Modified epoxy resin by organic silicon and its electronic packag material and preparation process thereof

A technology of epoxy resin and phenolic epoxy resin, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult to form uniformity, low water absorption, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

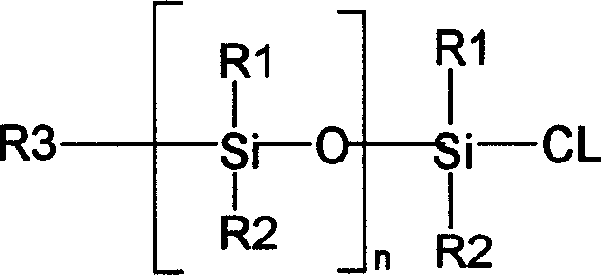

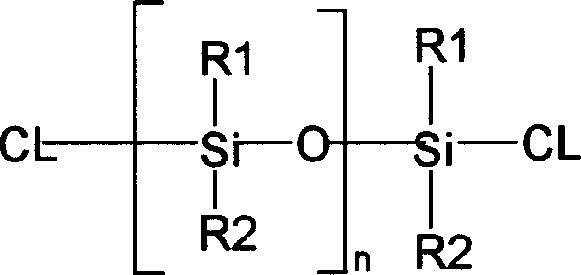

Method used

Image

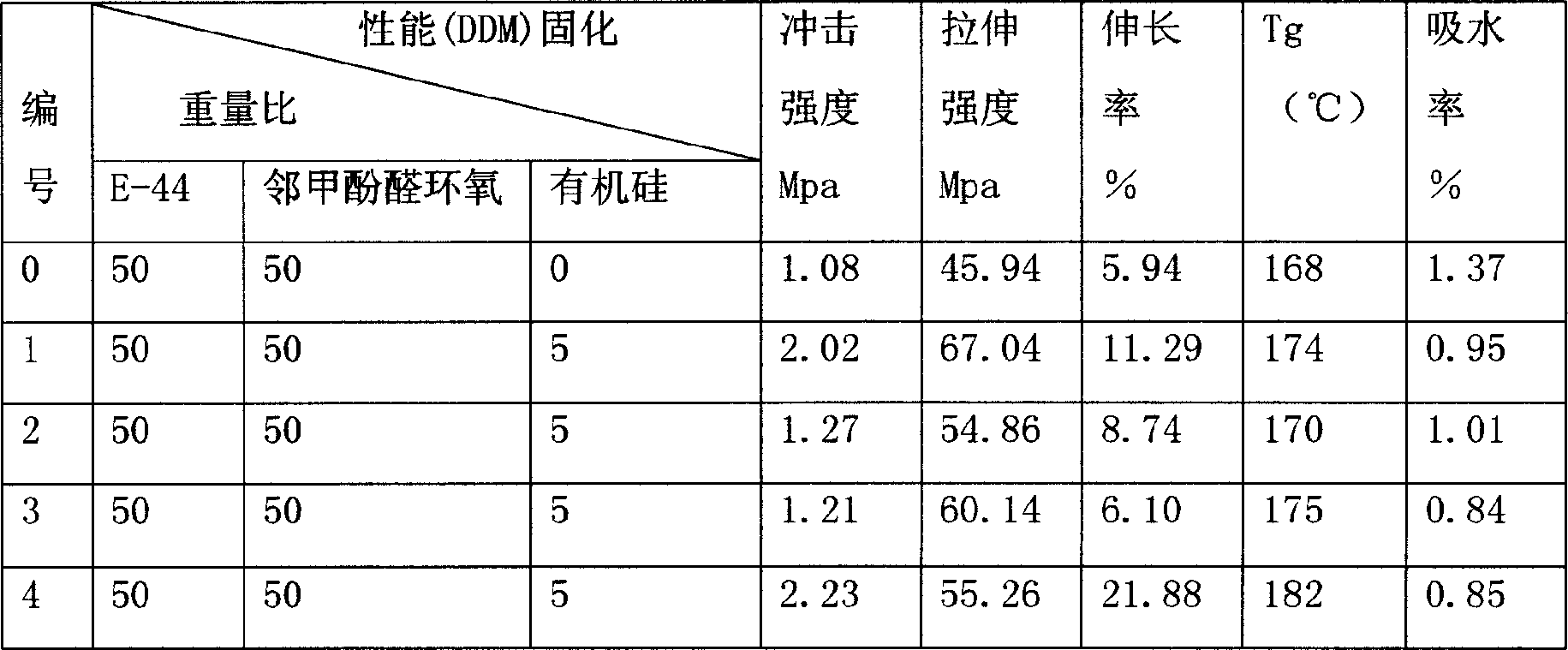

Examples

Embodiment 1

[0070] Take 60g of E-44 epoxy resin (epoxy value 0.44mol / 100g), dissolve it with toluene, and place it in a three-necked bottle; take 7.8g of triethylamine, also add it to the three-necked bottle, and stir at a high speed. Take 5g of dichlorodimethylsilane, dilute it with toluene, add it into a three-necked bottle, and react. After the reaction was completed, the resulting mixed solution was transferred into a separatory funnel, washed with distilled water, and stopped when the pH value of the solution was neutral. The solution was distilled under reduced pressure to remove the toluene to obtain a modified resin mixture. Then add 40g of tetrabromobisphenol A epoxy resin (epoxy value 0.245mol / 100g) and mix evenly, and the resulting resin mixture is solidified into a mold with DDM (100g resin~21gDDM), and its impact strength is measured to be 2.86MPa, tensile The tensile strength was 36.78 MPa, the elongation at break was 29%, the Tg was 201° C., and the water absorption was 0....

Embodiment 2

[0072] Take 50g of E-32 (epoxy value 0.32mol / 100g), dissolve it in toluene, and put it in a three-necked bottle; take 0.3g of triethylamine, also add it into the three-necked bottle, and stir at a high speed. Take 10.2 g of monochloro-terminated polydimethylsiloxane (molecular weight about 8000), dissolve it in toluene, put it into a three-necked bottle, and react. After the reaction was completed, the resulting mixed solution was transferred into a separatory funnel, washed with distilled water, and stopped when the pH value of the solution was neutral. The solution was distilled under reduced pressure to remove the toluene to obtain a modified resin mixture. Gained resin is mixed with 30g o-cresol novolak epoxy resin (epoxy value 0.51mol / 100g) at last and is solidified into a mold with phenolic resin curing agent (100g resin~40g phenolic resin), and its impact strength recorded is 2.93MPa, The tensile strength was 46.52 MPa, the elongation at break was 32%, the Tg was 194°C...

Embodiment 3

[0074] Take 40g of E-44 (epoxy value is 0.44mol / 100g), dissolve it in toluene, put it in a three-necked bottle, take 0.3g of triethylamine, also add it into the three-necked bottle, and stir at high speed at the same time. Take 10.2 g of dichloro-terminated polydimethylsiloxane (molecular weight about 8000), dissolve it in toluene, put it into a three-necked bottle, and react. After the reaction was completed, the resulting mixed solution was transferred into a separatory funnel, washed with distilled water, and stopped when the pH value of the solution was neutral. The solution was distilled under reduced pressure to remove the toluene to obtain a modified resin mixture. Finally the gained resin is mixed with 30g o-cresol novolac epoxy resin (epoxy value 0.51mol / 100g), 30g bis(3-glycidyl) phenyl phosphonate (epoxy value 0.24mol / 100g) The DDS curing agent (100g resin ~ 24gDDS) was cured into a mold. The measured impact strength was 1.76MPa, tensile strength was 35.78MPa, elon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com