Method for preparing N,N-dialkylacrylamide

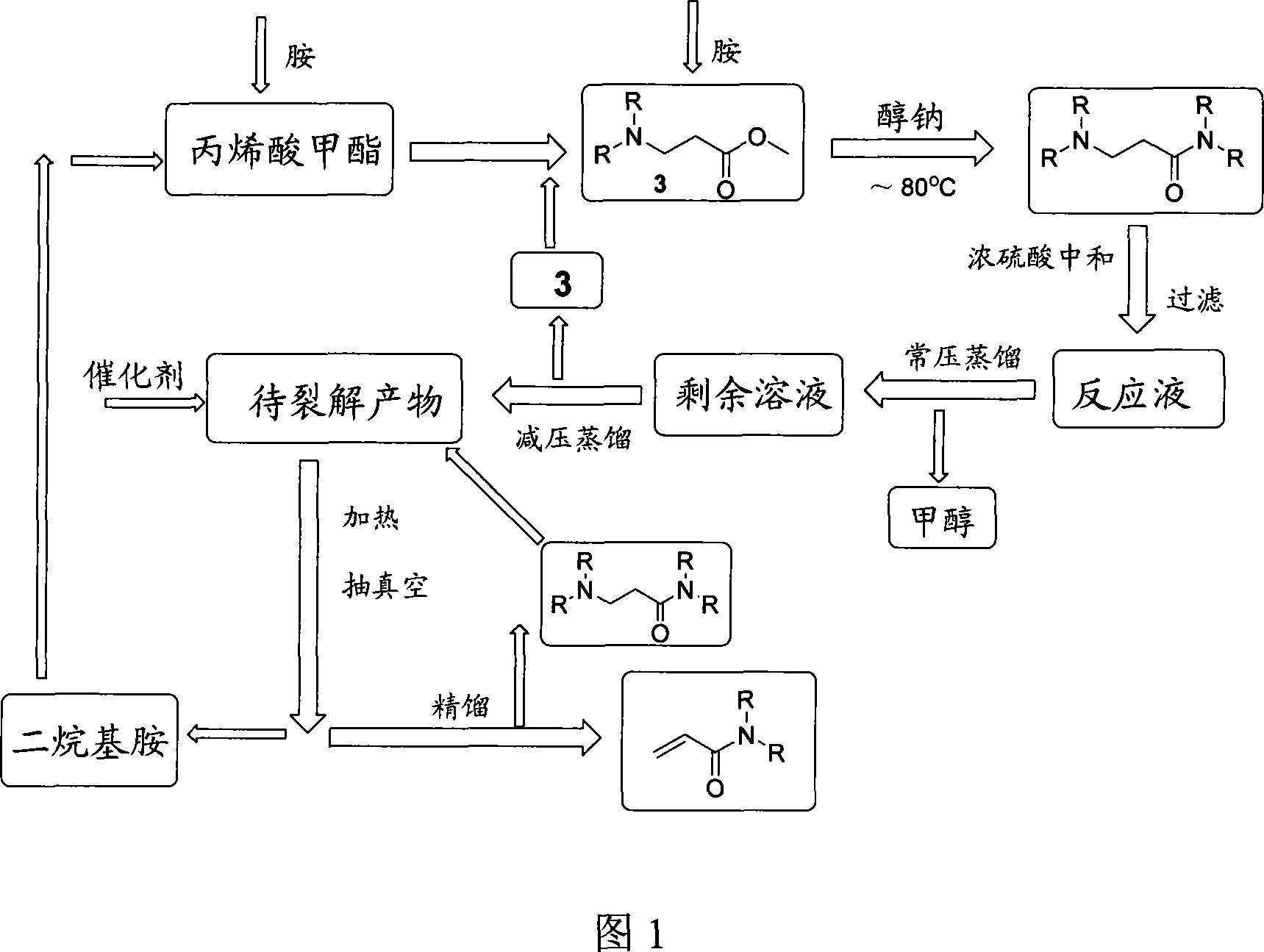

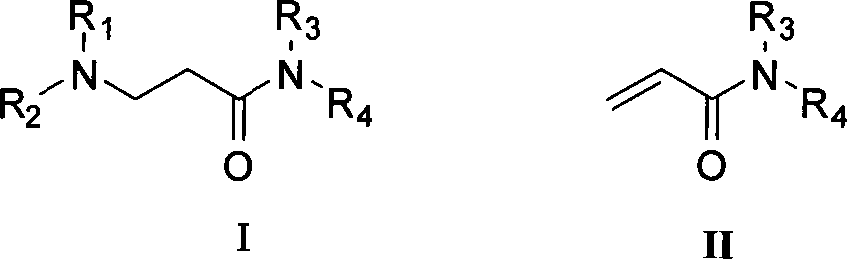

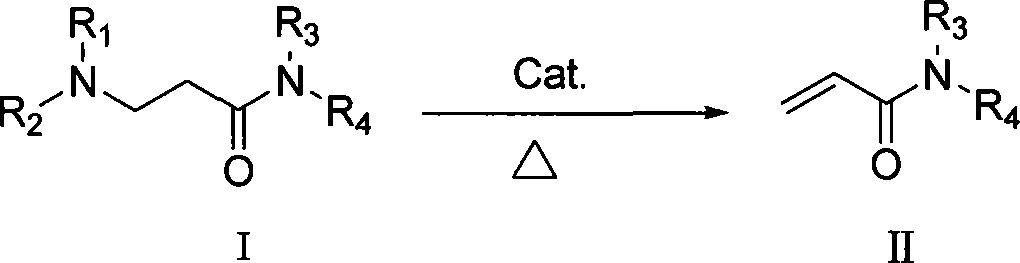

A technology of dialkylacrylamide and dialkylaminopropionamide is applied in the field of new polymer monomer N, which can solve the problems of low industrialization value, high reaction temperature, many by-products, etc., so as to reduce the activation energy and reduce the reaction time, the effect of reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh N,N-dimethyl-(3-dimethylamino)-propionamide 5g and add in the reactor, add 0.005g polymerization inhibitor 4010NA (0.1%), 0.05 gram hydrochloric acid (1%) simultaneously, control reaction The temperature was 140°C, the reaction pressure was kept at 400 mmHg, and the reaction was carried out for 3 hours, with a yield of 23.2%.

Embodiment 2

[0022] Weigh N,N-dimethyl-(3-dimethylamino)-propionamide 5g into the reactor, add 0.01g polymerization inhibitor 4010NA (0.2%), 0.1 gram p-toluenesulfonic acid (2%) , control the reaction temperature at 160°C, keep the reaction pressure at 300mmHg, react for 5h, and the yield is 54.6%.

Embodiment 3

[0024] Take by weighing N, N-dimethyl-(3-dimethylamino)-propionamide 5g adds in the reactor, adds 0.015g stopper hydroquinone (0.3%) simultaneously, 0.1 gram zinc chloride (2 %), control the reaction temperature at 180°C, keep the reaction pressure at 200mmHg, react for 8h, and the yield is 78.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com