Flat glass fiber reinforced flame-retardant PP composite material and preparation method thereof

A composite material and flat glass fiber technology, which is applied in the field of polymer material processing, can solve the problems of limiting the application of glass fiber reinforced polypropylene composite materials, glass fiber reinforced flame retardant PP materials, serious deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

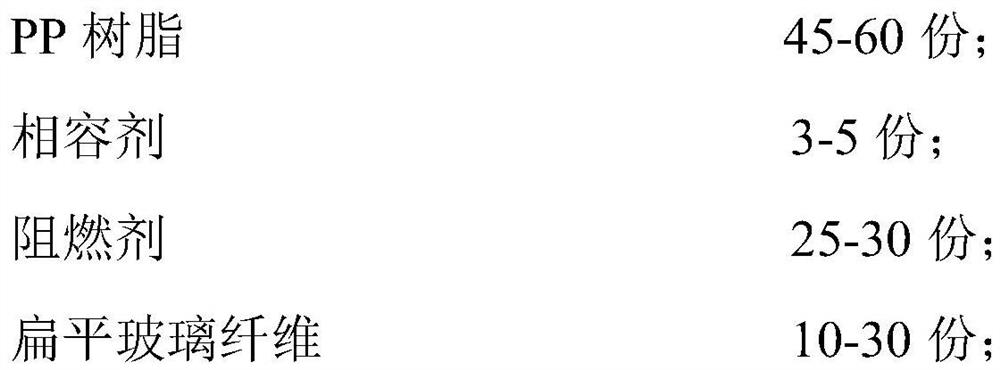

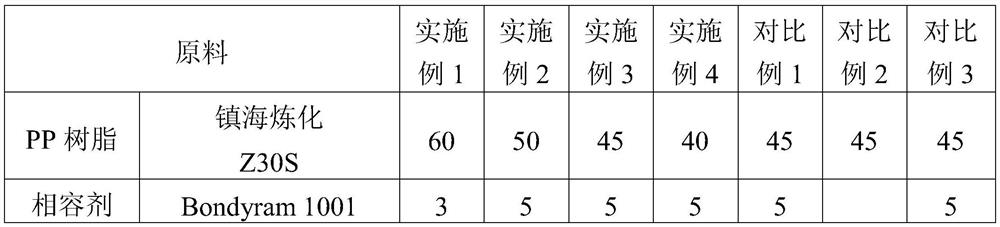

[0025] A flat glass fiber reinforced flame-retardant PP composite material, comprising the following components by weight:

[0026]

[0027]

[0028] Wherein, the PP resin is a PP resin with isotacticity ≥ 98%, crystallinity ≥ 70%, and a melt index of 10-30g / 10min at a temperature of 230°C and a test load of 2.16kg; the compatibilizer It is a PP masterbatch grafted with maleic anhydride; the flat glass fiber is a microscopically flat E glass fiber with a width of 20-30 μm, a thickness of 4-10 μm, and a length of between 2500-3000 μm; the glass flakes are glass fragments with a thickness of 5 microns; the flame retardant is an intumescent flame retardant compounded with nitrogen and phosphorus, and its nitrogen content is 15±2%, The phosphorus content is 20±2%; the antioxidant is a compound system of hindered phenol and phosphite, and the mass ratio of hindered phenol and phosphite in the antioxidant is 2:3; the lubricant It is pentaerythritol stearate.

[0029] Prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com