Novel synthetic process of tofacitinib citrate

A technology of tofacitinib and synthesis process, applied in the field of medicine, can solve problems such as long time and low yield, and achieve the effects of improving yield, reasonable route and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

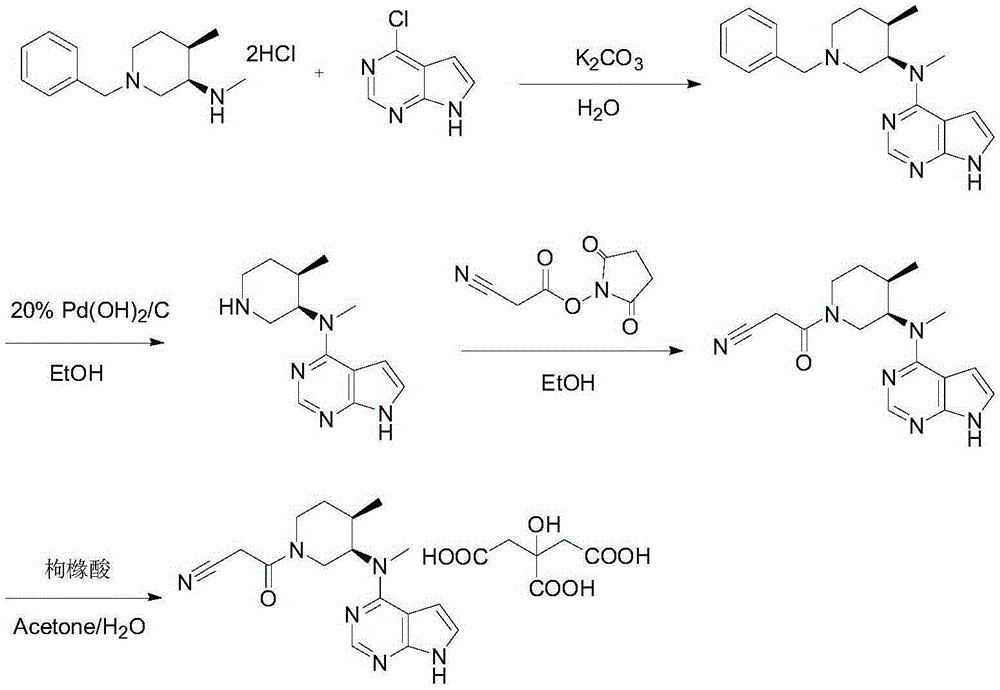

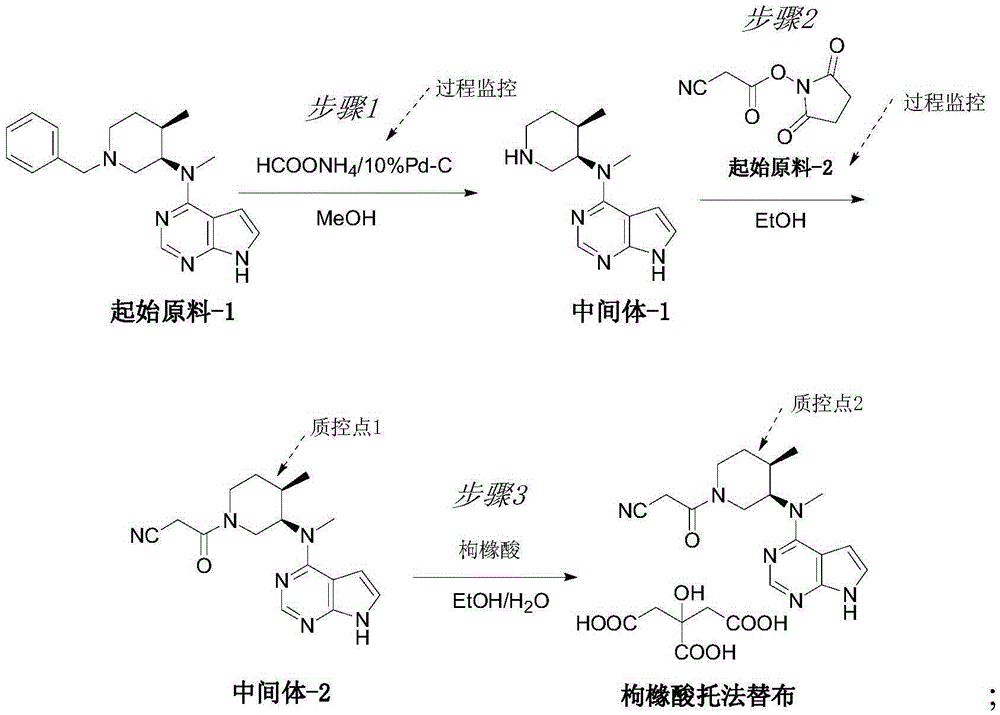

Method used

Image

Examples

Embodiment 1

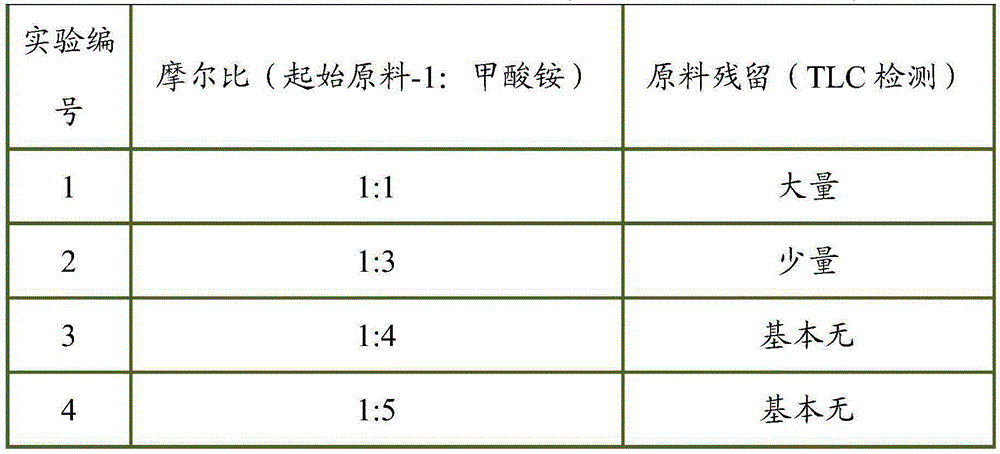

[0044] Embodiment 1 synthetic intermediate-1:

[0045] 1g of N-methyl-N-((3R,4R)-4-methyl-1-benzyl-3-piperidinyl)-7H-pyrrolo[2,3-d]pyrimidin-4-amine (from Starting material-1) and 0.2g of 10% palladium carbon were added to a three-necked reaction flask, 30ml of anhydrous methanol was added to stir and disperse, and 0.187g of ammonium formate was added. The temperature was raised to reflux, and the reaction was carried out for 2 hours, and the reaction was monitored by TLC.

Embodiment 2

[0046] Embodiment 2 synthetic intermediate-1:

[0047] 1g of N-methyl-N-((3R,4R)-4-methyl-1-benzyl-3-piperidinyl)-7H-pyrrolo[2,3-d]pyrimidin-4-amine (from Starting material-1) and 0.2g of 10% palladium carbon were added to a three-necked reaction flask, 30ml of anhydrous methanol was added to stir and disperse, and 0.561g of ammonium formate was added. The temperature was raised to reflux, and the reaction was carried out for 2 hours, and the reaction was monitored by TLC.

Embodiment 3

[0048] Embodiment 3 synthetic intermediate-1:

[0049] 1g of N-methyl-N-((3R,4R)-4-methyl-1-benzyl-3-piperidinyl)-7H-pyrrolo[2,3-d]pyrimidin-4-amine (from Starting material-1) and 0.2g of 10% palladium carbon were added to a three-necked reaction flask, 30ml of anhydrous methanol was added to stir and disperse, and 0.748g of ammonium formate was added. The temperature was raised to reflux, and the reaction was carried out for 2 hours, and the reaction was monitored by TLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com