Method of increasing quality of glycol

A glycol and quality technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as unsuitable for large-scale continuous production, inconvenient separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

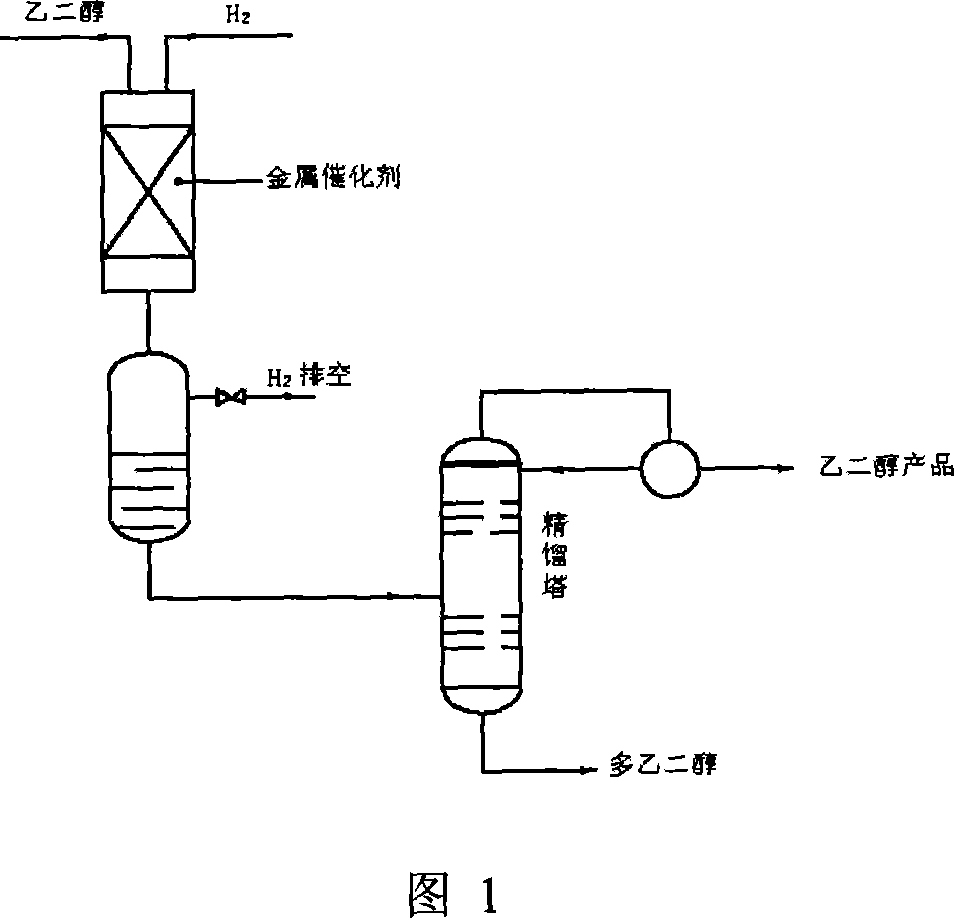

Method used

Image

Examples

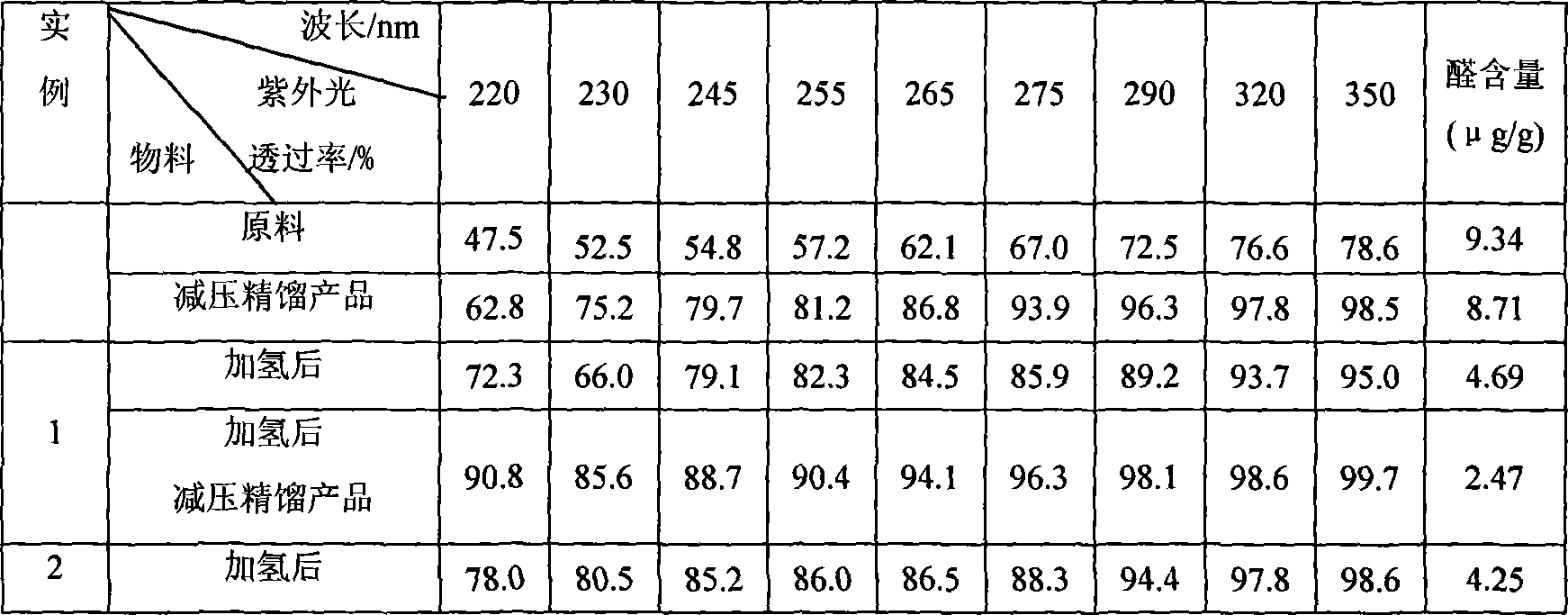

Embodiment 1

[0017] Add about 200g of ethylene glycol with a mass concentration of 85% in a 500mL four-neck flask equipped with a stirrer, thermometer, and reflux condenser, add 2mL of palladium carbon as a catalyst, control the reaction temperature at 75°C, stir and pass hydrogen for 1h. The UV value changes of materials before and after hydrogenation are shown in Table 1. The hydrogenated material was rectified under reduced pressure to obtain ethylene glycol product, and its ultraviolet light transmittance and aldehyde content were measured. The results were compared with those of the product without hydrogenation rectification, as shown in Table 1.

