Electric cabinet paying-off board and process thereof

A technology of electrical screens and pay-off boards, which is applied to the installation of electrical components, cables, and cable installation devices, and can solve problems such as long assembly time, low operating efficiency, and inability to mass produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

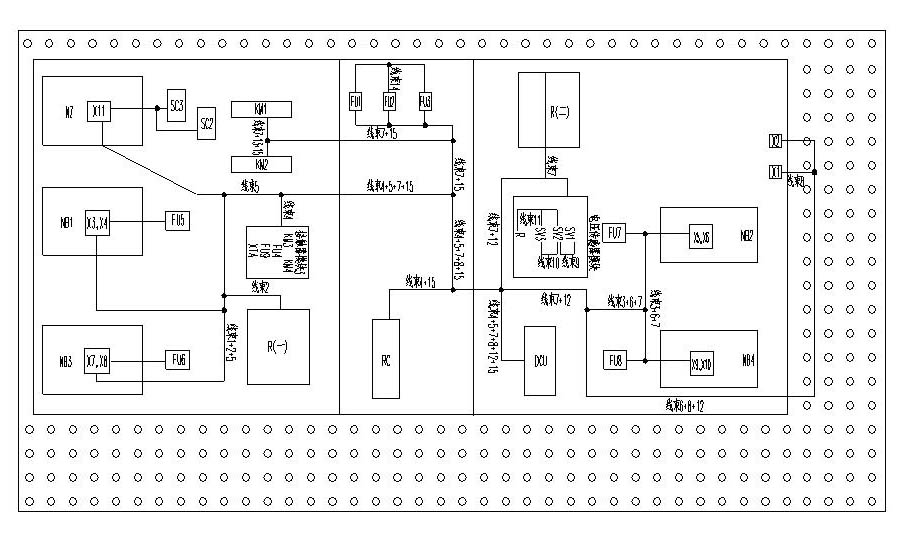

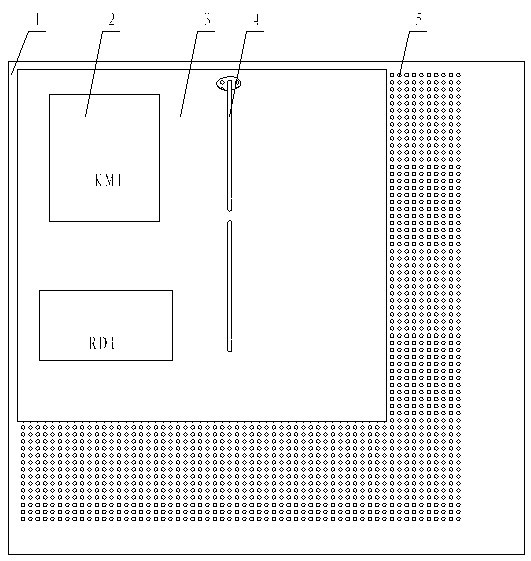

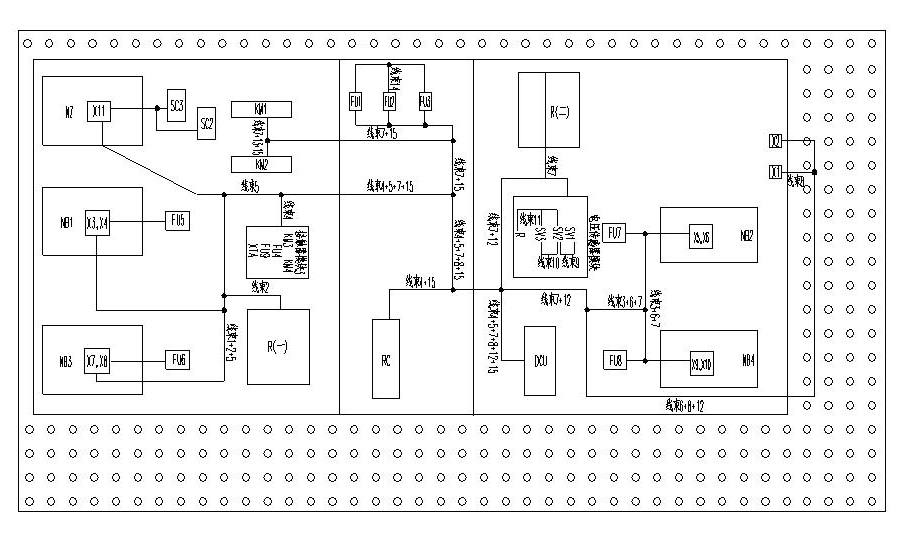

[0027] Such as figure 1 , figure 2 As shown, a discharge board for an electrical screen cabinet and its technology, the discharge board for an electrical screen cabinet includes a steel plate 1, a through hole 5 is provided on the steel plate 1, and a tie rod 4 can be installed in the through hole 5; the surface of the steel plate 1 is covered with The blank paper 3 is provided with a box 2 matching the maximum outline size of the electrical device and marking the component code. A through hole 5 of φ5 is opened on the steel plate at intervals of 10mm. The release board is a general-purpose piece, which is generally used for the discharge of electrical screen cabinets. The covered part of the white paper 3 on the steel plate 1 is consistent with the combined size of the two sides and the top surface of an electric screen cabinet. Use a thick pen to draw a box 2 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com