High-impact-strength ABS material used at -40 DEG C and preparation method thereof

An ABS material and high-impact technology, applied in the field of high-impact ABS material and its preparation, can solve the problem that ABS cannot meet the requirements of outdoor use, and achieve excellent low-temperature impact resistance, high normal temperature elongation at break, excellent resistance to The effect of impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

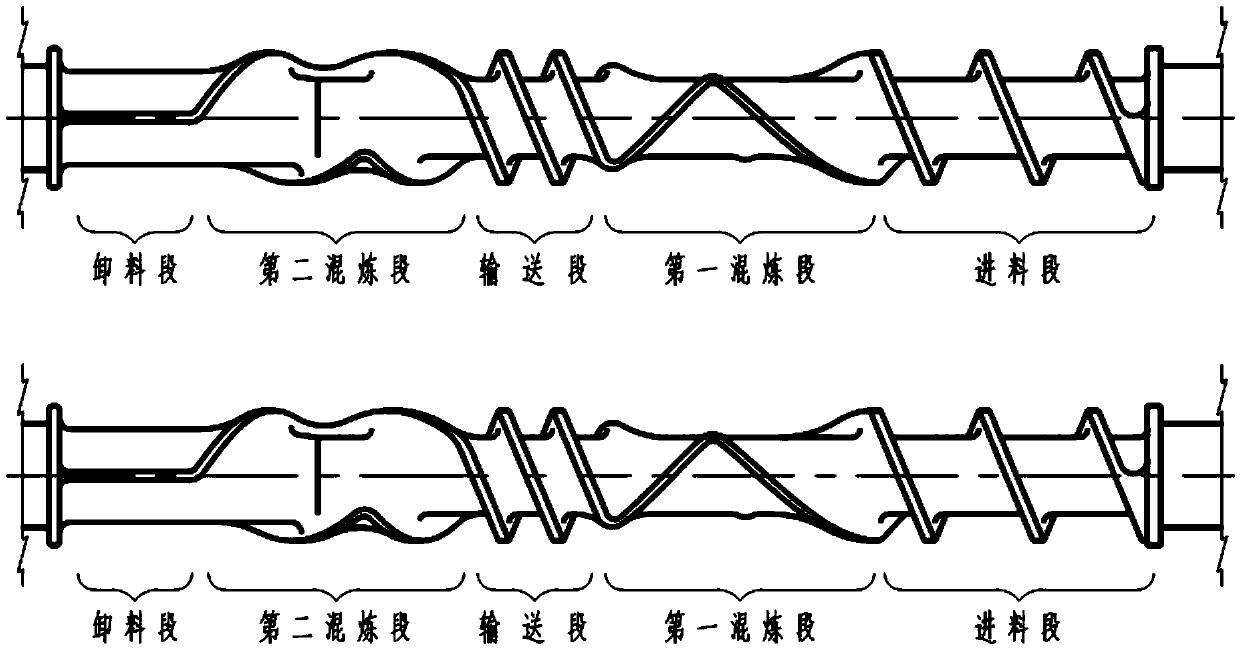

[0019] figure 1 It is a schematic diagram of a mixing section of a twin-rotor continuous kneader for preparing high-impact ABS materials for minus 40°C according to an embodiment of the present invention. Such as figure 1 As shown, each rotor of the double-rotor continuous mixer includes a feed section, a first mixing section, a conveying section, a second mixing section and a discharge section. In the preparation, the materials are added to the mixer according to the set ratio for pre-mixing. The pre-mixed material is fed into the feeding section of the double-rotor continuous mixer through the metering and feeding device, and the material is pushed to the first mixing section by the feeding screw, and then pushed to the second mixing section by the conveying section screw after blending section for secondary mixing. Due to continuous feeding, the finished mixed materials are discharged through the discharge section to complete the production. The rotor diameter of the mix...

