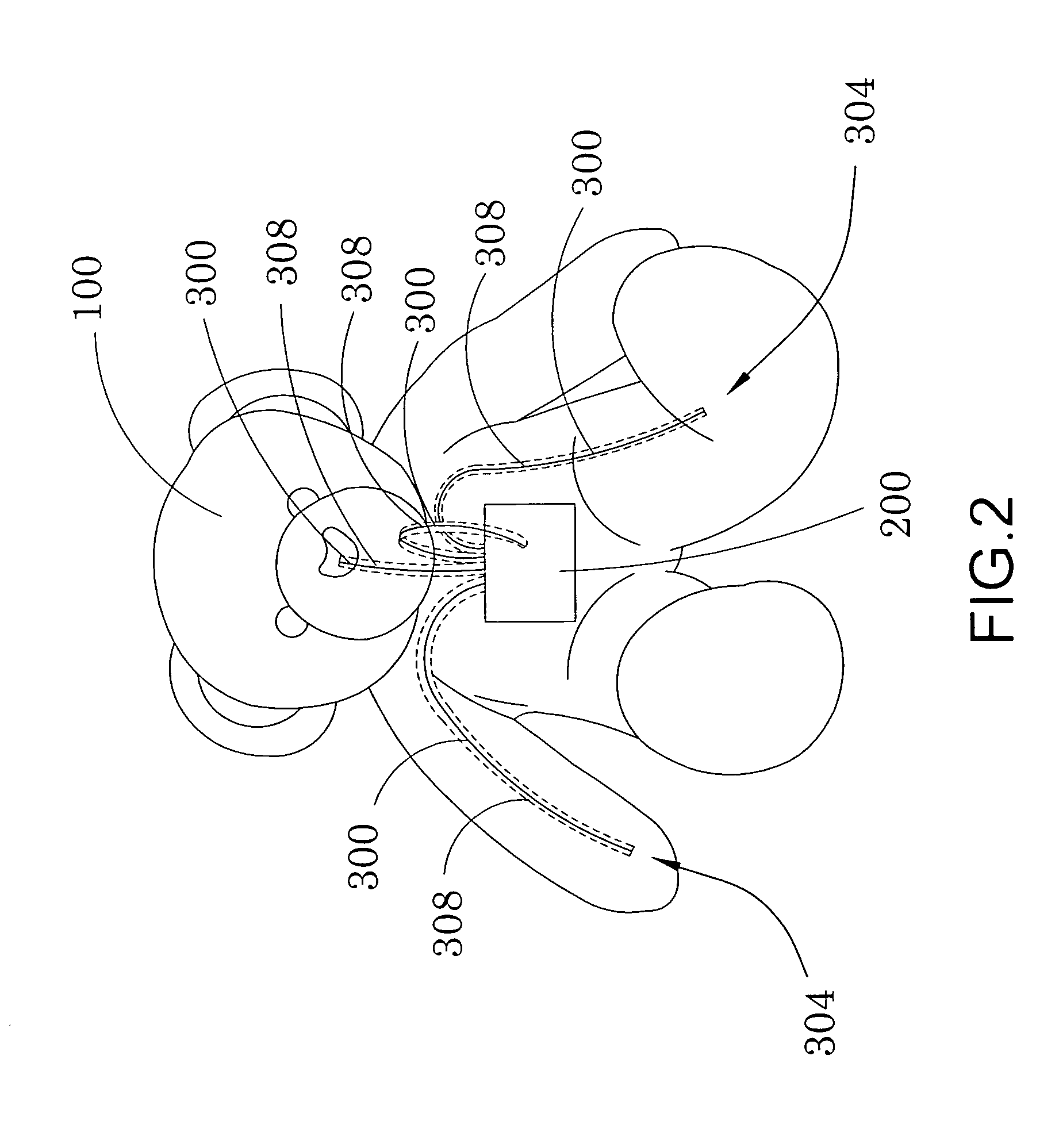

Low powered activation arrangement and method thereof

InactiveUS20120115392A1Free of non-washable partImprove rigidityDollsComputerized toysElectricityContact activation

