Preparation method of high heat resistance isosorbide type random copolyester

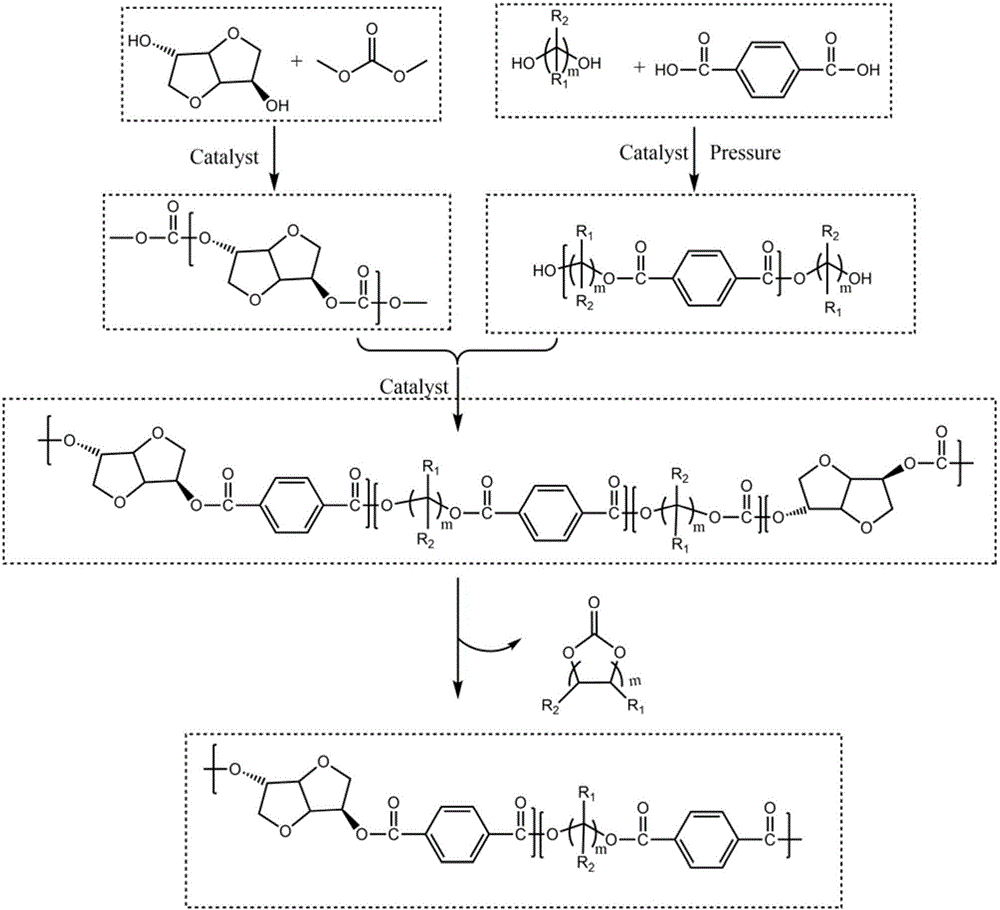

A technology of isosorbide type and isosorbide is applied in the field of preparation of high heat-resistant isosorbide-type random copolyester, and can solve the problems of low reaction activity of secondary hydroxyl group and poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

