Nylon alloy with high thermal deformation resistance and preparation method thereof

A technology with deformation performance and high heat resistance, applied in the field of nylon alloys, it can solve the problems of easy deformation, weak resistance, intolerant of alcohol ether compounds, etc., and achieve the effects of good toughness, light weight and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

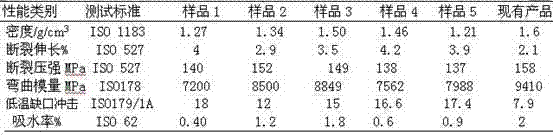

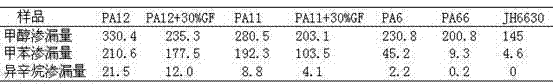

[0022] Embodiment 1 is based on the amount of nylon alloy, the following components by weight percentage: polyhexamethylene adipamide 40%, polypropylene 15%, compatibilizer 8%, antistatic agent 2% in the mixer Mix evenly, add extruder to granulate, mix evenly at 203-250°C, cut into pellets by plastic cutter; add 35% glass fiber to the pellets, mix evenly, and melt at 240-260°C After mixing, the modified nylon alloy was cut into pellets by a cutting machine, and the performance test of the product was carried out. The physical parameters are shown in Table 1, and the data on the penetration of alcohol and ether solvents are shown in Table 2.

Embodiment 2

[0023] Embodiment 2 is based on the amount of nylon alloy, the following components by weight percentage: polyhexamethylene adipamide 60%, polypropylene 8%, compatibilizer 4%, antistatic agent 3% in the mixer Mix evenly, add to the extruder to granulate, mix evenly at 220-240°C, cut into pellets by a plastic cutter, and cut into pellets by a plastic cutter; add 25% of glass fiber to the pellets, mix uniform, and then melted and blended at 240-260 ° C, cut into pellets by a cutting machine to obtain a modified nylon alloy, and the performance test of the product was carried out.

Embodiment 3

[0024] Embodiment 3 is based on the amount of nylon alloy, the following components by weight percentage: 45% of polyhexamethylene adipamide, 12% of polypropylene, 7% of compatibilizer, and 4% of antistatic agent in the mixer Mix evenly, add to the extruder to granulate, mix evenly at 203-250°C, cut into pellets by a plastic cutter; add 32% glass fiber to the pellets, mix evenly, and then add to the extruder, After melting and blending at 240-260°C, it is cut into pellets by a cutting machine to obtain a modified nylon alloy, and the performance test of the product is carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com