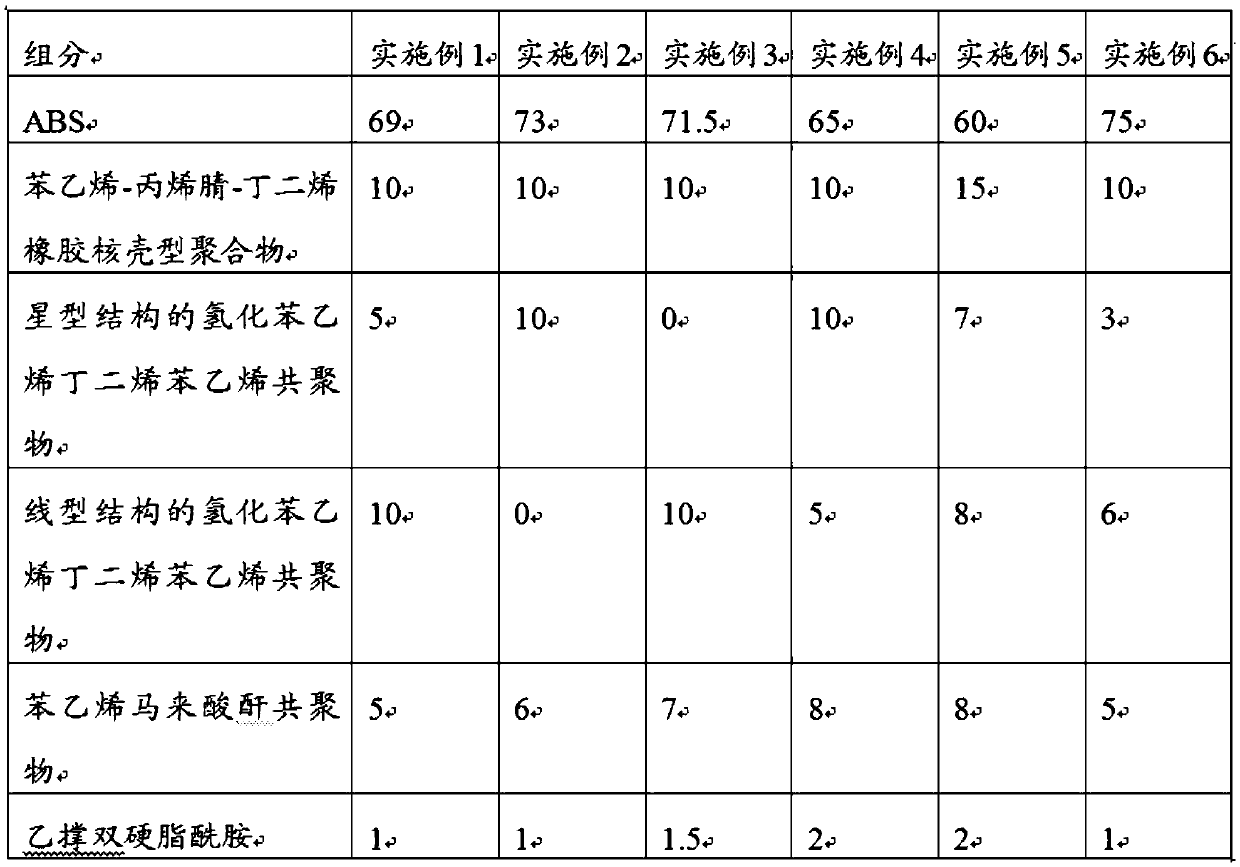

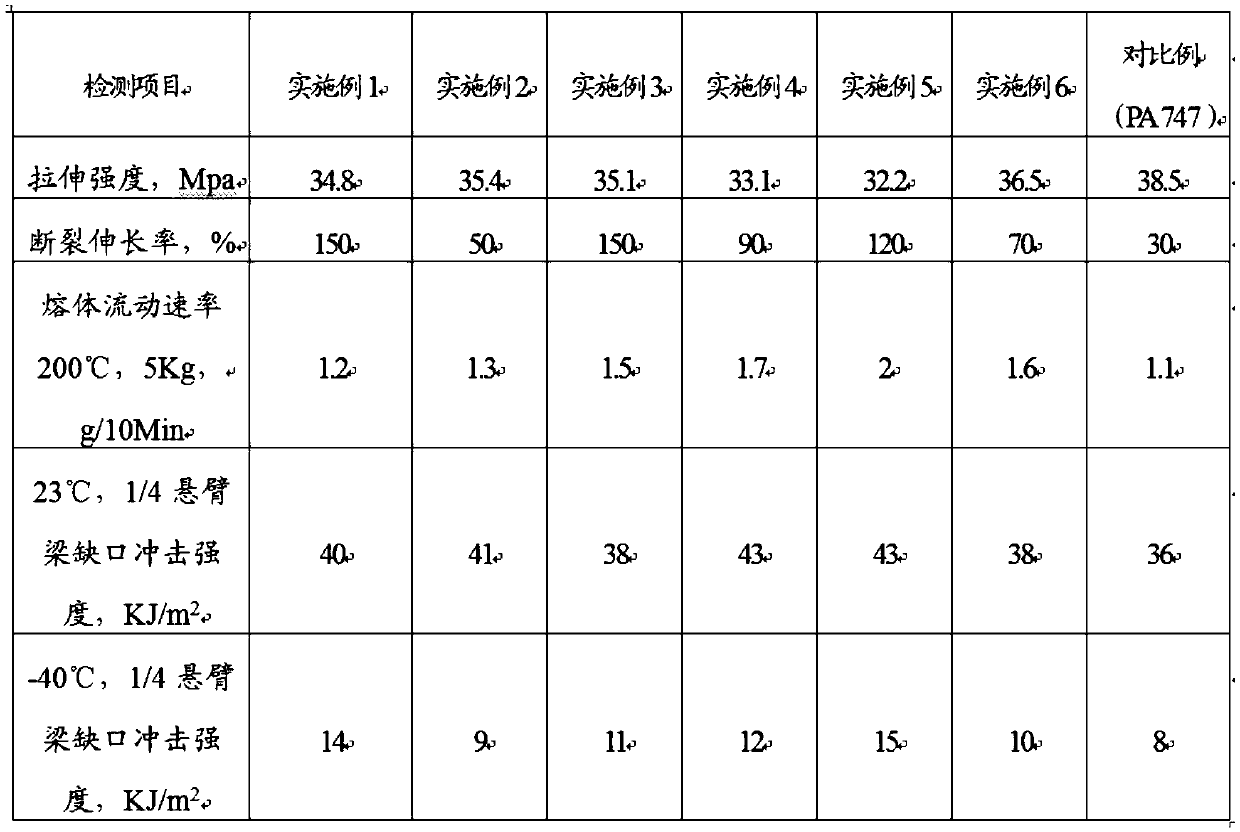

Embodiment 1

[0023] With 69 parts of ABS, 10 parts of styrene-acrylonitrile-butadiene rubber core-shell polymer (toughening agent), 5 parts of hydrogenated styrene butadiene styrene copolymer of star structure and 10 parts Hydrogenated styrene butadiene styrene copolymer (cold resistance modifier), 5 parts of styrene maleic anhydride copolymer (compatibilizer) and 1 part of ethylene bis stearamide (lubricant) ) into a twin-rotor continuous kneader through a feed port, and perform melt mixing and granulation at a kneading temperature of 170°C-200°C. A high-impact ABS material for minus 40°C is produced.

Embodiment 2

[0025] 73 parts of ABS, 10 parts of styrene-acrylonitrile-butadiene rubber core-shell polymer (toughener), 10 parts of hydrogenated styrene butadiene styrene copolymer of star structure, 6 parts Styrene maleic anhydride copolymer (compatibilizer) and 1 part of ethylene bisstearamide (lubricant) are added to the double-rotor continuous mixer through the feed port, and at a mixing temperature of 170°C-200°C Perform melt mixing and granulation. A high-impact ABS material for minus 40°C is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com