A fabric product with a low powered activation device and a conductive arrangement, which includes a body having an outer covering which is soft and flexible to providing an outer skin surface and an inner skin surface, and defines a body receiving cavity. The low powered activation device is an electronic unit received inside the body receiving cavity which comprises a casing, a power source, an activation circuit, and an operator which is activated through the activation circuit. The conductive arrangement electrically connects between the electronic unit and the outer skin surface, which includes one or more conductive threads affixed on the inner skin surface, each having one end portion defining an activation control which penetrates through the inner skin surface to the outer skin surface, thereby when the activation control is contacted by a user, the activation circuit is activated to activate the operator of the electronic unit.

Owner:CHU JACK

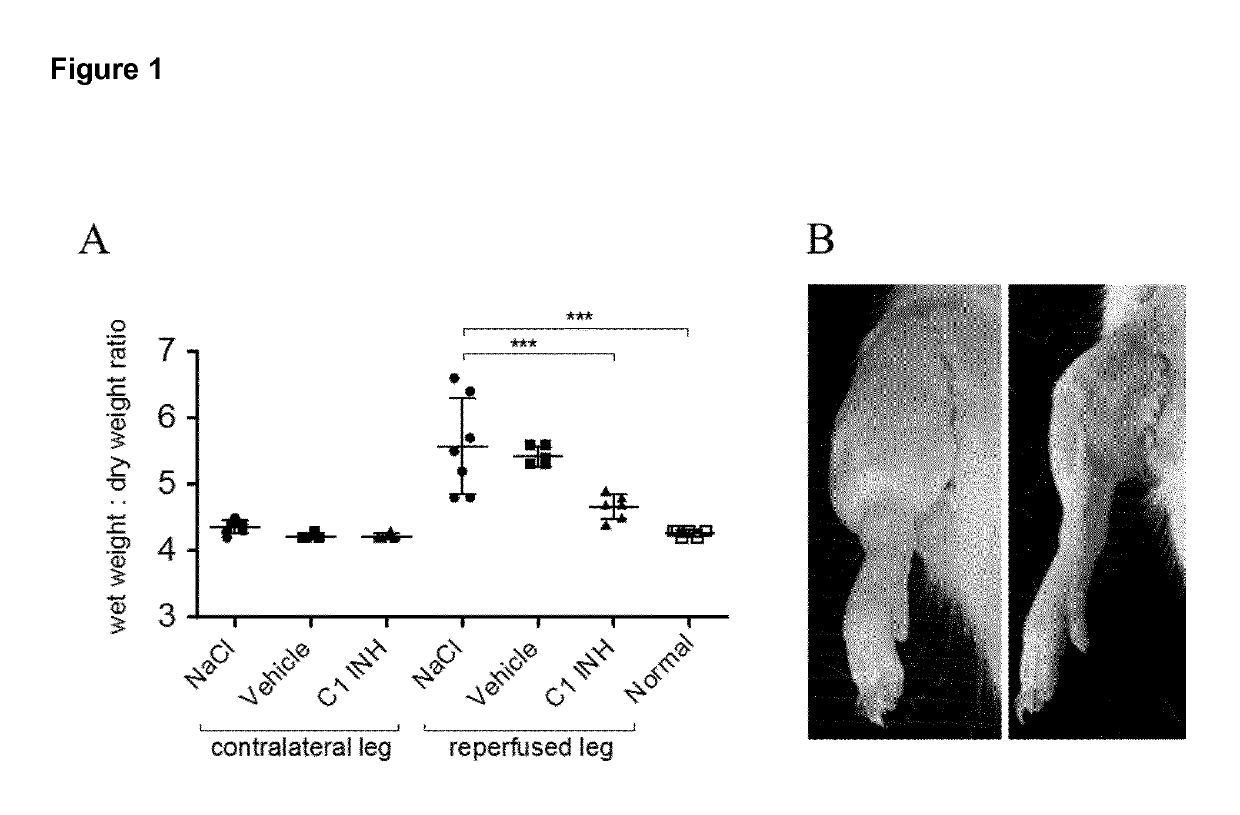

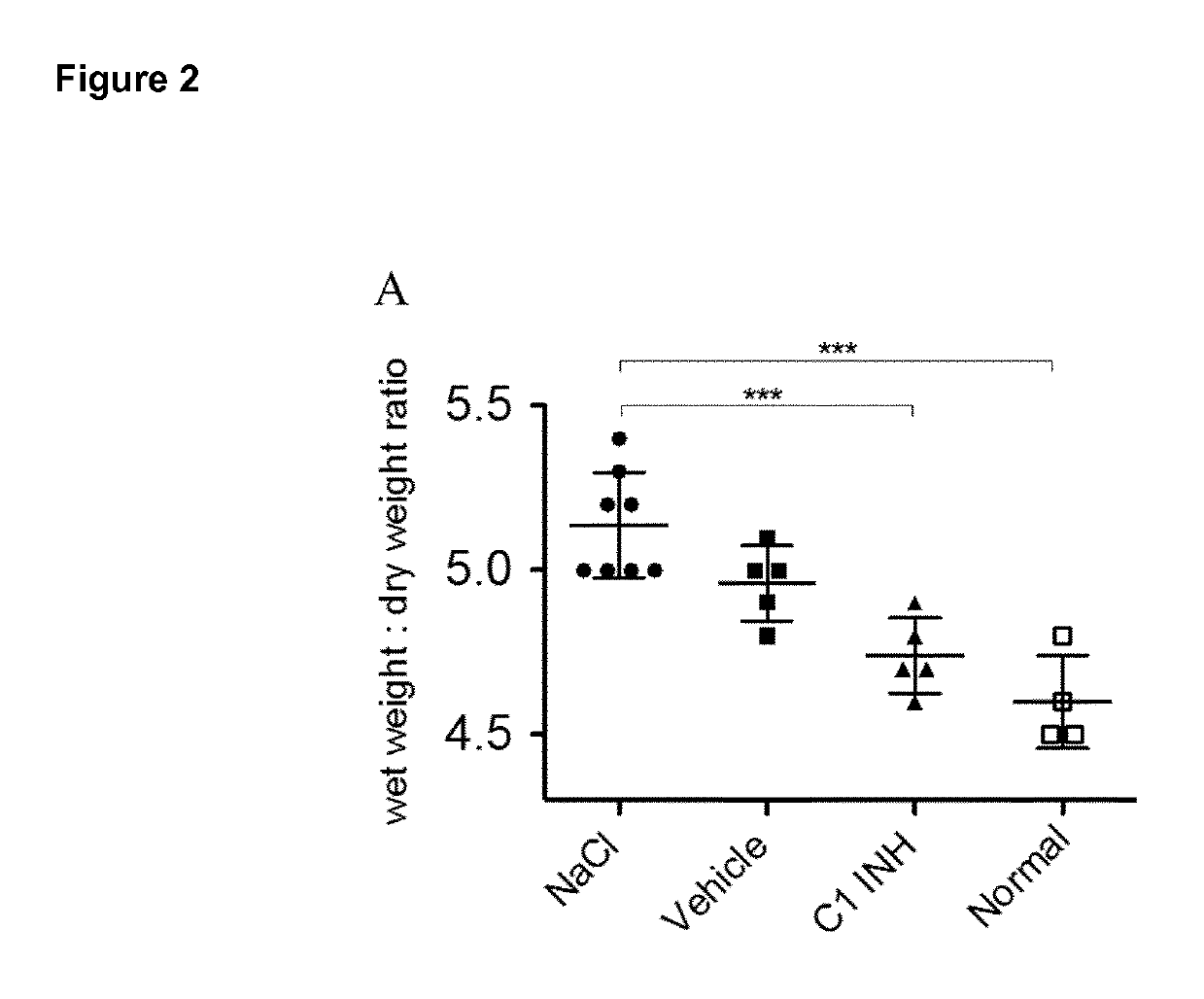

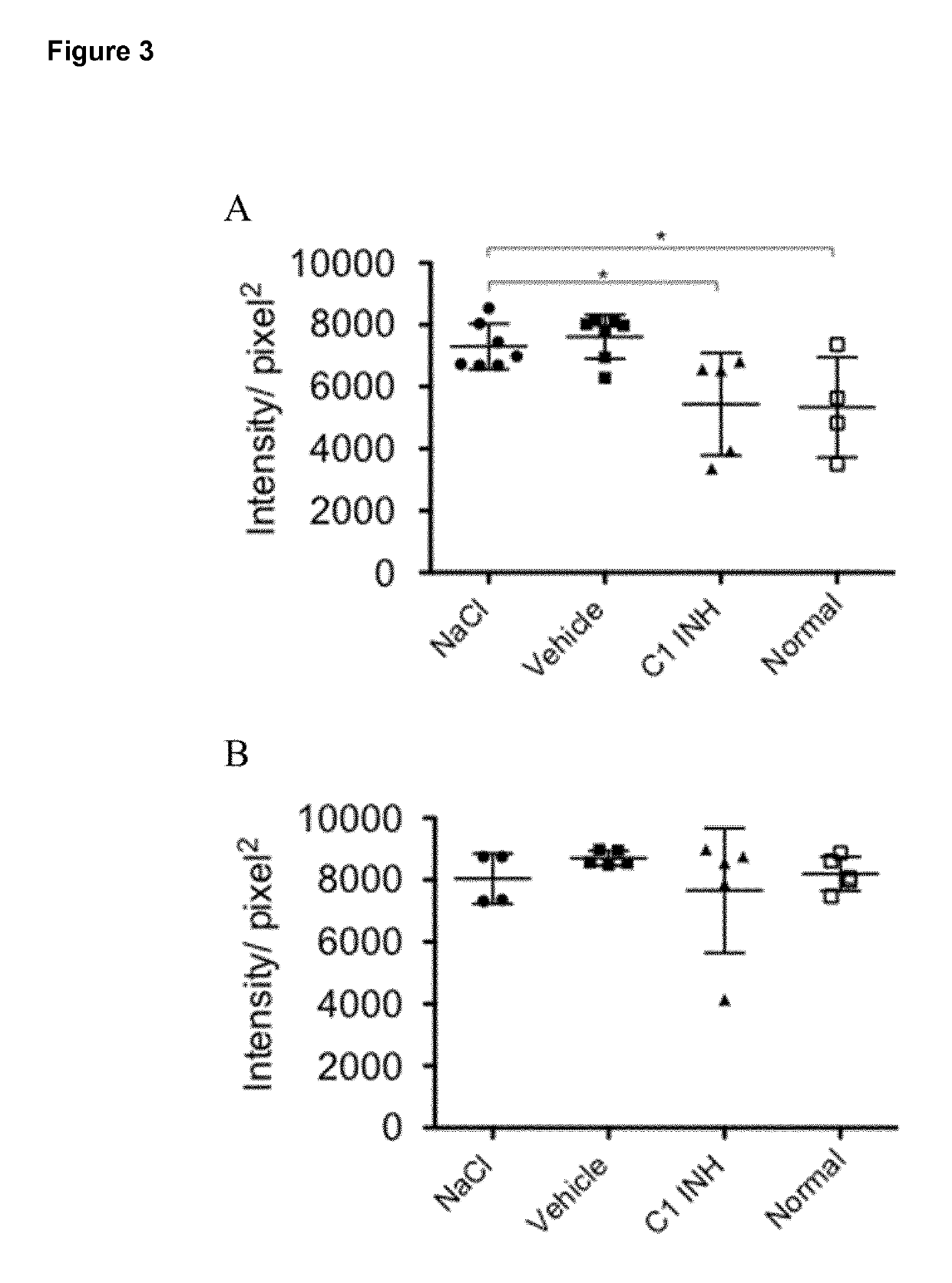

Treatment and prevention of remote ischemia-reperfusion injury

ActiveUS10286047B2Good treatment effectNervous disorderPeptide/protein ingredientsReperfusion injuryContact activation

