Low-temperature-resisting high-impact-resistance PVC modifying agent and preparation method thereof

A technology of high impact resistance and modifier, applied in the field of polymer material synthesis, can solve the problems of not obvious advantages in impact strength, hindering the promotion of impact ACR, not environmentally friendly low temperature impact strength, etc., to improve melt fluidity , excellent chemical stability, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation method of a low-temperature-resistant high-impact PVC modifier, comprising the following steps:

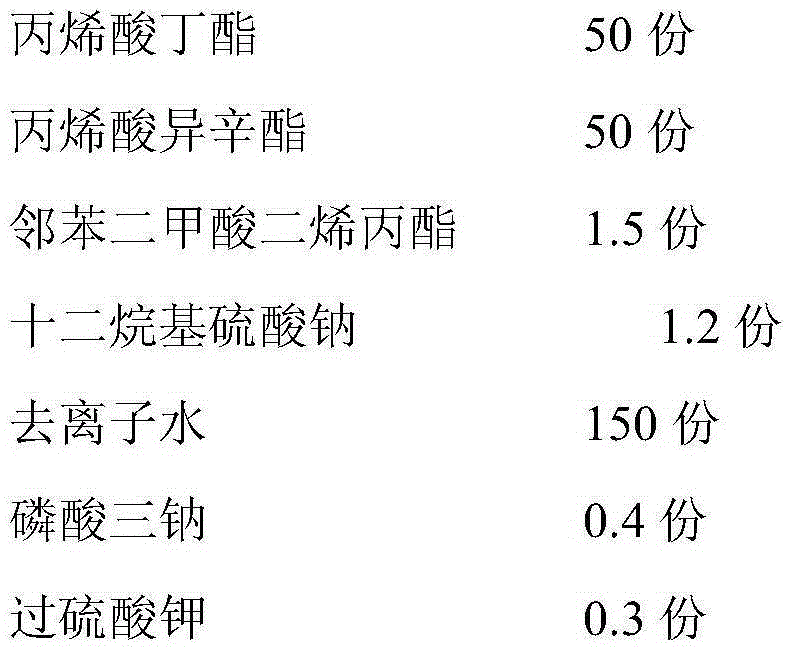

[0051] (1) Seed latex preparation: in the reaction kettle equipped with agitator, add each material according to the following proportions:

[0052]

[0053] Start stirring and heat up to 68° C., and react at this temperature for 4 hours to obtain seed latex with an average particle diameter of 80-95 nm.

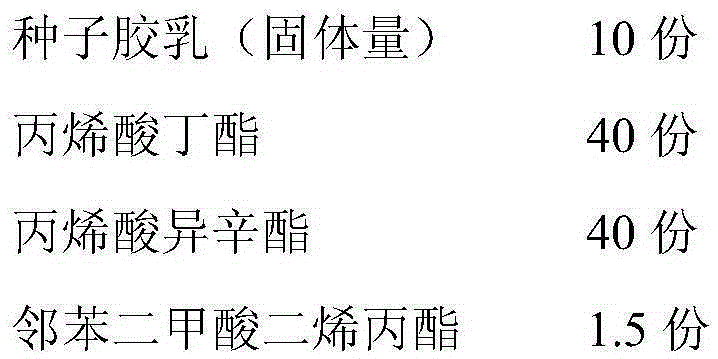

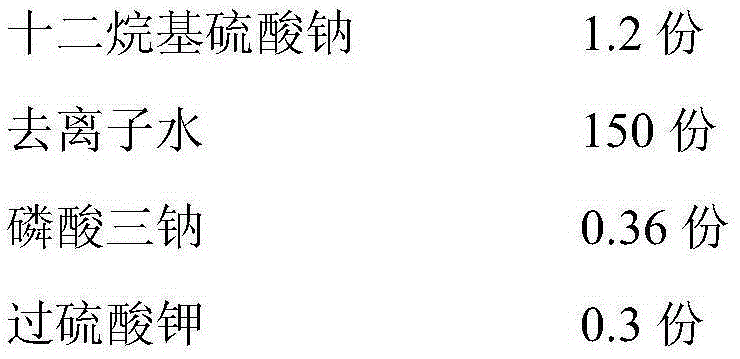

[0054] (2) Grafting of the core layer: the following components are added to a reactor with a stirrer:

[0055]

[0056]

[0057] Start the stirring and raise the temperature to 68° C., and react at this temperature for 4 to 5 hours to obtain the core layer graft emulsion.

[0058] (3) Shell layer grafting: Add 10 parts of methyl methacrylate and 0.03 parts of potassium persulfate to the reacted core layer graft emulsion, react at 68°C for 2 to 3 hours, and heat up to 85°C Aging for 1-1.5 hours, cooling down to 60°C to obtain PVC impact modifier emu...

Embodiment 4

[0068] In embodiment 1, diallyl phthalate is changed from 1.5 parts to 0.6 part, and diameter expander is changed from 0.4 part to 0.6 part, and all the other are the same as embodiment 1.

Embodiment 5

[0070] In embodiment 1, the amount of seeds is changed from 10 parts to 20 parts, butyl acrylate is changed from 40 parts to 30 parts, sodium lauryl sulfate is changed from 1.2 parts to 0.5 parts, and potassium persulfate is changed from 0.3 parts to 0.5 parts , all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com