High-fluidness PC/TPU (polycarbonate/thermoplastic urethane) alloy material and preparation method thereof

An alloy material and high fluidity technology, applied in the field of high fluidity PC/TPU alloy material and its preparation, can solve the problems of large melt viscosity processing, notch impact sensitivity, poor solvent resistance, etc., and achieve low cost and convenient operation , Excellent effect of solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of above-mentioned PC / TPU alloy material, comprises the following steps:

[0029] S1: Weigh each component according to the weight percentage content mentioned above;

[0030] S2: Mix the weighed components uniformly to form a mixed material;

[0031] S3: extruding and granulating the mixed material to obtain the high fluidity PC / TPU alloy material.

[0032] Specifically, in the above S1 step, the formulation of the PC / TPU alloy material of the present invention includes the above-mentioned formulation without additives or the formulation of another preferred embodiment containing additives. Among them, before weighing each component according to the above formula, it is preferable to dry the polycarbonate at a temperature of 120 ° C for 3 hours, or after weighing each component and before mixing each component, the weighed polycarbonate The ester was dried at 120°C for 3 hours. The purpose of preferably drying treatment is to minimize the part...

Embodiment 1

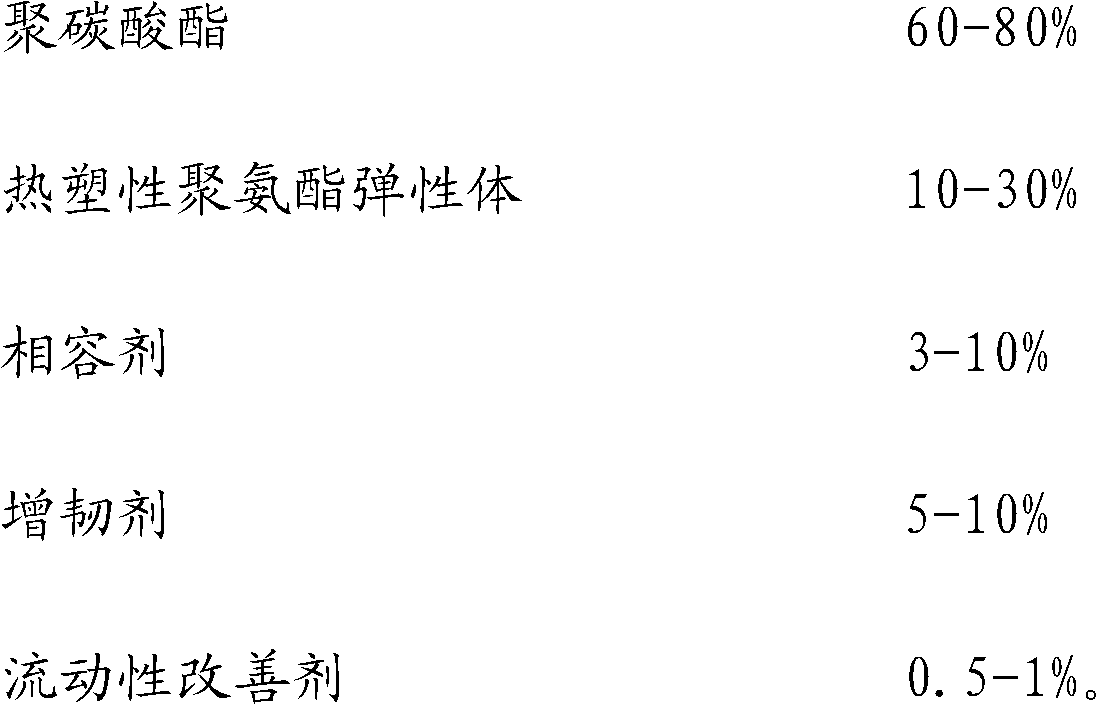

[0038] In this embodiment, the formula composition of PC / TPU alloy material percentage by weight of the present invention is as follows:

[0039] Polycarbonate with a preferred molecular weight of 38,000 60%, thermoplastic polyurethane elastomer with a Shore A hardness of 85HA 30%, polycarbonate polyurethane copolymer 4.5%, polyethylene octene co-elastomer 5%, pentaerythritol stearate- Methacrylic acid binary copolymer 0.5%.

[0040] The preparation method of above-mentioned PC / TPU alloy material is as follows:

[0041] S11: first dry the polycarbonate at 120°C for 3 hours, and then weigh each component according to the above PC / TPU alloy material formula;

[0042] S12: Mix the weighed components and put them in a mixer for 5 minutes until they are evenly mixed to form a mixed material;

[0043] S13: Add the mixed material into the hopper of the twin-screw extruder, extrude, and granulate to obtain a high-fluidity PC / TPU alloy material; the temperature of each section of the...

Embodiment 2

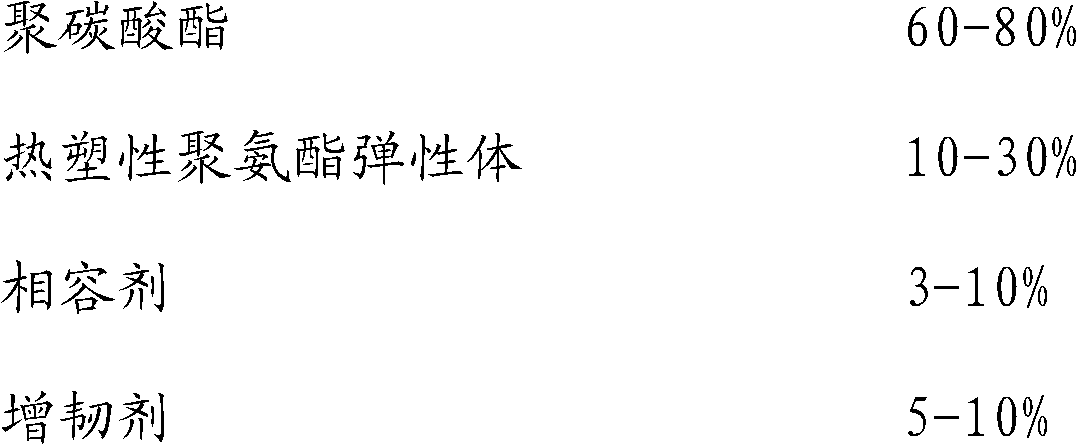

[0045] In this embodiment, the formula composition of PC / TPU alloy material percentage by weight of the present invention is as follows:

[0046] Polycarbonate with a preferred molecular weight of 30,000 60%, thermoplastic polyurethane elastomer with a Shore A hardness of 90HA 20%, polycarbonate polyurethane copolymer 10%, EPDM rubber 9.2%, pentaerythritol stearate-methyl Acrylic acid binary copolymer 0.8%.

[0047] The preparation method of above-mentioned PC / TPU alloy material is as follows:

[0048] S11: first dry the polycarbonate at 120°C for 3 hours, and then weigh each component according to the above PC / TPU alloy material formula;

[0049] S12: Mix the weighed components and put them in a mixer for 5 minutes until they are evenly mixed to form a mixed material;

[0050] S13: Add the mixed material into the hopper of the twin-screw extruder, extrude, and granulate to obtain a high-fluidity PC / TPU alloy material; the temperature of the mixed material in each section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com