The present invention relates to a contact activation system inhibitor, preferably a C1INH, for use in the treatment and / or prevention of remote ischemia-reperfusion injury (IRI), comprising administering the contact activation system inhibitory to an individual.

Owner:UNIVERSITY OF BERN +1

Medical biodegradable compound hemostatic sponge having high water absorption and preparation method thereof

InactiveCN107308487ANeat network structureUniform distribution of poresSurgical adhesivesContact activationPore distribution

The invention belongs to the technical field of medical apparatuses and instruments and particularly relates to a medical biodegradable compound hemostatic sponge having high water absorption and a preparation method thereof. The hemostatic material for the medical biodegradable compound hemostatic sponge is made from a copolymer and is stable in performance. Squid ink polysaccharide provides powerful and comprehensive hemostatic functions, the shortcoming that chitosan cannot activate a blood coagulation factor VII is overcome, and dodecyl chitosan can rapidly stop arterial bleeding. Oxidized microcrystalline cellulose is introduced into collagen liquid and has good hygroscopicity and stability, blood coagulation can be promoted through contact activation, and the hemostatic performance is excellent. Safe and non-toxic crosslinking is adopted, the hemostatic sponge is orderly in net-shaped structure, pore distribution is uniform, the organization is loose and soft, and the toughness is good.

Owner:TAICANG CUSTOM NEW MATERIALS CO LTD

Anti-overflow paint brush

InactiveCN108952099APrevent splashImprove efficiencyBuilding constructionsContact activationEngineering

The invention discloses an anti-overflow paint brush. The anti-overflow paint brush comprises a horizontally arranged U-shaped work mounting plate, wherein a work mounting cylinder is horizontally androtatably installed at the middle position of the upper half section of the U-shaped work mounting plate. A rotating guiding structure is arranged at the position, on the left side of the work mounting cylinder, in the U-shaped work mounting plate in a matched mode, and a power transmission structure is vertically arranged at the position, on the right side of the work mounting cylinder, in the U-shaped work mounting plate in an inlaid mode. A guiding operating rod is disposed vertically at the middle position of the lower part of the U-shaped work mounting plate, and a supporting mounting plate is horizontally disposed at the upper end of the guiding operating rod. Rotating mounting columns are separately disposed at the left and right ends of the supporting mounting plate through rotating shafts in an upward rotating mode, and the upper ends of the rotating mounting columns are separately and symmetrically fixed to the lower end of the U-shaped work mounting plate through rotating shafts. The anti-overflow paint brush has the advantages of compact structure design, high guiding efficiency, effective prevention of paint splashing by contact activation, continuous painting operation, high efficiency and the like.

Owner:佛山市北科科技创新服务中心

Low powered activation arrangement and method thereof

ActiveUS8946945B2Improve securityImprove rigidityBatteries circuit arrangementsDollsElectricityContact activation

A fabric product with a low powered activation device and a conductive arrangement, which includes a body having an outer covering which is soft and flexible to providing an outer skin surface and an inner skin surface, and defines a body receiving cavity. The low powered activation device is an electronic unit received inside the body receiving cavity which comprises a casing, a power source, an activation circuit, and an operator which is activated through the activation circuit. The conductive arrangement electrically connects between the electronic unit and the outer skin surface, which includes one or more conductive threads affixed on the inner skin surface, each having one end portion defining an activation control which penetrates through the inner skin surface to the outer skin surface, thereby when the activation control is contacted by a user, the activation circuit is activated to activate the operator of the electronic unit.