Embodiment 2

[0019] As in Example 1, Raney nickel is used as a catalyst, and its consumption is the same as in Example 1, and the reaction temperature is 70°C. The changes in UV value and aldehyde content of materials and ethylene glycol products before and after hydrogenation are shown in Table 1.

[0020] Table 1 Comparison of main quality indicators of materials and products before and after hydrogenation

[0021]

[0022] After hydrogenation

Embodiment 3

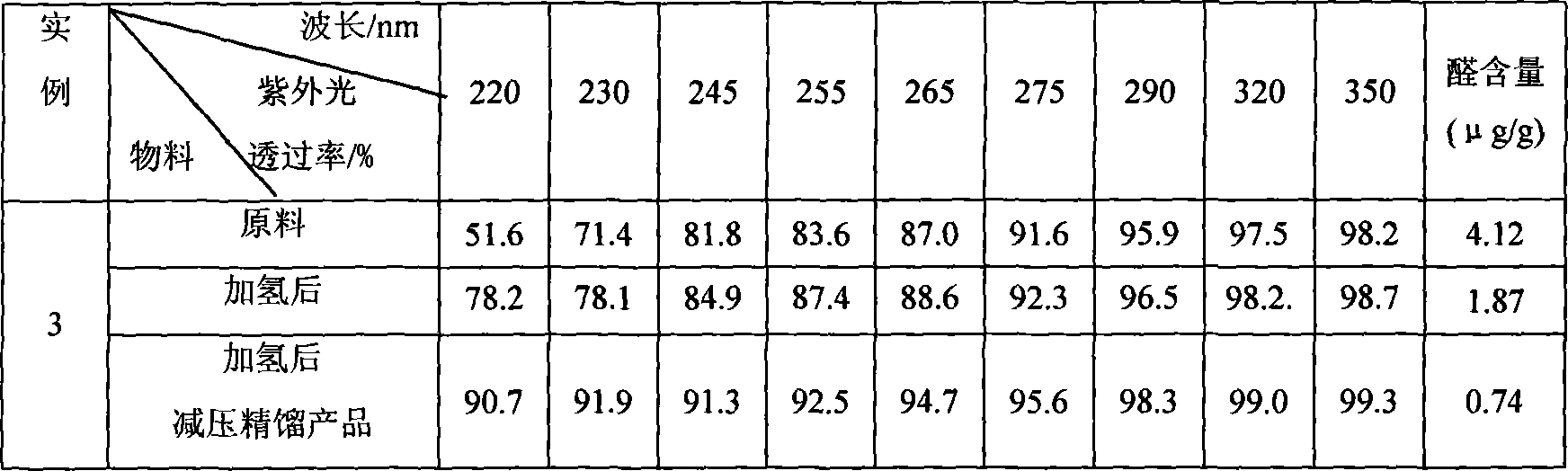

[0024] As example 2, the mass concentration of ethylene glycol is 100%, and the reaction temperature is 95°C. The results are shown in Table 2.

[0025] Table 2 Comparison of main quality indicators of materials and products before and after hydrogenation

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com