Thermal regeneration furnace for waste powdered activated carbon

A technology of powder activated carbon and thermal regeneration, which is applied in filter regeneration, filtration separation, petroleum industry, etc. It can solve the problems of destroying greening, wasting resources, violating circular economy, etc., and achieves reducing air velocity, increasing temperature, and reducing the amount of inert gas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

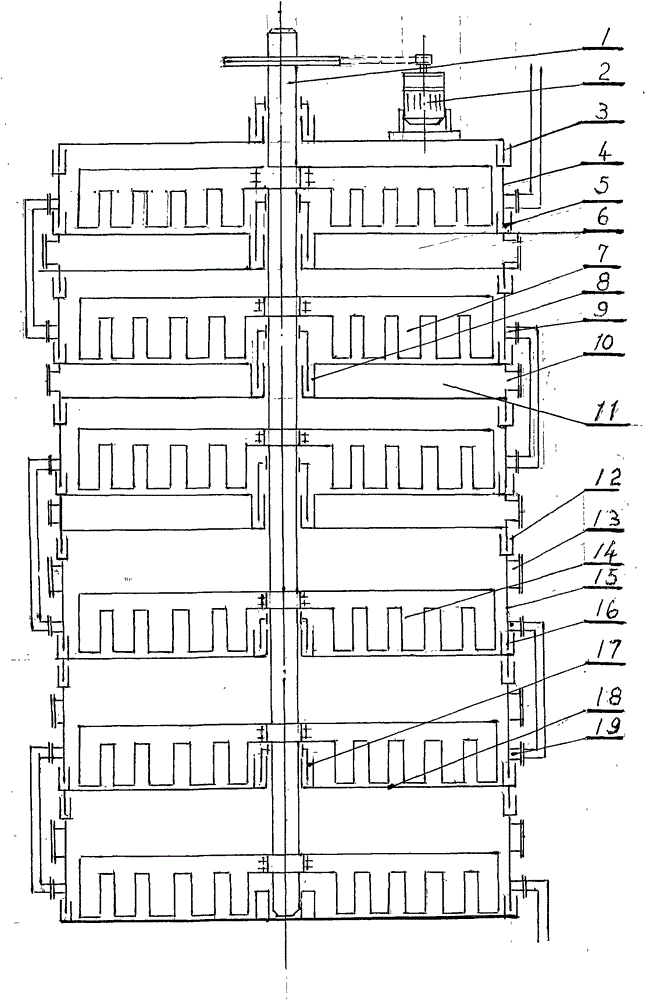

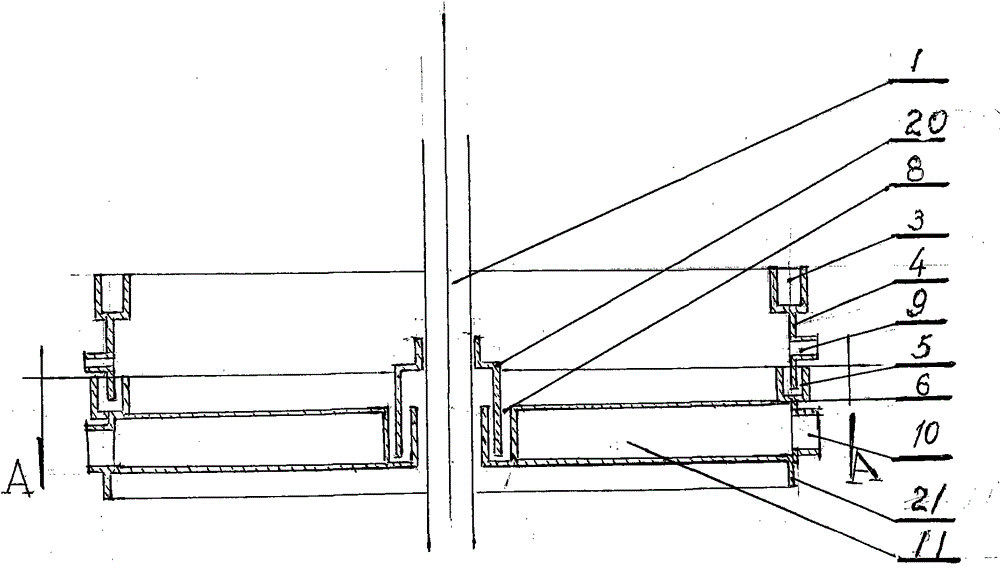

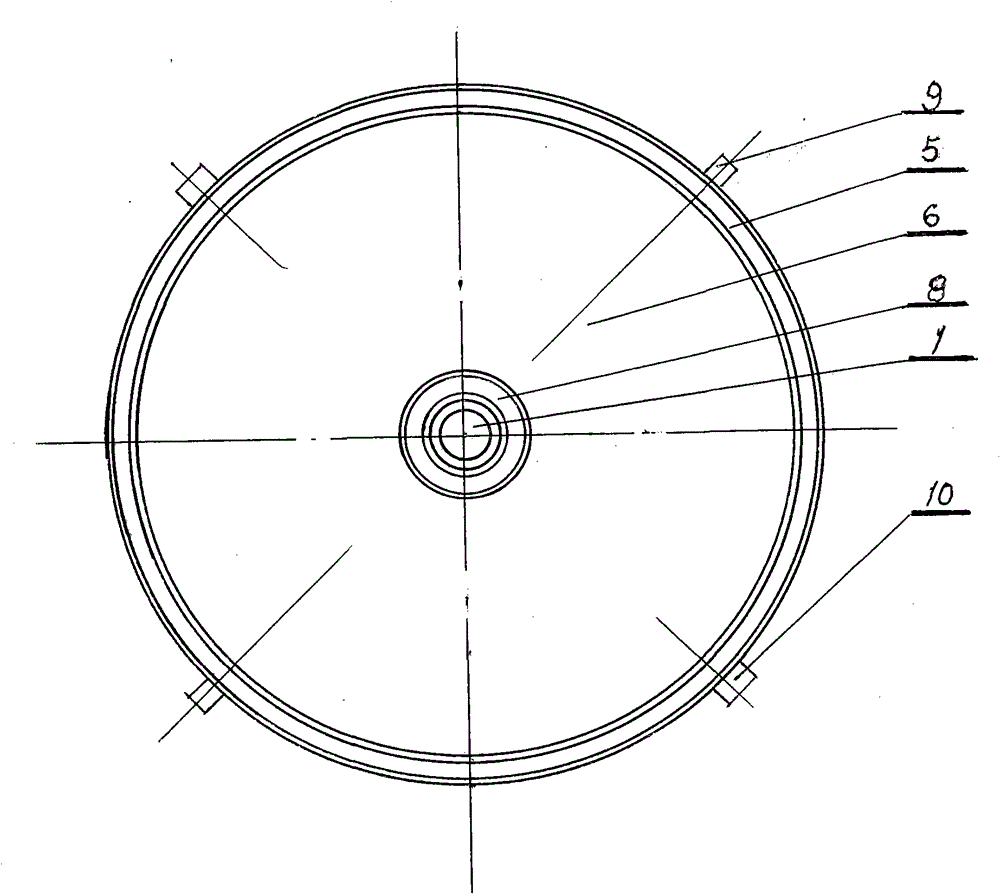

[0011] Embodiments of the present invention will be further described in conjunction with the accompanying drawings, as figure 1 As shown, the waste powder activated carbon thermal regeneration furnace includes a rotating stirring shaft (1), a driving machine (2), a dry distillation cylinder (4) with a waste powder carbon inlet and outlet (9), a dry distillation tray stirrer (7), Carbonization tray (6) with combustion gas inlet and outlet (10) and combustion gas heating chamber (11), activation cylinder (15) with activation gas inlet and outlet (13) and carbonization powder carbon inlet and outlet (19), activation tower Disc stirrer (14) and activation tray (18) etc. constitute. It is characterized in that: the dry distillation section composed of multiple retort trays (6) with agitators (7) and retort barrel (4) is placed vertically by multiple activation trays (18) with agitators (14). On the activation section formed by the activation cylinder (15), the two sections share ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com