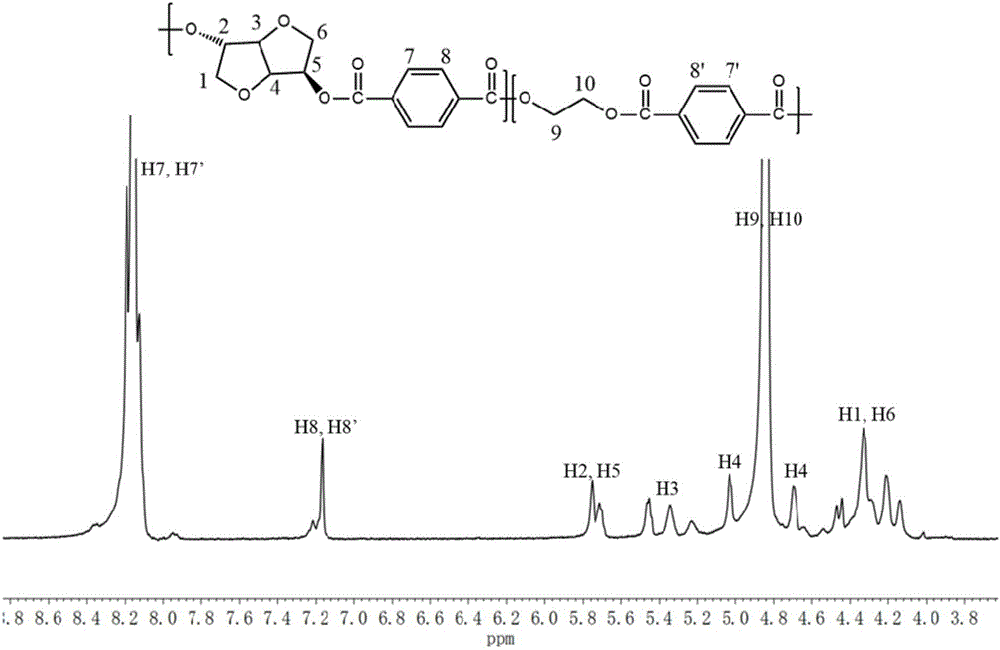

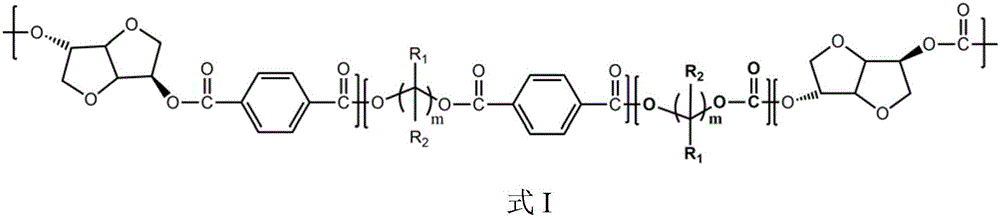

[0057] Embodiment 1. Preparation of high heat resistance (terephthalic acid-isosorbide-ethylene glycol) random copolyester by removing ethylene carbonate

[0058] (1) Under the protection of a nitrogen atmosphere, in a 250mL reaction vessel, add 29.2g (0.2mol) isosorbide, 90.0g (1.0mol) dimethyl carbonate and 0.0066g transesterification catalyst lithium acetylacetonate, (isosorbide The molar ratio of alcohol to dimethyl carbonate is 1:5), stirred and reacted at 60°C for 2 hours, then gradually raised the temperature to 180°C, and distilled out the by-product methanol produced by the reaction. After the by-product methanol and excess dimethyl carbonate are all distilled off, the reaction is complete to obtain a prepolymer of isosorbide polycarbonate;

[0059] (2) In a 250mL reaction vessel, add 41.5g (0.25mol) of terephthalic acid and 31.0g (0.5mol) of ethylene glycol under a nitrogen atmosphere (the molar ratio of terephthalic acid to ethylene glycol is 1: 2) Start stirring a...

Embodiment 2

[0063] Embodiment 2. Preparation of high heat resistance (terephthalic acid-isosorbide-ethylene glycol) random copolyester by decarbonating ethylene ester method

[0064] (1) Under the protection of a nitrogen atmosphere, in a 250mL reaction vessel, add 29.2g (0.2mol) isosorbide, 90.0g (1.0mol) dimethyl carbonate and 0.0066g transesterification catalyst lithium acetylacetonate, (isosorbide The molar ratio of alcohol to dimethyl carbonate is 1:5), stirred and reacted at 60°C for 2 hours, then gradually raised the temperature to 180°C, and distilled out the by-product methanol produced by the reaction. After the by-product methanol and excess dimethyl carbonate are all distilled off, the reaction is complete to obtain a prepolymer of isosorbide polycarbonate;

[0065] (2) In a 500mL reaction vessel, add 49.8g (0.3mol) of terephthalic acid and 37.2g (0.6mol) of ethylene glycol under a nitrogen atmosphere (the molar ratio of terephthalic acid to ethylene glycol is 1: 2) Start sti...

Embodiment 3

[0068] Embodiment 3. Decarboxylation method prepares high heat resistance (terephthalic acid-isosorbide-ethylene glycol) random copolyester

[0069] (1) Under nitrogen atmosphere protection, in the reaction container of 500mL, add 29.2g (0.2mol) isosorbide, 214.0g (1.0mol) diphenyl carbonate and 0.0066g transesterification catalyst lithium acetate, (isosorbide The molar ratio of diphenyl carbonate to diphenyl carbonate is 1:5), the stirring reaction was carried out at 60°C for 2 hours, and then the temperature was gradually raised to 200°C, and the by-product methanol produced by the reaction was distilled off. After the by-product methanol and excess diphenyl carbonate are all distilled off, the reaction is complete to obtain a prepolymer of isosorbide polycarbonate;

[0070] (2) In a 500mL reaction vessel, add 83.0g (0.5mol) of terephthalic acid and 62.0g (1.0mol) of ethylene glycol under a nitrogen atmosphere (the molar ratio of terephthalic acid to ethylene glycol is 1: 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com