Polyamide composition for high impact thick wall product

A polyamide composition and composition technology, applied in the field of polymer composition, can solve the problem of low impact of thick-walled products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

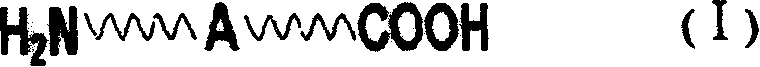

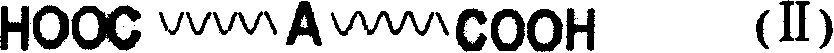

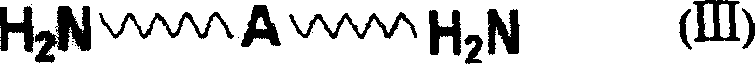

Image

Examples

Embodiment 1

[0096] Component a)

[0097] Nylon 6 with a relative viscosity of 2.3: The viscosity is measured at 25°C with a solution of 1 g / dl in 98% concentrated sulfuric acid.

[0098] Component b)

[0099] Polyolefin copolymer of ethylene, butadiene and a small amount of maleic anhydride: containing 70wt% ethylene, 29.5wt% butadiene and 0.5wt% maleic anhydride.

[0100] Component c)

[0101] Graft copolymer: a copolymer of 58 wt% styrene and acrylonitrile in a weight ratio of 71:29 is cross-linked and grafted in 42 wt% polybutadiene latex particles, which is produced by emulsion polymerization.

[0102] Ethylene-based copolymer: a styrene-acrylonitrile copolymer with a component ratio of styrene and acrylonitrile of 67:33 and an intrinsic viscosity of 0.34 dl / g (measured in a 0.4 g / 100 ml methyl ethyl ketone solution at 30° C.).

[0103] Component d)

[0104] 70 parts of styrene, 25 parts of acrylonitrile, 5 parts of maleic anhydride, 0.5 parts of dicumyl peroxide and 200 p...

Embodiment 2

[0109] The composition of each component in the composition is the same as in Example 1, and the parts by weight of each component are: a) 30, b) 5, c) 56.5, d) 6, e) 2, and additive 0.5.

Embodiment 3

[0111] The composition of each component in the composition is the same as in Example 1, and the parts by weight of each component are: a) 30, b) 10, c) 51.5, d) 6, e) 2, additive 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com