Preparation method of bis(2-dimethyl aminoethyl) ether

A technology of dimethylaminoethyl and dimethylaminoethoxyethanol, which is applied in the field of chemical synthesis, can solve the problems of complex post-processing, cumbersome process, and low total yield, and achieve easy post-processing, easy-to-obtain raw materials, The effect of high total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

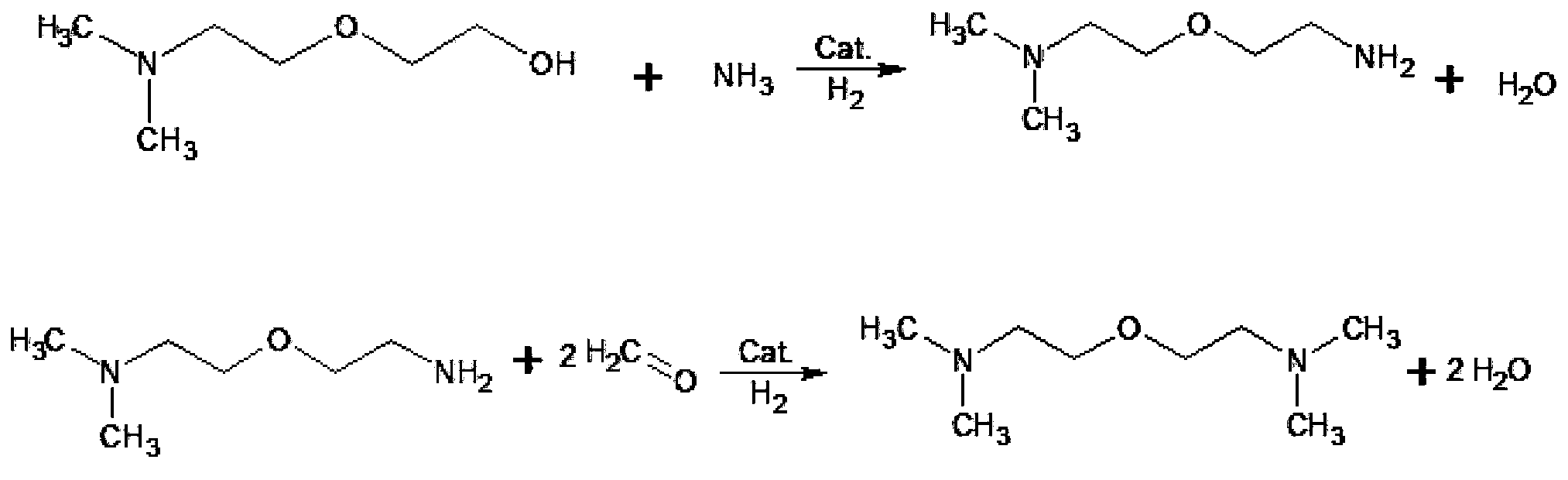

Method used

Image

Examples

Embodiment 1

[0021] (1) First add 133g (1mol) of dimethylaminoethoxyethanol to a 1L autoclave, then add 70g of water, then add 7g of Cu-Al / diatomite catalyst, and then blow nitrogen into the autoclave The air was replaced, and then 85g (5mol) of anhydrous liquid ammonia and 0.3Mpa hydrogen were introduced, and then the temperature was raised to 180°C, and the reaction was carried out at a reaction pressure of 10Mpa for 9 hours, and high-speed stirring was always maintained during the above reaction process; After completion, the temperature in the autoclave is lowered to normal temperature, the pressure is vented to normal pressure, then the material is discharged, the Cu-Al / diatomite catalyst is filtered, and the filtrate is rectified to obtain dimethylaminoethoxyethyl alcohol with a purity of 98.4%. Amine 95g;

[0022] (2), then put 66g (0.5mol) of dimethylaminoethoxyethylamine obtained in the previous step of rectification into the autoclave, then add 0.7g of Pd / C palladium carbon catal...

Embodiment 2

[0027] (1) First add 266g (2mol) of dimethylaminoethoxyethanol to a 1L autoclave, then add 150g of water, then add 27g of Cu-Al / diatomaceous earth catalyst, and then blow nitrogen into the autoclave Then, 180g (10.58mol) of anhydrous liquid ammonia and 0.5Mpa hydrogen gas were introduced, and then the temperature was raised to 160°C, and the reaction was carried out at a reaction pressure of 15Mpa for 5 hours, and high-speed stirring was always maintained during the above reaction process; After the reaction is completed, the temperature in the autoclave is lowered to normal temperature, the pressure is vented to normal pressure, then the material is discharged, the Cu-Al / diatomite catalyst is filtered, and the filtrate is rectified to obtain dimethylaminoethoxy with a purity of 98.5%. Ethylamine 195g;

[0028] (2), then put 132g (1mol) of dimethylaminoethoxyethylamine obtained in the previous step of rectification into the autoclave, then add 1g of Pd / C palladium carbon catal...

Embodiment 3

[0033](1) First add 266g (2mol) of dimethylaminoethoxyethanol to a 1L autoclave, then add 250g of water, then add 40g of Cu-Al / diatomaceous earth catalyst, and then blow nitrogen into the autoclave Then, 200g (11.76mol) of anhydrous liquid ammonia and 0.8Mpa hydrogen were introduced, and then the temperature was raised to 170°C, and the reaction was carried out at a reaction pressure of 8Mpa for 12 hours, and high-speed stirring was maintained throughout the above reaction process; After the reaction is completed, the temperature in the autoclave is lowered to normal temperature, the pressure is vented to normal pressure, then the material is discharged, the Cu-Al / diatomite catalyst is filtered, and the filtrate is rectified to obtain dimethylaminoethoxy with a purity of 98.6%. Ethylamine 199g;

[0034] (2), then put 132g (1mol) of dimethylaminoethoxyethylamine obtained in the previous step of rectification into the autoclave, then add 1.3g of Pd / C palladium carbon catalyst, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com