High-thermal conductivity resin composition and application thereof

A resin composition and high thermal conductivity technology, which is applied in the field of metal-based copper-clad laminates and high-thermal-conduction resin compositions, can solve the problems of reducing the interface binding between resin and thermally conductive fillers, defects in the electrical properties of metal-based copper-clad laminates, and reduced breakdown voltage. , to achieve the effects of high peel strength, high breakdown voltage and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

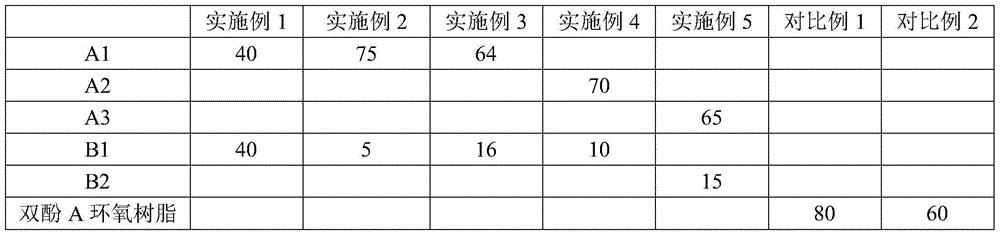

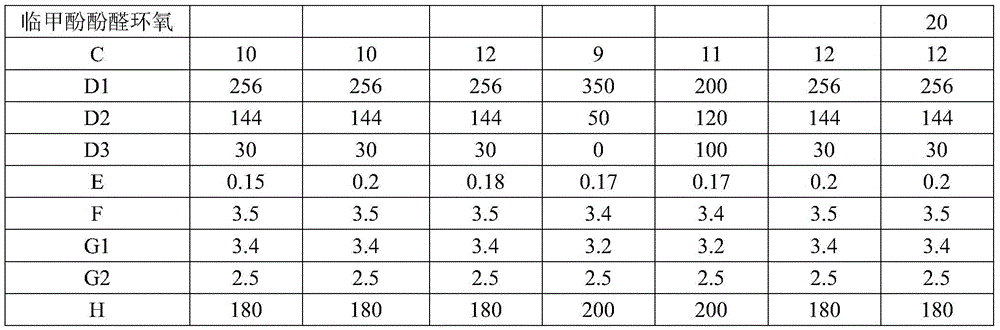

Embodiment 1~5 and comparative example 1~2

[0041] Each component used in the epoxy resin composition of embodiment 1~5 and comparative example 1~2 and content (by weight) are as shown in table 1; Each component code and its corresponding component name are as follows Shown:

[0042] (A) bismaleimide modified epoxy resin:

[0043] (A1) N-p-carboxyphenylmaleimide modified epoxy resin: prepared by reacting N-p-carboxyphenylmaleimide and bisphenol A novolak epoxy resin;

[0044] (A2) Diamine and bismaleimide compound modified epoxy resin: prepared by the copolymerization reaction of diaminodiphenyl sulfone, diphenyl ether bismaleimide and bisphenol A novolac epoxy resin;

[0045] (A3) Dihydric phenol and bismaleimide compound modified epoxy resin: prepared by copolymerization of allyl bisphenol A, diphenyl ether bismaleimide and bisphenol A epoxy resin;

[0046] (B) Flexible modified epoxy resin:

[0047] (B1) organosilicon modified epoxy resin, produced by Korea SHIN-A company;

[0048] (B2) Rubber modified epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com