Preparation method of halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile

A technology for wood-plastic profiles and cigarette packs, applied in the field of wood-plastic materials, can solve problems such as flame retardant properties that cannot meet actual needs and personnel hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

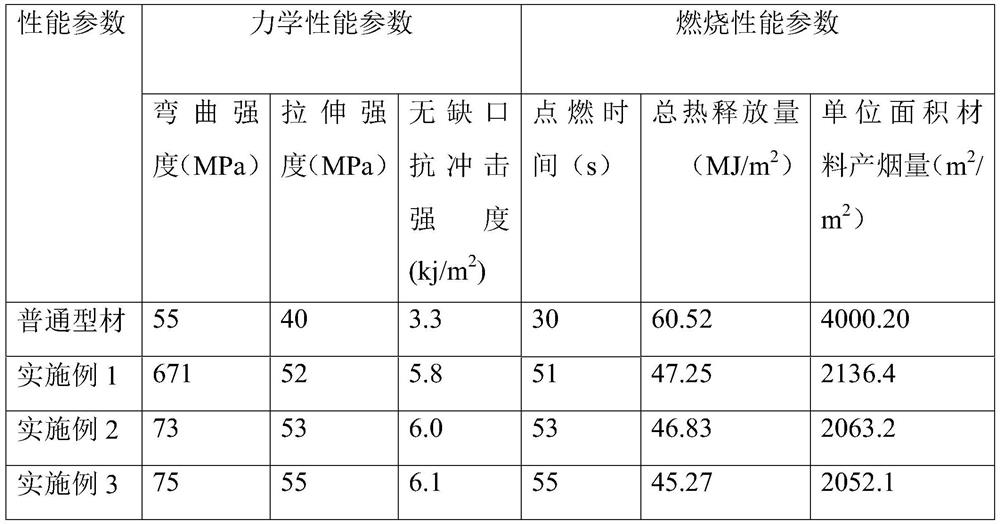

Examples

Embodiment 1

[0029] A method for preparing a halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile in this embodiment. process, the coating layer is coated on the core layer; the specific preparation method of the halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile is as follows:

[0030] (1) Configuration of core material:

[0031] 40 parts of high-density polyethylene, 30 parts of wood flour, 1 part of titanate coupling agent, 2 parts of stearic acid and metal salts thereof, 1 part of dibutyl phthalate, 8 parts of expanded graphite and 25 parts of composite halogen-free flame retardant and smoke suppressant were mixed in a high-speed mixer, the mixing temperature was 100°C, and the mixing time was 25 minutes; then, the mixed raw materials were added to an extrusion granulator for granulation, extruded The temperature of the main machine of the granulator is set at 160°C, the speed is 60r / min, the speed of the feeder is 6r / min, the melt...

Embodiment 2

[0038]A method for preparing a halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile in this embodiment. process, the coating layer is coated on the core layer; the specific preparation method of the halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile is as follows:

[0039] (1) Configuration of core material:

[0040] 60 parts of high-density polyethylene, 50 parts of wood flour, 3 parts of titanate coupling agent, 5 parts of paraffin, 3 parts of dioctyl phthalate, 10 parts of expanded graphite and Add 35 parts of compound halogen-free flame retardant and smoke suppressant to the high mixer for mixing, the mixing temperature is 110°C, and the mixing time is 30 minutes; then, the mixed raw materials are added to the extrusion granulator for granulation, and the temperature of the main machine of the extrusion granulator Set at 170°C, speed 80r / min, feeder speed 8r / min, extruder melt pressure 5MPa, head temperature 180°C, ext...

Embodiment 3

[0047] A method for preparing a halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile in this embodiment. process, the coating layer is coated on the core layer; the specific preparation method of the halogen-free flame-retardant low-smoke coated co-extruded wood-plastic profile is as follows:

[0048] (1) Configuration of core material:

[0049] 50 parts of high-density polyethylene, 40 parts of wood powder, 2 parts of titanate coupling agent, 3.5 parts of polyethylene wax, 2 parts of dibutyl phthalate, 9 parts of expansion Graphite and 30 parts of composite halogen-free flame retardant and smoke suppressant are mixed in a high-speed mixer, the mixing temperature is 105°C, and the mixing time is 28 minutes; then, the mixed raw materials are added to an extrusion granulator for granulation, and the extrusion granulator The temperature of the main machine is set at 165°C, the speed is 70r / min, the speed of the feeder is 7r / min, the melt pressure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com