Owner:CHU JACK

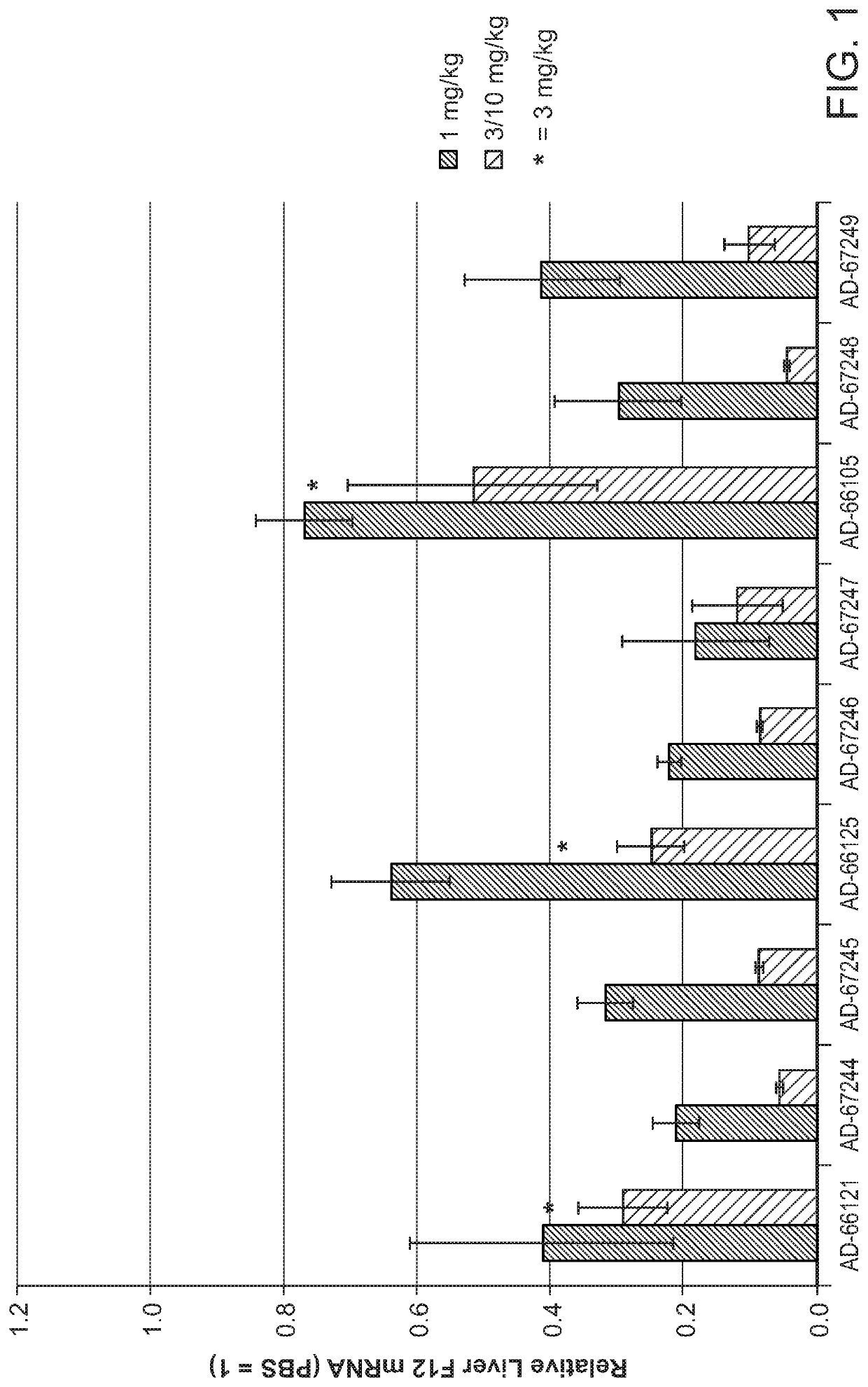

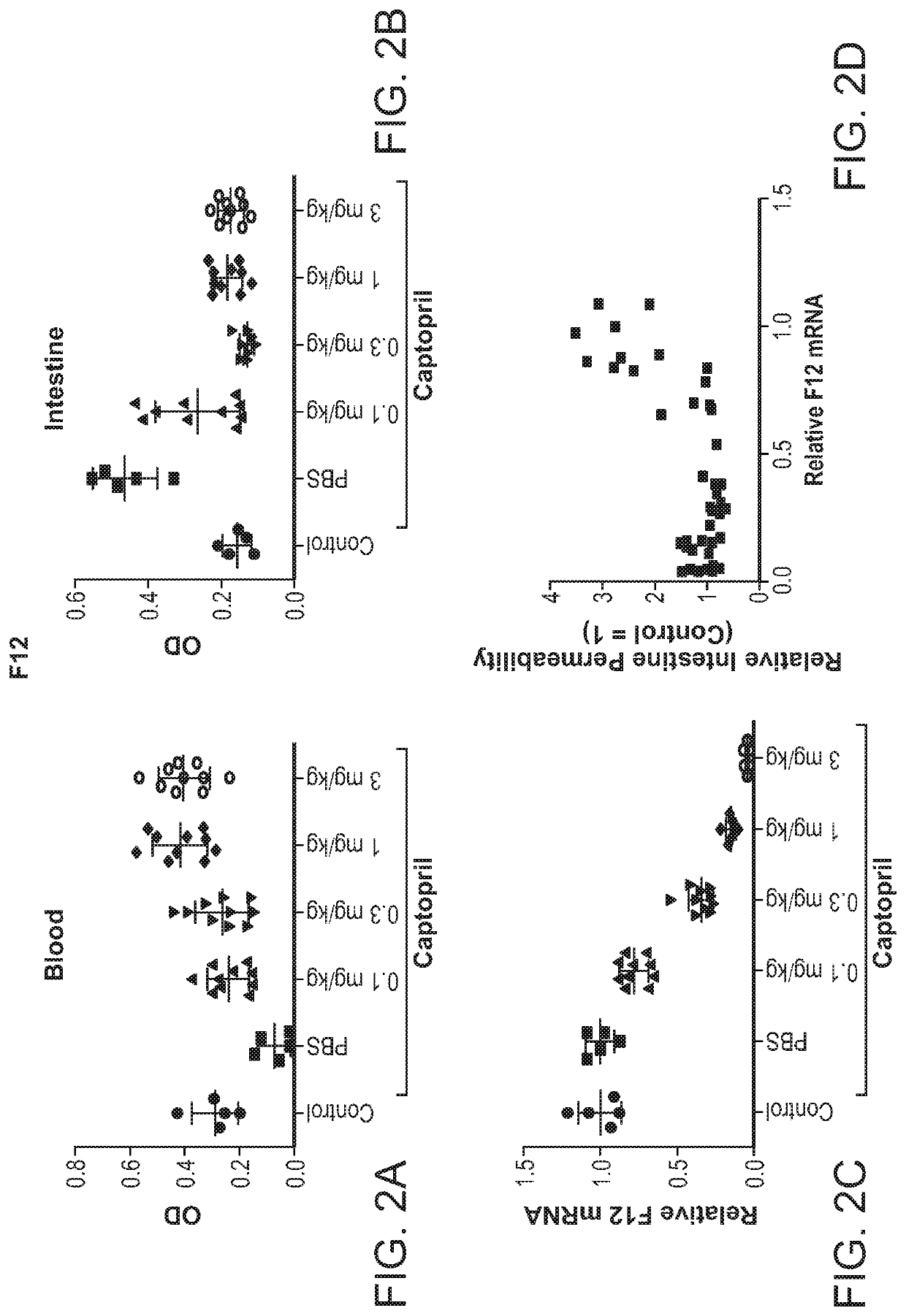

METHODS FOR TREATING OR PREVENTING CONTACT-ACTIVATION PATHWAY-ASSOCIATED DISEASES USING iRNA COMPOSITIONS TARGETING FACTOR XII (HAGEMAN FACTOR) (F12)

InactiveUS20200208150A1Reduce depositionCardiovascular disorderDNA/RNA fragmentationDiseaseContact activation

The present invention relates to methods of use of RNAi agents, e.g., double stranded RNAi agents, targeting a Factor XII (Hageman Factor (F12) gene, for treating subjects having a contact activation pathway-associated disease, such as a thrombophilia or hereditary angioedema (HAE), methods for preventing at least one symptom in a subject having a contact activation pathway-associated disease, such as a thrombus formation or an angioedema attack, and RNAi agents targeting an F12 gene, for use in the methods of the invention.

Owner:ALNYLAM PHARMA INC

Non-contact shutter activation system and method

A shutter operating system is provided that depends on electromagnetic energy to operate shutter blades. A permanent magnet and solenoid system operate the shutter blades. Movement of the magnet causes the shutter blades to move between an open and a closed position over a lens. The permanent magnet can be moved between a pair of spaced coils by selectively energizing first one coil then the other. The magnet can be attached directly to a shutter blade or in the case of a rotary shutter, the magnet can be attached to a drive ring that in turn is mechanically coupled to the shutter blades.

Owner:VA INC

Catalytic conversion method for directly processing high chlorine raw material

ActiveCN105368486AImprove conversion rateFully adsorbedRefining with non-metalsRefining with metalsContact activationProduct selection

The present invention relates to a catalytic conversion method for directly processing a high chlorine raw material. The method comprises that a pre-heated high chlorine raw material and a first catalytic conversion catalyst are subjected to a first contact reaction to make the chlorine-containing compound in the high chlorine raw material be adsorbed on the first catalytic conversion catalyst and decompose less than or equal to 30% by weight of the chlorine-containing compound to obtain a first contacting product; and the first contacting product and a second catalytic conversion catalyst are subjected to a second contact reaction to remove the chlorine-containing compound, wherein the reaction temperature of the second contact reaction is higher than the reaction temperature of the first contact reaction. With the method of the present invention, the high chlorine raw material can be directly processed while the high dechlorination rate can be obtained, the high chlorine raw material conversion rate can be improved, the product selectivity can be improved, and the dry gas yield and the coke yield can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Activation unit for explosive masses or explosive bodies

InactiveUS8714089B2Ideal energy inputShort reaction timeAmmunition projectilesFirework flares/torchesThermal energyContact activation

An activation unit for explosive masses or explosive bodies includes an ejector tube and high-performance heating elements mounted around the ejector tube, each made of at least one heating wire supplied with electrical power by a control unit. Each heating wire is enclosed in a casing and embedded in a material minimizing heat loss. When the explosive body is passed through the activation unit, the jacket surface of the explosive body contacts the individual elements of the activation unit in a direct or non-contact manner. Thermal energy is transferred to the explosive body by means of the heating wires, and the body ignites at the contact points. A further activation unit includes heating elements in the ejector tube, at least partially fed longitudinally through the ejector tube, made of heating wire clad with CrNi steel and contact plates soldered thereto.

Owner:RHEINMETALL WAFFE MUNITION GMBH

Folder binding device

Provided is a folder binding device comprising a binding assembly including a table inclined toward rear, two uprights at both rear corners of the table, a platen moveably provided across the uprights, a central rod extended upward from the platen, and two parallel guide posts extended upward from positions proximate both ends of the platen; and a detachable heater including a front heating member. Placing one or more folders on the table with a joint of each folder facing the platen wherein each folder has orderly sheets put together by adhesive, lowering the platen by pushing down the rod to press the joint of each folder and cause each joint to be in contact with the heating member, and activating the heating member will melt the adhesive in each folder to bind the sheets thereof after cooling.

Owner:FU CHUN FU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com